Аннотация

Fortification with iron, zinc and vitamin A of Vietnamese tamarind fish sauce has been studied. The Vietnamese tamarind fish sauce formula consisted of 42% of slurry, 37% of sugar and 21% of fish sauce, and was fortified with 36 mg of iron (Fe), 15 mg of zinc (Zn) and 10000 IU of vitamin A palmitate per 30 g of sauce. The sauce is acidic food with pH of 3.21, the total titratable acidity of 29.63% and the water activity of 0.87. The viscosity of fortified sauce was 777 cP and it was characterized by non-Newtonian behavior. The color coordinates L*, a* and b* were 20.71, 11.46 and 23.42, respectively, which was lower than those of traditional sauce. After pasteurization, the iron, zinc and vitamin A contents were reduced to 30.73 mg, 14.21 mg and 7306 IU per 30 g, respectively, while otherwise the physical and chemical quality did not significantly change. The sensory scores of the pasteurized and fortified sauce were slightly lower than that of the sauce before pasteurization or of traditional sauce, but without a significant difference.Ключевые слова

Vietnamese tamarind fish sauce, fortification, iron, zinc, vitamin A palmitate, pasteurizationВВЕДЕНИЕ

Micronutrient deficiencies (MNDs) are the significant factors that cause health problems, even though some deficiencies are not clinically evident. They have socioeconomic impacts particularly in the developing and low-income countries. While several micronutrient deficiency problems affect all age groups, they tend to have a more serious impact on young children and women of reproductive age [1]. Besides obvious and direct health effects, MNDs have profound implications to economic development and productivity, particularly in terms of inflating public health costs and reducing the human capital. While somewhat less than in other Asian countries, micronutrient deficiencies remain prevalent in Vietnam due to the Vietnamese diet, disproportionately comprised of rice and vegetables as staple foods that are low in micronutrient contents. Even in this era, the Vietnamese government has tried to campaign for dietary quality and diversity, encouraging the consumption of foods rich in protein and minerals while discouraging the consumption of the staple food rice or noodles that contain mainly carbohydrates. However, up to now the micronutrient deficiencies of iron, zinc and vitamin A remain unresolved problems for the Vietnamese people [2].

Iron deficiency is a major of micronutrient problems significantly related to public health, and is of primary importance today. An iron deficiency investigation in Vietnam in 2014–2015 by the National Institute of Nutrition of Vietnam showed that iron deficiency was common in three types of regions, namely the urban, rural and mountainous regions of the country, with a 47.3% rate in pregnant women, 23.6% in non-pregnant women and 50.3% in children under 5 years of age. The study covered 9 provinces: Ha Noi, Hue, Ho Chi Minh, Nam Dinh, Nghe An, Bac Lieu, Bac Can, Quang Ngai, and Kon Tum [3].

Zinc is involved in the activities of various enzymes, and in the expression of genotype, cell division and body development, immune function, appetite, and appetite regulation. According to the survey on a nutritional status in 9 provinces mentioned previously, the overall fraction of pregnant women with zinc deficiency was 80.3%, of children – 69.4%, and of women of reproductive age – 63.6%. The rates of zinc deficiency currently remain quite high [3].

Moreover, NIN also reported that between 2014 and 2015 the vitamin A deficiency rate in Vietnamese children under 5 was 8.2% in the urban areas, 13.1% in the rural areas and 16.1% in the mountainous areas [3]. [4] also reported that about 14 % of women were deficient in vitamin A.

Tamarind fish sauce is the signature sauce consumed regularly with rice and some vegetables by most Vietnamese families, because it is cheap, easy to make and appetizing. This sauce is consumed with a wide range of foods, particularly fried or steamed seafoods. According to market surveys, personal communications and international food exchange, this sauce is quite similar with the dips found in Thailand and in other Asian countries. With a busy lifestyle as in a single or small family, and with little cooking practice, it is believed that ready-to-cook and ready-toeat products will increase in popularity in Vietnam and other countries, as it has already happened in a lot of developed industrialized countries. However, tamarind fish sauce is generally composed of tamarind pulp, sugar and fish sauce plus some chili and garlic; all these ingredients have very low micronutrient contents, especially of iron, zinc and vitamin A. To prevent or contribute a reduction in micronutrient deficiency in a lot of countries, the micronutrient fortification of staple foods has been proven as a simple and effective way to increase micronutrients in daily meals. Therefore, the aim of this study was to develop Vietnamese tamarind fish sauce fortified with iron, zinc and vitamin A, to address the deficiency problems with a vision of a commercialized product for wide-spread consumption in future.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

Materials. Tamarind pulp without seeds, fish sauce, white sugar, finger chili, and garlic were purchased from a supermarket located in Songkhla province, then brought back to run an experiment at the Department of Food Technology, the Faculty of Agro-Industry, Prince of Songkla University, Thailand. Iron sodium ethylenediaminotetraacetate (FeNaEDTA · 3H2O), zinc sulfate (ZnSO4 · 7H2O) and vitamin A palmitate were bought from Merck Chemical Company (Darmstadt, Germany), all of a food grade. Sodium hydroxide (NaOH), phenophthalein, nitric acid (HNO3), hydrogen perioxide (H2O2) and sodium sulphate (Na2SO4) were provided by Fluka Chemical Company (Steinheim, Germany), all of an analytical grade. Methanol (CH3OH), chloroform (CHCl3) and hexane (C6H14) were obtained from Sigma-Aldrich Company (Steinheim, Germany), all of an HPLC grade.

