Аннотация

Traditional meat products are made with large amounts of saturated fat and binders such as starch, which increase calories and move away from current consumer trends that seek low-fat products with natural ingredients. Shiitake mushroom has beneficial health properties and it can be used as a fat substitute in processed meat products. We aimed to identify the effects of incorporating shiitake powder into chorizo sausages as a fat substitute.Shiitake powder was characterized and five formulations of chorizo sausage were developed: control and four experimental samples with 30, 40, 50 and 100% fat substitution (the latter included 50% of shiitake powder and 50% of olive oil).

The experimental sausage showed a greater moisture, lower lipid content, and less cooking loss. The samples with shiitake powder were darker and less red than the control. Texture parameters were not affected by substituting 40% of fat with shiitake powder. The treatment with 40% fat substitution had a greater insoluble fiber content and a lower aerobic mesophile count (CFU/g) than the control. No significant differences were found in the fatty acids profile. The samples with shiitake powder had a moderate level of sensory acceptance which might be associated with the consumers’ lack of familiarity with shiitake.

Consumers may accept comminuted sausages in which a maximum of 40% of fat is substituted with shiitake powder. Such products have an adequate nutritional composition, as well as acceptable physicochemical, technological, and microbiological properties.

Ключевые слова

Shiitake, fat substitute, comminuted sausages, processed meat, sensory acceptanceВВЕДЕНИЕ

Consumption of processed meat products has been questioned in recent years due to their potential contribution to cardiovascular diseases and colon cancer, as well as the impact of the meat industry on the environment [1–3]. With respect to its health effects, saturated fat is a component of meat that has generated the greatest concern.

Consumers have increasingly expressed their preference for natural ingredients and beneficial health effects [4, 5]. This has led the food industry to develop new products and seek ingredients and technologies that satisfy the demands of consumers who are increasinglybetter informed. Nevertheless, a gap still exists between the theoretical knowledge of non-meat ingredients and the viability of their incorporation into processed meat products due to synergetic or antagonistic effects among ingredients during processing, as well as their effects on texture or sensory parameters. Therefore, there is a need to study such effects for each ingredient in the product. With this aim, numerous studies have focused on improving the composition of processed meat products so that they contain the nutrients demanded by consumers [6, 7].

Conventional processed meat products such as sausage generally contain added animal fat, which not only provides sausage with sensory appeal but also contributes to its structure, juiciness, and the desired texture [8]. However, the resulting saturated fatty acids have been associated with long-term negative health effects [9]. Thus, there is a need to substitute animal fat in processed meat products with ingredients that simulate the desired functional and sensory characteristics.

Edible mushrooms are a viable ingredient for replacing meat, fats, salt, nitrites, and phosphates conventionally used in processed meat products. These mushrooms may have beneficial effects on consumers’ health due to their bioactive compounds, medicinal effects, and antimicrobial properties [10]. Specifically, shiitake mushrooms (Lentinula edodes (Berk.) Pegler) have been demonstrated to have anti-inflammatory, anti-tumor, antiviral, antibacterial, anti-diabetic, and anti-parasite properties, as well as to regulate blood pressure and cholesterol levels [10]. Furthermore, shiitake has been found to have a high content of bioactive compounds, such as phenols, which may act as antioxidants [11].

Shiitake mushrooms have a high level of acceptance when used as an antioxidant and salt substitute in sausages, improving their useful life without deteriorating their color or texture [11]. Additionally, the authors indicate that at levels of 0.8% shiitake reduced lipid oxidation and bacterial growth, as well as improved the sensory quality of the product after one day of refrigerated storage due to its flavor-enhancing components. Meanwhile, shiitake extract added to hamburgers increased consumers’ acceptance of color, aroma, texture, flavor, salinity, and general perception, although it provoked changes in some physiochemical characteristics such as pH, yield, and color [12].

Although the use of edible mushrooms in processed meat products has been demonstrated to be successful, fresh mushrooms deteriorate rapidly due to high respiration and metabolic rates [10, 13]. Moreover, they have a high microbiological charge (principally due to bacteria of the genera Pseudomonas and Enterobacter, as well as molds and yeasts), which degrades mushroom quality soon after harvest, making their use difficult and costly [13, 14]. Therefore, it is important to seek ways of incorporating dehydrated shiitake into processed food products in order to take advantage of their compositional and functional properties.

Given the lack of information on the use of dehydrated shiitake mushroom powder as a fat substitute and the need to make traditional processed meat products healthier, we aimed to determine the influence of shiitake powder incorporated into chorizo sausage as a fat substitute on the physiochemical, technological, microbiological, and sensory characteristics of the product, as well as its composition.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

Shiitake mushrooms were supplied by a local supplier in Funza Cundinamarca, Colombia, and dehydrated in an oven at 40°C for 15 h. Then, the mushrooms were ground into powder using a food processor, sifted using a #20 sieve (Standard Sieve Series, USA), vacuum packed, and stored at room temperature for two weeks.

Refrigerated pork fat and lean beef were purchased from a local market in Bogotá, Colombia. Other ingredients and additives were obtained from local suppliers specializing in inputs for processed meat products (Tecnas S.A., Colombia). Laboratory chemical reagents for proximate and other analyses were acquired from a local chemical supplier (Elementos Químicos LTDA).

Characterization of shiitake powder. Shiitake powder was characterized using a proximate analysis according to the methodology of the Association of Official Agricultural Chemists [15]. Water retention capacity, oil retention capacity, swelling capacity, pH, color, and solubility of the samples were determined as proposed by Yaruro Cáceres et al. [16]. For these parameters, the shiitake powder samples were compared with the samples of commercial oat bran used as a healthy ingredient in processed foods.

