Аннотация

Nowadays, the development of environmentally-friendly packaging materials is relevant worldwide. Biodegradable packaging materials are promising due to their safety and ability to extend shelf life of food products. This study aimed to investigate the properties of biodegradable film based on a bacterial exopolysaccharide (xanthan) with the view to extend the quality and shelf life of chilled meat products. We studied pork and carp samples packed in biodegradable film and stored at 0–2°C. Biodegradable packaging had positive effects on sensory, physicochemical, and microbiological parameters, as well as on ecological safety of the raw materials. During storage of packed chilled pork, its mass loss decreased from 2.16 to 0.21% (norm to 0.30%), and water activity reduced from 0.985 to 0.960, which had a positive effect on the microbiological resistance of pork during storage. The use of biodegradable film contributed to the preservation of quality and freshness of carp, which was confirmed by sensory and microbiological indicators. Total microbial contamination in carp packed in biodegradable film was significantly lower than that in unpacked samples, which extended its shelf life for one day compared to control. Biodegradable packaging also allowed mass loss and pH value to decrease during storage and inhibited oxidation processes in the samples under study. Free fatty acid content decreased by a factor of two, and peroxides, by 7%. Thus, biodegradable films can be effective film coatings to use in the food industry. This method of packaging not only preserves the functional and technological properties of food products, lowers their mass loss, and extends their shelf life, but also reduces costs and is environmentally friendly.Ключевые слова

Biodegradable packaging, film coating, xanthan, shelf life, food quality, meat productsВВЕДЕНИЕ

Among the fundamental principles of raw materials and foods quality are their safety, sustainability, and long-term nutritional value [1, 2, 14].

One of the promising directions in addressing the global pollution of human habitat by polymer waste is to create environmentally safe packaging [3, 4]. Much attention is paid to the development of biodegradable and edible packaging materials which simplify product dosing and portioning without polluting the environment [5–7].

Using natural polymers – polysaccharides – as a film-forming basis is highly promising in the production of biodegradable coatings. Polysaccharide-based films protect raw materials and food products from mass loss (due to reduced moisture evaporation rate) and from the penetration of oxygen and other substances. As a result, it slows down the changes in the product quality [8, 9].

Films based on microbial polysaccharides are not yet sufficiently used in national economies. They have lower barrier and mechanical properties (resistance to high product and environment moisture) than polymeric films. But their main advantage is that they do not pollute the environment because they are biodegradable [10].

In this regard, it is highly relevant to develop environmentally safe biodegradable coating for meat raw materials using exopolysaccharides of bacterial origin. Our aim was to study sensory, physicochemical, and microbiological parameters, as well as environmental safety and storage time of meat and fish raw materials packed in biodegradable film based on exopolysaccharide of bacterial origin (xanthan).

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

The objects of our study were xanthan (France), chilled pork, and pond carp. Pigs were slaughtered at “Products of the Volga Region” meat processing plant in accordance with the requirements of the Technical Regulations of the Customs Union on safety of meat and meat products (TR CU 034/2013). Carcasses were cut in accordance with State Standard 31778-2012. Pork meat (m. longissimus dorsi) was cut into portions (20–40 g) and packed in biodegradable xanthanbased film. Unpackaged raw materials were used as control samples. As for fish, we used freshly dead pond carp yearlings (90–110 g) grown at the Fish Cultivation Laboratory at Saratov State Agrarian University. Experimental fish samples were packed in a biodegradable film, while unpacked fish was used as a control. A film coating was made according to the method described in the Patent of the Russian Federation No. 2662008C1 “Biodegradable food film coating” [11].

Mesophilic aerobic and facultative anaerobic microorganisms in pork and carp were determined according to State Standard 10444.15-94 on meat-andpepton agar (MPA). Coliform bacteria were determined according to State Standard 31747-2012 on Kessler and Endo media. Salmonella was determined according to State Standard 31659-2012, using non-selective enrichment medium (buffered pepton water), selective enrichment medium (RVS broth), and differential diagnostic media (bismuth-sulfite agar and Endo agar). L. monocytogenes lysteria were determined according to State Standard 32031-2012, using PBL1, PBL2 (Listeria enrichment broth), and agar listeria Ottaviani-Agosti (ALOA-agar). Proteus bacteria in pork were determined according to State Standard 28560-90 on agar for Proteus release, and staphylococcus in carp, according to State Standard 31746-2012, using sodium chloride broth and salt-egg yolk agar.

To determine pork freshness, we selected experimental samples (packed in biodegradable film) and control (unpacked) samples stored at 0–4°C. The selection was carried out according to State Standard 7269-79. The pork samples were sent to the production laboratory. Each sample was wrapped in parchment paper and numbered. Chilled raw materials were stored at 0–2°C. Changes in acid and peroxide numbers, as well as thiobarbituric value, indicated the processes occurring in the lipid fraction during storage.

Toxic lead and cadmium were determined by the method of the Scientific Council on Analytical Methods 450xs (Methodological Guidelines 4.1.986-00).

