Аннотация

The main indicators of the quality and safety of dairy canned food in the range of low, intermediate and high humidity related to their distribution in Russia and abroad are considered. A comparative analysis of the quality parameters of traditional canned milk produced by the interstate standards in force in Russia, including obligatory conditions of compliance with technological requirements and sanitary and hygienic norms for production, when compared to similar products manufactured according to international standards, demonstrates competitive indicators of quality and safety. The basic technological approaches are investigated and a number of additional evaluation criteria for the utilization of various technologies and assessments of the quality of finished products are considered. Data on alternative raw ingredients, food additives and technological aspects that contribute to improving the quality of products, including storage stability, are reviewed. Separately presented are the integral criteria which, excludes the presence of falsified products. The principles of creating technologies for canned dairy products of functional purpose, including gero-dietetics, are described. Thus, based on a modern regulatory and technical base and using existing production capacities for the production of high-quality dairy canned food, the only necessary element for solving the problem of complete import substitution of canned dairy products in Russia is to increase the volume of raw material production.Ключевые слова

Canned milk, normative documents, product quality, evaluation criteria, storage stability, falsificationВВЕДЕНИЕ

The importance of milk and dairy products, including canned, in the structure of human nutrition cannot be overestimated. High nutritional value, the balance of macro- and microcomponents, the presence of biologically active substances, and good digestibility are all necessary elements for the normal functioning of the human body. Due to the production and use of canned milk, problems such as the seasonality of providing the population with dairy products, supplying them to remote regions of the Russian Federation, where the development of dairy cattle breeding is difficult. In addition, due to its long shelf life, canned milk is included in the nomenclature of food reserves to ensure food independence, which in turn is a component of Russia’s economic security.

According to the market survey of dairy products compiled by the Federal State Institution «Special Center-Aid in the Agro-Industrial Complex» of the Ministry of Agriculture based on Federal State Statistics Service of Russian Federation, Federal Customs Service of Russia, National Statistical Committee of Belarus and Eurasian Economic Commission data over the past five years, the annual production of canned milk in the Russian Federation was 330–370 thousand tons, with import of 200–240 thousand tons, and export of 40–70 thousand tons. The main share of production, import and export of canned milk (more than 70%) is in the form of four traditional types: milk powder, dry cream, condensed milk with sugar, and condensed cream with sugar. Great attention is given to the issues related to the product quality, security, falsification, both in our country and abroad [1, 2, 3].

Due to the significant transformations in the field of technical regulation that are a logical consequence of the establishment of the Eurasian Economic Union (EAEU) and the Customs Union (CU) in recent years, the following interstate standards have been developed, and are currently in effect in the case of traditional dairy preserves in Russia [4, 5, 6]:

– GOST 31688-2012 with the change № 1 “Canned milk. Milk and cream sweetened condensed. Specifications”, the date of introduction of the standard

– 01.07.2013, the date of introduction of the change - 01.05.2016;

– GOST 33629-2015 “Canned milk. Dry milk. Specifications”, the date of introduction of the standard - 01.07.2016;

– GOST 33922-2016 “Canned milk. Dry cream. Specifications”, the date of introduction of the standard - 01.09.2017.

In the territories of the EAEC and the CU, the main producing countries of these types of canned food are Russia and Belarus. Therefore, the basis of interstate standards was the content of national documents of these states:

– GOST R 53436-2009 “Canned milk. Milk and sweetened condensed cream. Specifications”;

– GOST R 52791-2007 “Canned milk. Dry milk. Specifications”;

– STB 1858-2009 “Dry milk. General specifications”;

– GOST R 54661-2011 “Canned milk. Dry cream. Specifications”.

In addition, international scientific requirements, regulated by the Codex Alimentarius, were taken into account when developing interstate standards.

Codex Alimentarius is a collection of food international standards, guidelines, and instructions adopted by the FAO/WHO International Commission covering the main types of food, regulating product safety and quality when entering the world market. The Codex Alimentarius Commission was formed in 1963 and currently has 188 members (187 countries and 1 organization – the European Union) and 219 participants (56 international government organizations, 147 private organizations, and 16 United Nations organizations) which includes 99% of the world population. The Russian Federation has been a member of the Code since 1993. The Codex standards are recommended for voluntary application by its members, forming the basis for the formation of national policy in the field of technical regulation [7].

The Codex Alimentarius Committee on Milk and Dairy Products has developed the following international standards for these types of canned milk:

– CODEX STAN 282-1971 “Standard for Sweetened Condensed Milks”, adopted in 1971;

– CODEX STAN 207-1999 “Standard for Milk Powders and Cream Powder”, adopted in 1999.

It should be stressed that when creating interstate standards for canned milk, the goal was to maximally harmonize the relevant Codex standards. As a result, a new classification group (partly defatted canned food) was introduced into interstate standards, new quality indicators were established and current norms were readjusted.

Since the industrial development of society, great attention has been constantly given to the issues of improvement of food quality. The complexity and multifaceted nature of the problem are obvious even now, as they affect various technical, technological, economic, and social aspects of human activities. In the accepted sense of the term, the quality of food products is a complex of product characteristics, including its safety, consumer properties, nutritional and energy value, that is meant to satisfy human need for food andhealth preservation.

The quality indicators for all of Russia's standardized canned milk products can be divided into three groups:

– organoleptic - product characteristics, determined by means of sensory systems, such as visual, tactile, olfactory and taste;

– physico-chemical - standardized physicochemical characteristics of specific types of products;

– safety indicators - microbiological indicators and identification of potentially dangerous substances in the quantities regulated by law.