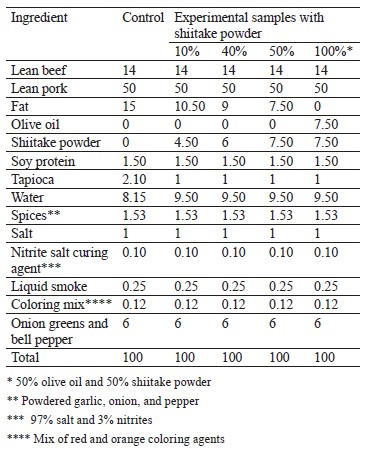

Preparation of chorizo sausage. Three 8-kg batches of sausage were prepared according to the following procedure. Meat was defrosted and its excess fat was removed. The resulting lean meat was cut and ground using a mill with an 8-mm disk (orifice plate). Pork fat was ground with a 6-mm disc. Liquid smoke was mixed with water to be used in the sausage. Then, the meat was mixed with salt (NaCl and nitral salt), powdered spices, finely chopped onion greens and bell pepper, cold water (1/3 of the total to be used), and artificial coloring with a mixer for approximately 60 s. Following this, soy protein, starch, and another 1/3 of the water were added. Finally, fat or the fat substitute (shiitake powder) was added according to the formula shown in Table 1. The remaining water was added immediately and the mixture was blended with an mixer for approximately 60 s. The temperature of the mixture was maintained below 12°C (beginning with the partially unfrozen meat at < 2°C and adding extra cold water). After that, the mixture was stuffed in 28 mm diameter collagen casings, tied, and scalded until obtaining a constant internal temperature of 72°C. Finally, the sausages were cooled by submerging them in cold water until they reached < 10°C.

Each batch (repetition) was divided into six parts: 500 g for the analysis of pH, texture profile, and color; 500 g for a proximate composition analysis, 500 g for a microbiological analysis; 300 g for a dietary fiber analysis; 300 g for a fatty acids profile analysis, and the remainder for a sensory analysis. Each part was placed in a polyethylene bag, vacuum packed, and refrigerated at 4.0 ± 0.5°C for later analysis. Three independent repetitions of the chorizo sausages (control and treatments) were performed during a three-week period, with one week between the repetitions, and three samples were taken for each treatment in each batch of the replicates. The same package (lot) of ingredients was used for each formulation and the mixing process was replicated as described above.

Characterization of chorizo sausage. All the samples were analyzed for their proximate composition, pH, cooking loss, color, and texture in order to determine which treatment presented the most desirable characteristics for the sausage. Following this, the treatment selected and the control were analyzed for total, soluble, and insoluble dietary fiber, as well as for a fatty acids profile, microbiological and sensory characteristics.

Proximate analysis. The samples’ proximate composition was analyzed using the AOAC methods for meat products. Moisture was measured using the AOAC method 950.45; lipids using the AOAC Soxhlet method 991.36 with petroleum ether; crude protein using the AOAC method 990.03 with 6.25 as a conversion factor; and ash using the AOAC method 920.153 [17–20].

Determination of pH. The samples’ pH was measured using a laboratory pH meter (Jenway 3520) as proposed by Vasquez Mejia et al. [21]. The pH meter was calibrated with buffer solutions with pH of 4.01, 7.00, and 9.21 (Mettlet Toledo In Lab). The equipment automatically corrected to the value expected at the actual temperature. Approximately 5.0 ± 0.5 g of each sample was weighed in a beaker and mixed with 20 mL of water. For each experimental unit, three direct readings of pH of the homogenized solution were taken and the results were averaged.

Cooking loss. The weight of each sample (3 sets of 10 sausages) was recorded before cooking (scalding in water until the interior of the product reached 72°C). After cooking, the sausages were cooled to 10°C and weighed again. Cooking loss, g/100 g was calculated using the following equation:

Color. Color was analyzed using a ColorQuest XE colorimeter (Hunter Associates Laboratory Inc., Virginia, USA), carrying out an evaluation using the CIE-Lab system (L *, a *, b *), with D65 illumination, aperture size 9.5 mm, and a 10° angle of observation. Each sausage was cut into 2 cm slices, and their color was measured three times from each analytical point as proposed by Vasquez Mejia et al. [21]. The lightness value (L*, with a scale of 0–100) ranged from black (0) to white (100). The first chromaticity coordinate value (a*) ranged from red (+50) to green (–50), and the second (b*) from yellow (+50) to blue (–50).

Texture profile analysis. The texture profile of the cooked samples was analyzed through compression tests using a texture analyzer (TA.XT2; Texture, Technologies Corporation, Scarsdale, NY, USA) as described by Vasquez Mejia et al. [21]. Texture was measured the day after preparing the samples, which were unrefrigerated and set out to reach room temperature before analysis. For each sample, several pieces from the core were cut out (10 mm in length × 20 mm in diameter) immediately before analysis. For each batch (replicate), 5 pieces were obtained. The pieces were compressed twice until reaching 75% of their original height using a cylindrical acrylic probe measuring 101.6 mm in diameter × 10 mm in height. For this, the probe was set at a test velocity of 1.5 mm/s and a velocity posterior to the test of 1.5 mm/s. The parameters under evaluation included hardness, adhesiveness, cohesiveness, springiness, gumminess, and chewiness.

Analysis of dietary fiber content. Total dietary fiber (including soluble and insoluble dietary fiber) was determined using the AOAC gravimetric enzymatic method 991.43 [22].