Mass fraction of antibiotics was determined by an express-method based on antibiotic suppression of dehydrogenase activity of testing cultures in a liquid nutrient medium (Methodological Guidelines 4.2.026-95).

Water-binding capacity (WBC) was determined by pressing method on filter paper by Grau-Hamm modified by Volovinska-Kelman [12].

Acid and peroxide numbers were determined according to standard methods of Gorbatov All-Russia Meat Research Institute to assess the quality and safety of meat and meat products.

Thiobarbituric index was determined according to the Sidwell method modified by Turner.

Concentration of hydrogen ions was determined by potentiometric method at a 2696 contact pH meter with automatic compensation in the range of 0 to 40°C for pH and temperature measurements of aqueous solutions.

Water activity (Aw) of raw materials was determined by a cryoscopic method based on the determination of the freezing temperature of the sample and its conversion into the indicator of water activity.

Fats were extracted from fish raw materials by an extraction-weight method according to State Standard 54053-2010. The content of individual fatty acid methyl esters in relation to total fatty acid content was determined by gas chromatography according to State Standard R 51486-99 and State Standard R 51483-99 using a Crystal 2000M gas chromatograph. The acid number of extracted fats was determined according to State Standard R 52110-2003. The peroxide number was determined by the Golovkina and Perkel method. Peroxides in fish fats were determined by pH titration.

Sensory analysis of pork and fish was carried out according to State Standard 23670-79 and State Standard 814-96XVII, respectively. The analysis included appearance, color, aroma, flavor, and texture.

The results were statistically processed using Microsoft Excel 2010 (Microsoft Corp. USA) and StatPlus 2009 Professional 5.8.4 for Windows statistical analysis package (StatSoft Inc., USA). The Student t-criterion was used to assess the validity of differences between samplings.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

We aimed to develop and investigate eco-safe packaging, namely bactericidal biodegradable film based on bacterial exopolysaccharide (xanthan) to extend the shelf life of animal raw materials.

At the initial stage, we assessed the sanitary and hygienic state of the raw materials (Tables 1 and 2).

The content of toxic elements (lead and cadmium) met the requirements of the Technical Regulations of the Eurasian Economic Union “On safety of meat and meat products”. We did not detect any antibiotics (levomycetin, grisin, bacitracin) or their traces in experimental pork samples packed in xanthan film (TR CU 034/2013).

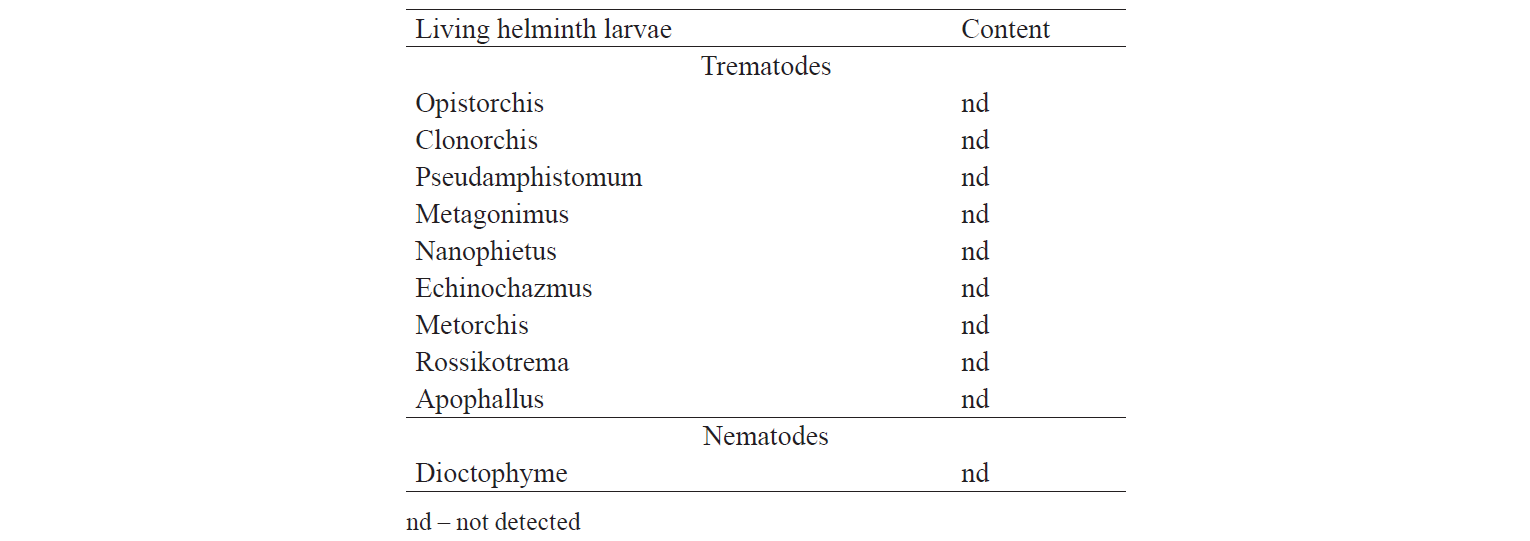

Further, we examined carp for parasitological parameters (Table 2).

