Аннотация

The consumption of fat raises the risk of coronary heart disease and a number of chronic diseases such as obesity. However, removing fat or reducing its level in the final product may give it undesirable properties since fat plays an important role in the quality of food, mainly its texture and flavor. Therefore, natural or artificial fat replacers are utilized in food formulations instead of natural fat. Fat mimics are based on carbohydrates, proteins, and/or lipids, with energy values of 0–38 kJ/g (0–9 kcal/g).They mimic physical properties and sensory attributes of fat but have less energy and calories. Fat substitutes have physical and functional characteristics of conventional fat molecules which are directly replaced with synthetic molecules that provide no calories or structured lipid molecules. Dairy products represent a principal part of consumer diet all over the world.

Therefore, this review aimed to expound how fat replacers can be used to overcome the defects of fat absence or reduction in dairy products. It was reviewed different types and sources of fat replacers, both micro- and nanoparticulated, and highlighted their application in cheese, ice cream, frozen yogurt, fermented milk, and fatty dairy products. Some of the currently applied micro-particulated proteins include Simplesse® (whey protein), APV LeanCreme™, and Dairy-Lo® (micro-particulate protein + micro-particulate cellulose).

While whey protein has a great role in the dairy sector today, there is a need for further research in this field.

Ключевые слова

Nano particles, dairy products, fat replacers, fat mimetic, ice cream, frozen yogurt, hard and soft cheeseВВЕДЕНИЕ

One of the challenges of modern food products is that consumers expect them to be simultaneously delicious and healthy, while fat, or lipid, is the most important energy source for the human body. Fat is vital for normal growth, supplying the body with fatty acids and fat-soluble-vitamins. However, the immoderate consumption of saturated and hydrogenated fat has resulted in the opposite impact on human health. High fat consumption may correlate to chronic diseases like obesity, type-2 diabetes, cancer, and cardiovascular diseases. On the other hand, fat is required in food for its palatability, acceptability, as well as textural and emulsion properties [1, 2].

In view of consumers’ health consciousness, food manufacturers need to produce low-fat products to lower cholesterol and the risk of coronary heart disease in humans [3–5]. The American Dietetic Association (ADA) described several terms such as reduced, light, low-fat, and non-fat, or no-fat, dairy products [6]. It is currently recommended that the fat intake should be reduced to < 30% of calories and that saturated fats should account for < 10% of total energy intake. The American Heart Association also recommends that people with elevated levels of low-density lipoprotein cholesterol or cardiovascular disease should restrict saturated fats to < 7% of calories. To achieve a healthier dietary pattern, people should increase the intake of vegetables, fruits, and grains, as well as modify the type and amount of fat consumed [7–10].

However, consumers are often discouraged from buying low-fat or non-fat food products since their texture and sensory properties are not as good as those of fullfat products. This gave rise to fat replacers which simulate the most abundant features of full-fat food [11].

Fat replacers are classified into fat substitutes and fat mimetics. Fat substitutes are the most novel molecules used to minimize fat ratios in food. They supply dairy products with sensory and functional characteristics of fat but are low in calories or have no calories at all. There is a variety of fat substitutes, including carbohydrate-derived fat substitutes, which can hold water and have a creamy texture close to that of fat (such as starches and gums), protein-derived fat substitutes (such as egg white, milk, and whey), synthetic fat substitutes, and fat compound substitutes. Fat mimetics are ingredients which partially mimic the organoleptic features of animal fat. They are comprised of food hydrocolloids such as gums, cellulose microfibrils, and pectin. They consist of protein, protein aggregates, protein-polsacy- charide composites, and emulsion gels, which have received more attention lately. Decreasing calorie intake by consuming low- or non-fat food is one of the most serious strategies to overcome many common diseases [11–13]. A high-protein diet could reduce the risk of sarcopenia and other types of muscle loss [14].The high reactive features of protein-based fat replacers towards pH, temperature, ions, and enzymes can be tuned with distinct physiochemical properties for expanded food and dairy applications, e.g., in yogurt, cream cheese, salad dressings, as well as cheese and frozen desserts. Animal proteins have a greater quality due to their well-balanced amino acid profiles and high digestibility and bioavailability compared to plant proteins, which are low in cysteine and methionine [15, 16].

There has been plenty of research into types of fat replacers, as well as their action, properties, and food applications. However, only few studies have discussed the development of protein-based fat substitutes and their effects depending on the source of protein, its partial weight and solubility. We aimed to present several types of fat replacers and describe their action and applications in some dairy products.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

The objective of this review was gathering the academic papers concerning with methods of application of various fat replacers in dairy products. For this, we used pertinent keywords, namely “fat mimetic”, “nanoparticles” and “dairy products”. We focused for English-language articles at most published in 1999–2023 because 1999 was the year when the issue of fat replacers was first raised, boosting scientific research. All papers have a citation index of more than 1000 and at least 50 citations in digital databases, namely Web of Science, eLIBRARY.RU, and Scopus. The list of publication was limited to high-quality peer-reviewed journals and all references were screened for relevant researches. There was no need to include books or non-academic materials into the review.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

Definition, classification, and action of fat replacers. Solanke et al. defined a fat replacer as a material that replaces all or some of the fat properties in food and gives it a taste, texture, or mouthfeel identical to those of full-fat food [17]. Fat replacers serve two purposes: they reduce the amount of fat and lower the caloric value of a food product. They have energy values of 0–9 kcal/g, as mentioned by Syan et al. [18]. Nourmohammadi et al. classified fat replacers into two groups according to their properties and processing method [11]. The first group includes fat substitutes that function similarly to fat and have few or no calories. There are three main types of fat substitutes based on their source, namely 1 carbohydrate-based fat substitutes, which can hold water and have a creamy texture close to that of fat (such as starches and gums); 2 protein-based fat substitutes (such as egg white, milk, and whey); and 3 fat-based fat substitutes, which are too large to be digested with little contribution to calories (such as Caprenin, a cocoa butter fat substitute and Olestra). The second group of fat replacers covers fat mimetics – constituents that partly imitate the sensory qualities of animal fat, such as hydrocolloids food (gums, cellulose microfibrils, pectin), proteins, protein aggregates, protein – polysaccharide composites, and emulsion gels. Fat mimetics are generally polar, water-soluble compounds which cannot replace some of the non-polar functional characteristics of fats. Their polar nature facilitates water binding, which helps generate a sense of creaminess in food similar to that in full-fat products [19, 20].