Fatty acids profile. Lipids were previously extracted using a 2:1 ratio of chloroform to methanol as a solvent and tricosanoic acid as an internal standard. Fatty acid methyl esters (FAME) were obtained according to the methods of the American Oil Chemistry Society. Saturated and unsaturated fat and trans-isomer content were determined by gas chromatography using a chromatograph (model 7890A, Agilent Tech., Santa Clara, CA, USA) equipped with a flame ionization detector and a highly polarized column with a BPX 70 phase (length 60 m, thickness of the layer 0.20 μm, internal diameter 0.25 mm) as proposed by Janiszewski et al. [23]. Individual fatty acids were identified by comparing retention times with those for the mixture of the methyl esters of standard fatty acids (Supelco 37 Component FAME Mix and C18FAME Isomers, Sigma-Aldrich, Darmstadt, Germany) and expressed as a relative proportion of all fatty acids in the sample.

Microbiological analysis. The samples were analyzed according to the methods of the International Commission on Microbiological Specifications for Foods (ICMSF). Immediately after production, the chorizo sausages were placed in polyethylene bags, vacuum packed, and refrigerated. On the following day, they were evaluated for aerobic mesophiles, total and fecal coliforms, Staphylococcus coagulase, sulphite reducing spores, Salmonella, Listeria monocitogenes, Escherichia coli count, mold count, yeast count, and Bacillus cereus count according to the 2008 Colombian Technical Regulation (NTC according to its Spanish initials) 1325 for cooked meat products [24].

Sensory analysis. Sensory analysis was carried out following the methodology of Moghtadaei et al. [25]. The samples were randomly selected two days after production, prepared on grill at 110 ± 3°C for 15 min, randomly numbered with a three-digit code, and placed at 50°C on a tray for the panelists to evaluate in random order. A single sensory session was performed with 70 untrained volunteer panelists (staff and students of the National University of Colombia, 42% women and 58% men, aged 18–52). The panelists analyzed the samples rating their appearance, color, texture, and flavor according to the 7-point hedonic scale, with 1 meaning “dislike very much” and 7 meaning “like very much”. The survey also gathered information regarding their age and frequency of consumption of meat products. After rating the samples, the panelists were asked, “Would you purchase the products consumed in this sensory test?”. Between the samples, they were asked to clean their palate with water and a cracker.

Statistical analysis. Three independent replicates were made using the same ingredients on three different days (the mixing process for each formulation was replicated). All statistical analyses were carried out using the SAS Studio version software (Copyright SAS® On Demand for Academics, 2022). A one-way ANOVA was carried out to compare the samples containing shiitake with the control samples. The Tukey test (p ≤ 0.05) was applied to compare significant differences.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

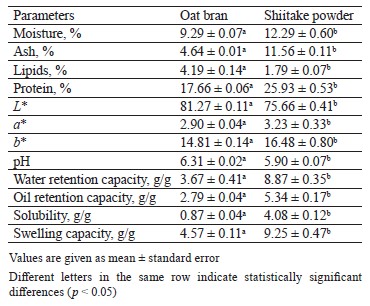

Characterization of shiitake powder. Table 2 presents the characterization of shiitake powder compared with oat bran used to incorporate fiber and substitute fats in processed meats.

As can be seen, shiitake mushrooms possessed higher percentages of protein and ash and lower percentages of lipids than oat bran, indicating that its nutritional quality was adequate to use in meat products. Studies of shiitake mushrooms carried out by Bisen et al. obtained values of 22.8% for protein, 2.1% for lipids, and 6% for ash [26].

The nutritional content of mushrooms, as well as their bioactive compounds, may vary according to the strain, crop, stage of development, age, storage conditions, and method of extraction [27]. Mushrooms are rich in fiber, carbohydrates, and protein. In particular, they are high in essential amino acids, phenolic compounds (e.g. gallic acid, protocatechuic acid, catechin, caffeic acid, ferulic acid, and myricetin), polyketides, flavonoids, terpenos, steroids, beta carotene, vitamins (including B, C, and D), and minerals (e.g. selenium, zinc, iron, potassium) [27–29]. Fresh shiitakes have an approximate moisture content of 86.3 ± 2.0%, although the level of moisture in dried shiitake varies according to the drying method [30].

Significant differences were found in color between the shiitake powder and oat bran samples, with the former having lower values for L* (being darker) than the latter. Shiitake powder showed greater values for a* and b*. Generally, variations in color among fresh, dried, and rehydrated mushrooms are caused by enzymatic browning or Maillard reactions during their processing [31].