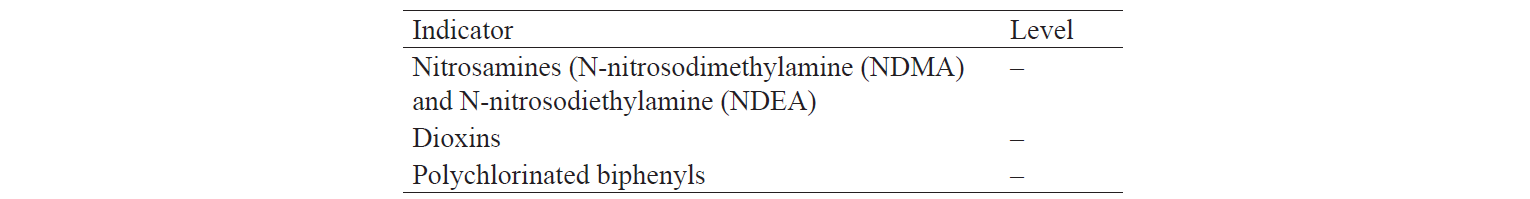

The hygienic parameters of carp are presented in Table 3.

The results of sanitary and hygienic analysis showed that the fish raw materials under study met the requirements of the TR EAEU 040/2016 (Tables 2 and 3).

The quality of chilled meat during storage and moisture loss are known to depend on temperature and cooling rate. Meat mass loss due to moisture evaporation during cooling is not only a quantitative characteristic. The product’s porous surface and thermal burns result in deteriorated marketable conditions. De-iced pores are filled with air, which accelerates oxidative processes reducing the quality and marketability of pork [13].

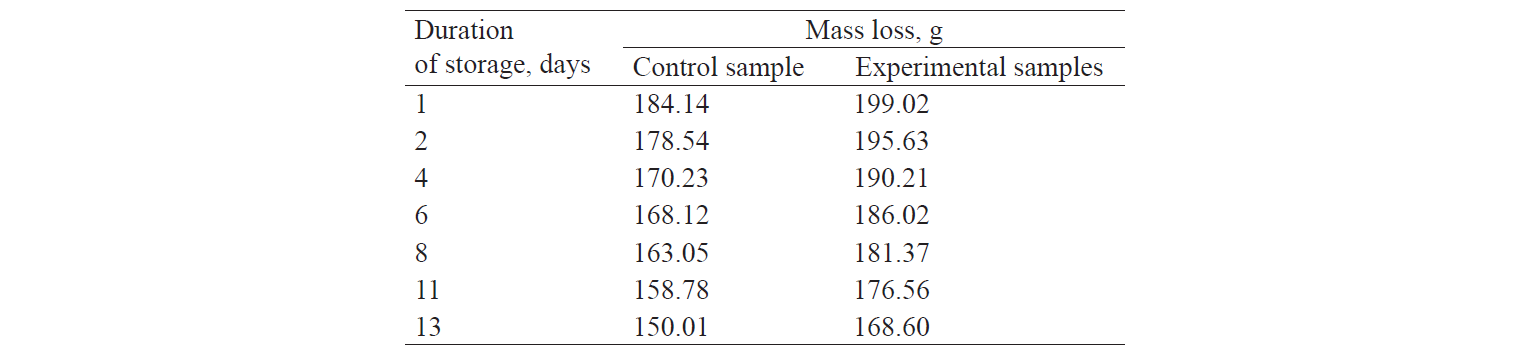

In our study, the mass loss of chilled pork packed in bio-degradable film decreased from 2.16% to 0.21% during storage (Table 4).

These results confirm that the biodegradable film is tightly attached to the surface of the raw material. This ensures reliable sealing of the packaging and prevents moisture exchange [19].

In our study, the storage of pork packed in biofilm in cardboard containers significantly weakened temperature fluctuations and had a positive effect on mass loss reduction. Biodegradable packaging not only ensures the microbiological stability of meat products, but also improves their sensory properties due to an increased meat water-binding capacity. The mass loss of pork packed in biodegradable film was lower and the meat was more dense than unpackaged pork.

In addition, biodegradable films slow down oxidation processes. The decreased rate of oxidation processes in the experimental samples correlates with their sensory indicators. Sensory evaluation showed that all packaged pork samples were fresh throughout the storage period, namely seven days. Packing in biodegradable film improves the sensory properties of raw materials, which could not be achieved when storing without packaging. The experimental samples had a more attractive appearance and preserved their flavor during the shelf life. The samples packed in biodegradable film had a brighter color, as the proposed packaging prevented oxidation of heme pigments. The control samples had a specific drying crust on the meat surface. The film did not degrade the taste, consistency, or color of pork.