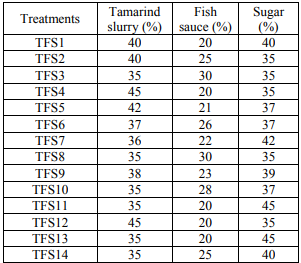

Vietnamese tamarind fish sauce preparation. The tamarind pulp was mixed with water (1 : 4 w/w) and then homogenized using a blender (Philips HR-2068, Thailand) to obtain tamarind slurry. The tamarind slurry (TS), 35–45% by weight, fish sauce (FS) (10–30%) and sugar (SG) (35–55%) were mixed following the experimental design by DesignExpert Statistical package version 7.0 (Statease, Inc., Minneapolis, MN). The 14 experimental formulations of Vietnamese tamarind fish sauce are shown in the Table 1. The mixture of tamarind slurry, fish sauce and sugar accounted for 95% of the actual formulation, while the rest was garlic (2.5%) and chili (2.5%). All the treatments were characterized by pH, the total titratable acidity, water activity, color, viscosity and sensory evaluation to find out the proper formulation mainly based on a sensory score.

Fortified Vietnamese tamarind fish sauce preparation. The fortificants were iron sodium ethylenediaminotetraacetate (FeNaEDTA · 3H2O), zinc sulfate (ZnSO4 · 7H2O) and vitamin A palmitate. The selected Vietnamese tamarind fish sauce from the above experiment was added with 18 or 36 mg of iron and 15 or 30 mg of zinc, and vitamin A palmitate at 5,000 or 10,000 IU per serving size (30 g) of the sauce, following the factorial experimental design, and the homogenization was reached using a blender again (Philips HR-2068, Thailand). All the fortified sauces were characterized by pH, the total titratable acidity, water activity, color, viscosity and sensory evaluation to find the suitable levels of the fortificants based on the sensory score.

Pasteurization of fortified Vietnamese tamarind fish sauce. The Vietnamese tamarind fish sauce was placed after fortification in a glass bottle (120 g) then heated in a water bath at the controlled 90–95°C temperature for 5 min. After that, the product was cooled down before evaluating pH, the total titratable acidity, water activity, color, viscosity, sensory scoring and the iron, zinc and vitamin A contents.

Chemical analysis. The pH value of the sauces in this study was determined at 25°C using a pH meter (Mettler 350, Singapore). Each sample was homogenized with sterilized distilled water in a 1 : 5 w/w sample:water ratio, and was allowed to stand for 2 min before measuring pH.

The total titratable acidity of sauces as % tartaric acid was determined based on the method of [5]. The sample was homogenized with sterilized distilled water at a 1 : 10 w/w sample:water ratio, then filtered using Whatman No.4 filter paper. Subsequently, 3 drops of phenolphthalein were added and mixed in. The samples were titrated with 0.1M NaOH. The total titratable acidity as % tartaric acid (TA) was calculated as follows:

![]()

The iron and zinc content obtained in the sauce were analyzed following AOAC, 2012. Samples of 0.5 gram were digested with 5 ml of concentrated nitric acid and 2 ml of 30% hydrogen peroxide under pressure in a closed vessel. Then heated in a microwave oven until the samples were digested. Afterwards, the samples were cooled down and filtered using Whatman No. 1 (110 nm pore size) filter paper. Each sample solution was transferred to a 25 ml volumetric flask and the volume was made up with distilled water [6]. The extract samples were used to determine iron and zinc by Inductively Couple Plasma Mass Spectrometry (ICP-MS) (Perkin-Elmer SCIEX, Shelton, CT, USA). The RF power was 1350 W, the plasma gas flow rate was 15 l/min, the carrier gas flow was 0.94 l/min and the make-up gas flow was 0.15 l/min. The sample take rate was 100 µl/min and the sample depth was 6.0 mm.

The vitamin A content was determined using highperformance liquid chromatography (HPLC) (Agilent Technologies 1200 series, Snoqualmie, Washington, USA). A five-gram sample was mixed with 25 ml of CH3OH:CHCl3 (3 : 7, v/v) then the mixture was shaken for 2 hours. Afterwards, 0.5 M Na2SO4 was added up to 50 ml and centrifuged at 2500 rpm for 5 min. The bottom layer was evaporated at 40°C until dryness, then the residue was diluted with 1 ml of C6H14 and injected to the HPLC system using the column LiChrospher 100RP-18 (4.6 × 250 mm, 5 µm) at 40°C for 30 min, with the mobile phase a mixture of methanol and water was freshly prepared (98 : 2 v/v). The flow rate was 2 ml/min, the injection volume – 20 µl, and the absorbance was observed at 325 nm [7].

Physical analysis. The color coordinates of the samples were measured using a color meter (Hunter Lab, Model Color Quest XT, United States), which was calibrated using a white standard porcelain plate (L* = 93.6, a* = –0.94 and b* = 0.40). The color is expressed as L*, a* and b*, where L* represents lightness within the range 0–100, a* means redness to greenness (+ is red, – is green), and b* means yellowness to blueness (+ is yellow, – is blue).

The viscosity was measured at rotation speeds of 20, 40, 60, 80, and 100 rpm at room temperature (30 ± 2°C) using a Brookfield Viscometer (model RTV, USA) fitted with a size 63 spindle. Thereafter, the viscosity (cP) versus speed (rpm) plots were assessed to classify a rheological behavior type.

