Аннотация

The research featured various types and strains of lactic acid bacteria (LAB) and yeast. The research objective was to study their ability to utilize β-lactoglobulin during sourdough fermentation. The present paper also described the effect of sourdough fermentation and baking on β-lactoglobulin degradation. A set of experiments with various types and strains of LAB showed that β-lactoglobulin decreased in gluten-free sourdough with 30%, 60%, and 90% of skimmed milk powder (SMP). L.plantarum E36 demonstrated the highest biodegradation of β-lactoglobulin (by 53%) with SMP = 30%. L.helveticus ATCC8018T showed the lowest content of β-lactoglobulin with SMP = 60% and 90%: the content fell by 48% and 40%, respectively. The largest decrease in the content of β-lactoglobulin was observed in the sourdough with Saccharomyces cerevisiae 17 (by 28–42%) and Candida milleri Pushkinsky (by 25–41%). The content of total protein increased, which was not associated with yeast biomass growth. The content was determined after fermentation in sourdoughs with SMP = 60% and 90% using a bicinchoninic acid reagent kit. The content of β-lactoglobulin in the control and experimental samples did not exceed 1 μg/g in the finished bakery products. This fact indicated a significant effect of thermal treatment on β-lactoglobulin degradation in baking. Thus, temperature processing (baking) had a greater impact on the destruction of β-lactoglobulin than enzymatic processing (fermentation).Ключевые слова

β-lactoglobulin, enzyme-linked immunosorbent assay, lactic acid bacteria, milk, sourdough, breadВВЕДЕНИЕ

These days, biochemists and food industry workers are facing an important task: they have to provide population with high-quality protein. Introducing dairy products into bakery formulae can solve the problem, since milk proteins are biologically valuable according to the content and ratio of essential amino acids. The amino acid composition of whey proteins is closest to that of human muscle tissue. Whey proteins are superior to all other animal or plant proteins in terms of essential amino and branched-chain acids, i.e. valine, leucine, and isoleucine [1–3].

However, there is the problem of people with lactose intolerance. According to the Institute of Immunology (Ministry of Health of the Russian Federation), 65% of allergic patients demonstrate intolerance to some kind of food, e.g. dairy products. This problem is especially common among children [4–7]. Therefore, dairy products as additives require a thorough research [8].

Although people of any age can digest unaltered milk proteins, cow’s milk remains one of the strongest and most common allergen [6–8]. It contains about 20 proteins with different degrees of antigenicity, including those with the highest clinical relevance, such as β-lactoglobulin, α-lactalbumin, bovine serum albumin (BSA), γ-globulin, and α- and β-caseins [9–11]. β-lactoglobulin is the predominant whey protein in cow’s milk: 50% of whey protein and about 10% of total protein. It is considered one of the main milk allergens, while α-lactalbumin and BSA have a lower immune reactivity [12]. Sensitisation to β-lactoglobulin is caused by numerous continuous epitopes located along the entire length of its molecule [2, 12, 13].

A β-lactoglobulin molecule consists of 162 amino acid residues and has a molecular weight of about 18300 Da. At pH 6.8–7, β-lactoglobulin can be found in milk as a dimer [14].

β-Lactoglobulin is relatively resistant to acid hydrolysis and intestinal proteases. As a result, when consumed with food, part of the protein remains intact in the gastrointestinal tract and can penetrate through the intestinal wall. Heat treatment reduces the IgEbinding ability in proportion to the degree of heating. However, new antigenic sites may form in denatured proteins. These sites were unavailable for binding in the native molecule or appeared during a chemical reaction with other food molecules. IgE obtained from patients with an allergy to β-lactoglobulin was found specific to both native and denatured proteins [2, 10].

Like any proteins, milk proteins are exposed to temperature, pressure, and enzymes. The following scheme is generally accepted for the thermal denaturation of β-lactoglobulin: deployment of protein molecules – dissociation of dimer – aggregation of denatured protein. Dimeric β-lactoglobulin reversibly dissociates into monomers at 30–55°C. At 80°C, the molecule is almost completely unfolded [11, 13]. The reversibility of β-lactoglobulin denaturation depends on the heating degree and time. After a low temperature heating, a small part of the denatured (unfolded) β-lactoglobulin molecules can restore their native structure. However, an hour at 95–97 °C leads to an active aggregation of β-lactoglobulin molecules. As a result, protein denatures irreversibly. After denaturation at ≥ 70°C, the β-lactoglobulin structure can partially stabilise as the chains re-clot and disulfide bridges are formed. At 130–140°C, the disulfide bonds break, and the protein polypeptide chains deploy completely and irreversibly [2, 15–17]. Denaturation and hydrolysis of β-lactoglobulin is possible when exposed to microwave radiation [18, 19]. Denatured or hydrolysed milk proteins used in dairy mixes are known to be less allergenic [20, 21].

During baking, the temperature of the crust can reach 180–230°C, while the core crumb warms up to no more than 95°C for several minutes [22]. In this regard, the effect of the baking process on the β-lactoglobulin content in bread with dairy products remains understudied.

In fermented milk products, most milk proteins are destroyed by various microorganisms, including LAB. Prebiotic cultures of LAB are known to reduce the allergenicity of cow’s milk due to the partial denaturation of allergenic proteins [24, 25].

Microorganisms play an important part in baking. For instance, fermentation process takes place in sourdough and dough. Various types of LAB are widely used in sourdough [22, 23]. Hence, it is necessary to study the effect of LAB sourdough and dough fermentation on the destruction of cow milk allergen protein. The research can result in a method of reducing the allergenicity of dairy products and creating new, safer bakery products.

Thus, the research objective was to study the effect of LAB and yeast on the destruction of β-lactoglobulin during baking.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

Effect of LAB on the β-lactoglobulin content and acidity of the sourdough. The research featured sourdough of 8 LAB strains: Lactobacillus plantarum E36, Lactobacillus plantarum E4, Lactobacillus plantarum E1, Lactobacillus parabuchneri E7, Lactobacillus paracasei/casei E31, Lactobacillus paracasei E3, Lactobacillus acidophilus 22n2, and Lactobacillus helveticus ATCC 8018T. As for the yeast strains, 8 types were employed: Saccharomyces cerevisiae – strains L-1, 90, 512, 17, XII, and Krasnodarsky; Candida milleri Chernorechensky; and Kluyveromyces marxianus Pushkinsky. The samples were obtained from the Collection of the St. Petersburg Branch of the State Research Institute of Baking Industry (St. Petersburg, Russia) [26].