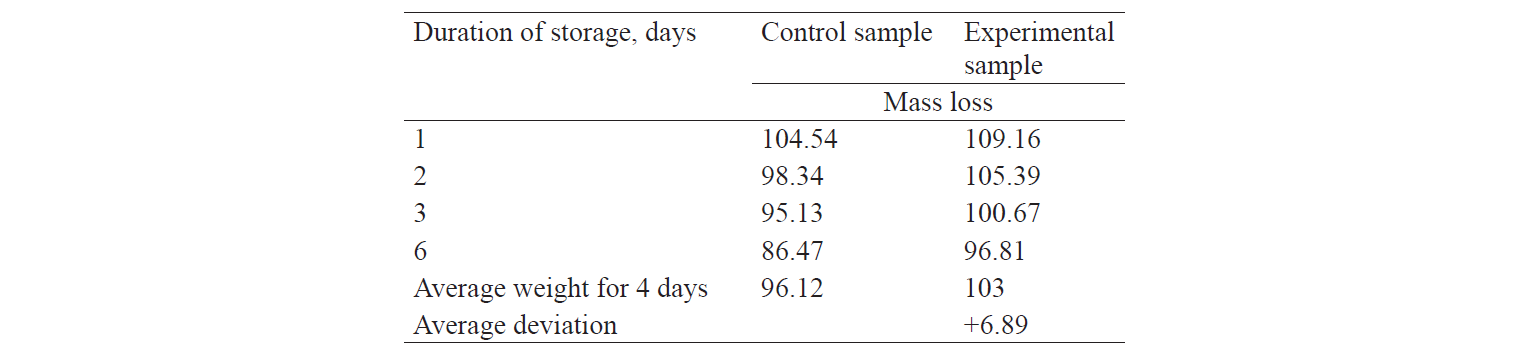

The sensory evaluation of carp packed in biodegradable film showed that the fish met all the criteria for this type of raw materials within the first four days, followed by a decline in the sensory indicators. The control (unpackaged) samples deteriorated as early as day 3 (Table 5).

A possible duration of refrigerated storage for fish raw materials is determined by their initial properties, as well as refrigeration and storage conditions. For example, sealed packaging eliminates the need to regulate the air humidity and prevents microbial contamination. As a result, sealed packaging can, to some extent, compensate for the lowering of the storage temperature by a few degrees.

We found that the use of biodegradable film contributed to the preservation of the quality and freshness of carp, keeping its sensory indicators at the required level for quite a long time and reducing the natural loss of product mass during storage.

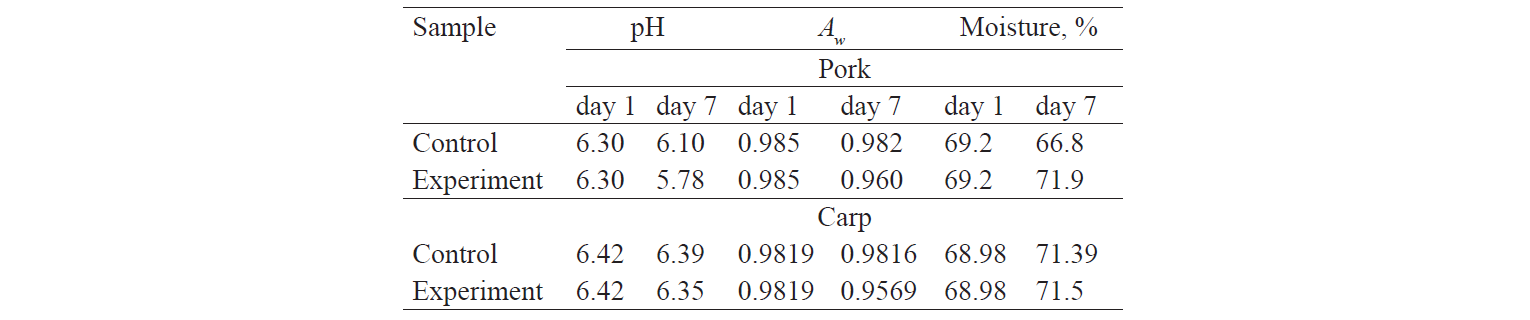

The analysis of Tables 5 and 6 showed the positive effect of biodegradable film packaging on the carp quality during short-term storage in a cold chamber without special conditions. The analysis of pork’s physicochemical indicators revealed that biodegradable film packaging inhibited the microbial and enzymatic activity, which reduced structural and chemical changes in the raw materials under study.

The activity of water is known to have a great impact on the growth of microorganisms. The initial water activity value of pork Aw was 0.985. Packing in biodegradable film based on exopolysaccharide of bacterial origin reduced this value to the level of 0.96 for 7 days. Thus, biodegradable film had a positive effect on microbiological stability of pork and carp during storage.

The data characterizing the functional and technological characteristics of the raw materials are presented in Table 7.

According to the data from Table 7, biodegradable film packaging decreased pH to 5.78, as a result of accelerating glycolysis, which contributed to the inhibition of bacterial growth on meat surface. In addition, pH values in the experimental samples were lower due to the biodegradable film’s pH (7.5). This contributed to an increase in moisture by 5.1% and improved hydration properties of muscle fibers during storage. The same trend was observed for the waterbinding capacity of experimental and control samples. Based on the data presented in Table 7, we can conclude that biodegradable film packaging showed an identical effect on both meat and fish raw materials; the mass loss and pH values of carp reduced during storage.