In 2006, Jones and Jonnalagadda mentioned that fat replacers facilitate the development of low-fat and fat-free food that have the taste and texture of high-fat food [21]. Urgu et al. pointed out that fat replacers or mimetics alter the casein matrix in cheese [22]. When added to milk, they do not interact with the casein network but do fill spaces. They are commonly used for a fat reduction of ≥ 50%. These materials are usually starches or denatured whey protein aggregates. Thomas et al. reported that fat mimetics tended to have a higher moisture-holding capacity than casein, so they promoted a higher moisture level in cheese [20]. Fat replacers and fat mimetics boosted the mellowness and softened the body. However, their exaggerated use could increase stickiness and reduce shreddability. Fat replacers increased the flow ability of cheese when heated. In addition, more whey released into the cheese matrix made the texture softer.

Fat replacers or mimetics cannot be used in cheese where the standard of identity does not allow for their use. They are typically synthetic molecules which provide no calories or structured lipid molecules. Fat substitutes can successfully maintain the palatability of food as they can imitate the texture and mouthfeel of fat. They are generally heat-stable. Thus, fat replacers exchange fat molecules in food for components with comparable properties and supply a minimal calorific value [23].

Fat substitutes available as artificial materials. In 2016, Ognean et al. listed the following fat replacers: – olestra, a mixture of hexa-, hepta-, and octa-esters of sucrose;

– caprenin (capro-capryl-obehenic-triacyl-glyceride) manufactured from glycerol by esterification with caprylic, capric, and behenic fatty acids;

– salatrim, which is the generic name for a family of structured triglycerides comprised of a mixture containing at least one short-chain fatty acid;

– emulsifiers (such as sucrose fatty acid esters, mono- and di-glycerides, lecithin, sodium stearoyl-2-lactylate, and poly-glycerol esters) containing both hydrophilic and lipophilic properties that enable them to act as emulsifiers;

– orbestrin, a mixture of tri-, tetra-, and penta-esters of sorbitol and sorbitol anhydrides with fatty acids;

– dialkyldihexadecylmalonate, a fatty alcohol dicarboxylic acid ester of malonic acid and alkylmalonic acid;

– esterified propoxylatedglycerols, a family of derivatives of propylene oxide prepared by reacting glycerol with propylene oxide; and

– tri-alkoxy-tri-carballylate, trialkoxycitrate, and trialkoxyglyceryl ether, polycarboxylic acids with two to four carboxylic acid groups esterified with saturated or unsaturated alcohols [9].

Other commercial fat replacers. Etenia™: an E-number-free fat substitute classified as starch and maltodextrin in Europe and malto-dextrin in the rest of the world. The product is easy to add when processing dairy and bakery products or emulsified low-fat products. It has unique thermo-reversible gelling characteristics. Etenia™ is used in indulgent products and saves the main cost in fresh and cream cheese, quark, and yogurt [24]. Etenia™ enhances creaminess and reduces fat in ice cream. It can also be used in fat-reduced cake mixes and dough. This thermo-reversible amylopectin hydrocolloid builds texture during 16–24 h only when the product is cooled (1–4°C). Small amounts of this fat replacer enhance the perception of creaminess in low-fat yogurt (1.5%) to that of full-fat yogurt (5%), as reported by Alting et al. [25].

Inulin: a non-digestible prebiotic fiber and carbohydrate polymer consisting of three to sixty units of D-fructose known as fructans. Fructans are linked together with beta(2-1) glucosidic bonds and usually have a D-glucose unit at one end. This fat replacer can be safely used without specific limitations in a wide variety of dairy products [26, 27]. Inulin, which is low in calories, possesses many health benefits, especially due to prebiotics that stimulate the growth of beneficial intestinal bacteria [28, 29]. In addition, inulin has been effectively used to modify textural and organoleptic enhancement in food products [29, 30]. Meyer et al. concluded that the effect of inulin on the rheological behavior and texture of dairy products depends not only on its concentration but also on the degree of its polymerization [31]. The ability of inulin as fat replacer is not only related to the modification thickness or hardness of the product but also to changes of other mouth feel. Junyusen et al., who studied the usage of inulin as a partial fat replacer in reduced-fat cheese, reported that it improved the product’s textural, thermal, and microstructural characteristics, making them comparable to those of full-fat cheese [5].

Micro- and nanoparticles as fat replacers in dairy products. Recently, policy-makers and consumers have sought reduced calorie intake, particularly through low-fat dairy products. However, low-fat products can have some defects. This motivated food scientists to design fat mimetics that could echo the functional and sensual features of fat [32]. For example, Peng and Yao differentiated between macromolecules and microparticles [33]. The former had similar properties to those of full fat, while the latter had shapes and sizes similar to those of fat globules, thus allowing them to behave like fat.

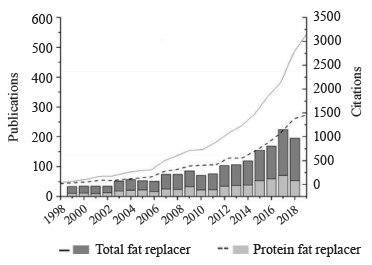

Fat mimetic substances imitate the organoleptic, physicochemical, and microstructural characteristics of fat by utilizing biocompatible and biodegradable proteins and/or carbohydrates in a native form, in an aggregated state, or in the form of bio-polymeric particles [34]. Figure 1 illustrates the reported bibliographic data for fat replacers, including protein-based fat replacers. It presents scientific literature and citations, with the highest number of publications produced in 2017, high-lighting the topical nature and importance of this field in the period from 1998 to 2018. A substantial yearly increase can be observed from 2012 for both total and proteinbased fat replacers, with the latter contributing to nearly one-third of the total publications to-date. The data characterize this filed as a priority area in the food science, as mentioned by Kew et al. [34].

Protein-based microparticles as fat replacers. Microparticulate proteins have a smaller particle size (0.1– 20 μm diameter) compared to concentrate/isolate protein. They are created using thermal treatments and high shear processes at low pH. Protein microparticles are known under such common names as Simplesse® (whey protein), APV LeanCreme™ (SPX Technology), or Dairy-Lo® (micro-particulate protein + micro-particulate cellulose) [34].

Torres et al. reported that reducing fat in yogurt contributed to higher syneresis, weaker body, and unsatisfying texture [35]. Milk whey protein might behave as “active fillers”, further increasing the viscosity of low-fat yogurt [36]. Furthermore, where milk whey protein is larger than the protein of fat globules, it creates a higher level of serum separation, increased graininess, and lower firmness compared to whey protein concentrate.

According to Li et al., the interaction of gel emulsion with yogurt proteins enhanced the stability of the network structure, resulting in a higher water-holding capacity and better texture or storage stability of emulsion gel yogurts [37]. However, the structure of the yogurt made with whey protein emulsion gel microparticles prepared from vegetable oil was more easily destroyed than that of the yogurt made with whey protein emulsion gel microparticles prepared from milk fat.