Due to the different approaches of food quality appreciation in Russia and abroad related to the content of regulatory acts, the control, testing, monitoring and allocation of responsibility between state bodies and industry, it is difficult to make a direct comparison "one to one" of the above indicators. Therefore, it is best to focus attention on the fundamental criteria of the assessments of quality.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

ASSESSMENT OF QUALITYM

Organoleptic indicators are a special category of comparison. The Technical Regulations of the Customs Union and the Alimentarius Codes have significantly different approaches to their narration. In TR specific quality indicators are used, established in correspondence with interstate or national standards and regulations. By contrast, the Alimentarius Codes requirements to the organoleptic indicators are not standardized. According to its concept, food quality characteristics like appearance, consistency, color, smell and taste are not a part of product controlling system. On the contrary, the market decides whether these characteristics are satisfactory, and the producers establish them in relation to the consumers' demand.

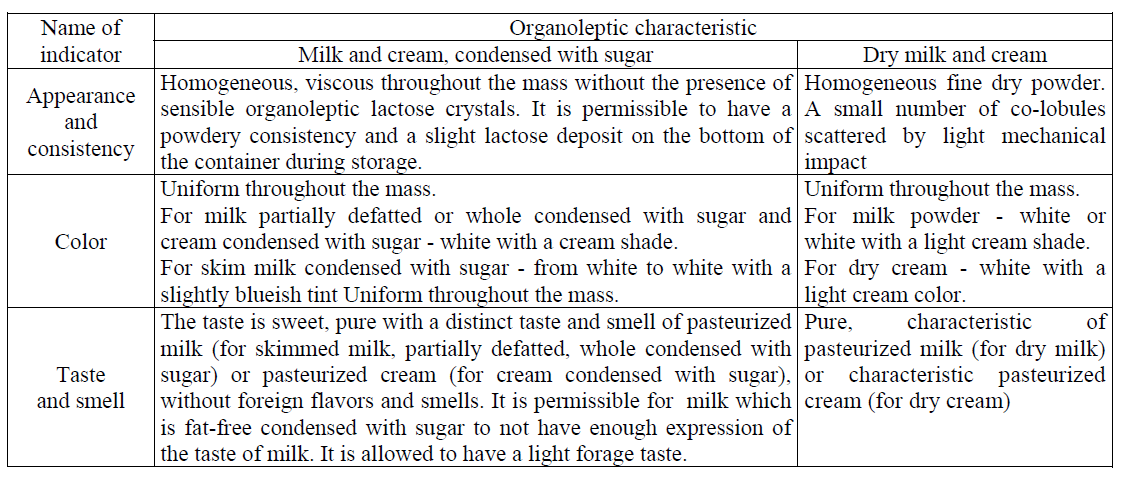

Organoleptic characteristics of condensed and dried dairy canned products in correspondence with TR CU 033/2013 “On Food Safety”, GOST 31688-2012, GOST 33629-2015, GOST 33922-2016 are given below in the unificated form in Table 1.

Qualitative assessment of Russian condensed with sugar and dried milk canned food throughout the shelf life of organoleptic indicators should meet the requirements as specified in Table 1.

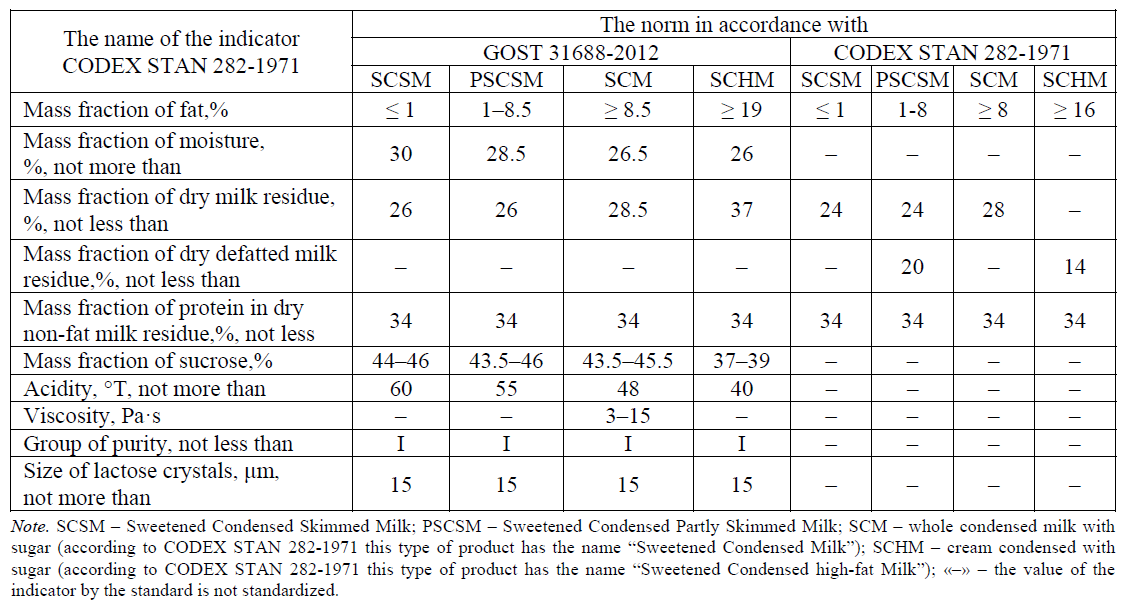

Tables 2 and 3 show the physicochemical parameters of dairy canned food, as regulated by intergovernmental and international standards.