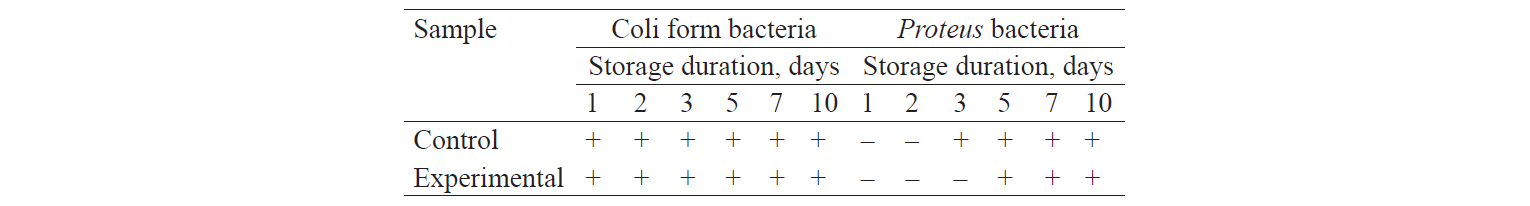

Thus, the packaging of animal raw materials in biodegradable film based on exopolysaccharides before cooling preserved the quality and increased their stability during storage by slowing chemical, microbiological, and enzymatic processes which cause spoilage. Microbiological characteristics of pork stored at 0–2°C for 10 days are presented in Tables 8 and 9.

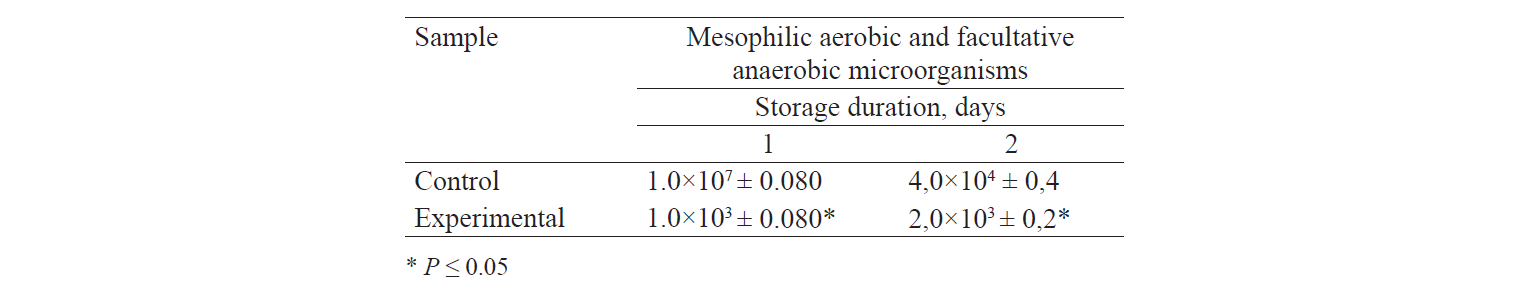

On days 1 and 2 of meat storage, we observed a gradual increase in the number of mesophilic aerobic and facultative anaerobic microorganisms, as well as coli form bacteria, both in the control and experimental samples. Three days later, the number of mesophilic aerobic and facultative anaerobic microorganisms decreased in the experimental samples, while in the control ones this indicator increased, compared to day 1. Proteus bacteria were detected in the control samples on day 3. This bacterial growth indicated the beginning of meat spoilage (rotting processes). In the experimental samples, Proteus was found only on day 5. Proteus bacteria count in the control samples was significantly higher than in the samples packed in biofilm. Pathogenic bacteria, including salmonella and L. monocytogenes, were not found in the samples.

Obviously, the packaging reduces oxygen access to raw materials and almost completely inhibits the growth of aerobic microorganisms. As a result, the shelf life of chilled pork in biodegradable film increased to 5 days.

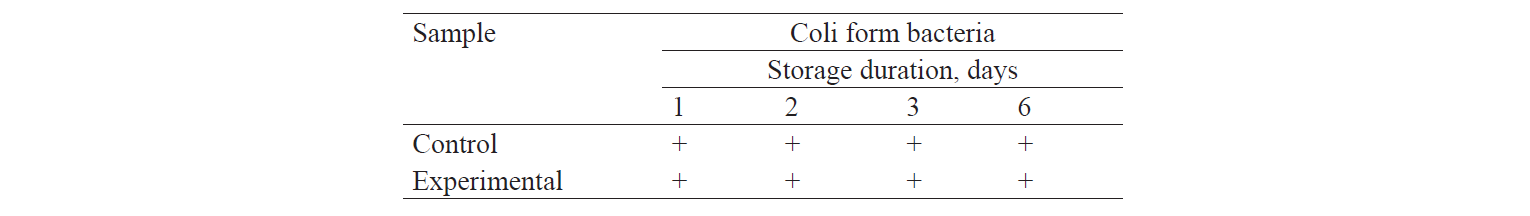

We also studied the influence of biodegradable film packaging on the microbiological processes occurring in carp meat. It was revealed that the biofilm significantly reduced the total contamination of fish on days 1 and 2, thereby increasing the storage duration. Microbiological characteristics of fish stored at 0–2°C for 2–6 days are presented in Tables 10 and 11.Pathogenic bacteria, including salmonella and L. monocytogenes and staphylococci, were not found in the samples under study. The data allowed us to conclude that the film contributed to extending carp shelf life. Thus, the microbiological results closely correlated with the sensory characteristics of carp.