El-Aidie et al. used three types of commercial microparticulate whey protein at 0.3–0.9% in low-fat Edam cheese and found that it reduced firmness, restored proteolysis and opaqueness, as well as improved sensory acceptability [38]. Milk whey protein acted as “inactive fillers” in yogurt [35]. The microstructure of low-fat pickled cheese significantly opened up after supplementation with Simplesse® at the 0.9% concentration, resulting in the lowest firmness. This effect was also seen in a study by Akin and Kirmaci, who used Simplesse® at 1% [39]. However, higher concentrations of this milk whey protein (3–7% w/w) increased the product’s hardness and firmness, which limits its effective use in cheese to small concentrations [40]. As for sensory properties, it was established that milk whey protein at 0.6% contributed to optimum body and texture and the cheese with DairyLo® and Protelo® had a better flavor than that with Simplesse® [38].

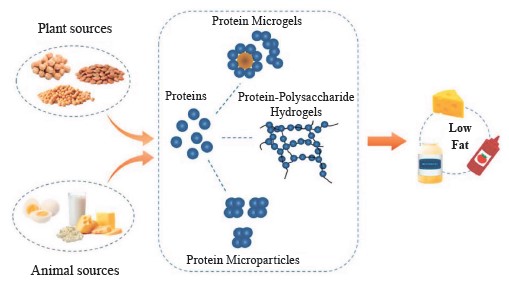

Many studies have explained how to design dairy products with little or no fat by using proteins and micro-particulate proteins to simulate full-fat products. Whey protein appears to dominate the dairy sector. Figure 2 shows some types of protein-based fat replacers [18]. Although there has been a recent interest in the use of plant proteins, their characterization, understanding, and application are still highly limited. In addition to rheology, particle size, and sensory evaluation, tribology is currently applied to understand the lubrication properties of fat replacers. Combining tribology with muco-adhesion techniques can provide powerful screening tools for identifying fat mimetics with justright mouthfeel properties. Besides proteins and commercial micro-particulate proteins, micro-gels have recently demonstrated superior rheological and lubrication performance as potential fat replacers. However, literature lacks information on the sensory perception of micro-gels and the challenges of their commercial production appear to be a bottleneck that delays their application in food [34].

Application of fat replacers in dairy products. Low- or reduced-fat dairy products are generally in high demand. Consequently, many fat substitutes are used to mitigate the textural and sensory disorders in the final products caused by minimizing fat content. Common fat replacers used in dairy products are oligo-fructose, inulin, maltodextrin, poly-dextrose, milk proteins, soy proteins, dietary fibers, and starches.

Fat replacers in cheese. Cheese is a favorite dairy product for people of all ages. Today, consumers are increasingly looking for low-fat cheese with favorable qualitative properties, which raises the importance of using fat replacers in cheese manufacture.

Processed cheese spread. Mounsey and O’Riordan reported that rice starch appears to have the greatest potential as a partial casein substitute in imitation cheese [41, 42]. The action of starch on processed cheese properties was referred to phase attitudes between protein and starch, as shown in confocal laser scanning micrographs by Diamantino et al. [43]. A study by Mehanna et al. also presented low-fat processed cheese spreads based on starch [44].

In 1999, Mounsey and O’Riordan manufactured processed cheese with various levels of pre-gelatinized maize starch and found that the product’s melt-ability decreased with increasing levels of starch [41]. In their study in 2001, the same authors used mixtures of Ras cheese and acid or rennet curd of skimmed milk with various fat replacers such rice powder, whey protein concentrate powder, Jerusalem artichoke, oat, and Simplesse®100 at a concentration of 0.5% [42]. Different microstructures observed in the low-fat spreads and the control reflected the differences in their fat contents and the contents of fat replacers. However, Wahed et al. replaced milk protein concentrate in low-fat spreadable cheese with a synergized filler branded as “Gervizol”, which contained soy proteins, soy fibers, maltodextrin, and modified starch [45]. El-Assar et al. revealed the impact of inulin on the physicochemical, rheological, and sensory characteristics of low-fat processed cheese spread and evaluated the stability or changes in these characteristics under cold storage conditions [46]. According to their results, replacing milk protein in low-fat processed cheese spread with 5% of inulin lowered the hardness and increased the adhesiveness of the product compared to low-fat cheese free of inulin.In 2020, Schädle et al. studied the influence of inulin, corn dextrin, polydextrose, and micro whey protein combined with rennet-casein on the melting behavior, dynamic rheological properties, and hardness of reduced-fat processed cheese [40]. They found that increasing concentrations of inulin and corn dextrin diminished the flow ability of cheese.

In recent study, Sołowiej et al. examined the effect of fat replacement with whey protein micro-coagulates on the physicochemical properties and microstructure of acid casein model processed cheese [47]. According to their results, partial replacement of anhydrous milk fat with whey protein micro-coagulates (3–8%) increased the hardness and viscosity of acid casein processed cheese. Whey protein micro-coagulates acted as a fat substitute without causing negative changes to the structure of the final product. Physiochemical properties showed higher viscosity or good melting properties.

Mozzarella cheese. There has not been much research into Mozzarella cheese. Daia et al. added konjac glucomannan to fat-reduced Mozzarella cheese, which mainly affected its texture, color, and browning, as well as slightly increased its moisture and Aw [48]. The authors recommended konjac glucomannan as a potential fat replacer to be used in fat-reduced Mozzarella cheese. Low-fat Mozzarella cheese was also prepared by Chatli et al. by incorporating 0.3% sodium alginate as a fat replacer with comparable and acceptable physiochemical, textural, color, and sensory attributes [49]. The cheese was almost by 44% lower in calories than full-fat Mozzarella cheese.

Esena and Güzeler indicated that the reduction of fat and the use of whey protein as a fat replacer affected the composition, proteolysis, texture, and melt-ability, as well as the microstructural and sensory properties of reduced-fat Boru-type Künefe cheese during storage [50]. Increased amounts of whey protein concentrate (especially in Boru-type Künefe cheese) allowed the authors to obtain low-fat cheese with similar characteristics to those of full-fat cheese.

Soft and semi-soft cheese. Abd El-Gawad mentioned that 1% fat Ricotta cheese supplemented with 2% Dairy-Lo® was superior in quality and sensory characteristics, having a whiter color and a smooth creamy texture [51]. Dairy-Lo® replaced fat globules with a gel structure, which decreased the junction in the casein matrix and increased the whiteness of the Ricotta cheese. In a study performed by Rahimi et al., indicated that the fat content of gum tragacanth and the ripening time had serious effects on the cheese-making yield, as well as chemical, rheological, and microstructural characteristics of Iranian white cheese [52]. As the fat content in cheese decreased, the instrumental hardness parameters increased and the microstructure became more compact. Adding gum tragacanth to the low-fat cheese increased its moisture content and improved its sensory properties. Gum tragacanth improved the rheological properties of texture due to its water-binding ability. The instrumental hardness parameters decreased during ripening, and the interactions with gum tragacanth caused visible undesirable effects on the cheese’s characteristics after 42 days of ripening.

