Аннотация

The article is devoted to some aspects of the engineering of complex technological systems designed in the agroindustrial complex. The focus is on solving the problem of Russia's food safety by creating the industrial agro- complexes that implement the technologies for agricultural production and the technology for its storage and processing. The range of issues under discussion includes the structural complication of agro-industrial complex technologies with their simultaneous simplification due to the stabilization of the leading processes of converting agricultural resources into food products. Particular attention is paid to the fluctuations in the processes of "large" technological systems that make up a system complex, under the influence of internal and external disturbing factors. These fluctuations are considered as a necessary condition for the development of complex technological systems. The information about the conditions of self-organization of system technological complexes and their main characteristics has been generalized: interoperability, nonlinearity and instability. The principles of designing such complexes in the agroindustrial complex and the dialectics of mutual reinforcement of the technologies combined into a complex have been outlined. The necessity of the industrialization of agricultural technologies as the dialectical inevitability of the creation of industrial agrocomplexes that implement a new stage of the innovative revolution in the agroindustrial complex has been proved. The main provisions of the paradigm for the development of agro-industrial complex technologies have been formulated. A conclusion has been made about the first steps in the implementation of the engineering of complex technological systems in research organizations and universities.Ключевые слова

Food safety, the mutual adaptation of agro-industrial complex technologies, system technological complex, the synergetics of complex technological systems, the interoperability, nonlinearity and instability of technological complexes, the self-organization of a technological complex, the mutual reinforcement of combined technologies, the industrialization of agricultural technologies, the main provisions of the paradigm for the development of agro- industrial complex technologiesВВЕДЕНИЕ

Russia is a great power that seeks to pursue its independent foreign policy, therefore, the issues of food safety and the reduction of dependence on imported supplies also refer to the strategic interests of the country.

Solving the problem of providing food safety is only possible by a significant increase in agricultural food production, while ensuring a more efficient use thereof, that is, reducing losses and increasing food production from a unit of raw materials.

Back in May 2009, Prime Minister of the Russian Federation V.V. Putin set such a task before the domestic agroindustrial complex. V.V. Putin also outlined the ways to achieve the task – the technological and technical re-equipment of the country's agro-industrial complex, which will allow to intensify all kinds of production in the agro-industrial complex, that is, to increase production not only due to the extensive growth of production capacities, but also due to the use of the fundamentally new technologies and machines that guarantee the efficiency and profitability of production, the high quality and competitiveness of products in the consumer market both within the country and abroad.

Until now, the food production (the food industry) and the production of raw materials for it (agriculture) function independently of each other in the domestic agro-industrial complex.

At the same time, a lot of technological problems of food production have always been solved, as a rule, due to the "adaptation" of agricultural products to the machines and devices of food production by selecting part of the raw materials suitable by conditions from the total amount of raw materials.

The time has come to mean not the selection of part of the manufactured agricultural products by the "adaptation" of agricultural production to food technologies, but their manufacture with the predetermined parameters and allowances for them. The narrower allowances of the parameters for the inputs and outputs of the technological processes of food production with a high technological discipline will provide not only the necessary product quality, but also the stability of both individual processes and the process stream as a whole, and, consequently, the efficiency and profitability of both food and agricultural productions.

The current methods for stabilizing the production processes of food production through a rapid response to external disturbances have largely exhausted themselves, and the machine technologies of continuous productions in the form of mechanized and automated production lines created in the 30–80s of the twentieth century are, in essence, the first and so far the only generation of such technologies.

The creation of lines of the second and the next generations is due to the development of self-regulation systems, which is extremely difficult in itself. Due to the fact that the deviation of the process parameter from the nominal value can depend on the power of an external action at various rates, there is the task to take into account the dynamic factor of a process, so that even with an insignificant amount of the deviation that has emerged, to develop a control action with the necessary anticipation avoiding any excessive increase in the deviation even with a powerful disturbing effect. In other words, a very complex automation system is needed, which significantly reduces the reliability of a process stream.