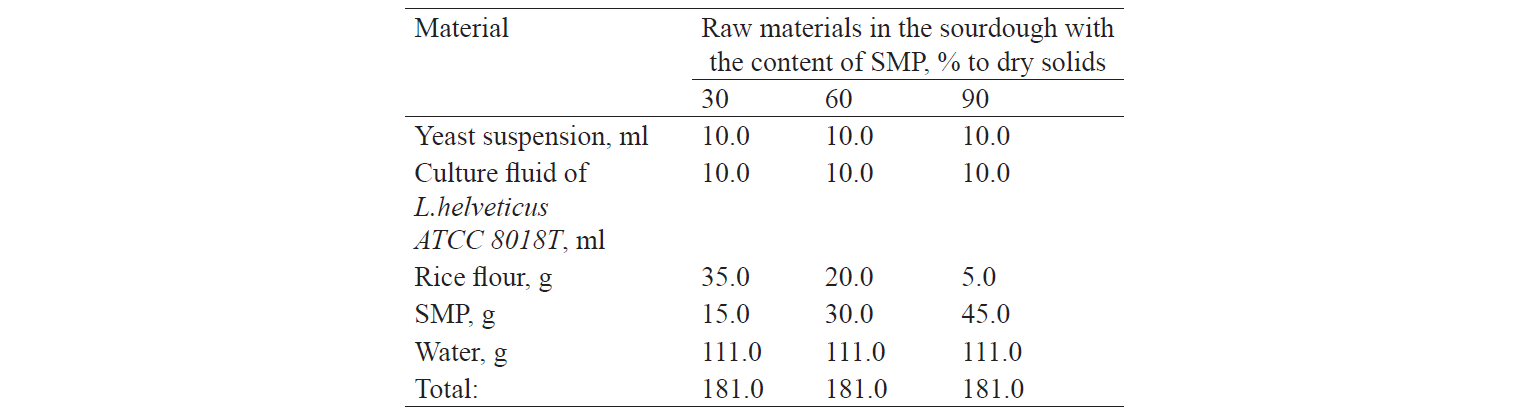

Preparing the sourdough: The nutritional mixture consisted of rice flour and SMP (30%, 60%, and 90% per 100 kg of mixture). The moisture content was 75%. The LAB culture fluid had a cell content of 108 CFU/ml cultivated in SMP for 48 h. During the first phase, it was added to a mixture of raw materials and water, stirred, and placed in a thermostat for 24 h at 30°C. The fermented sourdough was then added to the nutrient mixture in the ratio of 1:3 and allowed to ferment for 24 h at 30°C. Table 1 shows the formulae for sourdough of the propagating and production cycles. A nutritional mixture devoid of any LAB served as a control sample.

The quality of the sourdoughs was assessed according to their acidity. The acidity was determined by the common method used in baking industry. The sourdough suspension was titrated in water at H = 0.1 with NaOH solution and phenolphthalein [27].

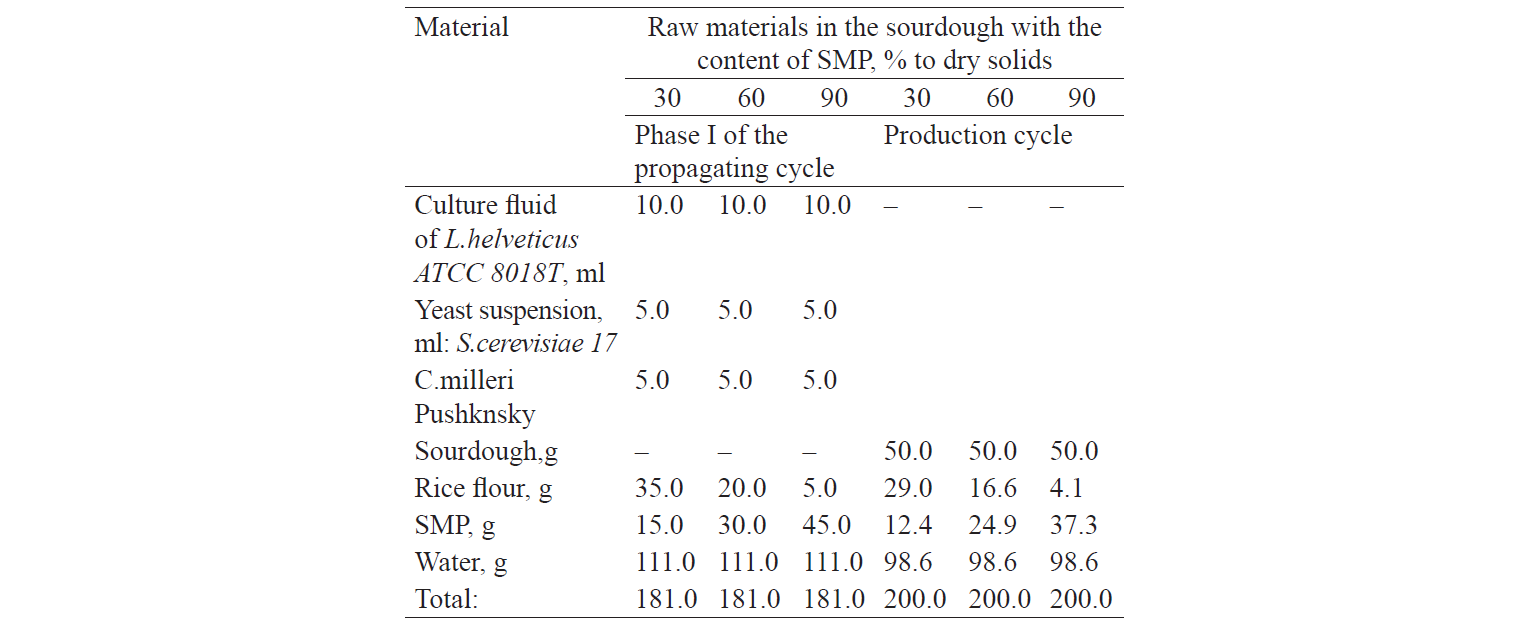

Effect of the yeast on the content of β-lactoglobulin in the sourdough. Preparing the sourdough: Yeast strains grown on malt wort slant agar (8% DS) were used to screen the allergen reducing activity of the yeast. 10 mL of yeast culture were introduced into an aqueous suspension with 10 CFU/ml cell content in the nutritional mixture (Table 2). The mixture consisted of rice flour, SMP (30%, 60%, and 90% per 100 kg of the mixture), and water. The moisture content of the mixture was 75%. To prevent the development of extraneous microflora, L.helveticus ATCC 8018T was added to the nutrient mixtures. The strain had been selected during the first stage of the experiment. It demonstrated the highest allergenreducing activity.