Sensory evaluation. All of the treatments were evaluated by serving to fifty untrained panelists including the graduate students and technicians from the Department of Food Technology, Prince of Songkla University, Thailand. The panelists were asked to evaluate the likabilities of appearance, color, odor, texture, taste and overall for each sample using a 9-point hedonic scale, from “1 – dislike extremely” to “9 – like extremely”.

Statistical analysis. All the experiments were run in triplicates. The data were subjected to Analysis of Variance (ANOVA) and the differences between the means were assessed by Duncan’s Multiple Range Test [8] for statistical significance. The data analysis was performed using an SPSS package (SPSS 6.0 for Windows, SPSS Inc, Chicago, IL, USA).

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

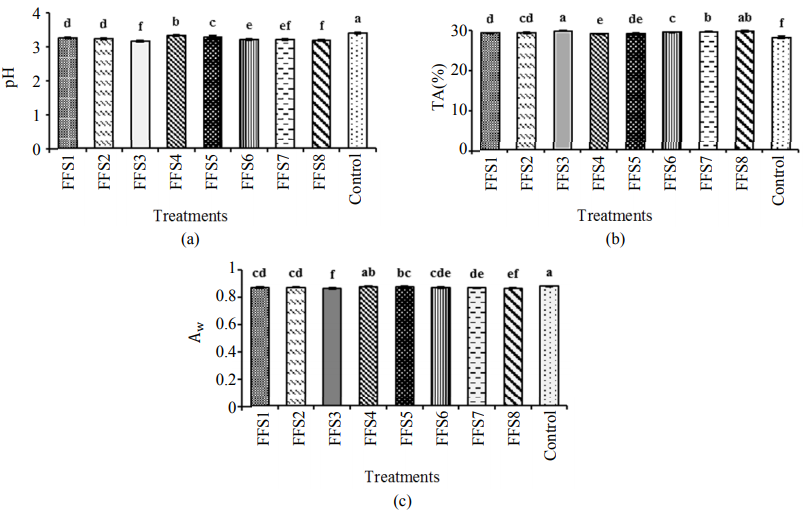

Vietnamese tamarind fish sauce. The pH of food indicates the free hydrogen ions present therein [9]. It was found that the pH of all the samples was within the range of 3.34–3.68 (Fig. 1a), which was indicated as acidic sauce, mainly because of tamarind slurry. Therefore, the more tamarind slurry was added the more acid with a lower pH was found as shown in Fig. 1b. This result agrees with the study of [10], who reported that chili sauce with the highest vinegar content (16%) was the most acidic sauce.

Water activity (aw) is an important factor related to the shelf life and quality of a food product. The water activity of Vietnamese tamarind fish sauce is shown in Fig. 1c. The TFS4 code had the highest aw of around 0.905, even though not significantly different from the code TFS12 (p > 0.05). In contrast, the lowest aw of the samples TFS3 and TFS8 was about 0.858. The significant differences in aw across the samples (p < 0.05) were due to the differences in salt concentration from fish sauce and in sugar used in the sauce. [11] reported that when the salt concentration of electro-dialysis treated fish sauce was reduced from 25% to 6%, the aw increased significantly.