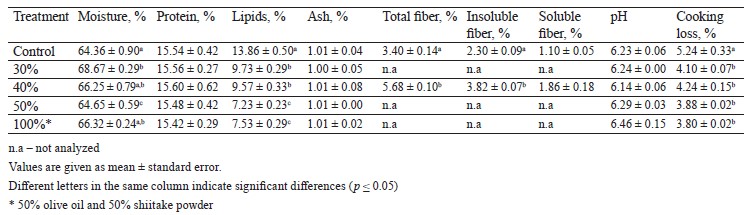

Technological and functional properties, such as water retention capacity, oil retention capacity, solubility, and swelling capacity, were significantly greater in shiitake mushrooms than in oat bran. Therefore, shiitake is expected to have a high level of performance as a functional ingredient, resulting in greater yields of processed meat products. According to Qiu et al., water retention capacity is an important factor in evaluating rehydrated shiitake because it greatly affects sensory properties and it is attributed to the mushroom’s proteins [32]. Having analyzed the secondary structure of the shiitake’s proteins, the authors found a relatively high content of α-helix links (approximately 17.52%), indicating a stable protein structure. They also found a high endothermic peak, which is generally associated with greater thermal stability. According to the authors, despite the condition of the fibrous matter of the cellular wall (β-1-3-glucan and β-1-6-glucan) and the cellular membrane, the fiber contributes little to changes in water retention capacity due to the loss of integrity upon drying and grinding. Nevertheless, the betaglucan content could positively affect the water retention capacity. It is possible that grinding the shiitake to facilitate its use as a dietary ingredient favored the functional characteristics presented in Table 2, since the finer the powder, the greater its solubility and swelling capacity [33].Characterization of the chorizo sausage. Proximate analysis. Table 3 presents the proximate composition and physiochemical characteristics of the samples analyzed. As can be seen, moisture and lipids significantly differed (p ≤ 0.05) among the treatments, with moisture being greater in the experimental samples than in the control. Moisture could be principally attributed to the shiitake’s fiber and protein contents that help retain water, as well as varying quantities of water in the formulations, while the lower lipid content in the samples might be down to fat substitution. Ash and protein contents did not show significant differences among the experimental sausage and the control (p > 0.05), indicating that despite a high content of shiitake powder (30% or more), which is rich in protein, the proportions employed did not modify these parameters in the final product. Similar results were reported for moisture content ranging from 66.8 to 70.64% in the sausage samples with shiitake [34].

Determination of pH. The results shown in Table 3 indicate that the substitution of fat with shiitake powder did not have any effect on the pH of the final product. Similar results were found by Wang et al., who reported no changes in the pH of sausages in which 25 or 50% of lean meat was substituted with shiitake [34].

Cooking loss. As shown in Table 3, the chorizo sausages with shiitake powder used to replace fat had a lower cooking loss than the control (p ≤ 0.05), apparently due to shiitake’s high level of water retention. Given that the capacity of the extenders of meat products to improve water and fat retention determines their level of shrinking upon cooking, it was expected that adding shiitake powder would lead to less contraction in the sausages’ diameter during cooking, as was reflected in their yield [35].

Shiitake powder’s high water retention capacity (Table 2) allows for greater yields, although a greater quantity of water was used in the samples with shiitake. This is important for the food industry in the search for technological solutions to reduce loss in yield during cooking, since water loss – aside from reducing yield – provokes the accumulation of liquid in the package, causing consequent changes in color and texture, which affects consumer acceptance [36]. Using less fat, as well as adding more water and less starch, as we proposed (Table 1), would allow for healthier processed meat products with fewer calories. Furthermore, additional water compensates for the loss of juiciness in processed meat products with reduced fat. As did the present study, previous investigations using aloe vera as a meat substitute in hamburgers and hydrated wheat bran as a substitute for meat and fats in hamburgers found that cooking loss was minimized upon increasing the use of extenders [5, 37].

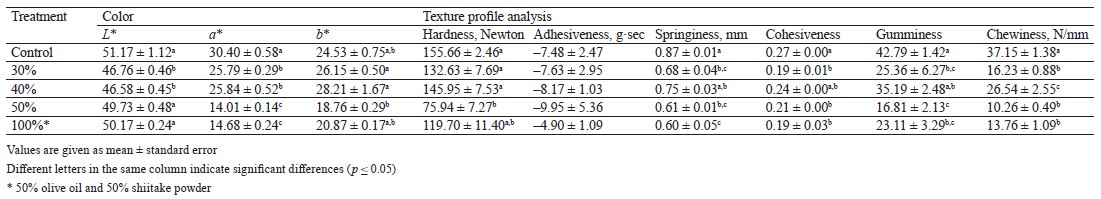

Color. The colors of the sausage samples with 30 and 40% fat substitution were statistically (p ≤ 0.05) less darker (L*), more yellow (b*), and less red (a*) (Table 4). The values of L* did not show a direct relationship with the concentrations of shiitake powder incorporated. Meanwhile, the values found for a* may have been influenced by the type of coloring agent used. Additionally, the red color (a*) resulting from the myoglobin of the meat might have been affected by incorporating shiitake powder, which is dark in color. A study by Martin et al. [38] reported the L* value of 48 and a* values of 12 to 16 for traditional Spanish cured chorizo sausages. Similar values were reported for a*

(24 to 37) in cured dried Spanish sausages in which carmine acid (E-120) was used as a coloring [39].

These results indicate that the color of meat products depends on many factors, including the type of meat used (beef, pork, chicken, rabbit, etc.), other ingredients (wheat flour, smoke, natural and/or artificial colorings, etc.), relative proportions of all ingredients, and technological processes (mixing, scalding, curing/fermenting, high pressure, etc.), all of which vary considerably from study to study. It is expected that noncured sausages made from ingredients such as those used in our study, including soy protein and starch (tapioca), will have a lighter color, principally due to the use of flours, fat substitution, and artificial coloring.

Texture profile analysis. Adding shiitake powder modified all the parameters of texture, except for adhesiveness (Table 4).

Hardness did not show a significant difference (p > 0.05) among the 30 and 40% samples and the control. Similar results for hardness (150.27 ± 19.75) were reported in a sample with 75% substitution of pork meat with shiitake mushroom [34]. Nevertheless, the sausage with 50 and 100% fat substitution were significantly less firm (p < 0.05). In general, our results indicated that substituting 50% of meat with shiitake powder decreased hardness, elasticity, and cohesiveness, making the samples less gummy and less chewable. The results for the 40% sample were similar to those for the control with respect to hardness, adhesiveness, springiness, cohesiveness, and gumminess. This indicated that substituting 40% of fat with shiitake powder maintained most of thetextural characteristics.

In a previous study by Royse et al., shiitake mushrooms were incorporated into processed meat products without affecting the texture [40]. The greater hardness in the control, as well as in the 30 and 40% sausage samples, may be attributed to the protein structure of shiitake, the structure of meat, and shiitake’s fiber that allowed for maintaining the structural network of the product formed by protein and fiber.

The values for springiness and chewiness in our study were lower than those recorded when using adzuki beans to substitute 25% of fat in meatballs, namely 1.19– 1.53 and 92.49–145.64 mm, respectively [6].