Analyzing the data of Table 2 and 3, it can be stated that the physico-chemical indicators of conserved dairy products produced by interstate standards are not inferior, with some standards exceeding similar indicators of the Codex Alimentarius standards.

Indicators of condensed milk canned with sugar.

In GOST 31688-2012 mass fractions of fat for whole condensed milk with sugar (not less than 8.5%) and cream condensed with sugar (at least 19%) are left unchanged with respect to the national standard that was in effect in the Russian Federation; their values do not contradict Norms CODEX STAN 282-1971 (not less than 8% and 16% respectively). This is due to the fact that since the second half of the last century and up to the present, Russia's dairy-canning industry produces products with the aforementioned mass proportions of fat on a scientifically based, experimentally tested, practically tested basis used when implementing technologies and recipes.

The mass fraction of the dry milk residue in Russian condensed canned food with sugar (26–28.5%) is 0.5–2% higher than in the corresponding types of products under the Code. Despite the fact that differences in values at first glance can be called small, they are due to a fundamentally different technological approach related to formation of the quality of finished products intended for long-term storage. In addition, the increased content of dry milk residue contributes to the increase in the food value of canned food, including consumer appeal due to the saturation of the taste and flavor of the dairy product.

Of particular importance is the indicator «the mass fraction of protein in the skimmed milk powder residue - not less than 34%», which was included in interstate standards for canned milk by analogy with the Codes. This indicator indirectly describes the naturalness of the milk material used, which is produced from cow's milk. In the production of canned goods, concentration of all its constituent parts, except for water which evaporates, takes place simultaneously with the preservation of the initial ratio between them, including between the protein and the dry, skimmed milk residue. Using the data from the identification of raw milk from different types of agricultural animals, given in Annex 6 of TR TC 033/2013, you can calculate this indicator, which will be different for other animals, or much lower (milk of the donkey – 19.5%, horse – 23.6%, goats – 26.4%, and camels – 31.7%), or significantly higher (sheep milk – 41.5%, and buffalo – 42.9%). This indicator, both in the world and in the national standardization, is included not only in documents for dairy, dairy components, but also for milk-based canned food and canned milk, namely:

– CODEX STAN 250-2006 “Standard for a Blend of Evaporated Skimmed Milk and Vegetable Fat”;

– CODEX STAN 251-2006 “Standard for a Blend of Skimmed Milk and Vegetable Fat in Powdered Form”;

– CODEX STAN 252-2006 “Standard for a Blend of Sweetened Condensed Skimmed Milk and Vegetable Fat”;

– GOST R 54649-2011 “Milk-containing dry canned foods. Specifications”;

– GOST R 54666-2011 “Canned milk. Sterilized condensed milk. Specifications”;

– GOST 31703-2012 “Canned milk-containing sweetened condensed. General specifications”;

– GOST 33921-2016 “Canned milk. Condensed sweetened cooked milk. Specifications”;

– GOST 33923-2016 “Canned compound sweetened condensed milk. Specifications”.

What is especially important, is the ratio of protein to dry skim milk remains one of three (two others - the mass fraction of fat and milk solids) included in the basic definitions of all types of dairy canned food TR CU 033/2013, such as Condensed milk, milk and cream condensed with sugar, milk and cream are dry.

GOST 31688-2012 obligatorily normalizes the requirements for the mass fraction of moisture, sucrose, acidity, viscosity, purity group and the size of lactose crystals (milk sugar), as important for quality control of the product during storage. In CODEX STAN 282-1971, these indicators are not standardized, with the exception of recommendations on the amount of sugar, the minimum value of which is limited by good manufacturing practice, allowing preservation of the quality of the product during storage, while the maximum quantities do not allow for crystallization of the sugar. However, long-term scientific and practical studies of condensed milk canned with sugar demonstrated that with long-term storage it is important to standardize the content of sucrose and moisture in the regulatory documentation. Due to the use of osmotically active substances, a «preserving» effect (osmoanabiosis) occurs, which significantly increases the storage capacity of the products. Osmoanabiosis - increased osmotic pressure (16 MPa or more) occurs at the border of the solution/microbial cell. Due to the difference in the concentration of substances in the solution and inside the cell, dehydration of the protoplasm of the cell occurs, accompanied by compression (plasmolysis), separation from the cell wall and disruption of vital functions. By the degree of exposure to bacteria, the most common sugars can be arranged in the following order: fructose ˃ glucose ˃ sucrose ˃ lactose. In both Russia and abroad, as applied to traditional condensed milk preserves, sucrose was introduced as an osmotically active substance into the condensed milk in the form of a water solution of beet or cane sugar. Lactose in condensed milk crystallizes without having a significant effect on osmotic pressure, and therefore does not have an individual preservative effect. Recently developed technologies of canned food for functional purposes, wherein osmotically active substances, not only various sugar mono-substances but also their compositions (isomaltulose, fructose, and lactulose) are used. In connection with the foregoing, the quantity and quality of sugar used in the production of canned dairy products is of great importance. In addition, to ensure the storage of products for a long period, it is necessary to regulate the ratio between sucrose and moisture in the product, with the concentration of sucrose, not less than 60.0% for condensed milk with sugar, not less than 58.7% for condensed cream and sugar. The concentration is understood as the ratio of the mass fraction of sugar to the sum of the mass fractions of sugar and water in the finished product («sugar number», «sugar ratio»). However, some microorganisms (Catenularia fuliginea, and Aspergillus glaucum) contaminating the product can adapt to increased osmotic pressure, so condensed milk or cream with sugar must be protected against the entry of secondary microflora with observation of the recommended temperature storage regimes [8–11].