The real way is to create a system complex by including the technological system of the appropriate agricultural production therein, that is, a transition to agrarian-food technologies of food products. This means that instead of solving the issues of creating the most complex technical means of control and management of technological processes for the existing food technologies, we should supply raw materials with the already known stable parameters to the input of these technologies, highly simplifying the entire further process of food production with the specified consumer properties [1].

Thus, the processes of agricultural production become the external supplement of food technologies in the creation of agrarian and food technologies.

The structural complication of a technology by no means excludes its functional simplicity, since there is a flexible and ambiguous link between the processes of complication and simplification. One of the consequences of this link is the mandatory simplification of technology due to the stabilization of all the leading processes. It is about simplifying production processes, since an increase in the structural complexity of food technologies is compensated by the significant simplification of the links between the leading processes due to the stabilization of the parameters of the initial processes. At the same time, the increasing volumes of information and the possibilities for unifying processes and aggregating machines, devices and bioreactors are used more efficiently.

The creation of agrarian and food technologies is the next stage of the natural development of the technological base of agrarian and food industries, a transition from the old technological basis of the "industrial era" to a qualitatively new basis of technologies in the form of the unified computerintegrated food productions.

The article aims at revealing and analyzing the engineering features of designing a systemic agroindustrial complex that arise under the influence of various system-forming factors when the processing and manufacturing technologies of the agro-industrial complex are combined into a single whole.

SYSTEM TECHNOLOGICAL COMPLEX

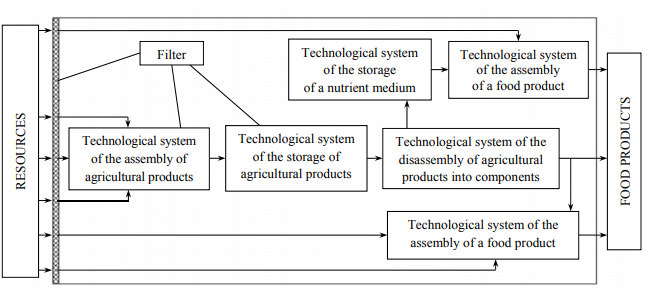

The system complex – an agrarian-food technology is a set of technological systems. Its generalized appearance, reflecting the most important features of its complex structure, can be represented in the form of a block diagram (Figure 1):

the technological system (TS) of the assembly (synthesis) of agricultural products;

the technological system (TS) of the disassembly (analysis) of agricultural products into anatomical parts;

the technological system (TS) of the assembly (synthesis) of food products from these parts.

These three types of "large" technological systems intersperse with technological storage systems. Such a complex technological system (system complex) is the result of convergence, connection and compression of agrarian, processing and food technologies in time and space. At the same time, various biological, biochemical, chemical, physical-chemical and physical processes, previously so remote from each other in time and space, and therefore weakly interacting with each other, sometimes not at all dependent on each other, now converge and are "compressed" taking into account rather close allowances for the values of the input and output parameters of all the leading processes that they begin to directly affect each other.

The figure also implies the concept of a "filter" of the system complex as a whole, as well as of each separate technological system, which is understood as the control and limitation of fluctuations of the input parameters of the leading processes in quality and quantity. And the process of effective functioning of a complex technological system is determined by the abilities of this filter, including the protection of the system and its constituent processes from disturbing external effects.

What distinguishes technological complexes, these complex technological systems, from "large" technological systems? First of all, the nature of internal links, the level of interaction, the mutual effect of the elements of the system (process operations), their interconsistency, interdependence and the ultimate goal. In the technological complexes of the agro-industrial complex, these properties assume decisive importance. It is complexes that are a new step in the development of systems of processes.

A technological system complex combines a large number of heterogeneous "large" systems – autonomous agricultural production, storage and processing technologies – into one. Such complexes have completely new properties, which are characteristic neither for the technologies of plant and animal production, nor for numerous technologies for its processing.