The sourdoughs were fermented for 24 h at 30°C and then examined for acidity, temperature, and moisture content.

The effect of sourdough and dough fermentation and baking on the content of β-lactoglobulin. Laboratory baking was used to study of the effect of the technological process (fermentation and baking) on the content of β-lactoglobulin in dough and gluten-free bread.

Preparing the sourdough: The nutritional mixture consisted of rice flour and SMP (0%, 30%, 60%, 90%, and 100%). The moisture content was 75%. LAB of L.helveticus ATCC 8018T strain and yeast of S.cerevisiae 17 and C.milleri Pushkinsky were added to the mixture in the quantities indicated in Table 3.

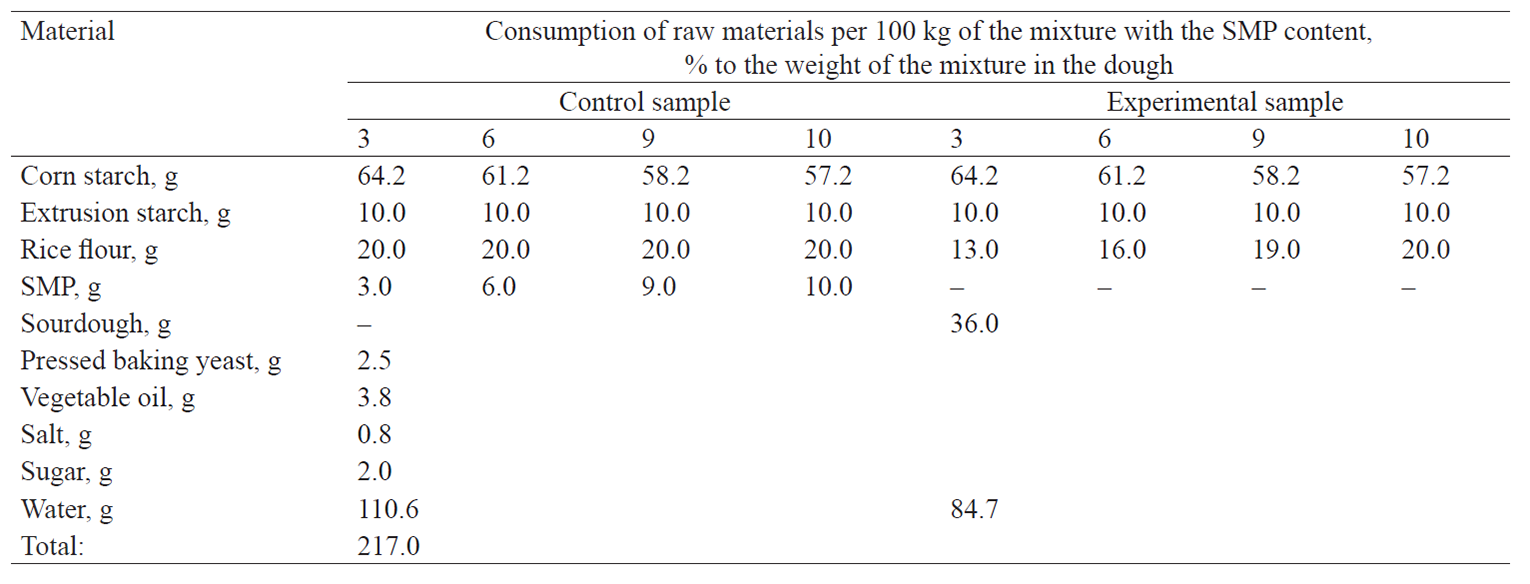

Preparing the dough: The dough for the control sample was kneaded from corn starch, extrusion starch, soy protein isolate, rice flour, and SMP in the amount of 3%, 6%, 9%, and 10% to the weight of the mixture. The mixture contained sugar, salt, pressed baking yeast, and vegetable oil. The moisture content was 53.5%.

The dough for the samples was prepared from the sourdough obtained at phase II of the propagating cycle (10% of the mixture in the intermediate product), corn starch, extrusion starch, rice flour, sugar, salt, pressed baking yeast, vegetable oil, and water. Table 4 shows the formulae of the dough.

The dough was poured into 250-gram moulds and allowed to rise at 35–40°C at an average humidity of 80 ± 2%. After that, the samples were baked in an oven at 210°C for 18 min with a 5-second steam supply.

Preparing samples for the immunoassay and gel electrophoresis. Preceding the analysis, the samples underwent the following procedures. 9 mL of phosphatesaline buffer (PBS, pH = 7.4) was added to 1g of the test sample (sourdough, dough, or bread). The buffer contained sodium azide to protect the samples from microorganisms. After that, a 12-hour extraction was performed using a shaker at 20 ± 1°C. After the extraction, the samples were centrifuged at 40°C and 14000 rpm in an Eppendorf Centrifuge 5417R to remove microorganisms and undissolved components. After the centrifugation, the samples were diluted 10 thousand times in a phosphate-buffered saline (20 mM phosphate, 150 mM NaCl, pH 7.2). The dilution was adapted to the concentration range defined by the test system.

The method of enzyme-linked immunosorbent assay (ELISA method) was used to measure the content of β-lactoglobulin in the sourdoughs at the onset and at the end of fermentation. The process involved antibody No. 362-beta-lactoglobulin – a set of reagents provided by OOO Hema (St. Petersburg, Russia).