A role in the evaluation of the quality of canned dairy products belongs to the dimensions of the crystals of milk sugar. The consistency of the product, including consumer properties, depends on their magnitude. The process of crystallization of milk sugar, including the transition from a molecular solution to a solid crystalline state, is very specific in the production of canned food. When the mixture of milk with sugar is thickened, the concentration of all dry substances, including lactose, increases by 2.5 fold (in proportion to the decrease in the water content). At the end of the condensation (not less than 69.0% of dry matter), the lactose content is 12.5%, and the water content is no more than 31.0%. Thus, the concentration of lactose in the aqueous part of the finished product («lactose number») is about 30.0% and, since the solubility of lactose is low (at 18°C in 100g of water only 15.5 g of lactose dissolves), under these conditions there is a saturated state and, under cooling, uncontrolled crystallization will inevitably occur. The temperature of the condensed milk mixture with sugar when discharged from the vacuum apparatus is 50–60°C, and the storage temperature of the finished product in accordance with the recommendations of the current regulatory documents should not exceed 10–20°C. Therefore, cooling the condensed milk mixture with sugar is a prerequisite. In this case, lactose passes from a saturated solution to a supersaturated state, and then to a crystalline state. Formation of the consistency of the product is achieved only by performing the necessary technological methods for cooling the product by introducing crystallization centers (embryos) in the form of fine crystalline lactose (seed) with a crystal size of not more than 4 μm. Other factors (raw material quality, primary milk processing, pasteurization, thickening) do not affect the crystallization of lactose. It is necessary to properly prepare the seed, carefully observe the cooling regimes, so as to maximize the amount of lactose. Otherwise, when the product is stored under low temperature conditions, then the system becomes supersaturated again, with further crystallization occurring in the remaining portion of the dissolved sugar. The crystals that have fallen as a result of the spontaneous event are large, which can reach a size of 20–25 microns instead of the standard of «no more than 15 microns». In this case, the product will have a flaw of consistency (mealyness, or sandiness) and it can be used only for industrial processing [12–15].

Indicators of dry milk canned food. The ranges of the fat content of Russian dry canned milk are practically the same as the Codex Alimentarius, in addition to dry whole milk, for which the upper limit of the range is limited to 41,9%, which corresponds to the identification indices regulated by TR CU 033/2013. Dry milk product with a fat content of 42% in the Russian Federation is a dry cream that has been standardized more than 60 years ago and is produced in this fat content since then to the present. In addition, the term «dry cream» is included in TR 033/2013, which is defined as a dry milk product with a mass fraction of milk solids – not less than 95%, fat – not less than 42% and mass fraction of milk protein in dry non-fatty substances Milk – not less than 34%.

The production of dry dairy products is based on the principle of xeroanabiosis, that is, from normalized milk, moisture is removed by drying, bringing it to the minimum amount at which microbiological and enzymatic processes cannot proceed intensively. For dry partially defatted and whole milk, as well as for dry cream, the mass fraction of moisture in interstate standards is represented by a more «rigid» value – 4% in relation to the standard in the Code. Moisture content in the range 2.5–4.0% is optimal for the listed species and corresponds to a monomolecular layer of adsorption-bound moisture. The mass fraction of moisture for skimmed milk powder (not more than 5%) is due to the increased content of protein and lactose it has. Moisture content of more than 7% in dry milk leads to destabilization of the fatty phase of milk powder and the crystallization of lactose, which contributes to the appearance of various defects worsening its quality. Excessively low mass fraction of moisture (less than 2.4%) lead to the appearance of a salty aftertaste in the product during storage [12].

In dry milk products, as well as in condensed canned foods, the protein content of the skimmed milk powder is normalized (at least 34%). The significance of this indicator was noted above.

The standards for milk powder and cream, which are in force in the Russian Federation, stipulate mandatory requirements for acidity and solubility index, while the GOST for milk powder also regulates the mandatory standards for the mass fraction of lactose and the purity group. In the Code, acidity, solubility index and burnt particles are additional indicators of quality that are intended for voluntary application by commercial organizations but do not presume their use at the state level.

Comparing the norms on acidity and solubility index in GOSTs and CODEX STAN, as well as taking into account the nuances of the methods of their determination in different countries, it can be concluded that they are consistent. Thus, the determination of acidity in the Russian Federation is carried out in a sample of a certain mass calculated by a special computer program, depending on the type of product [16]. In the Codex, however, a sample of the product containing 10 g of a skimmed milk powder is used to determine the titrated acidity. Differences in the norms of the solubility index in accordance with GOST (cm3 of wet cake) and CODEX STAN (ml) are related to the instruments and equipment used, as well as the mass of the sample. To assess the correlation of the norm specified in the Code, the value of the solubility index according to GOST is multiplied by 5.

The determination of the lactose content in Russian dry canned milk is needed due to the widespread industrial use of this product as a raw material component for the production of various food products, and also to detect cases of falsification by unscrupulous producers of dried milk [4, 17].

The value of the indicator «burnt particles» by interstate standards for dry dairy products is not currently standardized, which is due to the lack of a standard for the method for determining this parameter. The method of determining the purity group burnt particles does not refer to mechanical contamination. The probability of the appearance of burnt particles in dry milk is unpredictable, since in the course of the technological process, there may be cases of molten milk in places where hot air is supplied to the drying tower with a temperature of more than 140°C. As a result, deposits may appear on the internal surfaces of the equipment, where the product is exposed to prolonged thermal effects. Burnt particles are detected visually in the form of small brown or black spots in the mass of milk powder or when it is restored. In accordance with the interstate standardization plan for 2016–2018, the Russian Federation is developing an interstate standard for milk powder for the production of baby food products, which is intended to include this indicator with the words of the method of its determination, as well as additional indicators compared with «regular Heat treatment class» and «bulk density».