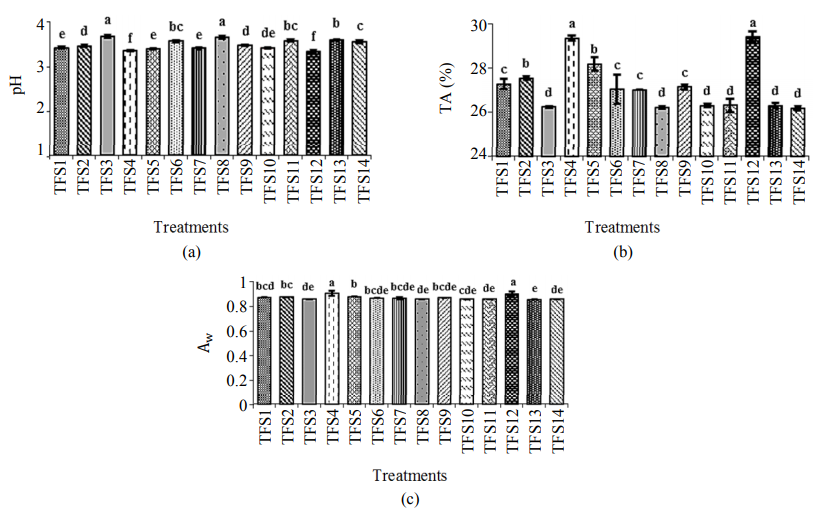

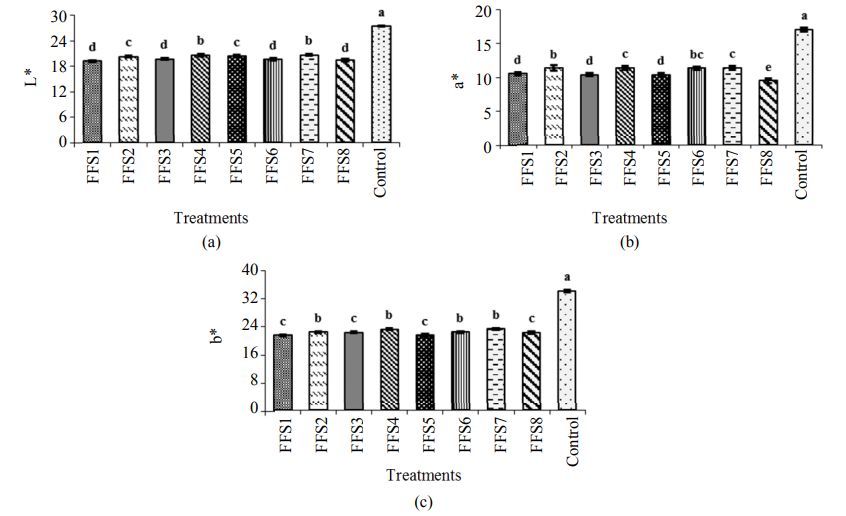

Color is the most conspicuous characteristics of food perceived by consumers [12]. The color coordinates of Vietnamese tamarind fish sauces are shown in Fig. 2. The L* coordinate ranged from 26.56 to 29.22. Generally, the L* of the sauce depended on tamarind slurry and fish sauce, mainly due to the brownish-red color of tamarind pulp [13] and the amber color of fish sauce [14]. The L* increased when the amounts of tamarind slurry and fish sauce decreased (p < 0.05).). The L* of TFS11 and TFS13 was the highest at 29.22, whereas TFS2 gave the least L* value at 26.56. The values of a* were within the range of 15.9–18.18. Significantly the highest a* was found for the samples TFS3 and TFS8 at 18.18, while the cases of TFS4 and TFS12 had a* at 15.9 which is below the others (p < 0.05). The b* values ranged from 33.25 to 34.88. In this parameter, the case TFS8 had the highest values at 34.88, whereas TFS11 gave the least b* at 33.25. This result suggests that the a* and b* color coordinates of the sauces also depended on tamarind slurry and fish sauce. Generally, the color of a food product depends on its raw materials or the compounds produced during processing, storage, etc. [15]. In this study, the color of tamarind fish sauce was affected by its ingredients such as tamarind slurry, fish sauce, sugar and red chili.

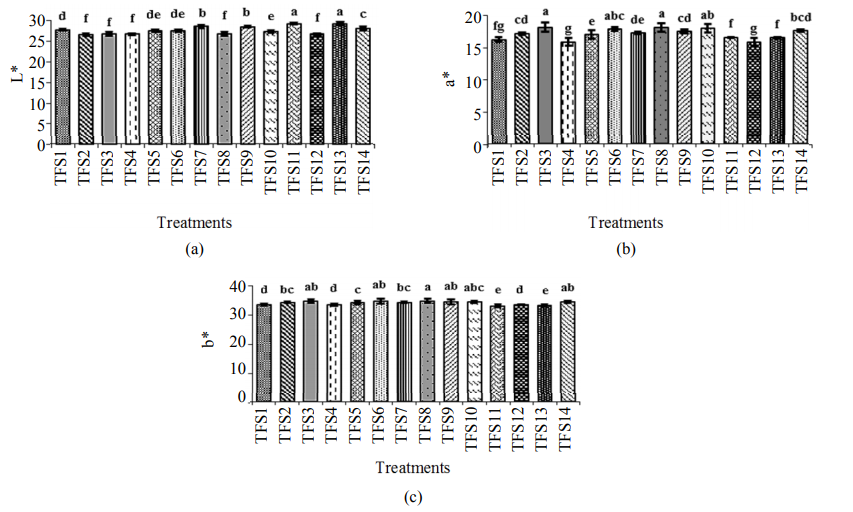

The viscosity of Vietnamese tamarind fish sauce is shown in Fig. 3a. The viscosities of the cases of TFS11 and TFS13 were the highest at about 563 cP, followed by TFS5, TFS7 and TFS14 as 512, 520 and 519 cP, respectively. In contrast, the sauces TFS4 and TFS12 had the lowest viscosities of about 420 cP due to their least amount of sugar. The tamarind fish sauces were not characterized by non-Newtonian behavior with shear thinning, with an increase in the shear rate the apparent viscosity decreased significantly (Fig. 3b). The viscosity and concentration of the solutions can be directly proportional [16]. When a food product contains more dissolved particles, the higher friction between the particles leads to higher viscosity (p < 0.05). It pointed out that sugar is the major determinant of TFS11 and TFS13 with 45% sugar. [17] mentioned that the highest viscosities were found for the sauce and ketchup determined by the brown sugar addition and a CMC thickening agent.

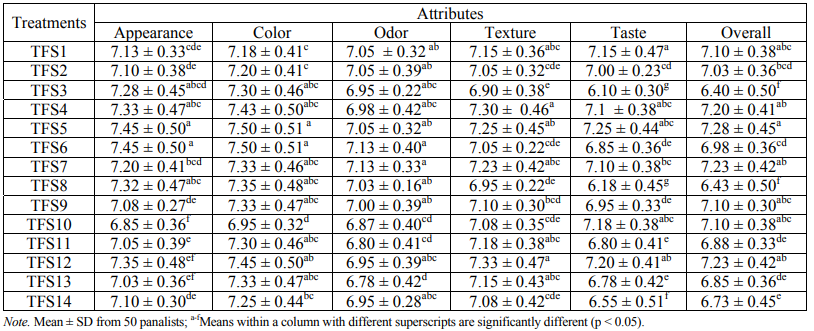

The sensorial scores of Vietnamese tamarind fish sauces from fifty non-trained panelists are summarized in Table 2. Each treatment was evaluated for appearance, color, odor, texture (smoothness and good blend), taste and overall liking. The four codes TFS1, TFS2, TFS5 and TFS7 exhibited comparatively high scores for all the attributes. The code TFS5 had the highest scores for all the attributes, significantly better than the others (p < 0.05). In addition, the data analysis gave the optimum blends suggesting two formulations. The first formulation has 41.8% TS, 20.4% FS and 37.7% SG; and the second formulation has 42.1% TS, 20% FS and 37.9% SG. These formulations were prepared and subjected to sensory tests, with TFS5 included for comparison. The sensory scores did not significantly differ between the three formulations. This indicates that the TFS5 formula was appropriate for further experiments.