However, Alnemr et al. recommended adding 2 and 4% inulin to Karish cheese to promote its sensory properties and nutritional value [53]. In 2016, the authors produced high-quality low-fat Domiati cheese (Gbnah-Beeda) by using hydrocolloids as a fat mimetic. As a result, low-fat cheese showed a significant augmentation in the physiochemical characteristics, yield, and moisture. Furthermore, its sensory properties were both highly acceptable and comparable to those of full-fat cheese during 75 days of ripening.

In a study by Alnemr et al., the authors improved the quality of low-fat Domiatti cheese by using Simplesse or Z-trim as fat replacers [54]. The composition, proteolysis, and voluptuous properties of low-fat cheese (70% fat reduction) were examined throughout aging for 60 days. All the control low-fat products demonstrated decreased yield and significantly increased moisture and protein content. However, the low-fat cheeses made with the fat replacers showed a significantly increased extent of proteolysis and lipolysis compared to the control cheese.

Rashidi et al. used fat replacers to produce low-fat UF Feta cheese with good textural and sensory characteristics [55]. The response surface methodology showed improving effects of WPC80 (0–20 g/kg), lecithin (0–2 g/kg), and a mixture of xanthan and guar (0–1 g/kg) on the sensory and instrumental texture characteristics of low-fat UF-Feta cheese made with 6% fat retentate. Lecithin and xanthan-guar had positive effects, while WPC80 had negative effects, on the product’s hardness, chewiness, and gumminess. Furthermore, lecithin had positive effects on taste, acceptance, and appearance, as well as a positive effect on sensory texture. Whey protein concentrate improved the taste, while xanthan-guar enhanced the sensory texture and acceptance scores.

Basiony et al. manufactured low-fat Munster cheese as a semi-soft French type from whole cow’s milk [56]. They concluded that adding fat replacers such as Slendid®200 and Simplesse®100 increased the moisture and ripening indices. Also, these fat replacers decreased the product’s hardness, adhesiveness, cohesiveness, gumminess, and chewiness, as well as increased its springiness.All the sensory properties of low-fat Munster-like cheese were improved by adding fat replacers to the cheese milk.

Saraiva et al. added inulin to reduced-fat cheese, which induced fat and protein recovery [57]. Furthermore, the use of inulin markedly reduced the hardness of the cheese, particularly after 7 days. Kadpe et al. produced low-fat Quarg cheese by using such fat replacers as carrageenan and Simplesse-100@ [58]. The cheese was tested for its sensory, physiochemical, and microbial characteristics. The ultimate score was awarded to the Quarg cheese prepared with 0.5% Simplesse-100.

In 2019, NurAinie et al. described the formulation of analogue cheese produced with sweet corn extract used as a fat replacer [59]. This analogue cheese satisfied the people’s need for alternative cheese prepared from cow’s milk. Its sensory characteristics were similar to those of cheese from cow’s milk. In particular, the product had a yellowish-white color, distinctive aroma of cheese, soft texture, good spreadability, and no sour taste.

Recently, Giha et al. summarized the effects of milk fat replacement with vegetable oils on the rheological, textural, and microstructural properties of cheese analogues [60]. Their findings suggest that the primary effects of modifying fat in cheese analogues are associated with an alteration in the interactions between the components of the protein matrix caused by milk fat extraction. Overall, changes in the functional properties of analogue cheese depend on the sort of oil, the percentage of fat modification, and the type of cheese microstructure and fat globule size. Processing causes structural bonds to break, thus creating different size particles.

In 2020, Sharaf et al. optimized the textural hardness of ultra-filtrated, low-fat cheese by using galactomannan and novagel (0.1–0.5%) [61]. AI-Bedrani et al. manufactured low-fat, low-calorie soft cheese from reconstituted skim milk by adding whey protein concentrate as a fat substitute [62]. This improved the product’s rheological properties such as compressibility and springiness. In addition, whey protein concentrate increased the percentage of total solids (especially protein content) and the cheese yield, reduced total energy, and improved the product’s sensory properties.

The consumer’s desire for plant-based cheese analogues is expanding due to the ease and versatility of their use. However, the products available on the market are nutritionally poor. They are low in protein, high in saturated fat and sodium, and are often composed from a long list of ingredients. Mefleh et al. applied dry-frac- tioned pea protein concentrates combined with emulsion gel with inulin and emulsion volatile olive oil to develop, on a laboratory scale, a clean label and nutritious spreadable plant-based cheese analogue [63]. The authors masked the typical bean flavor offered by the dry-fractionated pea by adding spices without causing any adverse sensory characteristics. They concluded that expanding the range of plant-based products with alternatives characterized by a clean label and a higher nutritional value will better accommodate a broader audience of “healthy” consumers aware of the importance of a plant-based diet.

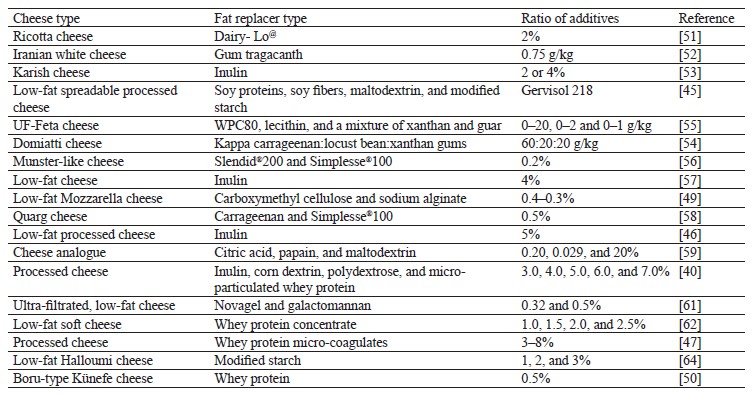

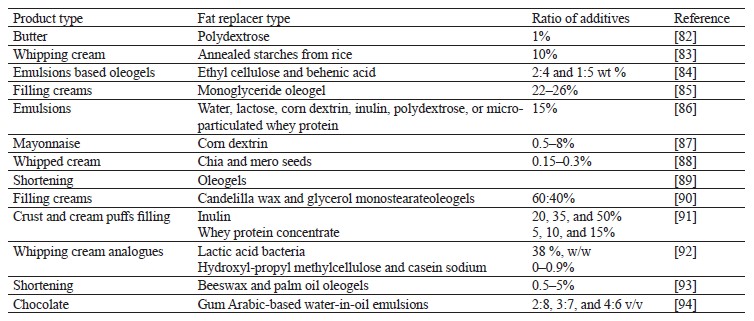

Basiony and Hassabo studied the effect of modified maize starch used as a fat replacer on low-fat Halloumi cheese [64]. The addition of modified starch to cow’s milk decreased the time of rennet coagulation and curd syneresis but increased curd tension. The overall results showed a possibility of producing low-fat Halloumi cheese with attractive appearance, good body, and acceptable flavor by adding modified starch. Table 1 presents some of the fat replacers that have been used in cheese production in the last two decades.