In international practice, the indicator «heat treatment class» or «heat class» is used and normalized quite some time ago. It is defined as the ratio of the difference between the total protein and the sum of whey proteins to the total protein at a certain value of the active acidity. In the process of production of milk powder, raw milk is heat treated (pasteurization, thickening, and drying), causing its chemical and technological properties to undergo changes. The lower the overall temperature effect on the initial milk, the less transformations and technological changes occur in it, and therefore more physiologically significant (useful) components will remain in the dried milk, allowing it to have a wider range of uses. Therefore, it is important for both the manufacturer and the consumer of dry milk to estimate the degree of the overall heat treatment in order to solve the problem of its specific application in order to obtain high-quality products, for example, to direct milk powder for the production of dairy products, in the production of which a good clot Cottage cheese, cheese), or produce dairy products, canned milk, cereals, etc. Currently, the following classification is used, which is based on the fact that as the degree of heat treatment increases, an increasing proportion of whey protein in milk is denatured and becomes associated with casein:

– low-temperature heat treatment (not less than 6.0 mg UNWON per gram);

– moderate heat treatment (from 1.51 to 5.99 mg UNWON per gram);

– high-temperature heat treatment (not more than 1.5 mg UNWON per gram), where UNWON is the concentration of un-denatured whey protein nitrogen.

Proceeding from the foregoing, it will be logical and expedient to introduce into the draft standard for dry milk, which will be used in the production of various dairy products for children's nutrition, the indicator «heat treatment class» with the norm corrected on the basis of numerous studies of at least 4.5 mg UNWON per gram, indicating a moderate or low-temperature heat treatment.

The indicator «bulk density» is of great practical importance. It is used both for technological and marketing purposes to manage the process of drying milk; Evaluation of the quality of construction of drying plants and diagnostics of their condition in the process of work; In forecasting the suitability of products for long-term storage; When assessing the state of production after long-term storage; To calculate the required volumes of storage tanks and storage facilities; and When dosing dry milk into various types of consumer and shipping packaging. In addition to the above, this indicator can serve as additional indirect evidence in detecting the falsification of the product. The density of dry milk depends on the density of its constituent particles, their size, surface appearance, shape, compactness, the chemical composition of the raw milk raw materials, etc. In GOST 31977-2012 “Dried milk products. Method for determination of bulk density” defines three types of indicator “bulk density”:

– volumetric bulk density – the ratio of the mass of the product to its volume in a graduated cylinder without sealing the product;

– loose bulk density – the ratio of the mass of the product to its volume after 100 strokes;

– Bulk density – the ratio of the mass of the product to its volume after 625 strokes. Based on numerous scientific and practical studies, the following values of the "bulk density" indicator for dry milk will be included in the draft standard:

– fat-free – from 0.560 to 0.680 g/cm3;

– partially defatted – from 0.520 to 0.640 g/cm3 (for dry milk with a mass fraction of fat from 25 to 26% – from 0.440 to 0.550 g/cm3);

– solid – from 0.330 to 0.420 g/cm3.

In the near future, introduction of such physical and chemical indicators as burnt particles, heat treatment class and bulk density into the interstate standard for milk powder will significantly improve the quality of Russian products.

The main characteristic of any food products entering the domestic or foreign markets is its security. Presence of such dangerous factors as biological, chemical, physical substances, present in food products or coming in contact with them, can become a potential cause of negative impact or even constitute a serious threat to human health.

In CU, the relevant documents are accepted: TR CU (Technical Regulations of Custom Union) 021/2011 «On Food Safety» and TR CU 033/2013, establishing the maximum permissible standards for microbiological indicators and potentially dangerous substances of specific types of canned food. In the Codex Alimentarius, the requirements for microbiological criteria for condensed with sugar and dry canned milk are regulated by CAC/GL 21-1997 «Principles and guidelines for the establishment and application of microbiological criteria related to foods», and to the permissible levels of potentially dangerous substances (contaminants) – CODEX STAN 193-1995 «General standard for contaminants and toxins in food and feed» аnd CAC/RCP 57-2004, «Code of hygienic practice for milk and milk products», which formulate general principles and requirements for food safety. Comparative analysis of the features of the requirements of TR CU and Codex with respect to the permissible levels of microbiological indicators, chemicals, veterinary drugs, pesticide residues is a complex of complex issues from different scientific and technical subject areas.

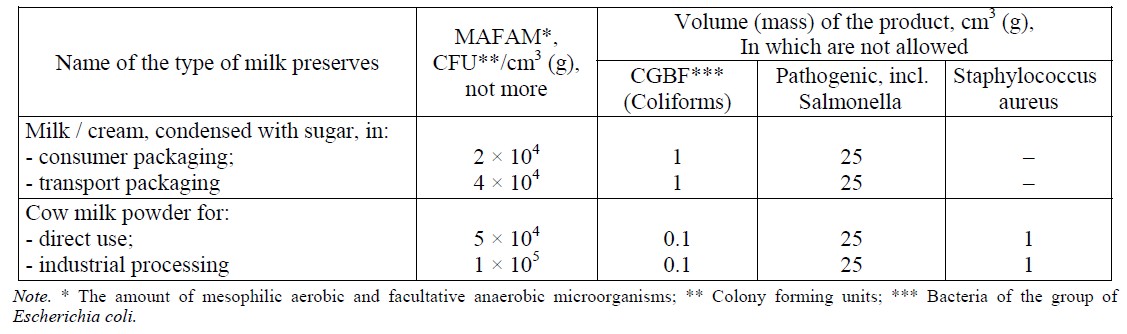

Microbiological safety standards are noted in Annex 1 of TR CU 021/2011, as applied to milk preserves, wherein only the indicator «pathogenic microorganisms, incl. Salmonella». The remaining permissible levels of microorganisms are established in TR CU 033/2013 (Annex 8). The summary requirements for the permissible microbiological standards in canned milk are presented in Table 4.