Vietnamese tamarind fish sauce fortified with iron, zinc and vitamin A. The Vietnamese tamarind fish sauce consisted of 42% of tamarind slurry, 37% of sugar and 21% of fish sauce fortified with NaFeEDTA · 3H2O (18 mg and 36 mg of Fe/30 g), ZnSO4 · 7H2O (15 mg and 30 mg of Zn/30 g) and vitamin A palmitate (5000 IU and 10000 IU/30 g). Therefore, 8 treatments of fortified Vietnamese tamarind fish sauces and the control sample were made as indicated in Table 3.

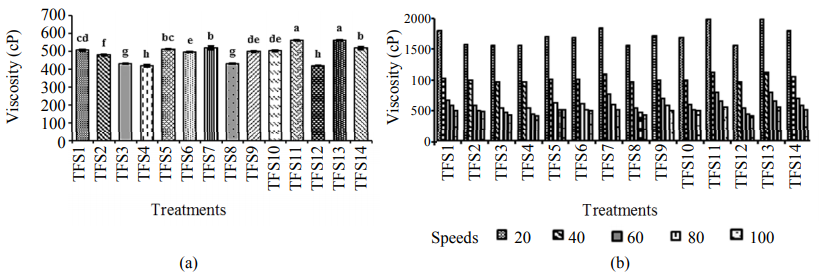

pH of fortified tamarind fish sauce is shown in Fig. 4a. There was a significant difference in pH between the control sample and the fortified samples (p < 0.05) with the control sample that had pH at 3.41 while the fortified ones had 3.18–3.33. [18] reported that the pH of the fortified pumpkin solution (containing 500 ppm of L–(+) ascorbic acid and 500 ppm Fe2+ with the addition of 2.49 g/l FeSO4· 7H2O) was 3.60, while the control solution containing 500 ppm of L–(+) ascorbic acid had pH 4.00 because of the acid hydrolysis of Fe2+ ions [Fe(H2O)6 2+ + H2O Fe(H2O)5 + (OH)2+ + H3O] and the exchange of iron ions and micellar bound H+ [19]. In addition, this current study had higher titratable acidity for the fortified sauces than for the control sample (Fig. 4b). The titratable acidity of fortified sauces was between 29.12 and 29.83 while the control sample had 28.18.

The water activity (aw) ranged within 0.865–0.881 as shown in Fig. 4c. Although there were no significant differences between the eight fortified tamarind fish sauces (p > 0.05), the aw of the fortified sauces was lower than that of the control ones, due to the added salts. [18] reported that the aw of the control pumpkin solution was 0.940 and it decreased to 0.930 with fortification. According to [20], the higher dissolved solid concentration in the solution had a lower water activity, which supported a decrease in aw in the fortified sauce affected by mineral salts fortification.

The color coordinates of the control sample were higher than those of the fortified sauces (Fig. 5). The L* of the control sample was 27.47 while the fortified sauces had values within the range of 19.24–20.71. The a* of the control sample was 20.2 while the fortified sauces were within the range of 9.54–11.46. The b* of the control sample was 34.9, and the fortified ones gave values between 21.59 and 23.42. The color can be strongly affected by iron addition [21]. It was observed that the added FeEDTA was pale-yellow in color [22] and affected on the color of sauce. [22] also mentioned that FeEDTA-fortified sugar added to tea gave blackish discoloration. While the food fortified with zinc and vitamin A does not in general lose its sensory acceptability.

The viscosity of the fortified Vietnamese tamarind fish sauce remained non-Newtonian (Fig. 6a). Fig. 6b, indicates that the viscosity of the control case was 622 cP while the fortified sauces were within the range of 731–796 cP. This result pointed out that the viscosity was increased by fortification with salts (p < 0.05). The higher amount of salts and higher viscosity may be due to the absorption of water by salts and increasing concentration of a solid in the sauce.