The system agrocomplex is created to obtain a significant increase in food production efficiency. But not every holding that connects an agricultural technology (for example, wheat production) and processing technologies (for example, flour, bread and pasta production) can make up a system technological complex. Only a set of those technologies, which themselves consist of a large number of heterogeneous and complex parts – subsystems that are closely interrelated, saturated with machines, apparatus, bioreactors, automation, information and computing systems and are well controlled – has the properties of system agrocomplexes. These agro-complexes are a natural, but qualitatively new stage in the development of technological systems, a stage that is directly connected with the innovation revolution in the agroindustrial complex. In such complex and responsible business as the creation of complexes of such a scale as "Agrarian-food technology", a rigorous engineering base is needed.

Complex technological systems are a newer, higher level of development of productive forces in comparison with the previous "large" technological systems in plant growing and cattle breeding, as well as classical production lines for the production of flour, cereals, bread, milk, meat, canned goods, etc.

The creation of the system complex "Agrarian-food

technology" will allow to solve in full or in part the

main technical contradiction of any process stream:

"efficiency – quality." A condition for the organization

of such a complex is the creation of large agroindustrial enterprises on a new technological and

technical basis, the effect of which can be represented

in the form of:

an increase in labor efficiency;

expanding the targeting of agricultural production;

strengthening the technological properties of

agricultural raw materials;

ensuring the lifetime formation of food quality;

implementing the traceability of food safety;

approximating processing and food enterprises to the

facilities of production of agricultural raw materials;

developing the cooperative forms of labor

organization;

an increase in the technological discipline in

agricultural production, the processing and food

industries;

creating highly automated and robotic food

productions at processing and food enterprises;

developing resource-saving and environmentally

friendly processes for the entire process chain.

The creation of system technological complexes is, of course, a matter of future, but not of so distant as it might seem. In 50 years, it will be difficult to find the workers who manufacture agricultural products using the technologies of the beginning of the 21st century and the workers of processing and food enterprises engaged in workshops of a modern kind. Today, it is necessary to understand the mechanism of the emergence of very complex holistic formations (technological complexes) from "large" technological systems that have unfamiliar properties, features and regularities, which will have to be encountered in their organization, functioning and development. And we need to prepare for this right now. The fact is that the dialectics of the further development of man-made integrated systems leads to their complication, but simplifies the operation process and increases the efficiency of such systems.

The role of highly organized complex technological systems in the country's economy will undoubtedly increase, and their number will multiply. There will be new industrial, transport, mining, metallurgical and food complexes. When creating the complex "Agrarian-food technology", special attention should be paid to the possibilities, conditions and prospect for the further development of such a complex technological system, since the features of the seventh technological order, the roots of which are in the sixth technological order, are already visible on the horizon.

SYSTEM TECHNOLOGICAL COMPLEX: SYNERGETICS AND ENGINEERING

The approach to the creation of exceptionally complex systems begins to form the strategy of research frontiers. This relatively new scientific trend was called "Synergetics." There is no doubt that synergetics will allow us to take a fresh look at modern agro-industrial technologies and accelerate their qualitative transformation [2, 3, 4].

The origins of synergetics can be seen in the basics of cybernetics, the development of which in the Soviet Union dates back to the 50–60's of the 20th century [5]. In elaboration of separate provisions of cybernetics, the general system theory was developed in the 70's [6]. And in the 80's and 90's there is the promising field of scientific research on the basis of the synthesis of cybernetics and the system theory – the theory of selforganization of very complex systems – synergetics.

The principles of cybernetics feedbacks work for the creation of processes of technologies of various industries and automated object management systems. Synergetics is just what reveals the mechanisms of development and self-organization of complex systems in general. And this is extremely important in the period of rapid development of the material and technical component of civilization, including the objects of the agro-industrial complex of Russia.

Analyzing the stages and trends of the historical development of cybernetics, the general system theory and synergetics, it can be concluded that in the second half of the 20th century a new, previously unknown approach of scientific and engineering research is being formed, due to the increasing complexity of anthropogenic systems of processes. This approach is manifested in the form of an "enzyme" or "catalyst", which does not replace the basic scientific and engineering disciplines, but stimulates the development of knowledge within their framework [7].