Gelation of the miosin as a result of hydrophobic interactions and the disulfide-sulfhydryl interactions among proteins has been reported to provide meat systems with greater springiness [41]. Thus, the differences in springiness among the samples in our study may be attributed to the effects of shiitake’s dietary fiber. This fiber may interfere with the aggregation of globular heads of miosin, which is the first step in the gelation of proteins during cooking. Furthermore, given that chewiness is a result of gumminess multiplied by springiness, it is expected that a significant increase in springiness caused by adding shiitake powder will directly increase the sample’s chewiness.

Based on the proximate analysis, as well as the measurements of pH, cooking loss, color, and texture, we determined that the sample with 40% fat substitution approached the most desirable outcome for these parameters. Thus, we recommend a 40% substitution of animal fat with shiitake powder and only this sample and the control were used in the further analyses of the final product.

Dietary fiber content. Table 2 shows the values for total, soluble, and insoluble dietary fiber of the 40% fat substitution sample and the control. As can be seen, the treatment showed significantly higher values (p < 0.05) for insoluble fiber than the control.

Shiitake mushrooms contain dietary fiber which has a high water-retention capacity in addition to increasing the quantity of insoluble fiber in the final product [42]. This is because fiber reinforces the tridimensional structure of the emulsified protein network, resulting in greater stability, as well as water and oil retention [43].

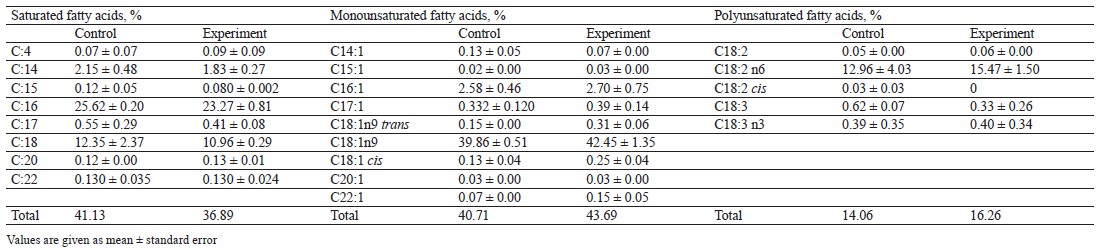

Fatty acids profile. Table 5 presents the fatty acids profile of the chorizo sausage with 40% of fat substituted with shiitake powder as compared to the control. No significant difference was found (p > 0.05) for the values of fatty acids between the experimental and control samples. Myristic (C:14), palmitate (C:16), and stearic (C:18) fatty acids were found to make up a large proportion of saturated fatty acids: 41.126% in the control and 36.899% in the experimental sausage. This is consistent with the results of Nieto and Lorenzo as beef and pig fat have a high content of saturated fatty acids [44].

Oleic acid (C18:1n9) was the most abundant monounsaturated fatty acid, making up 39.86% of all monounsaturated fatty acids in the control and 42.4% in the 40% fat substitution sample. With respect to the polyunsaturated fatty acids profile, linoleic acid (C18:2 n6) was the most abundant in the control and in the 40% fat substitution sample.

The fact that no significant differences were found in unsaturated fatty acids between the samples under study indicates that the quantity of shiitake powder was not sufficient to increase the amount of unsaturated fatty acids in the final product. Although shiitake contains unsaturated fatty acids, its fat content is low (< 2%) [45]. Therefore, the level of these healthy compounds in the final product can be improved by using higher quantities of shiitake to substitute animal fat (higher than 40%) and/or other sources of unsaturated fatty acids.

While its content of unsaturated fatty acids was not significant, shiitake powder contributed to decreasing caloric intake from animal fats in processed meat products. Additionally, shiitake mushrooms provide antioxidant properties and extend the shelf life of the final product [11].

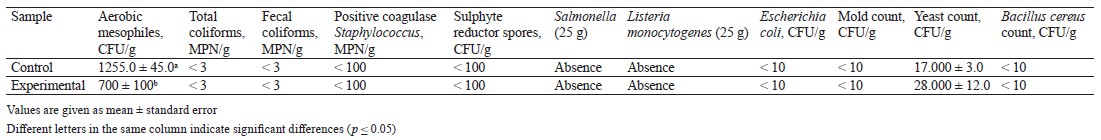

Microbiological analysis. Table 6 shows the microbiological results of the control sausage as compared to the 40% fat substitution sample. Significant differences (p ≤ 0.05) were found only in the aerobic mesophile count (CFU/g), with higher values in the control samples, indicating that shiitake may have an antibacterial effect against these microorganisms. According to Pil-Nam et al., at levels of 0.8%, shiitake reduced bacterial growth as well as lipid oxidation [11].

The microbiological parameters indicated that the levels of microorganisms in the control and in the experimental sausage were within those established by Colombia’s 2008 Regulation NTC 1325 for cooked meat products [24]. Therefore, the samples were apt for human consumption.

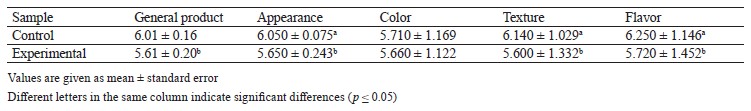

Sensory analysis. Table 7 demonstartes the sensory attributes of the 40% fat substitution sample as compared to the control. Significant differences were found between the general average scores for various characteristics, ranging from 5.4 to 6.3 on a 7-point hedonic scale.

Incorporation of shiitake powder as a substitute for 40% of animal fat significantly modified all sensory attributes compared to the control. The only exception was color with values of 5.708 ± 1.169 vs. 5.662 ± 1.122 for the control and experimental samples, respectively, corresponding to the rating “like moderately”. Although the experimental chorizo sausages were darker and less red – tending toward brown – in the instrumental assessment (Table 4), this had no effect on the panelists’ ratings (Table 7).