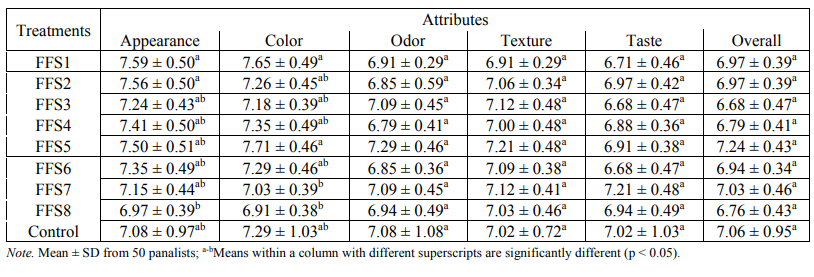

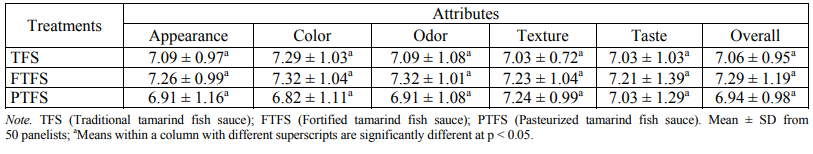

The organoleptic testing of the fortified Vietnamese tamarind fish sauces by fifty non-trained panelists for appearance, color, odor, texture (smoothness and good blend), taste, and overall likability is summarized in Table 4. There were no significant differences between the control and the fortified sauces in most attributes, except for the appearance and color of the FFS8 sample (p > 0.05). The statistical analysis of the sensorial score showed that the sauce FFS7 exhibited a higher score compared to the other fortified sauces and was close to the control sample (p < 0.05). Based on the Vietnamese Recommended Dietary Allowances, the levels of iron and zinc were acceptable in the FFS7 sauce. It is known that vitamin A is sensitive to light, oxygen, moisture and to some extent to heat [23], so it could be lost during processing. The FFS7 sauce could serve well as a fortified sauce.

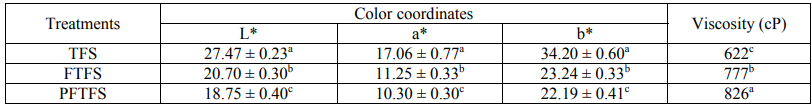

Pasteurization of the fortified Vietnamese tamarind fish sauce. Pasteurization is a technology used to preserve foods, but it can affect some enzyme activities and the flavor and color of some food products [24]. The color coordinates of the PFTFS sauce (L*= 18.75, a* =10.3, b*= 22.19) were below those of TFS (L* = 27.95, a* = 19.19, b* = 35.3) and FTFS (L* = 20.7. a* = 11.25, b* = 23.24) (Table 5). The color of the fortified tamarind fish sauce after pasteurization was darker than before the thermal processing due to the Maillard reaction that causes the non-enzymatic browning of food products [25]. In addition, the sauce fortified with transition metal, such as iron and zinc, was darker due to a catalyst function. PFTFS also showed increased viscosity at 826 cP, higher than the others (p < 0.05). [26] also reported that the rheological parameters of the tomato paste increased with an increase in the heating temperature (60, 80 and 90°C). Moreover, the solid content of the sauce increased during pasteurization due to water evaporation, and protein unfolding caused increased solvation.

TFS (Traditional tamarind fish sauce); FTFS (Fortified tamarind fish sauce); PTFS (Pasteurized tamarind fish sauce). Mean ± SD from the triplicate measurements of 2 different lots. a-bMeans within a columns with different superscripts are significantly different at p < 0.05.

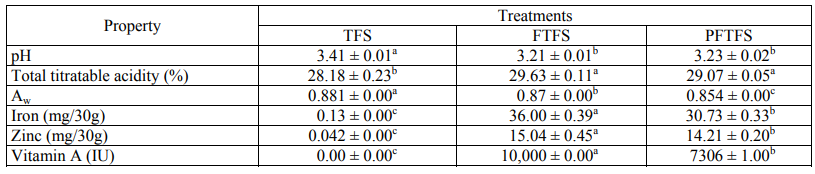

The pH value of sauce changed between 3.21 and 3.41. pH seemed to slightly increase after pasteurization even with not a significant difference (p > 0.05). [27] reported that the pH of apple juice was directly exposed to pasteurization at 73, 80 and 83°C for 27s. pH increased with temperature due to the evaporation of organic acids in the juice. The total acidity values were within the range of 29.07–29.63, which was a slight decrease but not a significant difference between all of the treatments (p > 0.05) (Table 6). It was pointed out that tartaric acid contained in the sample was quite heat stable. During the pasteurized process, aw decreased from 0.87 to 0.854 due to the water evaporation from the lid and an increase in the dissolve of a solid in the sauce by heating.

The iron, zinc and vitamin A contents were decreased by pasteurization. The iron content in the fortified sauce FTFS was 36 mg/30 g and declined to 30.73 mg/30 g (p < 0.05). [28] reported that pasteurization at 65°C for 30 min reduced the iron level of breast milk by 6.5% because of iron binding to proteins. They postulated that the milk contained mucins, caseins and whey proteins [29]. The heat treatment caused protein to absorb on solid surfaces and changed the physical and chemical properties of ironbinding proteins [30]. Thus, the iron content was reduced by milk pasteurization. In terms of a zinc content, this study showed a slight decrease from 15.04 mg/30 g to 14.21 mg/30 g after pasteurization. [31] reported that a post-pasteurized colostrum contained less zinc (by about 3%) when compared to the initial content. [32] mentioned that when iron and zinc minerals were fortified into dairy products such as milk, iron bound with amino acids in casein micelles, while the zinc was associated with colloidal calcium phosphate in casein micelles. Thus, the content of available iron and zinc may be reduced. The reductions in the iron and zinc of tamarind fish sauce by pasteurization might be due to the interactions of the iron, zinc and sauce components, especially proteins in the fish sauce. The vitamin A palmitate content in the fortified sauce after pasteurization significantly decreased, from 10000 IU to 7306 IU (p < 0.05) (Table 6).