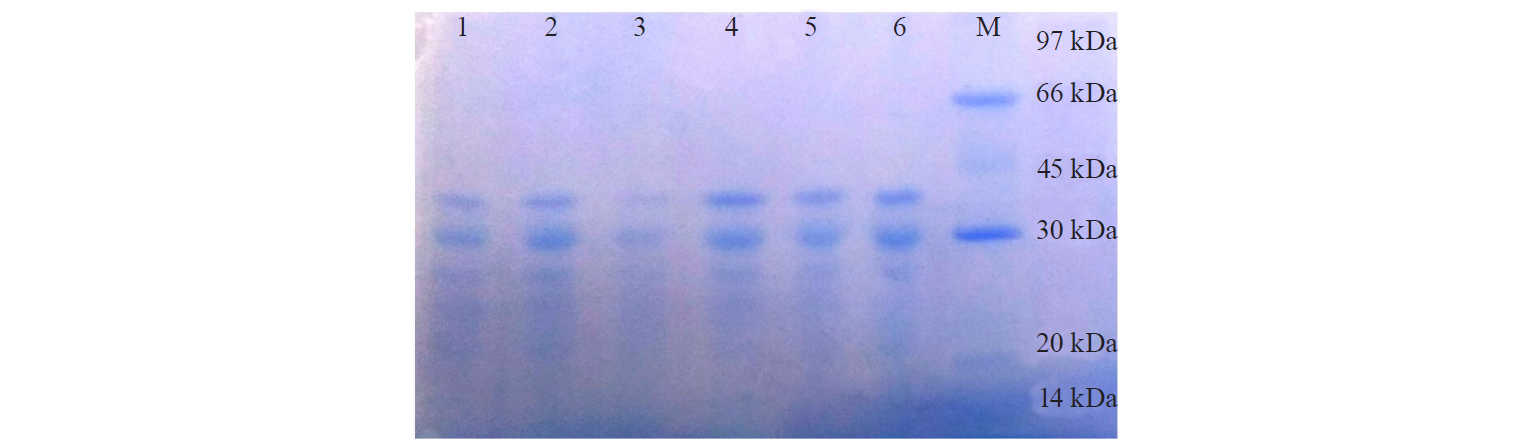

Electrophoresis in a sodium dodecyl sulphate polyacrylamide denaturing gel was employed to confirm the presence of β-lactoglobulin in the sourdoughs at the onset and at the end of fermentation, as well as in the bread.

A bicinchoninic acid reagent kit (BCA, Pierce) was used to define the total protein in the sourdoughs at the onset and at the end of fermentation and in the produced bread. The disc electrophoresis was conducted in nonreducing conditions according to Laemmli method. The samples were diluted to a protein concentration of 1 mg/ml before they were applied to a 13% separating gel.

Statistics. The statistical analysis was performed using Excel software. The method of two-way ANOVA was used to compare the effects of the SMP amount and the type of strain on the content of β-lactoglobulin in the sourdoughs, dough, and bread. The research also assessed the correlation and covariance between the β-lactoglobulin content and the sourdough acidity.

The data show the confidence intervals, which prove the accuracy of the methods for determining protein content and acidity.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