Synergetics develops certain concepts that were introduced by cybernetics and the general system theory. First of all, it refers to the concept of feedback, moreover, not only the negative feedback responsible for the process of maintaining the function of an object, its homeostasis, but also the positive feedback responsible for the process of forced development of an object. Therefore, synergetics can be considered as an instrument of our penetration into the future of technologies of the agro-industrial complex.

The term "synergetics" means a joint action, emphasizing the coherence of the links between the parts, reflected in the functioning of the system of processes as a whole. For example, the system complex "Agrarian-food technology" consists of 5–6 "large" systems (technologies) and is a set of 20–30 or more subsystems. The complex contains from 75 to 100 or more elements – the leading technological operations in machines, apparatus, bioreactors and devices, connected by hundreds of links (material, energy and information) with certain allowances regulated by technological instructions.

To be an object of synergetics, such a complex must have the characteristics of a self-organizing system: interoperability, nonlinearity and instability.

Interoperability is the ability of the system to constantly exchange material, energy and information with the environment and to have both the sources of raw materials and energy resources, as well as the information from outside, and waste in the form of products, material wastes, energy and information dissipation. Interoperability is a necessary condition for the existence of relatively stable technological processes in the leading parameters.

In open technological systems, the crucial role is played by random factors, fluctuation processes. This concerns not only the agricultural part of a system technological complex, in view of natural and climatic features, but also its processing part. It refers to the failures regarding the requirements of instructions in terms of the quality and quantity of the material resources supplied at all stages of a process stream, power supply failures and management failures. The fluctuation can be so intensive that it leads to the output of defective products after ploughing through the elements and links of the system as a wave. But on the other hand fluctuation processes are necessary, since they stimulate development processes. Moreover, in the conditions far from the states of processes with the maximum information entropy, weak fluctuations can have a strong impact on a technological system, destroying the existing structure and contributing to its radical qualitative change. In particular, this concerns the downward accuracy of dispensers, since this is necessarily followed by significant (depending on the formulation) changes in the physical and mechanical properties of the treated media, and, as a result, the failures of the leading processes, which requires the revision (development) of technical support of technologies.

Nonlinearity is the conceptual basis of synergetics. Whenever the pattern of a complex object can be described by a system of equations, these equations turn out to be nonlinear. Nonlinear equations can have several qualitatively different solutions. This implies the physical meaning of nonlinearity: a set of trends of development of the system described by this non-linear model corresponds to a set of solutions of a non-linear equation.

A set of processes of the system complex "Agrarian-food technology" is nonlinear, since at different times and under different external effects, its pattern is determined by various laws. This is expressed, in particular, in a variety of technical solutions to a particular technological problem.

The most important conclusion on the organization of their scientific and technical prediction and management follows from this behavioral peculiarity of non-linear systems of the agro-industrial complex.

Instability can be defined as the state of an open system, when the macroscopic parameters of its elements (technological operations), links and performance change. It should be noted that the system complex, which is in an unstable state, is sensitive to external effects consistent with its own properties. Therefore, such fluctuations in the environment are not "noise", but a driving factor in the development of its elements, links and structure. In this case, external effects that are small but consistent with the internal state of a complex may prove to be more effective than large ones. This is what the mechanism of resonant excitation consists in, which leads to the appearance of branch points for the further development of a complex. These bifurcation points can bring a system both to a stable state (which is of interest for the future functioning of the system in the same capacity) and to an unstable state (which is of interest from the point of view of its transition to a new quality state) [8].

Therefore, synergetics prompts us to realize the concept of the development of very complex technological objects in the agroindustrial complex as open nonlinear systems that, in an unstable state, are carriers of the diverse forms of their future organization.

SYSTEM TECHNOLOGICAL COMPLEX: ISSUES OF SELF-ORGANIZATION

Nonlinear systems, being unstable and open by themselves, create and maintain fluctuations in the environment. In such conditions, the relations of the positive feedback between the system and the environment can develop, i.e. the system affects the environment in such a way that some conditions are created in the environment that cause changes in the environment itself. The consequences of such interaction of an open system and its environment can be the most unexpected. And we can see these phenomena in the technologies of the agroindustrial complex.