TFS (Traditional tamarind fish sauce); FTFS (Fortified tamarind fish sauce); PTFS (Pasteurized tamarind fish sauce). Mean ± SD from the triplicate measurements of 2 different lots. a-bMeans within a column with different superscripts are significantly different at p < 0.05.

It is known that vitamin A is fat soluble [23] and with a low fat content in the tamarind fish sauce, vitamin A seemed to move up to the surface of the sauce where it was oxidized or easily degraded by thermal processing. Moreover, in a transparent bottle, light also causes loss of vitamin A. [33] reported that the content of vitamin A in milk was decreased by heating. Pasteurization not only reduced the trace elements and vitamin A content in the tamarind fish sauce but also degraded its organoleptic properties (Table 7). After pasteurization, the appearance was darker with a slight unpleasant smell, and the texture was no longer homogenous.

ВЫВОДЫ

Iron, zinc and vitamin A are essential micronutrients for human health, but the deficiencies therein remain an unsolved problem in a lot of countries including Vietnam. To solve micronutrient deficiency, fortification is normally applied to a popular food ingredient, such as tamarind fish sauce. The basic formulation of Vietnamese tamarind fish sauce consisted of 42% of tamarind slurry, 37% of sugar and 21% of fish sauce. The appropriate fortification levels with NaFeEDTA, ZnSO4 and vitamin A palmitate in this sauce were found to be 36 mg of Fe, 15 mg of Zn and 10,000 IU per 30 g of sauce. The pasteurization did not significantly affect the physical or chemical quality of fortified sauce, and panelists accepted this product with the overall score of 7/9.

БЛАГОДАРНОСТИ

This study was supported by the Higher Education Research Promotion and the Thailand’s Education Hub for Southern Region of ASEAN Countries Project Office of the Higher Education Commission.

The authors would like to thank Asst. Prof. Kongkarn Kijroongrojana for the Design-Expert Statistical package version 7.0, and the team of Research and Development Office (RDO) of Prince of Songkla University, Thailand for the assistance with English.

СПИСОК ЛИТЕРАТУРЫ

- Allen L.H., de Benoist B., Dary O., and Hurrell R. (eds). Guidelines on food fortification with micronutrients. Geneva: World Health Organization and Food and Agriculture Organization of the United Nations (WHO/FAO), 2006. 341 p.

- Ninh N.X., Khan N.C., Vinh N.D., and Khoi H.H. Micronutrient deficiency control strategies in VietNam, 2007. n.p.

- National Institute of Nutrition (NIN). Micronutrient survey, 2014-2015. Available at: http://vichat.viendinhduong.vn/vi/so-lieu-thong-ke-vcdd.nd29/so-lieu-thong-ke-ve-tinh-hinh-thieu-vi-chat-dinhduong-o-viet-nam-qua-cac-nam.i103.html. (accessed 4 November 2015).

- Laillou A., Berger J., Le B.M., et al. Improvement of the Vietnamese diet for women of reproductive age by micronutrient fortification of staples foods and condiments. PLoS One, 2012, no. 7, article number e50538. DOI: 10.1371/journal.pone.0050538.

- Sulieman A.M.E., Alawad S.M., Osman M.A., and Abdelmageed E.A. Physicochemical characteristics of local varieties of tamarind (Tamarindus indica L), Sudan. International Journal of Plant Research, 2015, vol. 5, no. 1, pp. 13-18. DOI: 10.5923/j.plant.20150501.03.

- Latimer G.W. Official methods of analysis of AOAC international. 19th ed. The association of official analytical chemists. Gaithersburg, Md.: AOAC International, 2012. n.p.

- Kwiecień A., Hubicka U., and Krzek J. Determination of retinyl palmitate in ointment by HPLC with diode array detection. Acta Poloniae Pharmaceutica-Drug Research, 2010, vol. 67, no. 5, pp. 475-479.

- Steel R.G.D. and Torrie J.H. Principles and procedures of statistics: A Biometrical Approach. 2nd ed. Tokyo: McGraw-Hill Kogakusha Ltd, 1980. 633 p.

- Zhang X. Study of novel nanoparticle sensors for food pH and water activity. Dr. Diss., Rutgers University-Gra, 2009. n.p.

- Gamonpilas C., Pongjaruvat W., Fuongfuchat A., et al. Physicochemical and rheological characteristics of commercial chili sauces as thickened by modified starch or modified starch/xanthan mixture. Journal of Food Engineering, 2011, vol. 105, no. 2, pp. 233-240. DOI: 10.1016/j.jfoodeng.2011.02.024.

- Chindapan N., Devahastin S., and Chiewchan N. Effect of electrodialysis pretreatment on physicochemical properties and morphology of spray-dried-fish sauce powder. Journal of food engineering, 2010, vol. 99, no. 1, pp. 31-39. DOI: 10.1016/j.jfoodeng.2010.01.027.

- Mustafa S.O., Khan R.A., Sultana I., Nasir N., and Tariq M. Estimation of Para Red Dye in Chilli Powder and Tomato Sauces by a Simple Spectrophotmetric Method followed by Thin layer Chromatography. Journal of Applied Sciences and Environmental Management, 2013, vol. 17, no. 2, pp. 177-184. DOI: 10.4314/jasem.v17i2.2.

- Obulesu M. and Bhattacharya S. Color changes of tamarind (Tamarindus indica L.) pulp during fruit development, ripening, and storage. International Journal of Food Properties, 2011, vol. 14, no. 3, pp. 538-549. DOI: 10.1080/10942910903262129.