On the 7-point hedonic scale, both the samples were rated as “good” to “above average”, corresponding to “like slightly” (point 5), “like moderately” (point 6), and “like very much” (point 7). In all the cases, the consumers rated the control (without fat substitution) higher. Although the 40% fat substitution sample was less accepted than the control, it was not totally rejected with respect to any of the attributes.

In response to the question, “Would you purchase the product?”, 90.77% of the panelists responded that they would purchase the control product, while only 66.15% stated that they would purchase the sausage with shiitake. We recommend that future studies use a panel trained to be able to identify sensory aspects that should be improved in the final product.

To a certain extent, these sensory ratings may be attributed to the consumers’ lack of familiarity with hybrid products (those containing meat and plants as ingredients) and their lack of familiarity with the flavor of shiitake, which has a high content of umami compounds [46]. Although sensory modifications of a conventional product would be better tolerated by those consumers who are familiarized with its health benefits, pleasant sensory characteristics of meat products – e.g., color, texture, and flavor – are essential to their acceptance [47]. In any case, developing foods that contribute to adequate nutrition is still a relevant topic [48, 49]. Therefore, there is a need to further explore which conventional ingredients may be substituted by functional ingredients and to what extent, without affecting the sensory quality of processed meat products.

ВЫВОДЫ

Our study showed that shiitake powder’s technological and functional properties were preferable to those of oat bran, making it viable for incorporation into processed meat products. This functional ingredient provides the product with protein, ash, and fiber, and is low in lipids. While shiitake powder was found to be darker in color than oat bran, it did not affect the consumer acceptance of chorizo sausages with this ingredient.

The chorizo sausages in which 40% of fat was substituted with shiitake powder had greater contents of moisture and insoluble fiber, a lower percentage of lipids, less cooking loss, and lower mesophile counts than the control. No differences were found with respect to the protein value or fatty acids profile.

The sausages’ textural parameters were not affected by substituting 40% of fat with shiitake power. Nevertheless, the samples with 50% fat substitution had a significantly lower hardness than the control.

Finally, the fact that the control was more highly accepted by the panelists than the samples with 40% fat substitution was attributed to their lack of familiarity with hybrid products containing plant ingredients.

Вклад авторов

All the authors read and approved the final article. E.M. Rincón Soledad: investigation, formal analysis, writing of the original draft. M.A. Arredondo Nontién: investigation, formal analysis, writing of the original draft. J.W. Castro: investigation. D. Barrios: validation, review and editing. S.M. Vásquez Mejía: conceptualization, methodology, formal analysis, visualization, validation, writing, review and editing.

КОНФЛИКТ ИНТЕРЕСОВ

The authors declare that they have no known competing financial interests or personal relationships that may have influenced the results reported in this paper.

БЛАГОДАРНОСТИ

The authors would like to thank the sensory analysis panelists for their contribution to the study.ФИНАНСИРОВАНИЕ

This work was supported by the Universidad Nacional de Colombia (UNAL) (Project number: HERMES 49072- QUIPU: 302010032172).СПИСОК ЛИТЕРАТУРЫ

- Kim S-A, Shin S. Red meat and processed meat consumption and the risk of dyslipidemia in Korean adults: A prospective cohort study based on the Health Examinees (HEXA) study. Nutrition, Metabolism and Cardiovascular Diseases. 2021;31(6):1714–1727. https://doi.org/10.1016/j.numecd.2021.02.008

- Zhang J, Hayden K, Jackson R, Schutte R. Association of red and processed meat consumption with cardiovascular morbidity and mortality in participants with and without obesity: A prospective cohort study. Clinical Nutrition. 2021;40(5):3643–3649. https://doi.org/10.1016/j.clnu.2020.12.030

- González N, Marquès M, Nadal M, Domingo JL. Meat consumption: Which are the current global risks? A review of recent (2010–2020) evidences. Food Research International. 2020;137. https://doi.org/10.1016/j.foodres.2020.109341

- Barone AM, Banovic M, Asioli D, Wallace E, Ruiz-Capillas C, Grasso S. The usual suspect: How to co-create healthier meat products. Food Research International. 2021;143. https://doi.org/10.1016/j.foodres.2021.110304

- Carvalho LT, Pires MA, Baldin JC, Munekata PES, de Carvalho FAL, Rodrigues I, et al. Partial replacement of meat and fat with hydrated wheat fiber in beef burgers decreases caloric value without reducing the feeling of satiety after consumption. Meat Science. 2019;147:53–59. https://doi.org/10.1016/j.meatsci.2018.08.010

- Aslinah LNF, Mat Yusoff M, Ismail-Fitry MR. Simultaneous use of adzuki beans (Vigna angularis) flour as meat extender and fat replacer in reduced-fat beef meatballs (bebola daging). Journal of Food Science and Technology. 2018;55(8):3241–3248. https://doi.org/10.1007/s13197-018-3256-1

- Patinho I, Selani MM, Saldaña E, Bortoluzzi ACT, Rios-Mera JD, da Silva CM, et al. Agaricus bisporus mushroom as partial fat replacer improves the sensory quality maintaining the instrumental characteristics of beef burger. Meat Science. 2021;172. https://doi.org/10.1016/j.meatsci.2020.108307

- Oh I, Lee JH, Lee HG, Lee S. Feasibility of hydroxypropyl methylcellulose oleogel as an animal fat replacer for meat patties. Food Research International. 2019;122:566–572. https://doi.org/10.1016/j.foodres.2019.01.012