Fat replacers in ice cream or frozen yogurt. Ice cream is one of the most popular dairy products that has a distinctive taste and contains a high percentage of fat. Replacing milk fat in ice cream with either carbohydrates or protein-based fat substitutes is one of the new strategies to reduce the fat content and produce a safe and healthy product. Mahdian and Karazhian produced low-fat ice cream (5% fat) using milk protein concentrate (65%) and multiple contents of inulin as a fat replacer (0, 2, and 4%), as well as two sorts of commercial stabilizer-emulsifier blends (Stab-IC80 and Stab-6924) at 0.3 and 0.4% concentrations [65]. The product’s hardness was not affected by the type or amount of fat replacers or stabilizers. However, the overrun values decreased with increasing concentrations of milk protein concentrate, inulin, and stabilizers in the formulation.

In another study, Junyusen et al. manufactured ice cream (6% fat) with 2 and 4% of inulin and compared it with regular ice cream (10% fat) and inulin-free fat-reduced ice cream [5]. Their results confirmed that the lower fat content (6%) significantly affected the physicochemical characteristics of the ice cream products. The addition of inulin motivated the clustering of fat globules, resulting in the growth of larger-sized particles (1–10 µm), but it significantly decreased the hardness of the reduced-fat ice cream. Furthermore, 4% of inulin lowered the melting average of the reduced-fat ice cream and enhanced the physicochemical characteristics. In a study by Salem et al., the fat content in ice cream was partially replaced with whey protein, dietary fibers, oat, wheat germs, and modified starch. The use of oat and wheat germs increased the fiber content of the product. Additionally, all ice cream treatments had a significant free radical scavenging activity similarly to the control [66].

Babu and Parimalavalli used modified sweet potato starch (2%) in ice cream [67]. Although it did not significantly affect the protein content, it decreased the overrun. The product’s hardness increased with 1% replacement but decreased with 2% starch. According to Warren and Hartel, the overrun can affect the size of air cells in ice cream products during the freezing and storage processes [68]. The use of modified sweet potato starch as a fat substitute reduced the melting rate in ice cream. This can be affected by the weakening of ice cream’s structural texture due to the lower amount of fat.

In 2020, Hatipoğlu and Türkoğlu studied the quality properties of fat-reduced ice creams produced with some fat substitutes [69]. The authors found that 10% fat ice cream behaved similarly to the control group. Then, they added 6% Simplesse®100 or 2% Maltrin040 as fat substitutes to 7.5, 5, and 2.5% fat ice cream. According to the results, the viscosity of the 7.5% fat ice cream with Maltrin040 or Simplesse®100 was higher than that in the control group. Furthermore, decreasing the fat content in ice cream had the opposite effect on the sensory properties and viscosity. Thus, the quality defect caused by the lack of fat can be remedied by protein and starch fat replacers. These fat substitutes can also help solve obesity problems by offering calorie-reduced ice creams. The findings showed that the 7.5% fat ice cream with 6% Simplesse®100 can be recommended as fat-reduced ice cream.

El-Shafei manufactured three types of probiotic frozen goat’s yogurt using full-fat (4%) goat’s milk (control), low-fat (2%) and non-fat (0.5%) goat’s milk with probiotic bacteria and chia flour (1, 2, and 3%) as a fat replacer, as well as stabilizers [70]. The study showed that increased levels of chia flour decreased the specific gravity and melting resistance of low-fat and non-fat probiotic frozen goat’s yogurt.

Abdou et al. prepared low-fat ice cream by partially replacing buffalo milk fat with various fat substitutes (inulin, maltodextrin, modified starch, whey protein concentrate powder, and oat) [71]. Milk fat was standardized to 2% to meet the consumer’s demand for low- energy foods (control), while full-fat ice cream was standardized to 6% fat. The best treatment was the low- fat ice cream with maltodextrin as it achieved the same panelist scores as the full-fat ice cream, followed by the sample with inulin.

Silantjeva et al. used pumpkin puree, sugar, and whey concentrate in ice cream [72]. They found that larger amounts of pumpkin puree and gelatin decreased the product’s hardness and increased its overrun and viscosity. In 2022, Hamad et al. produced low-fat and low-calorie frozen yogurt using Etenia 457 as a fat replacer and Sativoside as a sweetener [73]. The control and four treatments were prepared with 0, 25, 50, 75, and 100% of the fat replacer and sweetener. The treated samples were lower in fat and calories compared to the control. According to the results, the product’s specific gravity and viscosity increased with larger amounts of the additives, while its overrun decreased. The sensory evaluation showed that the sample with 25% of the fat replacer and sweetener had the best properties, as well as the highest total scores among all the treatments.

Shahein et al. evaluated the potential benefits of adding Jerusalem artichoke tuber powder (0, 5, 10, 15, and 20% w/w) as a fat and sugar replacer for the physicochemical properties and survival of probiotics in frozen yogurt [74]. The sample with 10% of this fat replacer showed the highest viability of probiotics. The results also revealed that the frozen yogurt with Jerusalem artichoke tuber powder had higher acidity, melting resistance, overrun, viscosity, and sensory attributes compared to the control. The authors concluded that enriching frozen yogurt with 20% of this fat replacer will provide it with functional properties to benefit consumers’ health.

Fat replacers in fermented milk. The use of skim milk is a strategy to increase milk yogurt acceptability. However, it can negatively influence yogurt’s rheology because fat plays a crucial role in dairy structural integrity. Salem et al. used inulin as a fat replacer to produce low-fat Labneh [66]. The findings showed that inulin stimulated the growth of Lactobacillus reuteri, Lactobacillus johnsonii, and Lactobacillus salivarius, resulting in ameliorated viability of the organisms.

Atallaha et al. produced low-fat yogurt fortified with whey protein concentrates, Ca-caseinates (Ca-Cns), and spirulina (Spirulina platensis) powders [75]. They found that the yogurt with spirulina powder had a high total phenolic content, while the yogurt containing whey protein concentrates had higher (p < 0.05) viscosity and water-holding capacity than the other samples. In the whey protein concentrates-fortified low-fat yogurts, the gel exhibited a various structure with a fine network containing numbers with very small pores. The gel from the Ca-Cns-fortified yogurt had a dense and finely perforated microstructure, similar to that of the whey protein concentrates-enriched yogurt. Generally, the low-fat yogurt fortified with whey protein concentrates performed best in the sensory evaluation, followed by the sample with Ca-Cns.Abd El-Galeel et al. studied the effect of adding different levels (0.5 and 1%) of fat replacers (Dairy-Lo or Maltrin) on the quality of non-fat yogurt [76]. They found that the fat replacers had no significant effect on the chemical composition of the resultant yogurt but increased the soluble nitrogenous compounds, as well as the formation of acetaldehyde, diacetyle, and total volatile fatty acids (flavor compounds). Also, there was an improvement in the yogurt’s syneresis and viscosity. Overall, the non-fat yogurt containing 0.5 and 1% of Maltrin was similar in quality characteristics to the fullfat control yogurt.