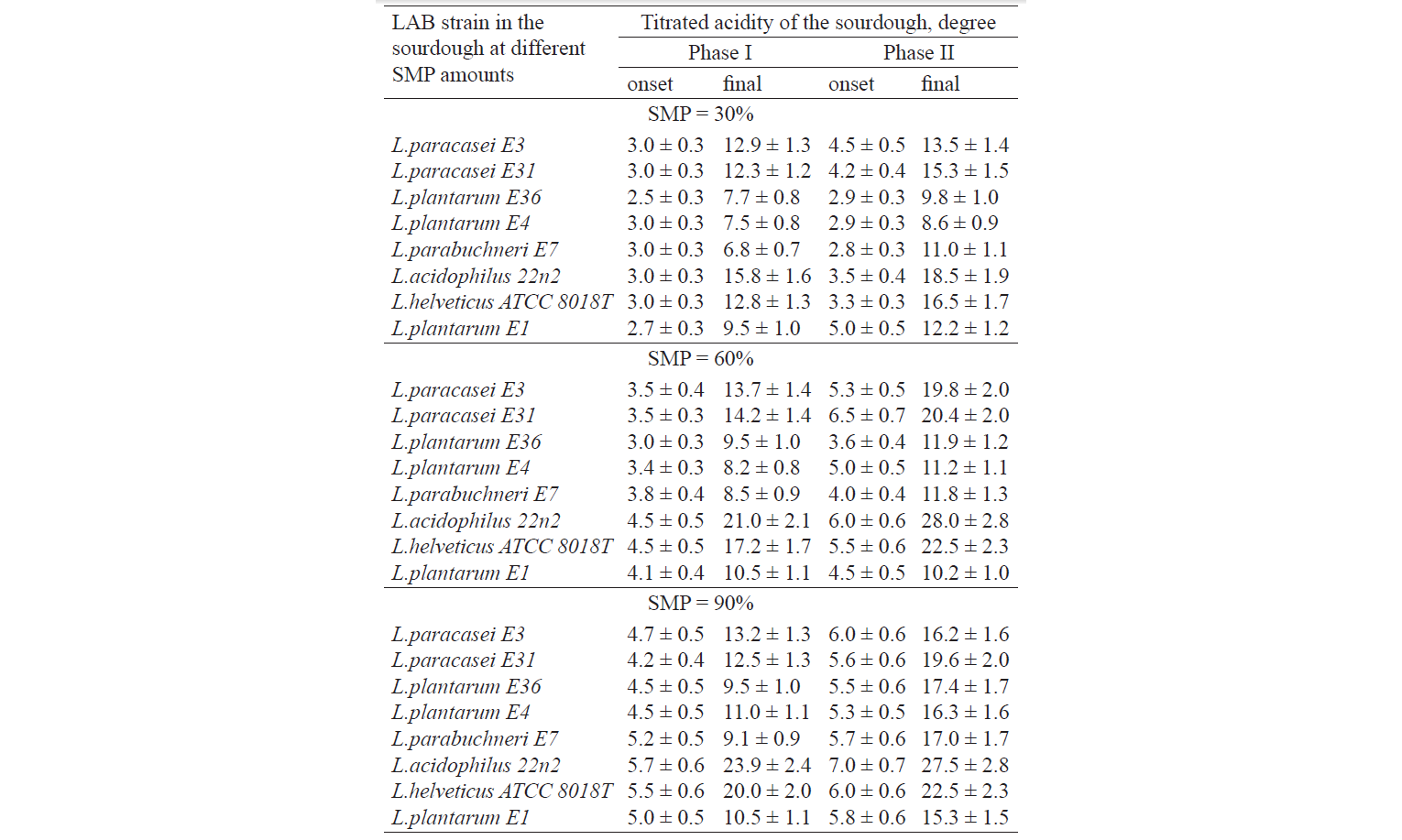

The experiment measured the acidity in the sourdoughs based on various strains with different content of SMP. Acidity reflects the development of microorganisms in the environment. A high level of acidity improves the absorption of nutrients from the environment. High acidity values accelerate proteolysis, which is important for the destruction of protein and its constituents, including the allergenic ones. During phases I and II of fermentation, L.acidophilus 22n2 and L.helveticus ATCC 8018T showed the highest titrated acidity indicators at the end of phase II (Table 5). These strains demonstrated the maximum titratable acidity with SMP = 60%.

All the LAB strains had different effects on β-lactoglobulin (Fig. 1). The degree of β-lactoglobulin degradation decreased with the increase in the SMP concentration in the nutritional mixture, while different strains reacted differently to the increase in the SMP concentration. At SMP = 30%, the sourdough sample with L.plantarum E36 showed the biggest drop in β-lactoglobulin content in the fermentation process – by 53%. However, at SMP = 60% and 90%, it was the L.helveticus ATCC8018T sample that showed the biggest drop in the content of the allergen – by 48 and 40%, respectively. In the sourdoughs, the SMP amount might have a different effect on the vital activity of lactic acid bacteria, since they normally live in silage and flour, except L.acidophilus 22n2 and L.helveticus ATCC8018T.

The two-way ANOVA method gave the following results. The SMP amount had a significant effect on the β-lactoglobulin content in the sourdough after fermentation: alpha = 0.05, P < 0.001, F = 27.78, Fcritical = 3.63. However, the type of LAB strain factor produced no effect: alpha = 0.05, P = 0.25, F = 1.46, Fcritical = 2.59. A strong positive correlation and covariance was revealed between the final β-lactoglobulin content and the final acidity level of the sourdough for L.plantarum E4 and L.acidophilus 22n2. The correlation coefficients were 0.99 and 0.91, respectively. The covariance coefficients were 3270 and 2449, respectively. L.paracasei E31 demonstrated a weak inverse correlation (coefficient = 0.25).

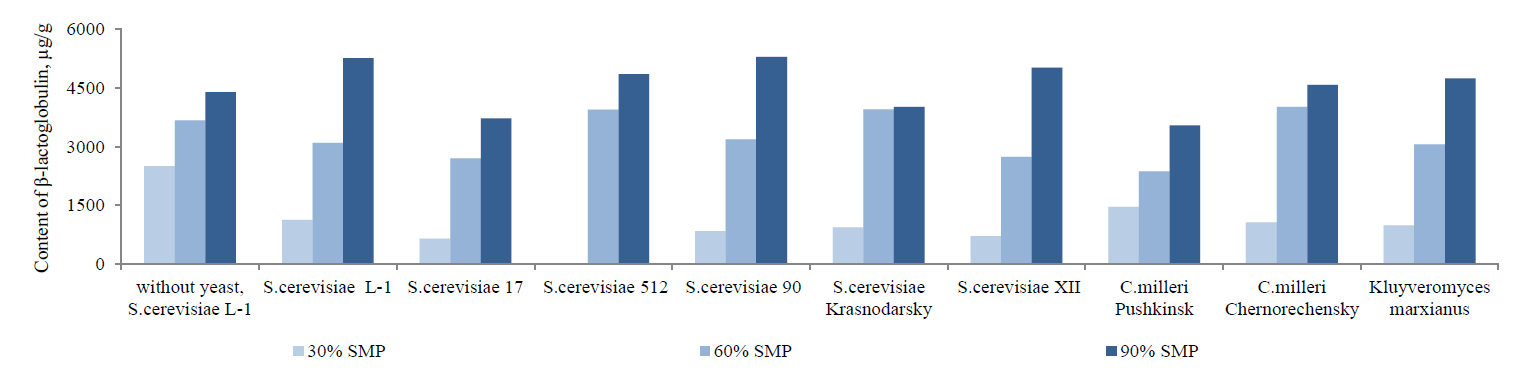

The screening of the allergen-reducing activity of various yeast strains (Fig. 2) showed that the strains produced a different effect. As for Saccharomyces cerevisiae, strain 17 demonstrated the highest allergenreducing activity: the β-lactoglobulin content fell by 28–42%. As for the Candida milleri, it was Pushkinsky strain: the β-lactoglobulin content fell by 25–41%.

The two-way ANOVA method gave the following results. The SMP amount had a significant effect on the β-lactoglobulin content in the sourdough after fermentation: alpha = 0.05, P < 0.001, F = 93.60, Fcritical = 3.56. However, the type of yeast strain factor produced no effect: alpha = 0.05, P = 0.37, F = 1.17, Fcritical = 2.46.

Lactic acid bacteria strain L.helveticus ATCC 8081T and two yeast strains, S.cerevisiae 17 and C. milleri Pushkinsky, were selected for further research, which featured the effect of fermentation and baking on the β-lactoglobulin content in sourdough, dough, and bread.