- Kouzounis D, Lazaridou A, Katsanidis E. Partial replacement of animal fat by oleogels structured with monoglycerides and phytosterols in frankfurter sausages. Meat Science. 2017;130:38–46. https://doi.org/10.1016/j.meatsci.2017.04.004

- Pérez-Montes A, Rangel-Vargas E, Lorenzo JM, Romero L, Santos EM. Edible mushrooms as a novel trend in the development of healthier meat products. Current Opinion in Food Science. 2021;37:118–124. https://doi.org/10.1016/j.cofs.2020.10.004

- Pil-Nam S, Park K-M, Kang G-H, Cho S-H, Park B-Y, Van-Ba H. The impact of addition of shiitake on quality characteristics of frankfurter during refrigerated storage. LWT. 2015;62(1):62–68. https://doi.org/10.1016/j.lwt.2015.01.032

- Mattar TV, Gonçalves CS, Pereira RC, Faria MA, de Souza VR, Carneiro JdDS. A shiitake mushroom extract as a viable alternative to NaCl for reduction in sodium in beef burgers: A sensory perspective. British Food Journal. 2018;120(6):1366–1380. https://doi.org/10.1108/BFJ-05-2017-0265

- Tejedor-Calvo E, Garcia-Barreda S, Sánchez S, Marco P. Effect of bacterial strains isolated from stored shiitake (Lentinula edodes) on mushroom biodeterioration and mycelial growth. Agronomy. 2020;10(6). https://doi.org/10.3390/agronomy10060898

- Schill S, Stessl B, Meier N, Tichy A, Wagner M, Ludewig M. Microbiological safety and sensory quality of cultivated mushrooms (Pleurotus eryngii, Pleurotus ostreatus and Lentinula edodes) at retail level and post-retail storage. Foods. 2021;10(4). https://doi.org/10.3390/foods10040816

- Official Method of Analysis of the AOAC International, 19th ed. Gaithersburg: The Association of Official Analytical Chemists; 2012.

- Yaruro Cáceres NC, Suarez Mahecha H, de Francisco A, Vásquez Mejia SM, Diaz-Moreno C. Physicochemical, thermal, microstructural and paste properties comparison of four achira (Canna edulis sp.) starch ecotypes. International Journal of Gastronomy and Food Science. 2021;25. https://doi.org/10.1016/j.ijgfs.2021.100380

- Official Method of Analysis of the AOAC International. Method 950.46. Loss on drying (moisture) in meat, 20th ed. Arlington: The Association of Official Analytical Chemists; 2016.

- Official Method of Analysis of the AOAC International. Method 991.36. Fat (crude) in meat and meat products, 20th ed. Gaithersburg: The Association of Official Analytical Chemists; 2016.

- Official Method of Analysis of the AOAC International. Method 990.03. Protein (crude) in animal feed, combustion method, 18th ed. Arlington: The Association of Official Analytical Chemists; 2005.

- Official Method of Analysis of the AOAC International. Method 920.53. Ash in meat and meat products, 20th ed. Gaithersburg: The Association of Official Analytical Chemists; 2016.

- Vasquez Mejia SM, Shaheen A, Zhou Z, McNeill D, Bohrer BM. The effect of specialty salts on cooking loss, texture properties, and instrumental color of beef emulsion modeling systems. Meat Science. 2019;156:85–92. https://doi.org/10.1016/j.meatsci.2019.05.015

- Official Method of Analysis of the AOAC International, 18th ed. Gaithersburg: The Association of Official Analytical Chemists; 2005.

- Janiszewski P, Grześkowiak E, Lisiak D, Borys B, Borzuta K, Pospiech E, et al. The influence of thermal processing on the fatty acid profile of pork and lamb meat fed diet with increased levels of unsaturated fatty acids. Meat Science. 2016;111:161–167. https://doi.org/10.1016/j.meatsci.2015.09.006

- Norma Técnica Colombiana NTC 1325. Instituto Colombiano de Normas Técnicas y Certificación; 2008.

- Moghtadaei M, Soltanizadeh N, Goli SAH. Production of sesame oil oleogels based on beeswax and application as partial substitutes of animal fat in beef burger. Food Research International. 2018;108:368–377. https://doi.org/10.1016/j.foodres.2018.03.051

- Bisen PS, Baghel RK, Sanodiya BS, Thakur GS, Prasad GBKS. Lentinus edodes: A macrofungus with pharmacological activities. Current Medicinal Chemistry. 2010;17(22):2419–2430. https://doi.org/10.2174/092986710791698495

- Ramos M, Burgos N, Barnard A, Evans G, Preece J, Graz M, et al. Agaricus bisporus and its by-products as a source of valuable extracts and bioactive compounds. Food Chemistry. 2019;292:176–187. https://doi.org/10.1016/j.foodchem.2019.04.035

- Buruleanu LC, Radulescu C, Georgescu AA, Danet FA, Olteanu RL, Nicolescu CM, et al. Statistical characterization of the phytochemical characteristics of edible mushroom extracts. Analytical Letters. 2018;51(7):1039–1059. https://doi.org/10.1080/00032719.2017.1366499

- Adebayo EA, Martínez-Carrera D, Morales P, Sobal M, Escudero H, Meneses ME, et al. Comparative study of antioxidant and antibacterial properties of the edible mushrooms Pleurotus levis, P. ostreatus, P. pulmonarius and P. tuber-regium. International Journal of Food Science and Technology. 2018;53(5):1316–1330. https://doi.org/10.1111/ijfs.13712

- Subramaniam S, Wen X-Y, Zhang Z-T, Jing P. Changes in the morphometric, textural, and aromatic characteristics of shiitake mushrooms during combined humid-convective drying. Drying Technology. 2021;39(16):2206–2217. https://doi.org/10.1080/07373937.2020.1760878