Carob bean gum is widely used in food systems as a carbohydrate-based fat replacer to modify quality attributes and shelf-life as a thickening and gelling agent. Sonmez and Ozcan prepared reduced-fat (12%) and low-fat (6%) yogurt using Carob bean gum an found that it increased the textural and sensory attributes of the product [77]. The low-fat yogurts with Carob bean gum showed significant firmness and stickiness, as well as a higher yellowness index. Thus, the addition of Carob bean gum to reduced-fat and low-fat yogurts improved their sensory properties and acceptance index.

Zbikowska et al. explored the influence of various concentrations of inulin (3, 6, 9, 12, and 15% w/w) added to natural yogurt on its physicochemical properties [78]. They found that these concentrations of inulin significantly enhanced the product’s physical stability. Godoygarcia et al. prepared fat-reduced Greek-style yogurt by using glycomacropeptide powder as a fat replacer [79]. Adding 0.75% of glycomacropeptide reduced the granular consistency and syneresis of the yogurt by 50 and 10%, respectively. The flow curves and firmness analysis showed that this fat replacer decreased the elastic and viscous modulus, as well as the yoghurt’s firmness. The consumer acceptance of low-fat Greek-style yogurt containing 0.75% of glycomacropeptide decreased only after 30 days of storage. The resulting product showed lower syneresis and graininess.

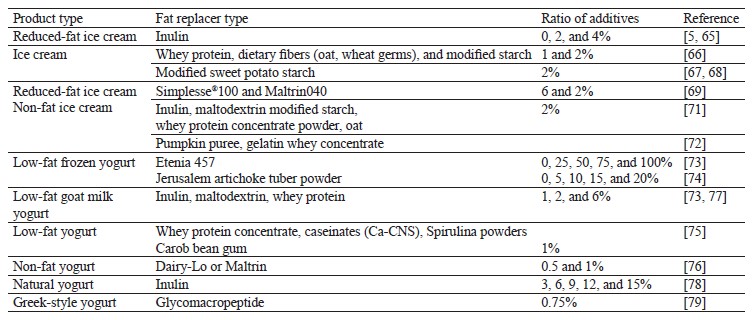

Costa et al. prepared goat milk yogurts with inulin [80]. The authors reported a decrease in firmness and consistency during storage. On the other hand, the viscosity index significantly increased during refrigerated storage. Furthermore, all the treatments exhibited viscoelastic behavior [81]. Table 2 summarizes some of the fat replacers used in ice cream and yogurt (frozen yogurt) production in the last decade.

Fat replacers in fatty products. Consumers often associate reduced-fat food products with poor taste, despite the potential benefits they can offer for managing diet-related health problems. Therefore, it is important to use high-quality fat substitutes to create appealing reduced-fat options. In a study by Míčková et al., polydextrose was used as a low-calorie fat replacer and bulking agent in butter [82]. The presence of polydextrose was confirmed through the use of petroleum ether extraction to remove fats from the butter. Solid fractions of both regular butter and butter with polydextrose were prepared and analyzed using FT-IR spectroscopy. The IR marker bands specific to poly-dextrose,

which appear at 1150, 1076, and 1040 cm–1, were only observed in the butter sample containing poly-dextrose.

In 2020, Iftikhar and Dutta conducted a study using raw, retrograded, and retrograded-annealed starches from three rice varieties with varying amylose contents (22.7, 9.8, and 0.3%) to replace some of the fat in fresh cream [83]. The goal was to create a whipped cream consistency with around 15% of fat. The study found that the fat replacement reduced the whipping time to 60 s and improved the stability of the whipped cream foam, resulting in a significant overrun of up to 44%. The use of starch also improved water retention and structural stability, reducing the amount of liquid that weeps out upon freezing and thawing. When using modified waxy starch, the resulting creamy texture was closest to that of the commercial cream standard, indicating that efficient fat replacement had been achieved. Overall, it was concluded that whipped cream with the fat content of more than by 62% less than in the commercial variants could be produced by incorporating starch.

Ahmadi et al. optimized the thermal, functional, and rheological properties of ethyl cellulose-based oleogel by using different concentrations of behenic acid and assessing the stability of water in oleogel (w/og) emulsions [84]. Similarly, Palla et al. investigated the formulation and characterization of filling creams for sandwich cookies using mono-glyceride oleogel as a fat material [85]. The study revealed that the filling creams formulated with 260 g/kg oleogel had viscoelastic moduli values similar to those in a filling cream of commercial sandwich cookies used as a reference. However, the oil-binding capacity of the filling creams decreased with an increase in the oleogel content. Furthermore, larger amounts of oleogel in the formulation resulted in decreased hardness, but increased adhesiveness and cohesiveness. The replacement of animal fat with vegetable fat offers an additional advantage, since it agrees with the increasing demand for animal-free products by consumers.

Schädle et al. examined the impact of fat replacers on reduced-fat emulsions, including their rheological, tribiological, and aroma release properties [86]. The authors emphasized the importance of high-quality fat replacers in developing appealing reduced-fat products. They reduced the fat content of a full-fat emulsion by replacing it with water, lactose, corn dextrin, inulin, poly-dextrose, or micro-particulated whey protein. Corn dextrin exhibited similar values to the full-fat emulsion in terms of Kokini oral shear stress and viscosity, while micro-particulated whey protein strongly increased these properties. All the four fat replacers improved the lubricity of the reduced-fat samples. None of the formulations had a significant effect on the droplet size distribution. The aroma of the emulsions comprising micro-particulated whey protein and corn dextrin were most similar to those of the full-fat emulsion. Thus, the authors found corn dextrin a promising fat replacer for reduced-fat emulsions. Butanoic acid, heptan-2-one, ethyl butanoate, and nonan-2-one were more affected by changes in the formulation than butane-2, 3-dione, and 3-methylbutanoic acid.

Schädle et al. also conducted another study in which they used varying concentrations of corn dextrin as a replacement for fat in mayonnaise [87]. The findings indicated that tri-biological measurements could replace sensory analysis in determining the stickiness attribute. Furthermore, the use of Stevens’ power law demonstrated a strong correlation between Kokini oral shear stress and the creaminess sensory attribute. Additionally, the instrumental texture properties (firmness, stickiness) were also related to sensory perception. These correlations obtained by comparing different methods could aid in predicting the potential applications of new fat replacers and assist in innovative product development.