As can be seen in Table 4, microbiological TR requirements are a combination of indicators for pathogenic and indicator microorganisms that are evaluated in the final product. In CAC/GL 21-1997, the requirements for microbiological criteria are aimed to identify microorganisms that are directly related to fooddependent diseases throughout the food chain from farm to consumer. Control of microorganisms is performed during the production process. The results are confirmed again, when the products are already in circulation in the market. From the point of view of health threats, when comparing the micro-biological safety of canned milk in our country and abroad the most important group of micro-organisms are pathogenic microorganisms, the permissible standard of which is the same. In fact, only these microorganisms are the only group on which it is possible to make a comparison. Thus, in the countries of the European Union (EU), according to Commission Regulation (EC) 2073/2005 «On microbiological criteria for foodstuffs», which is built on the principles of CAC/GL 21-1997, milk powder except for the absence in 25g of pathogenic microorganisms of the genus Salmonella, in 25g not allowed staphylococcal entero toxins, and during the process determine the Enterobacteriaceae (less than 10 CFU/g) and coagulasepositive staphylococci (maximum 10 CFU/G). The last two criteria do not apply to milk powder, intended for further processing in the food industry. In addition, provisions of Commission Regulation 2073/2005 entitle the inspection agency, if there is reasonable threat to security, to conduct research on the production organisms are not identified in the Regulations, and also require market participants to identify other food organisms (other than those listed in Regulations) as microbiologically significant risks in the framework of self-control programs based on HACCP principles. Thus, this makes it possible, as necessary, to expand the list of controlled microorganisms.

The index «a potentially dangerous substance», used in the TR CU or «contaminants» up, use, being operated in the Codex Alimentarius, means any substance inadvertently trapped in the food proinduction during the manufacturing process, the packaging, transportation or storage of such products, or by Pollution from the environment. Since it is generally believed that the pollution has a negative impact on food safety and may pose a risk to human health, domestic and international public authorities have taken measures to control the content of the hard exponents in foods.

In Table 5 shows allowable levels of potentially hazardous substances (toxic elements, mycotoxins, antibiotics, pesticide, radionuclide, dioxins, melamine) in canned milk under Annex 3 and 4 TR CU 021/2011.

Codes, guidelines and guidelines set maximum levels of contaminants in food products and apply to a wide range of foods. However, it is significantly inferior in coverage to the norms of the CU. In the case of milk, these documents set the following maximum permissible levels:

– lead – 0.02 mg/kg (if the milk is partially or completely dehydrated, then the appropriate concentration ratio is used);

– tin – 250 mg/kg;

– aflatoxin M1 – 0.5 mg/kg (if the milk is partially or completely dehydrated, then the appropriate concentration ratio is applied);

– levomycetin – in the EU countries this antibiotic is prohibited in the treatment of animals; EU MRLs are not

– tetracycline group – 0.1 mg/kg; In the treatment of animals

– penicillin and its derivatives – the norms are established for each specific derivative;

– cesium-137 – 1000 Bq/kg;

– strontium-90 – 100 Bq/kg;

– melamine – 2.5 mg/kg.

With regard to pesticides, for example, in the EU their list and maximum allowable doses represent a constantly updated database in the form of an Internet portal that includes both authorized and unauthorized substances.

When comparing the Russian and international security indicators, it is clearly possible to establish compliance of the requirements with the permissible levels of Aflatoxin M1. The remaining parameters have different values, in one case in the TP more rigid (the content of tin, antibiotic tetracycline, cesium-137, melamine), in the other – in the Codes (lead content, strontium-90, prohibition on the use of levomycitin).

For the production of condensed with sugar and dried milk canned food, a variety of dairy raw materials are used, the list of which is presented in Table 6.

All dairy raw materials used in the Russian Federation for the development of traditional types of canned milk products are standardized in the form of national and interstate documents. In international practice from the listed in Table 6 raw materials. These codes only regulate the requirements for plums, dried milk and dried cream.

The quality of raw milk and other dairy raw materials depends on the quality of the finished product. If we consider the problem «from the field», it is necessary to carry out measures to increase thenumber of cattle and carry out selection work aimed at creating breeding stock and the formation of certain quality indicators of milk, respectively [18, 19]. In recent years, the requirements to the quality and safety of dairy raw materials on the territory of the EAEU and CU member countries have been tightened, and almost all its types are subject to either national or interstate standards.

Traditional canned milk can be attributed to products of multi-purpose. In addition to their direct consumption in food, their other purpose is to use a huge amount of various food products in production, the quality of which, of course, is affected by the species and the component amount of its raw materials.