The oxidation processes in lipids are important in the storage of raw meat. Lipids are relatively unstable because they contain unsaturated fatty acids that are easily oxidized. The oxidation of lipids, as well as the pigments of muscle tissue, depends on oxygen partial pressure. Oxidative changes in lipids under aerobic conditions have a limited rate of hydroperoxic radical formation [15, 16].

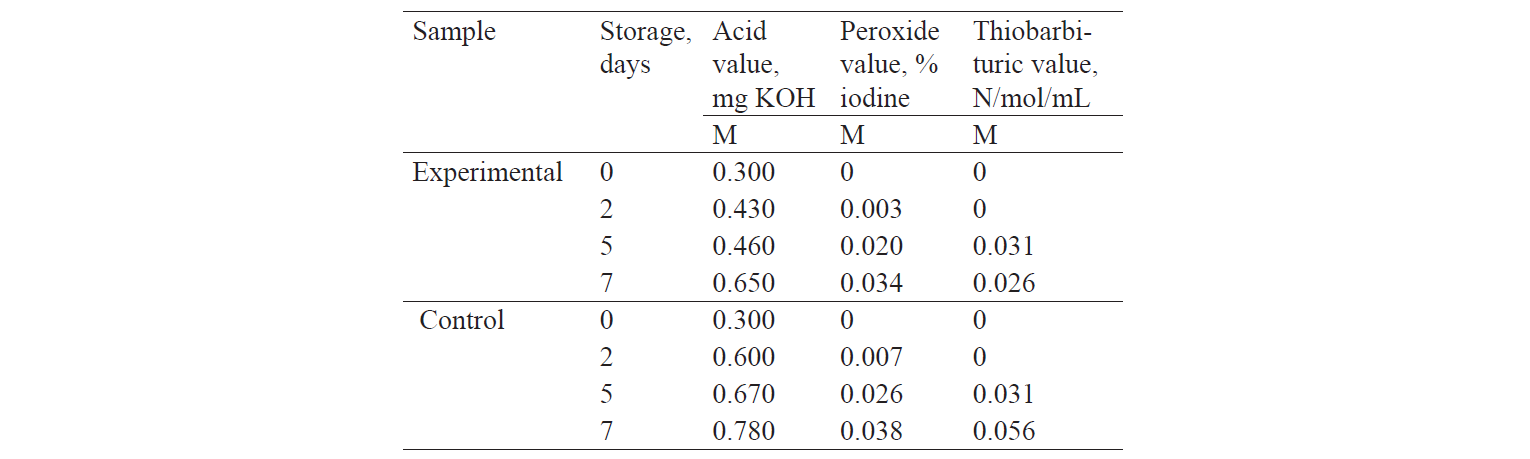

We studied oxidation processes of raw meat packed in biodegradable film and their effect on meat shelf life. The shelf life of pork to a large extent depends on the resistance of the lipid fraction to oxidation, which, in its turn, depends on the content of radicals of unsaturated fatty acids and the degree of their unsaturation. To evaluate the rate of oxidative processes occurring in cooled meat during storage, we determined peroxide, acid, and thiobarbituric values in the experimental samples (packed in biodegradable film based on exopolysaccharide of bacterial origin) and in the control samples (Table 12).

As one can see from Table 12, the control samples showed a more intensive enzymatic hydrolysis rate of triglycerides and phospholipids in the control samples.

The accumulation of secondary oxidation products depends on the initial thiobarbituric value and has a negative effect on the sensory parameters and shelf life of products. By the end of storage (day 7), the value was 0.056 for unpackaged meat and 0.026 for pork packed in biodegradable film, which confirms the prospects of the proposed packaging. The analysis of lipid parameters of pork stored at 0–2°C showed that by day 7, the thiobarbituric value in pork packed in biodegradable film was 2.2 times lower than in the control samples. We found that the duration of induction increased and the rate of peroxides accumulation decreased with reduction of air oxygen access to raw materials.

A slight increase in peroxide value indicated the inhibition of oxidative processes. At the final stage of pork storage (day 7), the growth of peroxide values for packaged and control samples was 0.034 and 0.038%, respectively. The slower oxidation process in packaged pork can be explained by a low gas permeability of the packaging film combined with the ability of muscle tissue to absorb oxygen. A low amount of oxygen in the package inhibits oxidative processes and, in combination with low temperature, creates favorable conditions for raw materials.

A determining factor of the fish shelf life is often lipid oxidation, which causes negative changes in its sensory properties (taste, flavor, color, texture) and nutritional value, as well as possible formation of toxic oxidation products. The processes of lipid change are quite complex since they occur as a result of chemical, biological, and enzymatic transformations. These processes often occur simultaneously, but lead to the formation of the same intermediate end products such as peroxides, free fatty acids, aldehydes, ketones, as well as products of their polymerization. The oxidizing properties of fats depend on the degree of fat unsaturation and factors inhibiting oxidation, namely heat, light, traces of heavy metals, etc.