The self-organization of a technological complex takes place only in the case of the predominance of the positive feedbacks that act in an open system over negative feedbacks. And synergetics directs the engineer to reveal the mechanisms of self-organization of such exceptionally complex systems created by man and functioning with his participation.

Dozens and hundreds of elements of a system complex, i.e. technological processes in equipment, are endowed with such properties as stability and variability, technological reliability and unreliability, linearity and nonlinearity, controllability and uncontrollability, sensitivity and insensitivity to extrasystemic and intrasystemic effects, etc. All this set of properties of elements leads under certain conditions to complete unpredictability in the pattern of a complex system as a whole. And the pattern of the same system can be absolutely predictable and natural when the external conditions change.

In general, a transition (with the participation of man) of an open, unstable nonlinear system from less to more complex and ordered forms of its organization is meant by self-organization. At the same time, the development of such systems proceeds with an increase in complexity and order with the simultaneous simplification of the operation process. One of the trends of development of complex systems is the creation of low-sensitivity processes in a process stream [1].

SYSTEM TECHNOLOGICAL COMPLEX: MUTUAL REINFORCEMENT OF COMBINED TECHNOLOGIES

The experience of developing system complexes in

other areas of the national economy makes it possible

to formulate the following basic principles for the

design of such complexes in the agro-industrial

complex:

the rational choice of technologies that provides the

fulfillment of all the tasks by a system complex as a

whole;

the careful integration of technologies into a single,

well-functioning process stream;

the overall, scrupulous autonomous verification of

technological reliability of each component of a

complex;

the quantitative assessment of the level of stability of

each of the integrated technologies as a subsystem of a

complex;

the quantitative assessment of the level of integrity

(level of organization) of a system complex as a whole

and determining its efficiency in solving the set tasks.

It is necessary to note the culmination of this paradigm in the development of technologies of the agro-industrial complex – the circumstances under which the integrity of an industrial system complex is formed, providing the integrated technologies of agricultural production, storage technologies, processing technologies and food processing technologies with super abilities and super efficiency. It refers to the system-forming factors that can be different in terms of technological solutions in each of the technologies that make up a complex. For example, in one technology, this is the synchronization of the functioning of processes, in another, this is the narrow specialization of processes, in the third, it is the high stability of the outputs of processes, and so on. Thus, the basis of the additional effect of the functioning of each unit (a technology within a system complex) is its system-forming factor. And the effect of a system complex as a whole is determined by the level of implementation of these system-forming factors in separate technologies that make up a complex. And if in one of the technologies the system-forming factor is realized below the design abilities, the "junctions" between technologies, their links and the chain of processes will be broken and the effect of a complex will decrease or even fall to an unacceptably low value.

Thus, the mutual reinforcement of the technologies integrated into a complex is the source of the effect of complex systems.

SYSTEM TECHNOLOGICAL COMPLEX: INDUSTRIALIZATION OF AGRICULTURAL TECHNOLOGIES

The processing part of the system complex "Agrarian-food technology" has already been quite strictly organized into a process stream and operates at works, factories, mills and other large food enterprises with a minimum of external disturbing factors and a high level of mechanization and automation, unlike the part of the production complex that manufactures vegetable and animal raw materials. For this reason, it is absolutely necessary to organize agricultural production on an industrial basis. In agriculture, the regularities that describe the structure, functioning and development of technological processes are much more complex than the regularities of technological processes at processing and food enterprises and are primarily of a probabilistic nature. This is due to the features of the main means of production – the ground with its productive capacity that highly changes depending on weather conditions. Plants and animals also have their own biological characteristics of growth and development. Therefore, the solution of the problem of manufacturing agricultural products stable in quality and quantity should be sought in the creation of fundamentally new technologies of an industrial type [10], which in turn requires the creation of new high-yield plant crops and new highly productive animal breeds.

The basis of industrial technologies of crop production should be the organization of the harmonious system of soil cultivation, fertilization, precision sowing, the mechanized care of crops, fighting diseases and pests, harvesting and storage. At the same time, precision seeding is only possible after special treatment: sorting, grinding, calibrating and pelleting with giving them a spherical shape. Precision seeding, in terms of agrotechnical parameters of seeding, is just what the agrarian-food technology of food products from plant raw materials, which has the close allowances of parameters of all the leading production processes, up to the process of packaging the finished products, should begin with.