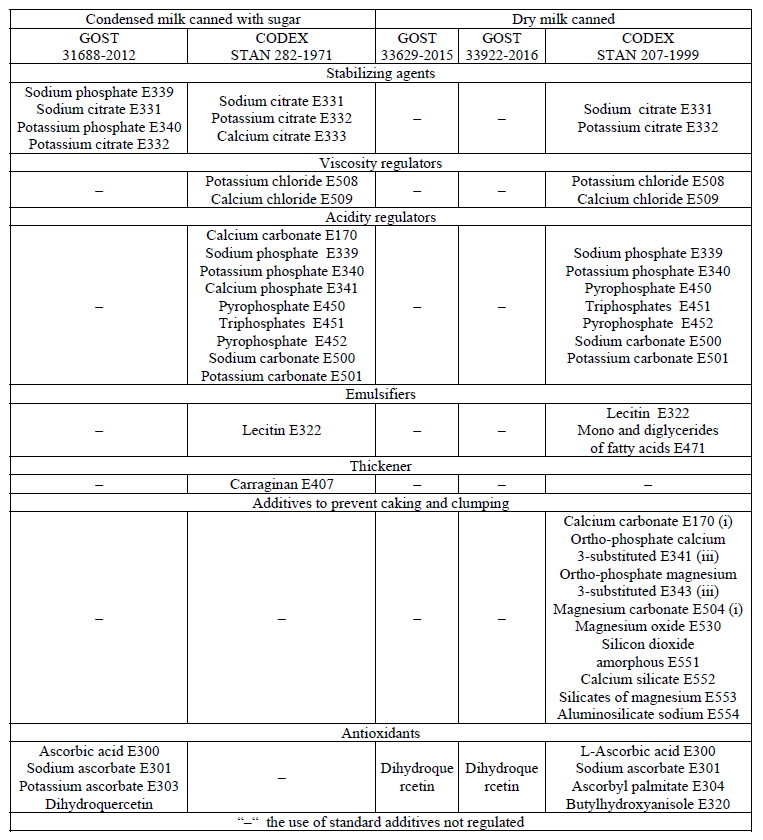

In this regard, attention should be paid to allowing the Codex Alimentarius to use in the production of dry and condensed milk canned foods an extremely large list of different food additives: acidity regulators and viscosities, hardeners, stabilizers, thickeners, emulsifiers, caking and clumping inhibitors, synthetic antioxidants (Table 7). Although these food additives in Russia are also included in the list for use in the production of food products TR CU 029/2012 «Safety requirements for food additives, flavors and technological aids», but not all of their use in the development of canned dairy products is technologically justified and eco-friendly and economically feasible. Therefore, the use of only four salt-stabilizers (citrates and phosphates of sodium and potassium) and antioxidants (dihydroquercetin, ascorbic acid and its salts), and for dry canned food - only dihydroquercetin, the introduction of which is scientifically justified, is normalized for the production of Russian condensed milk canned food with sugar standards, which has been experimentally confirmed by many years of research and numerous studies with positive results.

In CODEX STAN 207-1999 as an antioxidant recommended is ascorbic acid, its salts and butylhydroxyanisole. Long-term research by the All-Russian Research Institute of Dairy Industry, since the 70th of the last century, as there are numerous publications and scientific reports, the introduction of the above-mentioned antioxidants is ineffective with regard to whole milk powder, in addition, they are synthetic antioxidants. In the last decade, both in Russia and abroad, natural antioxidants are preferred. Such an antioxidant is currently recognized as dihydroquercetin (DHQ).

DHQ is a biologically active substance of plant origin of domestic production and belongs to the group of bioflavonoids - flavananol. As a result of many years of research, the organic part of Siberian and Dahurian larch wood, which grows in Western and Eastern Siberia, and also in the Far East, is recognized as an environmentally friendly plant raw material for industrial production in Russia. Currently, only the Russian Federation is the only producer of DHQ in the world on an industrial scale from larch wood. The capacities of its production, which do not depend on seasonality, make it possible to meet the needs of chemical, pharmaceutical and food enterprises, both in Russia and for export . DHQ is non-toxic, does not have allergic, embryotoxic, immunotoxic, or mutagenic properties, being characterized by high antioxidant activity, superior to quercetin, rutin, β-carotene and a number of synthetic antioxidants. In addition, dihydroquercetin is characterized by a wide spectrum of biological activity, has a capillary-strengthening, lipid-lowering (anti-sclerotic), radioprotective action, helps normalize microcirculation and improves the rheological properties of the blood. DHQ was investigated for all the necessary parameters required for the production of medicines and food additives in the 90s of the 20th century. Technical specifications were developed for it, a pharmacopoeia article providing for its use in medicines and dietary supplements was developed. The results obtained allowed to consider it not only as a pharmaceutical preparation, but also as a food additive for use in various branches of the food industry, both as an antioxidant and as a functional ingredient. DHQ was introduced in SanPiN 2.3.2.1293-03 «Hygienic requirements for the use of food additives» in the list of food additives and is classified as a class of antioxidants that do not have a harmful effect on human health when used for food production, and subsequently, in the same quality – in TR CU 029/2012. At the present time GOST 33504-2015 «Food additives. Dihydroquercetin. Specifications», which regulates the requirements for DHQ for its use in the food industry as an antioxidant. The use of DHQ in the technology of dairy canned food provides an opportunity to significantly increase their shelf life while preserving the original properties of the products [20].

ВЫВОДЫ

Comparative analysis of quality indicators of traditional canned milk produced by the interstate standards in force in Russia, with the obligatory condition of compliance with technological requirements and sanitary and hygienic norms for their production, in relation to similar products manufactured according to international standards, has shown that they have a competitive indicator Quality and safety.