In addition, the degree of lipolysis is of importance, since this process is the first stage of degradation of the product. Enzymes (e.g. lipoxygenases) catalyze lipid oxidation, interacting mainly or exclusively with free fatty acids. The stability of food material in relation to lipolytic decomposition is an indicator of biochemical activity of enzymes, cofactors, and lipid substrates. Water-insoluble lipids tend to aggregate, forming a boundary layer. Thus, the sensitivity to lipolysis and subsequent lipid oxidation is determined by the physicochemical properties of this unique twodimensional medium. In the case of fish, of great importance is its physiological condition, which affects its quality and shelf life.

The fatty acid composition of carp fat phase showed that its lipids were characterized by high biological efficiency, but at the same time by instability during storage due to their unsaturation (Table 13).

Since peroxide and acid values are indicators of the product’s safety, we determined these parameters in the control and experimental carp samples (Table 14).

Table 13 demonstrates that the content of free fatty acids in the experimental samples was almost half as large as in the control samples on day 1 of storage. This suggests that hydrolytic processes in the tissues of the experimental carp samples occurred more slowly during storage. Nevertheless, the content of free fatty acids exceeded the current norm six to seven times at the final stage of research.

According to the data presented in Table 14, the content of peroxides on day 1 of storage corresponded to the norms (less than 10 meq/kg) in both groups and was higher in the control compared to the experimental samples. By the end of the experiment, it reached the levels that did not meet the safety requirements.

Thus, the change in the fat fraction in carp packed in biodegradable film slowed down the oxidation of its lipids. However, it should be noted that the carp samples under study had an increased initial content of free fatty acids and peroxides that did not meet the requirements of technical regulations, which may be due to the diet used in carp cultivation.

The results of our research are largely comparable with numerous studies on the influence of various biodegradable films on the quality and shelf life of animal raw materials. Jeevahan et al. showed a positive effect of starch-based nanocellulose film on food products [17]. Another work was devoted to the use of biodegradable nanocomposite pigment films for food conservation [18].

Wang et al. and Pavlath revealed that biodegradable cellulose composite film based on corncob lignin and made by an anti-solvent precipitation method is effective in food technologies [19, 20]. In addition, water-soluble Vivos (MonoSol) film has been recently studied. However, its use is limited, as it dissolves only in hot water [9]. Promising are film coatings based on polysaccharides (chitosan, alginates), as well as calcium or magnesium salts, which were developed by Harvard University researchers [21].

ВЫВОДЫ

This paper suggested the use of bacterial exopolysaccharides (xanthan) as the main ingredient for food film coatings. We revealed that this packaging reduced oxygen access to raw materials and almost completely inhibited the growth of aerobic microorganisms, resulting in extended shelf life resistance of meat and fish during storage. Under such a coating, myoglobin retained its native state, so the meat had a richer color, which appeals to consumers. Biodegradable film packaging increased not only the microbiological stability of meat, but also its waterbinding capacity and sensory properties. Pork packed in the biodegradable film has higher juiciness and denser texture compared to unpacked samples. In addition, we observed the significant inhibition of aerobic and coliform bacteria growth in experimental samples at 0–2°C.

The storage temperature of 0–2°C for pork and carp, relative air humidity of 85–90%, and air speed of 0.2–0.3 m/s provided high quality for 10 days for pork and 2 days for fish. It should be noted that the chosen temperature did not prevent the development of microflora, enzymatic processes, and processes of fat fraction oxidation. Nevertheless, biodegradable film extended the shelf life of chilled meat products and protected it from microbial and oxidative damage.

The packaging of meat raw materials in biodegradable film can be very promising to use in the food industry. This method of packaging not only preserves the functional and technological properties of food products, lowers their mass loss, and extends their shelf life, but also reduces costs and is environmentally friendly.

The findings were presented at the 20th Russian agro-industrial exhibition “Golden Autumn-2018” and awarded a diploma and a bronze medal.

In addition, we developed technical documentation for the production of pork cuts 9213-012-00493497-18 (“Pork cuts packed in biodegradable film”). The technology was tested and adopted at “Products of the Volga Region” meat processing plant (Engels, Saratov region).

КОНФЛИКТ ИНТЕРЕСОВ

The authors state that there is no conflict of interest.

ФИНАНСИРОВАНИЕ

This research was funded by the Russian Scientific Foundation 19-76-10013 “Development and implementation of technology for production and storage of environmentally safe lamb enriched with essential trace elements”.СПИСОК ЛИТЕРАТУРЫ

- Johnson RA, Bhattacharyya GK. Statistics. Principles and methods. 6th ed. USA: John Wiley & Sons, Inc; 2010. 706 p.

- Lisitsyn AB, Semenova AA, Kuznetsova TG, Dydykin AS, Nasonova VV. Study of the effect of sex and type of muscles on the development of quality defects in turkey meat after the slaughter. Foods and Raw Materials. 2018;6(1):63–70. DOI: http://doi.org/10.21603/2308-4057-2018-1-63-70.