- Tungkawachara S., Park J.W., and Choi Y.J. Biochemical properties and consumer acceptance of Pacific whiting fish sauce. Journal of Food Science, 2003, vol. 68, no. 3, pp. 855-860. DOI: 10.1111/j.1365-2621.2003.tb08255.x.

- Quiles A., Llorca E., Hernández-Carrión M., and Hernando I. Effect of Different Cornstarch Types in New Formulations of Gluten- and Lactose-Free White Sauces with High Protein Content. Journal of Food Quality, 2012, vol. 35, no. 5, pp. 341-352. DOI: 10.1111/j.1745-4557.2012.00461.x.

- Witono Y., Windrati W.S., Taruna I., Afriliana A., and Assadam A. Characteristics and Sensory Analysis of Ketchup and Sauce Products from. American Journal of Food Science and Technology, 2014, vol. 2, no. 6, pp. 203-208. DOI: 10.12691/ajfst-2-6-6.

- Suprapti. L. Ketchup coconut water. Issue of food processing technology. London: Canisius, 2005. n.p.

- De Escalada Pla M.F., Campos C.A., Gerschenson L.N., and Rojas A.M. Pumpkin (Cucurbita moschata Duchesne ex Poiret) mesocarp tissue as a food matrix for supplying iron in a food product. Journal of Food Engineering, 2009, vol. 93, no. 4, pp. 361-369. DOI: 10.1016/j.jfoodeng.2008.11.013.

- Gaucheron F., Le Graet Y., Raulot K., and Piot M. Physicochemical Characterization of Iron-Supplemented Skim Milk. International dairy journal, 1997, vol. 7, no. 2-3, pp. 141-148. DOI: 10.1016/S0958-6946(96)00054-4.

- Buckle K.A., Edwards R.A., Fleet G.H., and Wootton M. Food Science. Jakarta: Indonesian University Press. 1987. 365 p.

- Kiskini A., Kapsokefalou M., Yanniotis S., and Mandala I. Effect of iron fortification on physical and sensory quality of gluten-free bread. Food and Bioprocess Technology, 2012, vol. 5, no. 1, pp. 385-390. DOI: 10.1007/s11947-011-0651-2.

- Akhtar S., Anjum F.M., and Anjum M.A. Micronutrient fortification of wheat flour: Recent development and strategies. Food Research International, 2011, vol. 44, no. 3, pp. 652-659. DOI: 10.1016/j.foodres.2010.12.033.

- Diósay L.L. and Venkatesh-Mannar M.G. Vitamin A Fortification of Cooking Oils. In: Preedy V.R., Srirajaskanthan R., and Patel V. (eds). Handbook of Food Fortification and Health: From Concepts to Public Health Applications, Volume 1. New York: Springer, 2013, pp. 275-290.

- Palou E., López-Malo A., Barbosa-Cánovas G.V., Welti-Chanes J., and Swanson B.G. Polyphenoloxidase activity and color of blanched and high hydrostatic pressure treated banana puree. Journal of Food Science, 1999, vol. 64, no. 3, pp. 42-45. DOI: 10.1111/j.1365-2621.1999.tb09857.x.

- Sánchez M.C., Valencia C., Ciruelos A., Latorre A., and Gallegos C. Rheological properties of tomato paste: Influence of the addition of tomato slurry. Journal of Food Science, 2003, vol. 68, no. 2, pp. 551-554. DOI: 10.1111/j.1365-2621.2003.tb05710.x.

- Charles-Rodríguez A.V., Nevárez-Moorillón G.V., Zhang Q.H., and Ortega-Rivas E. Comparison of thermal processing and pulsed electric fields treatment in pasteurization of apple juice. Food and Bioproducts Processing, 2007, vol. 85, no. 2, pp. 93-97. DOI: 10.1205/fbp06045.

- Mohd-Taufek N., Cartwright D., Davies M., et al. The effect of pasteurization on trace elements in donor breast milk. Journal of Perinatology, 2016, vol. 36, no. 10, pp. 897-900. DOI: 10.1038/jp.2016.88.

- Lönnerdal B. Nutritional and physiologic significance of human milk proteins. The American journal of clinical nutrition, 2003, vol. 77, no. 6, pp. 1537S-1543S.

- Rabe M., Verdes D., and Seeger S. Understanding protein adsorption phenomena at solid surfaces. Advances in colloid and interface science, 2011, vol. 162, no. 1-2, pp. 87-106. DOI: 10.1016/j.cis.2010.12.007.

- Da Costa R.S., do Carmo M.G.T., Saunders C., et al. Characterization of iron, copper and zinc levels in the colostrum of mothers of term and pre-term infants before and after pasteurization. International Journal of Food Sciences and Nutrition, 2003, vol. 54, no. 2, pp. 111-117. DOI: 10.1080/0963748031000084052.

- Gamal El-Din A.M., Hassan A.S.H., El-Behairy S.A., and Mohamed E.A. Impact of zinc and iron salts fortification of buffalo's milk on the dairy product. World Journal of Dairy & Food Sciences, 2012, vol. 7, no. 1, pp. 21-27. DOI: 10.5829/idosi.wjdfs.2012.7.1.1102.

- Abd-El-Gawad I.A., El-Abd M.M., Ragab F.H., and El-Aasar M.A. Study on vitamin B2 in milk and some milk products. Egyptian Journal of Food Science, 1988, vol. 16, no. 1-2, pp. 175-192.