The basis of industrial technologies of livestock production should be the organization of automated livestock management processes so that man is engaged not in managing animals, but in maintaining automated production systems. This technology leads to the concept of "farm – plant", when agricultural labor acquires the features of factory labor and livestock production is conducted in a single production – technological cycle.

Thus, the industrialization of fields and farms should make some fundamental quality changes in the technology of agricultural production.

How, then, should agricultural production technologies obtain an industrial image? The answer to this question is given by Leonid Pogorely, Academician of the Russian Academy of Agricultural Sciences, Director of the Ukrainian Research Institute for Forecasting and Testing of Machinery and Technologies for Agricultural Production in 1991–2003 [9].

At the end of the 20th century, important initial prerequisites for the design of agro-bioplants and agrozoofarms were obtained in our country.

In field husbandry, such a path is possible if you withdraw from the traditional tractor pulling concept. This concept of the function of a mobile energy device must be radically changed: working power machines must be converted into the carriers and transmitters of energy to the working bodies and machines that move along a special track or artificial paths. One of the trends in the development of the field husbandry model is the creation of bridge mobile systems. It is nothing more than a mobile agricultural plant.

The factory trends in the development of the agrarian part of the industrial system complex "Agrofood technology" are also characteristic of industrial livestock production. Cattle breeding complexes can become plants and factories due to the introduction of the advanced technologies based on the integrated mechanization and automation of line production methods and modern management systems. The similarity of this concept of organization of an agricultural enterprise with the concept of an industrial processing plant is ensured by the high concentration of production with its narrow specialization.

The accuracy, stability and technological reliability of agricultural production processes can be provided at agricultural factory-type enterprises. It is these processes that can provide the quality of links along the entire technological chain of the system complex "Agro-food technology", which will enable processing and food enterprises to use the rotary technology and rotary machinery [1].

SYSTEM TECHNOLOGICAL COMPLEX: THE MAIN PROVISIONS OF THE DEVELOPMENT PARADIGM

The methodological crisis in the engineering of the agro-industrial complex of Russia can be overcome if the ideology of creating industrial system complexes, leading to an excessive positive effect, is a new paradigm in food production. This is the essence and inevitability of the dialectical development of anthropogenic systems. The main provisions of the paradigm are as follows.

The first provision is a change in the thinking style of the scientist and engineer. The old deterministic physicochemical pattern of separate technological processes is replaced with a new stochastic pattern, since all the technologies as the complex systems of processes function according to the laws of the probability theory, mathematical statistics and information theory.

The second provision is the comprehension of the need for analysis and synthesis. At the present time, it seems that differentiation processes in science prevail over synthesis processes. But this impression is related to the class of the problems being solved. The synthesis procedure already requires the account of external disturbing factors and the account of the mutual effect of the leading processes in technology. This leads to a change in the mathematical apparatus and the construction of a stochastic model of the object.

The third provision is the consideration of

technologies for the production and processing of

agricultural products as systems of processes. Such

technologies as the objects of research and

optimization should meet the following requirements:

– there should be a system-forming factor that

determines the interconnection of subsystems in a

system and has a synergistic effect;

– a quantitative measure should be established that

determines the level of organization (integrity) of a

system;

– a system should be part (subsystem) of the system it

is enclosed in (supersystem).

The fourth provision is the construction of a graphical model of cross-cutting technology as a complex system of processes. The procedure for constructing the model of such an object, as the technology of a system complex, consists in the sequential use of analysis and synthesis. The complete graphic model of a system complex is synthesized from subsystems. The outputs of subsystems are the points of quality control of the technology of this complex.

The fifth provision is the diagnosis of a technological system in terms of its performance. It is necessary to perform two diagnostics: before and after the appropriate intervention in a particular technology. The comparison of the quantitative results of these two diagnostics is what will show the depth of elaboration of R&D.