Bayat et al. decreased the fat content of whipped creams by using two types of gums derived from chia and mero seeds [88]. Their study evaluated various physicochemical characteristics such as acidity, pH, viscosity, humidity, volume, water content, and sensory attributes of the treatments on days 1, 5, and 10. The findings indicated that the use of gums did not affect the acidity or pH of the treatments. However, the samples containing chia seed gum alone and chia seed gum with mero showed a reduction in moisture and an increase in viscosity and overrun. In conclusion, the study demonstrated that chia and mero seed gums can be effectively used to produce whipped creams with reduced fat content.

Additionally, Cui et al. noted that animal fats and shortenings are commonly used in various food preparations [89]. However, these types of fats are high in saturated fatty acids, and partially hydrogenated shortenings contain trans fats, which have been linked to an elevated risk of coronary heart disease. Consequently, nutrition experts suggest reducing the consumption of saturated and trans fats in people diets. Hence, food technologists and scientists are collaborating to create healthy substitutes for these types of fats. One promising solution is to use oleogels, which are solid-like structures formed by structuring edible oils. While several types of oleogels have been developed and shown potential, some technological hurdles limit their widespread use in the food industry.

Kim et al. created canola oil oleogels for filling creams by combining candelilla wax and glycerol monostearate in different ratios, resulting in a firmer texture and lower melting point than the traditional shortening substitutes [90]. The use of binary blends of oleo-gelators in oleogels could be a promising approach to improving the quality and healthfulness of food products by mitigating the drawbacks and limitations associated with using a single oleo-gelator.

In a study conducted by Onsri et al. in 2022, the use of inulin and whey protein concentrate in the crust and cream puff filling was investigated at varying percentages [91]. The addition of inulin and whey protein concentrate resulted in a significant decrease in viscosity and specific volume. However, using 20% of inulin in

crust puff filling helped maintain the structure. In sensory evaluations, the formula containing 20% of inulin and 10% of whey protein concentrate received the highest scores for appearance and taste. For cream puff filling, the treatments with 35 and 50% of inulin resulted in high viscosity. The panelists preferred the 20% inulin and 5% whey protein concentrate formulas for texture, taste, odor, and overall acceptability. These formulas helped reduce total energy from fat and increase dietary fiber and protein contents. Thus, inulin and whey protein concentrate proved to be successful fat replacers, extending shelf life from 9 to 13 days while meeting microbiological standards.

Recently, in a 2023 publication by Jiang et al., lactic acid bacteria were combined with hydroxyl-propyl methylcellulose and casein sodium salt to replace the saturated fat content in whipping cream analogues [92]. By using both hydrophobic and hydrophilic strains, the whipping cream had similar overrun (107%) and drainage stability (drainage area 1.4 mm2) compared to those of commercial dairy whipping cream (30% and 2.7 mm2, respectively). The Pickering capability and aggregating properties of the strains affected the foam stability of the whipped cream. The addition of the components and the whipping process did not have any negative effects on bacterial viability. Therefore, the use of edible lactic acid bacteria as fat replacers could offer viable alternatives to using naturally derived components as active structural building blocks for colloidal food systems such as whipping cream.

Suriaini et al. conducted a study to examine how beeswax and palm oil concentrations affect the properties of oleogels, which were then compared to a commercial shortening to determine their potential as shortening substitutes [93]. Crude palm oil and palm oil-based cooking oil both contain high levels of palmitic acid (C16:0), oleic acid (C18:1), and linoleic acid (C18:2), but the former has more total saturated fatty acids than commercial cooking oil. The researchers used binary blends of palm oil (crude palm oil and cooking oil) and beeswax in different concentrations to produce palm oilbased oleogel. The results showed that the oleogels with higher beeswax concentrations had a greater oil-binding capacity and produced needle-like and spherical crystals. The crude palm oil-based oleogel had higher heat resistance and was more similar in profile to shortening than the cooking oil-based oil. The palm oil-based oleogel products had properties comparable to commercial shortening and can thus be used as substitutes.

A recent study by You et al. created 3D printed chocolate with a reduced fat content by substituting cocoa butter with water-in-oil emulsions made from gum Arabic [94]. The optimal formulations for 3D printability contained cocoa butter, icing sugar, and cocoa powder in a ratio of 2:1:2.5. Various levels of cocoa butter (25, 50, and 75%) were replaced with water-in-cocoa butter emulsions with different water/oil ratios (2:8, 3:7, 4:6 v/v) to produce the fat-reduced 3D printed chocolate. The results indicated that these chocolates retained the desired polymorphic form V of cocoa butter, and higher emulsion contents led to improved snap quality. The study successfully developed a functional reduced-fat chocolate using gum Arabic-based water-in-oil emulsions that could potentially incorporate both hydrophilic and lipophilic bioactives in the future. Table 3 provides examples of fat replacers that have been used in fatty products in the last decade.

ВЫВОДЫ

Most research in the last decade has focused on designing low- or no-fat products that mimic the features of full-fat products. Fat replacers can be divided into two categories, fat substitutes and fat mimetics. They are molecules that have the physical and functional characteristics of conventional fat molecules (e.g., triglycerides). Using proteins and micro-particulated proteins has been a popular trend as nanotechnology plays a critical role in the food sector nowadays. In addition to proteins and commercially available micro-particulated proteins, microgels designed under laboratory conditions have recently demonstrated superior rheological and lubrication performance with the ability to act as potential fat replacers. While whey protein is the most common fat replacer in the dairy field today, there is some interest in other plant proteins which have not been studied as widely yet.

The application of fat replacers in dairy products is expected to witness significant advancements in the coming years, with the growing consumer demand for healthier alternatives and the increasing focus on reducing fat content in food products. Researchers and food scientists are actively exploring novel fat replacers that can mimic the sensory and textural properties of traditional dairy products while offering improved nutritional profiles. One promising trend is the utilization of plant-based fat replacers derived from nuts, seeds, and legumes, which not only provide a creamy mouthfeel but also offer additional health benefits, including higher levels of unsaturated fats and essential nutrients. Another emerging trend is the incorporation of microencapsulation techniques to enhance the stability and release properties of fat replacers, ensuring their efficient delivery and functionality throughout the shelf life of dairy products. Additionally, advancements in biotechnology and genetic engineering may enable the development of tailored fat replacers that closely mimic the complex structure and composition of natural fats, further enhancing the overall sensory experience and consumer acceptance of low-fat dairy products. As research in this field continues to evolve, it is anticipated that these future trends will contribute to the development of innovative and nutritious reduced-fat dairy products that meet the demands of health-conscious consumers while maintaining their palatability and quality.

Вклад авторов

Hayam M. Abbas wrote the first section including the definition, classification, and action of fat substitutes available as artificial materials. Mona A. M. Abd El-Gawad reviewed the application of fat replacers in different types of cheese. Jihan M. Kassem described the use of fat substitutes in fermented dairy products and corresponding author. Mohamed Salama wrote the application of fat replacers in fatty products. All the authors were involved in reviewing the article.