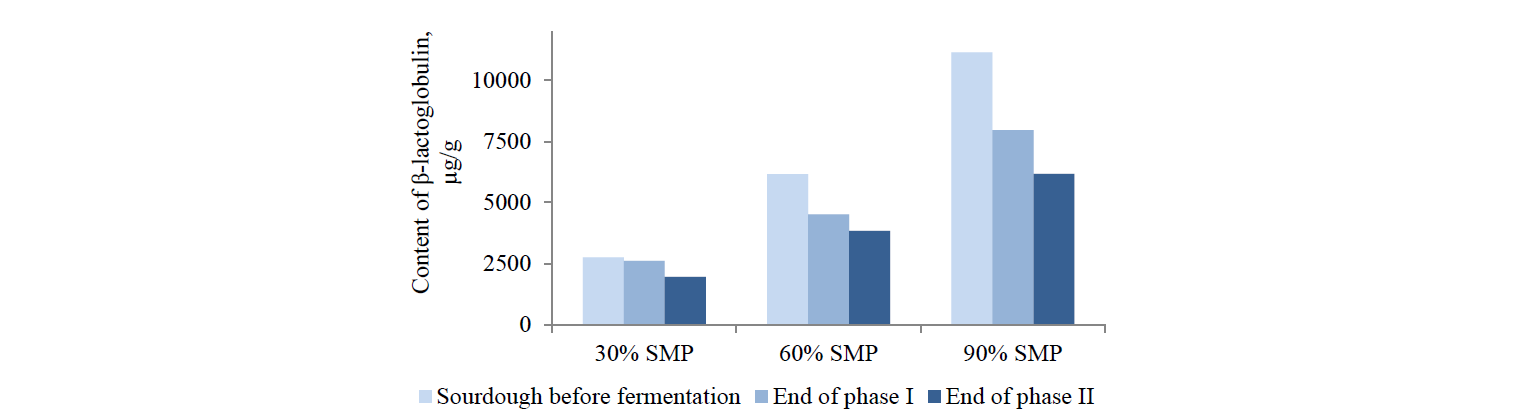

The enzyme immunoassay showed a decrease in β-lactoglobulin at the end of phases I and II by 1.4–1.8 times, if compared with its content in the nutrient mixture immediately after mixing (Fig. 3). Thus, the allergen was destroyed by the LAB enzymes.

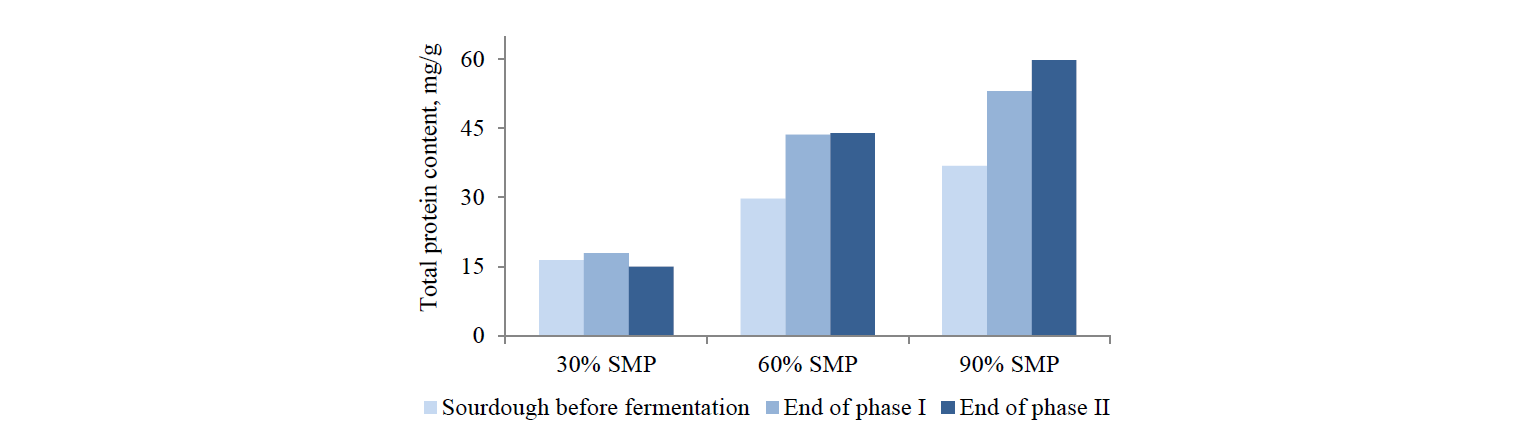

Despite the destruction of β-lactoglobulin, the total protein content in samples with SMP = 60% and 90% increased in the fermentation process, if compared with the initial amount (Fig. 4). The total protein content was determined using a bicinchoninic acid reagent kit. Presumably, there are two ways additional protein could appear during the experiment. First, it could increase during fermentation due to the accumulation of yeast biomass. Second, it could be released from any supramolecular or covalent complexes with other macromolecules – proteins or polysaccharides. To understand how the increase in the microbial biomass affected the increase in total protein, an experiment was conducted with sourdough based on rice flour, without SMP. In this case, the amount of total protein in the sourdough without SMP remained virtually unchanged during the fermentation. It was 3.8 mg/g before fermentation and 4.0 mg/g at the end of phase I. The increase in the total protein in the sourdoughs with SMP might have been caused by the release of the previously bound protein. It happened under the influence of yeast and LAB enzymes, not because their biomass increased.

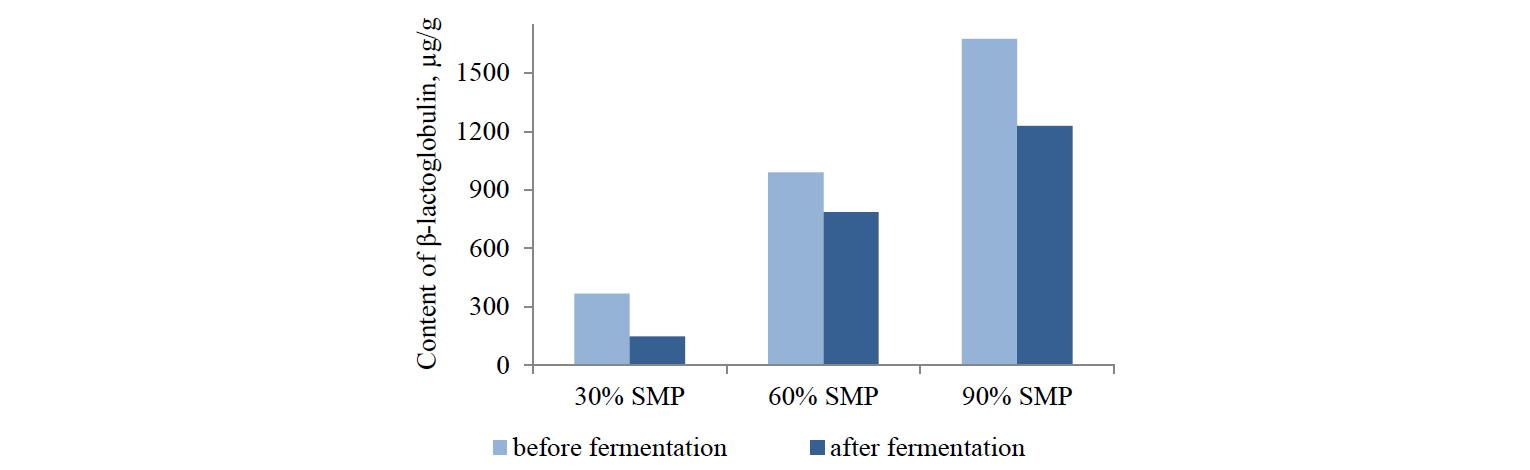

The experiment revealed a decrease in β-lactoglobulin in the dough after fermentation, compared with its content immediately after kneading (Fig. 5). Due to the fact that the kneading involved pressed yeast, the decrease in β-lactoglobulin could be explained by the combined effect of fermenting microflora enzymes and industrial yeast.