The sixth provision is the actual development of the technological system based on the results of the first diagnostics, which results, for example, in the mutual adaptation of the technological properties of the initial agricultural raw materials to the processes of its transformation, on the one hand, and the mechanisms of processes in the machines, apparatus and bioreactors of processing industries to the technological properties of raw materials, from the other hand.

The seventh provision is the search for the most effective methods for supplying energy to the processes of production, storage and processing of agricultural raw materials into food products. It refers, first of all, to the wave actions on the processed media: the variable electromagnetic field of ultrahigh and low frequencies, magnetic fields, light pulses, pulsating electric fields, infrared and ultraviolet radiation, cavitation, ultrasound, the electrochemical and laser action. Widespread prospects are seen in a combination of these wave processes with the traditional methods for supplying energy to the processed media.

ВЫВОДЫ

We should learn to look 40–50 years ahead. If we turn back and look at the 50-year old technology and machinery of agriculture and processing enterprises (these are the 60s of the 20th century) and compare them with the modern technologies and machinery in the agro-industrial complex, then we could note the same technological shift by looking at the current technologies of the agro-industrial complex from the 60–70s of the 21st century. Therefore, a backward look from the present to the past and from the future to the present is highly advisable. It stimulates scientists and engineers to predict and create the inordinary innovative technologies and equipment of the agroindustrial complex.

In this connection it is necessary:

to analyze the modern technologies of the agroindustrial complex of Russia and their technical

support from the point of view of the possibility and

expediency of creation in the long term of system

technological complexes of industrial production and

processing of agricultural production into food

products;

to develop the long-term programs of search,

fundamental, applied and experimental design works

with state budgetary financing for the cross-cutting

technologies of a system complex for the period up to

the second half of the 21st century and beyond;

to organize the training of scientific and engineering

personnel by combining agricultural and food higher

educational institutions or establish agrarian and food

technology faculties in agricultural higher educational

institutions.

СПИСОК ЛИТЕРАТУРЫ

- Panfilov V.A. Teoriya tekhnologicheskogo potoka [Theory of the process stream]. 2nd ed. Moscow: Kolos Publ., 2007. 319 p.

- Barantsev R.G. Sinergetika v sovremennom estestvoznanii [Synergetics in modern natural science]. Moscow: LIBROKOM Publ., 2009. 160 p.

- Kurdyumov S.P., Malinetskiy G.G., and Potapov A.B. Sinergetika - novye napravleniya [Synergetics - new trends]. Мoscow: Znanie Publ., 1989. 48 p.

- Haken H. Synergetics: Introduction and Advanced Topics. New York: Springer-Verlag Berlin Heidelberg, 2004. 764 p. (Russ. ed.: Haken H. Sinergetika: Printsipy i osnovy. Perspektivy i prilozheniya. 2nd ed. Moscow: URSS: LENAND Publ., 2015. 448 p.).

- Kafarov V.V. Metody kibernetiki v khimii i khimicheskoy tekhnologii [Methods of cybernetics in chemistry and chemical technology]. Moscow: Khimiya Publ., 1968. 380 p.

- Sadovskiy V.N. Osnovaniya obshchey teorii sistem [Foundations of the general theory of systems]. Moscow: Nauka Publ., 1974. 280 p.

- Knyazeva E.N. and Kurdyumov S.P. Sinergetika: nelineynost' vremeni i landshafty koevolyutsii [Synergetics: nonlinearity of time and landscapes of coevolution]. Moscow: KomKniga Publ., 2014. 272 p.

- Prigozhin I. Philosophy of Instability. Issues of Philosophy, 1991, no. 6, pp. 46-57. (In Russian).

- Pogorelyy L.V. Sel'skokhozyaystvennaya tekhnika i tekhnologiya budushchego [Agricultural machinery and future technologies]. Кemerovo: Urozhay Publ., 1988. 176 p.

- Prosekov A.Yu., Krieger O.V., Milentieva I.S., and Babich O.O. Osnovy biotekhnologii [Fundamentals of biotechnology]. Kemerovo: KemIFST Bubl., 2015. 214 p.