Using the existing production facilities for the development of high-quality dairy products due to the increase in the volume of processing of dairy raw materials and the current regulatory framework, in the near future in Russia it will be possible to implement a complete import substitution of these types of products.

СПИСОК ЛИТЕРАТУРЫ

- Churshudyan S.A. Consumer and Food Quality. Food Industry, 2014, no. 5, pp. 16-18. (In Russian).

- Prosekov A.Yu. and Ivanova S.A. Providing food security in the existing tendencies of population growth and political and economic instability in the world. Foods and Raw Materials, 2016, vol. 4, no. 2, pp. 201-211. DOI: 10.21179/2308-4057-2016-2-201-211.

- Gnezdilova A.I., Tuvaev V.N., and Ostretsov V.N. Increase the competitiveness of milk-based canned food on the food market. Economic and social changes: facts, trends, forecast, 2012, no. 5, pp. 107-113. (In Russian).

- Radaeva I.A., Chervetsov V.V., Galstyan A.G., et al. Changes in regulatory documentation for condensed milk and milk-containing canned foods with sugar. Dairy Industry, 2016, no. 2, pp. 52-54. (In Russian).

- Radaeva I.A., Chervetsov V.V., Galstyan A.G., et al. Interstate standard for milk powder. Dairy Industry, 2016, no. 3, pp. 36-37. (In Russian).

- Radaeva I.A. Galstyan A.G., Turovskaya S.N., Illarionova E.E., Petrov A.N., et al. Dry cream: the past, the present, the future. Dairy Industry, 2017, no. 2, pp. 23-24. (In Russian).

- Codex Alimentarius. International Food Standards. Available at: http://www.fao.org/fao-who-codexalimentarius/ about-codex/en/ (accessed 20 February 2017).

- Goschanskaya M.N. Razrabotka tekhnologii molokosoderzhashchego obogashchennogo produkta s promezhutochnoy vlazhnost'yu dlya obshchego i gerodieticheskogo pitaniya [Development of technology of milk-containing enriched product with intermediate moisture for general and gerodietic nutrition]. Cand. eng. sci. diss., Kemerovo, 2012. 118 p.

- Goshchanskaya M.N., Turovskaya S.N., Chervetsov V.V., Kuznetsova A.E., and Galstyan A.G. Osmotically the active composition for products with an intermediate moisture content of milk-based. Storage and processing of farm products, 2012, no. 1, pp. 43-45. (In Russian).

- Gnezdilova A.I. and Vinogradova Yu.V. The influence of some parameters on crystallization kinetics of lactose. Storage and processing of farm products, 2010, no. 12, pp. 24-26. (In Russian).

- Chervetsov V.V. and Gnezdilova A.I. Intensifikatsiya protsessov kristallizatsii pri proizvodstve molochnykh produktov [Intensification of crystallization processes in the production of dairy products]. Moscow: Rossel'khozakademiya Publ., 2011. 196 p.

- Galstyan A.G., Petrov A.N., Radaeva I.A., et al. Teoriya i praktika molochno-konservnogo proizvodstva [Theory and practice of dairy canning]. Moscow: The Publishing House "Fedotov DA", 2016. 181 p.

- Ryabova A.E. Razrabotka tekhnologii geterogennoy kristallizatsii laktozy v proizvodstve sgushchennykh molochnykh produktov v sakharom [Development of the technology of heterogeneous crystallization of lactose in the production of condensed milk products in sugar]. Cand. eng. sci. diss., Kemerovo, 2014. 112 p.

- Ryabova A.E., Galstyan A.G., Malova T.I., Radaeva I.A., and Turovskaya S.N. Нeterogeneous crystallization of lactose in technology of sweetened condensed milk. Food Processing: Techniques and Technology, 2014, vol. 32, no. 1, pp. 78-83. (In Russian).

- Gnezdilova A.I., Vinogradova Yu.V., and Muzykantova A.V. The influence of some admixtures on the stability of oversaturated lactose solutions. Molochnokhozyaistvenny Vestnik, 2011, no. 1, pp. 35-38. (In Russian).

- Semipyatniy V.K., Galstyan A.G., Pryanichnikova N.S., and Turovskaya S.N. Programma dlya opredeleniya massy naveski sukhikh molochnykh produktov dlya provedeniya fiziko-khimicheskikh i organolepticheskikh analizov [A program for determining the weight of a sample of dry dairy products for conducting physicochemical and organoleptic analyzes]. Certificate of state registration of the computer program, no. 2014615898, 2014.

- Petrov A.N., Khanferyan R.A., and Galstyan A.G. Current aspects of counteraction of foodstuff’s falsification. Problems of Nutricion, 2016, vol. 85, no. 5, pp. 86-92. (In Russian).

- Valiullina E.F., Zaripov O.G., Tyulkin S.V., Akhmetov T.M., and Vafin R.R. Characterization of bull-producers with different combinations of kappa-casein & beta-lactoglobulin genotypes by milk production their mothers. Veterinary practice, 2007, nо. 4, pp. 59-63. (In Russian).

- Tjulkin S.V., Akhmetov T.M., Valiullina E.F., and Vafin R.R. Polymorphism of genes for somatotropin, prolactin, leptin, and thyroglobulin in stud bulls. Vavilov journal of genetics and breeding, 2012, vol. 16, no. 4-2, pp. 1008-1012. (In Russian).

- Radaeva I.A., Galstyan A.G., Turovskaya S.N., et al. New intergovernmental standard on the antioxidant dihydroquercetine. Dairy Industry, 2016, no. 4, pp. 57-59. (In Russian).