- Akshaykranth A, Rao TV, Kumar RR. Growth of ZnO nanorods on biodegradable poly (lactic acid) (PLA) substrates by low temperature solution method. Materials Letters. 2020;259. DOI: https://doi.org/10.1016/j.matlet.2019.126807.

- Fakhouri FM, Nogueira GF, de Oliveira RA, Velasco JI. Bioactive edible films based on arrowroot starch incorporated with cranberry powder: Microstructure, thermal properties, ascorbic acid content and sensory analysis. Polymers. 2019;11(10). DOI: https://doi.org/10.3390/polym11101650.

- Giro TM, Adreeva SV, Litvishko KA. Edible food coating based on sodium alginate: prospects for use. Meat Industry. 2017;(5):35–37. (In Russ.).

- Giro TM, Egorova ZhG, Avdeenko VS, Molchanov AV. Ante-mortem formation of the qualitative characteristics of environmentally friendly meat raw material by intensification of the mechanisms of the metabolic processes in gilts. Theory and Practice of Meat Processing. 2016;1(1):32–45. (In Russ.). DOI: https://doi.org/10.21323/2114-441X-2016-1-32-45.

- Yang C, Tang H, Wang Y, Liu Y, Wang J, Shi W, et al. Development of PLA-PBSA based biodegradable active film and its application to salmon slices. Food Packaging and Shelf Life. 2019;22. DOI: https://doi.org/10.1016/j.fpsl.2019.100393.

- Menzel C. Starch structures and their usefulness in the production ofpackaging materials. Uppsala: Swedish University of Agricultural Sciences; 2014. 57 p.

- MonoSol: Dissolvable film for food ingredients [Internet]. [cited 2019 Jan 25]. Available from: https://www.packworld.com/company/monosol-ll c/products.

- Savitskaya TA. Edible polymer films and coatings: background and current state. Polymer materials and technology. 2016;2(2):6–36. (In Russ.).

- Beloglazova KE, Ulyanin AA, Gornevskaya AD, Palagin VI, Rysmukhambetova GE, Gorelnikova EA, et al. Biodegradable food film coating. Russia patent RU 2662008C1. 2017.

- Zhuravskaya NK, Gutnik BE, Zhuravskaya NA. Tekhnokhimicheskiy kontrolʹ proizvodstva myasa i myasoproduktov [Techno-chemical control of meat and meat products]. Moscow: Kolos; 2001. 174 p. (In Russ.).

- Kozyrev IV, Mittelshtein TM, Pchelkina VA, Kuznetsova TG, Lisitsyn AB. Marbled beef quality grades under various ageing conditions. Foods and Raw Materials. 2018;6(2):429–437. DOI: http://doi.org/10.21603/2308-4057-2018-2-429-437.

- Osnovy gosudarstvennoy politiki Rossiyskoy Federatsii v oblasti zdorovogo pitaniya naseleniya na period do 2020 goda [Fundamentals of the state policy of the Russian Federation in the field of healthy nutrition for the period up to 2020] [Internet]. [cited 2019 Jan 25]. Available from: https://rg.ru/2010/11/03/pravila-dok.html.

- Jensen C, Lauridsen C, Bertelsen G. Dietary vitamin E: Quality and storage stability of pork and poultry. Trends in Food Science and Technology. 1998;9(2):62–72. DOI: https://doi.org/10.1016/S0924-2244(98)00004-1.

- Leistner L. Basic aspects of food preservation by hurdle technology. International Journal of Food Microbiology. 2000;55(1–3):181–186. DOI: https://doi.org/10.1016/S0168-1605(00)00161-6.

- Jeevahan J, Chandrasekaran M. Influence of nanocellulose additive on the film properties of native rice starch based edible films for food packaging. Recent Patents on Nanotechnology. 2019. DOI: https://doi.org/10.2174/1872210513666190925161302.

- Mahmoodi A, Ghodrati S, Khorasani M. High-strength, low-permeable, and light-protective nanocomposite films based on a hybrid nanopigment and biodegradable PLA for food packaging applications. ACS Omega. 2019;4(12):14947–14954. DOI: https://doi.org/10.1021/acsomega.9b01731.

- Wang X, Wang S, Liu W, Wang S, Zhang L, Sang R, et al. Facile fabrication of cellulose composite films with excellent UV resistance and antibacterial activity. Carbohydrate Polymers. 2019;225. DOI: https://doi.org/10.1016/j.carbpol.2019.115213.

- Pavlath AE, Orts W. Edible films and coatings: why, what, and how? In: Huber KC, Embuscado ME, editors. Edible films and coatings for food applications. New York: Springer; 2009. pp. 1–23. DOI: https://doi.org/10.1007/978-0-387-92824-1_1.

- The WikiCell: Nature-inspired edible packaging [Internet]. [cited 2019 Jan 25]. Available from: https://www.designindaba.com/articles/creative-work/wikicell-nature-inspired-edible-packaging.