- Wang X-M, Zhang J, Wu L-H, Zhao Y-L, Li T, Li J-Q, et al. A mini-review of chemical composition and nutritional value of edible wild-grown mushroom from China. Food Chemistry. 2014;151:279–285. https://doi.org/10.1016/j.foodchem.2013.11.062

- Qiu Y, Bi J, Jin X, Hu L, Lyu J, Wu X. An understanding of the changes in water holding capacity of rehydrated shiitake mushroom (Lentinula edodes) from cell wall, cell membrane and protein. Food Chemistry. 2021;351. https://doi.org/10.1016/j.foodchem.2021.129230

- Xu Z, Meenu M, Xu B. Effects of UV-C treatment and ultrafine-grinding on the biotransformation of ergosterol to vitamin D2, physiochemical properties, and antioxidant properties of shiitake and Jew’s ear. Food Chemistry. 2020;309. https://doi.org/10.1016/j.foodchem.2019.125738

- Wang L, Guo H, Liu X, Jiang G, Li C, Li X, et al. Roles of Lentinula edodes as the pork lean meat replacer in production of the sausage. Meat Science. 2019;156:44–51. https://doi.org/10.1016/j.meatsci.2019.05.016

- Borrajo P, Pateiro M, Munekata PES, Franco D, Domínguez R, Mahgoub M, et al. Pork liver protein hydrolysates as extenders of pork patties shelf-life. International Journal of Food Science and Technology. 2021;56(12):6246–6257. https://doi.org/10.1111/ijfs.15359

- Bastos SC, Pimenta MESG, Pimenta CJ, Reis TA, Nunes CA, Pinheiro ACM, et al. Alternative fat substitutes for beef burger: Technological and sensory characteristics. Journal of Food Science and Technology. 2014;51(9):2046–2053. https://doi.org/10.1007/s13197-013-1233-2

- Soltanizadeh N, Ghiasi-Esfahani H. Qualitative improvement of low meat beef burger using Aloe vera. Meat Science. 2015;99:75–80. https://doi.org/10.1016/j.meatsci.2014.09.002

- Martín MJ, García-Parra J, Trejo A, Gómez-Quintana A, Miguel-Pintado C, Riscado A, et al. Comparative effect of high hydrostatic pressure treatment on Spanish and Portuguese traditional chorizos and evolution at different storage temperatures. Journal of Food Processing and Preservation. 2020;45(1). https://doi.org/10.1111/jfpp.15082

- Martínez-Zamora L, Peñalver R, Ros G, Nieto G. Substitution of synthetic nitrates and antioxidants by spices, fruits and vegetables in Clean label Spanish chorizo. Food Research International. 2021;139. https://doi.org/10.1016/j.foodres.2020.109835

- Royse DJ, Baars J, Tan Q. Current overview of mushroom production in the world. In: Zied DC, Pardo-Giménez A, editors. Edible and medicinal mushrooms: Technology and applications. John Wiley & Sons Ltd; 2017. https://doi.org/10.1002/9781119149446.ch2

- Savadkoohi S, Shamsi K, Hoogenkamp H, Javadi A, Farahnaky A. Mechanical and gelling properties of comminuted sausages containing chicken MDM. Journal of Food Engineering. 2013;117(3):255–262. https://doi.org/10.1016/j.jfoodeng.2013.03.004

- Selani MM, Shirado GAN, Margiotta GB, Saldaña E, Spada FP, Piedade SMS, et al. Effects of pineapple byproduct and canola oil as fat replacers on physicochemical and sensory qualities of low-fat beef burger. Meat Science. 2016;112:69–76. https://doi.org/10.1016/j.meatsci.2015.10.020

- Mehta N, Ahlawat SS, Sharma DP, Dabur RS. Novel trends in development of dietary fiber rich meat products – A critical review. Journal of Food Science and Technology. 2015;52(2):633–647. https://doi.org/10.1007/s13197-013-1010-2

- Nieto G, Lorenzo JM. Use of olive oil as fat replacer in meat emulsions. Current Opinion in Food Science. 2021;40:179–186. https://doi.org/10.1016/j.cofs.2021.04.007

- Pathak MP, Pathak K, Saikia R, Gogoi U, Ahmad MZ, Patowary P, et al. Immunomodulatory effect of mushrooms and their bioactive compounds in cancer: A comprehensive review. Biomedicine and Pharmacotherapy. 2022;149. https://doi.org/10.1016/j.biopha.2022.112901

- Harada-Padermo SDS, Dias-Faceto LS, Selani MM, Conti-Silva AC, Vieira TMFdS. Umami ingredient, a newly developed flavor enhancer from shiitake byproducts, in low-sodium products: A study case of application in corn extruded snacks. LWT. 2021;138. https://doi.org/10.1016/j.lwt.2020.110806

- Urruzola N, Santana M, Gámbaro A. Aceptabilidad sensorial de una hamburguesa de carne vacuna y vegetales. Innotec. 2018;15(1):15–22. https://doi.org/10.26461/15.03

- Sadovoy VV, Shchedrina TV, Trubina IA, Morgunova AV, Franko EP. Cooked sausage enriched with essential nutrients for the gastrointestinal diet. Foods and Raw Materials. 2021;9(2):345–353. https://doi.org/10.21603/2308-4057-2021-2-345-353

- Koneva SI, Zakharova AS, Meleshkina LE, Egorova EYu, Mashkova IA. Technological Properties of Dough from a Mix of Rye and Wheat Flour with Processed Sea Buckthorn. Food Processing: Techniques and Technology. 2023;53(2):247–258. (In Russ.). https://doi.org/10.21603/2074-9414-2023-2-2431