As for the finished products, the content of β-lactoglobulin in the control and experimental bread samples did not exceed 1 μg/g. Hence, the temperature degradation of β-lactoglobulin proved highly efficient for bakery products.

The electrophoresis was conducted according to Laemmli’s method in sodium dodecyl sulphate polyacrylamide gel with non-reducing conditions. It also confirmed a decrease in the content of β-lactoglobulin (Fig. 6 and 7). Neither blotting of polyacrylamide gel proteins to nitrocellulose, nor detection of β-lactoglobulin by antibodies from the ELISA test system gave any results. Neither of the antibodies was able to identify the antigen after electrophoresis in such conditions. That proved that the content of β-lactoglobulin in the finished products was extremely low.

Thus, the research proved that thermal treatment has a greater impact on the destruction of β-lactoglobulin than enzymatic treatment.

ВЫВОДЫ

The research investigated the effect of various LAB and yeast strains on the β-lactoglobulin content in gluten-free sourdough with SMP. Increasing the amount of SMP had an inhibitory effect on the utilization of β-lactoglobulin by L.plantarum E36, L.plantarumE1, and L.helveticus ATCC8018T. The last demonstrated the highest allergen-reducing activity when SMP equalled 60% and 90% of the solid weight: β-lactoglobulin decreased by 48% and 40%, respectively. The yeast strains Saccharomyces cerevisiae 17 and Candida milleri Pushkinsky showed the biggest decrease in the content of β-lactoglobulin: by 28–42% and 25–41%, respectively. S.cerevisiae L-1, S.cerevisiae 512, S.cerevisiae 90, and S.cerevisiae XII demonstrated an increase in the content of β-lactoglobulin at SMP concentration of 90%. This might have been connected with a release of β-lactoglobulin, previously bound to other proteins.

The content of β-lactoglobulin in the control and experimental samples of bread did not exceed 1μg/g, which proved a high efficiency of temperature degradation of β-lactoglobulin in the baking process. Therefore, temperature processing (baking) had a greater impact on the destruction of β-lactoglobulin than enzymatic processing (fermentation).

КОНФЛИКТ ИНТЕРЕСОВ

The authors declare that there is no conflict of interest related to this article.

БЛАГОДАРНОСТИ

The authors would like to express their deepest gratitude to Yevgeny Alexandrovich Kozhevnikov (OOO Hema) for his consultations on the biochemistry of cow’s milk proteins, Pavel Pavlovich Kornev (St. Petersburg Branch of the State Research Institute of Baking Industry) for the baking, and Vasily Mikhailovich Matveyev (St. Petersburg Branch of the State Research Institute of Baking Industry) for IT support.

ФИНАНСИРОВАНИЕ

The research was conducted on the premises of the St. Petersburg branch State Research Institute of a Baking Industry within the framework of the following research topic: 0593-2014-0017 ‘Biotechnologies for sourdoughs based on the microbial composition of lactic acid bacteria and yeast with an allergen-reducing abilities to develop technology and assortment of baked goods with reduced allergenicity’, a basic program of fundamental scientific researches of the state academies.

The research employed microorganisms from the Collection of the St. Petersburg branch State Research Institute of a Baking Industry (St. Petersburg, Russia). The Collection is on the list of collections that deposit non-pathogenic microorganisms for government use, as approved by the Decree of the Government of the Russian Federation (June 24, 1996 No. 725-47) and the Order of the Ministry of Agriculture and Food of Russia (August 15, 1996 No. 14c).

СПИСОК ЛИТЕРАТУРЫ

- Rogozhin VV. Biokhimiya moloka i molochnykh produktov [Biochemistry of milk and dairy products]. St. Petersburg: GIORD; 2006. 320 p. (In Russ.).

- Gorbatova KK, Gunʹkova PI. Biokhimiya moloka i molochnykh produktov [Biochemistry of milk and dairy products]. St. Petersburg: GIORD; 2015. 360 p. (In Russ.).

- Dyshluk LS, Sukhikh SA, Ivanova SA, Smirnova IA, Subbotina MA, Pozdnyakova AV, et al. Prospects for using pine nut products in the dairy industry. Foods and Raw Materials. 2018;6(2):264–280. DOI: https://doi.org/10.21603/2308-4057-2018-2-264-280.

- Nazarenko LI, Baranovskiy AYu. Pishchevaya neperenosimostʹ [Food intolerance]. Novye sankt-peterburgskie vrachebnye vedomosti [New St. Petersburg Medical Bulletin]. 2016;(2):20–36. (In Russ.).

- Fedotova MM, Ogorodova LM, Fyodorova OS, Evdokimova TA. Molecular and epidemiological basis of cow’s milk allergy. Bulletin of Siberian Medicine. 2011;10(6):86–92. (In Russ.).

- Ricci C. Cow’s Milk Allergy: Management and Prevention. International Journal of Food and Nutritional Science. 2015;2(2):92–97. DOI: https://doi.org/10.15436/2377-0619.15.013.

- Allen KJ, Davidson GP, Day AS, Hill DJ, Kemp AS, Peake JE, et al. Management of cow’s milk protein allergy in infants and young children: an expert panel perspective. Journal of Paediatrics and Child Health. 2009;45(9):481–486. DOI: https://doi.org/10.1111/j.1440-1754.2009.01546.x.

- van Neerven RJJ, Savelkoul H. Nutrition and Allergic Diseases. Nutrients. 2017;9(7). DOI: https://doi.org/10.3390/nu9070762.

- Koletzko S, Niggemann B, Arato A, Dias JA, Heuschkel R, Husby S, et al. Diagnostic approach and management of cow’s-milk protein allergy in infants and children: ESPGHAN GI Committee practical guidelines. Journal of Pediatric Gastroenterology and Nutrition. 2012;55(2):221–229. DOI: https://doi.org/10.1097/MPG.0b013e31825c9482.

- Bloom KA, Huang FR, Bencharitiwong R, Bardina L, Ross A, Sampson HA, et al. Effect of heat treatment on milk and egg proteins allergenicity. Pediatric Allergy and Immunology. 2014;25(8):740–746. DOI: https://doi.org/10.1111/pai.12283.

- Villa C, Costa J, Oliveira MBPP, Mafra I. Bovine Milk Allergens: A Comprehensive Review. Comprehensive Reviews in Food Science and Food Safety. 2018;17(1):137–164. DOI: https://doi.org/10.1111/1541-4337.12318.

- Creamer LK, Loveday SM, Sawyer L. Milk Proteins | β-Lactoglobulin. In: Fuquay JW, editor. Encyclopedia of Dairy Sciences (Second Edition). Academic Press; 2011. pp. 787–794. DOI: https://doi.org/10.1016/B978-0-12-374407-4.00433-7.

- Restani P, Ballabio C, Di Lorenzo C, Tripodi S, Fiocchi A. Molecular aspects of milk allergens and their role in clinical events. Analytical and Bioanalytical Chemistry. 2009;395(1):47–56. DOI: https://doi.org/10.1007/s00216-009-2909-3.

- Ostroumova TA. Khimiya i fizika moloka [Chemistry and physics of milk]. Kemerovo: Kemerovo Institute of Food Science and Technology; 2004. 196 p. (In Russ.).

- Raikos V. Effect of heat treatment on milk protein functionality at emulsion interfaces. A review. Food Hydrocolloids. 2010;24(4):259–265. DOI: https://doi.org/10.1016/j.foodhyd.2009.10.014.

- Grácia-Juliá A, René M, Cortés-Muñoz M, Picart L, López-Pedemonte T, Chevalier D, et al. Effect of dynamic high pressure on whey protein: A comparison with the effect of continuous short-time thermal treatments. Food Hydrocolloids. 2008;22(6):1014–1032. DOI: https://doi.org/10.1016/j.foodhyd.2007.05.017

- Osborn DA, Sinn JKH, Jones LJ. Infant formulas containing hydrolysed protein for prevention of allergic disease and food allergy. Cochrane Database of Systematic Reviews. 2017;2017(3). DOI: https://doi.org/10.1002/14651858. CD003664.pub4.

- El Mecherfi K-E, Rouaud O, Curet S, Negaoui H, Chober J-M, Kheroua O, et al. Peptic hydrolysis of bovine betalactoglobulin under microwave treatment reduces its allergenicity in an ex vivo murine allergy model. International Journal of Food Science and Technology. 2015;50(2):356–364. DOI: https://doi.org/10.1111/ijfs.12653.

- Zellal D, Kaddouri H, Grar H, Belarbi H, Kheroua O, Saidi D. Allergenic changes in β-lactoglobulin induced by microwave irradiation under different pH conditions. Food and Agricultural Immunology. 2011;22(4):355–363. DOI: https://doi.org/10.1080/09540105.2011.582094.

- Boyle RJ, Ierodiakonou D, Khan T, Chivinge J, Robinson Z, Geoghegan N, et al. Hydrolysed formula and risk of allergic or autoimmune disease: Systematic review and meta-analysis. BMJ (Online). 2016;352. DOI: https://doi.org/10.1136/bmj.i974.

- Esmaeilzadeh H, Alyasin S, Haghighat M, Nabavizadeh H, Esmaeilzadeh E, Mosavat F. The effect of baked milk on accelerating unheated cow’s milk tolerance: A control randomized clinical trial. Pediatric Allergy and Immunology. 2018;29(7):747–753. DOI: https://doi.org/10.1111/pai.12958.

- Auehrman LYa. Tekhnologiya khlebopekarnogo proizvodstva [Technology of bakery production]. St. Petersburg: Professia; 2009. 412 p. (In Russ.).

- Nevskaya EV, Borodulin DM, Potekha VL, Nevskiy AA, Lobasenko BA, Shulbaeva MT. Development of integrated technology and assortment of long-life rye-wheat bakery products. Foods and Raw Materials. 2018;6(1):99–109. DOI: https://doi.org/10.21603/2308-4057-2018-1-99-109.

- Boyle RJ, Tang ML-K, Chiang WC, Chua MC, Ismail I, Nauta A, et al. Prebiotic-supplemented partially hydrolysed cow’s milk formula for the prevention of eczema in high-risk infants: A randomized controlled trial. Allergy: European Journal of Allergy and Clinical Immunology. 2016;71(5):701–710. DOI: https://doi.org/10.1111/all.12848.

- Braegger C, Chmielewska A, Decsi T, Kolacek S, Mihatsch W, Moreno L, et al. Supplementation of infant formula with probiotics and/or prebiotics: a systematic review and comment by the ESPGHAN Committee on Nutrition. Journal of Pediatric Gastroenterology and Nutrition. 2011;52(2):238–250. DOI: https://doi.org/10.1097/MPG.0b013e3181fb9e80.

- Afanasʹeva OV, Pavlovskaya EN, Kuznetsova LI. Katalog kulʹtur mikroorganizmov ‘Molochnokislye bakterii drozhzhi dlya khlebopekarnoy promyshlennosti’ iz Kollektsii Sankt-Peterburgskogo filiala GNU GOSNIIKHP Rosselʹkhozakademii [Catalogue of cultures of microorganisms ‘Lactic acid bacteria yeast for baking industry’ from the Collection of the St. Petersburg branch of the State Research Institute of Baking Industry, Russian Agricultural Academy]. Moscow: Russian Agricultural Academy; 2008. 98 p. (In Russ.).

- Puchkova LI. Laboratornyy praktikum po tekhnologii khlebopekarnogo proizvodstva [Laboratory workshop on bakery technology]. St. Petersburg: GIORD; 2004. 264 p. (In Russ.).