КОНФЛИКТ ИНТЕРЕСОВ

The authors declare that there is no conflict of interest.СПИСОК ЛИТЕРАТУРЫ

- Pimentel TC, de Oliveira LIG, de Souza RC, Magnani M. Probiotic ice cream: A literature overview of the technological and sensory aspects and health properties. International Journal of Dairy Technology. 2022;75(1):59–76. https://doi.org/10.1111/1471-0307.12821

- Serikov MS, Nurgaliyeva MT, Myrzabek KA, Toishimanov MR, Baktybayeva FK. Defining the composition of fat phase in foods. Food Processing: Techniques and Technology. 2022;52(4):685–693. (In Russ.). https://doi.org/10.21603/2074-9414-2022-4-2398

- Tosh SM, Bordenave N. Emerging science on benefits of whole grain oat and barley and their soluble dietary fibers for heart health, glycemic response, and gut microbiota. Nutrition Reviews. 2020;78(S1):13–20. https://doi.org/10.1093/nutrit/nuz085

- Recuero-Virto N, Valilla-Arrospide C. Forecasting the next revolution: Food technology’s impact on consumers' acceptance and satisfaction. British Food Journal. 2022;124(12):4339–4353. https://doi.org/10.1108/BFJ-07-2021-0803

- Junyusen T, Petnom G, Chienwiboonsook B. The effects of inulin on the physicochemical characteristics of reduced-fat ice cream. Suranaree Journal of Science and Technology. 2017;24(1):13–22.

- Position of the American dietetic association: Fat replacers. Journal of the American Dietetic Association. 2005;105(2):266–275. https://doi.org/10.1016/j.jada.2004.12.011

- Krauss RM, Eckel RH, Howard B, Appel LJ, Daniels SR, Deckelbaum RJ, et al. AHA dietary guidelines. Revision 2000: A statement for healthcare professionals from the Nutrition Committee of the American Heart Association. Circulation. 2000;102(18):2284–2299. https://doi.org/10.1161/01.CIR.102.18.2284

- Wylie-Rosett Ju. Fat substitutes and health. An advisory from the Nutrition Committee of the American Heart Association. Circulation. 2002;105(23):2800–2804. https://doi.org/10.1161/01.CIR.0000019402.35632.EB

- Ognean CF, Darie N, Ognean M. Fat replacers – Review. Journal of Agroalimentary Processes and Technologies. 2006;12(2):433–442.

- Grujić S, Grujčić M. Factors affecting consumer preference for healthy diet and functional foods. Foods and Raw Materials. 2023;11(2):259–271. https://doi.org/10.21603/2308-4057-2023-2-576

- Nourmohammadi N, Austin L, Chen D. Protein-based fat replacers: A focus on fabrication methods and fat-mimic mechanisms. Foods. 2023;12(5). https://doi.org/10.3390/foods12050957

- Atik I, Cakmak ZHT, Avcı E, Karasu S. The effect of cold press chia seed oil by‐products on the rheological, microstructural, thermal, and sensory properties of low‐fat ice cream. Foods. 2021;10(10). https://doi.org/10.3390/foods10102302

- Colla K, Costanzo A, Gamlath S. Fat replacers in baked food products. Foods. 2018;7(12). https://doi.org/10.3390/foods7120192

- Phillips SM, Chevalier S, Leidy HJ. Protein “requirements” beyond the RDA: Implications for optimizing health. Applied Physiology, Nutrition, and Metabolism. 2016;41:565–572. https://doi.org/10.1139/apnm-2015-0550

- Bohrer BM. Review: Nutrient density and nutritional value of meat products and non-meat foods high in protein. Trends in Food Science and Technology. 2017;65:103–112. https://doi.org/10.1016/j.tifs.2017.04.016

- Tikhonov SL, Tikhonova NV, Gette IF, Sokolova KV, Danilova IG. Antihyperglycemic activity of colostrum peptides. Foods and Raw Materials. 2024;12(1):124–132. https://doi.org/10.21603/2308-4057-2024-1-586

- Solanke ND, Pawar PA, Deshmukh GP, Gadhave RK. Fat substitutes: A systematic review. Anveshana’s International Journal of Research in Engineering and Applied Sciences. 2016;1(11):90–99.

- Syan V, Kaur J, Sharma K, Patni M, Rasane P, Singh J, et al. An overview on the types, applications and health implications of fat replacers. Journal of Food Science and Technology. 2022. https://doi.org/10.1007/s13197-022-05642-7

- Chavan RS, Khedkar CD, Bhatt S. Fat replacer. In: Caballero B, Finglas PM, Toldrá F, editor. Encyclopedia of food and health. Academic Press; 2016. pp. 589–595. https://doi.org/10.1016/B978-0-12-384947-2.00271-3

- Thomas DT, Erdman KA, Burke LM. Nutrition and athletic performance. Medicine and Science in Sports and Exercise. 2016;48(3):543–568. https://doi.org/10.1249/MSS.0000000000000852

- Jones JM, Jonnalagadda S. The use of fat replacers for weight loss and control. In: Mela DJ, editor. Food, diet and obesity. Woodhead Publishing; 2005. pp. 281–291. https://doi.org/10.1533/9781845690540.2.281

- Urgu M, Türk A, Ünlütürk S, Kaymak-Ertekin F, Koca N. Milk fat substitution by microparticulated protein in reduced-fat cheese emulsion: The effects on stability, microstructure, rheological and sensory properties. Food Science of Animal Resources. 2019;39(1):23–34. https://doi.org/10.5851/kosfa.2018.e60

- Yashini M, Sunil CK, Sahana S, Hemanth SD, Chidanand DV, Rawson A. Protein-based fat replacers – A review of recent advances. Food Reviews International. 2021;37(2):197–223. https://doi.org/10.1080/87559129.2019.1701007.

- Abbas HM, Hammad MNEF, El-Saba NB. Evaluation of low calories ice cream properties prepared by using fat replacer and sweetener. Egyptian Journal of Chemistry. 2022;65(4):591–603. https://doi.org/10.21608/EJCHEM.2021.85969.4163

- Alting AC, van de Velde F, Kanning MW, Burgering M, Mulleners L, Sein A, et al. Improved creaminess of low-fat yoghurt: The impact of amylomaltase-treated starch domains. Food Hydrocolloids. 2009;23(3):980–987. https://doi.org/10.1016/j.foodhyd.2008.07.011

- Birkeland E, Gharagozlian S, Birkeland KI, Holm OKS, Thorsby PM, Aas A-M. Effect of inulin-type fructans on appetite in patients with type 2 diabetes: a randomised controlled crossover trial. Journal of Nutritional Science. 2021;10. https://doi.org/10.1017/jns.2021.70

- Chaito C, Judprasong K, Puwastien P. Inulin content of fortified food products in Thailand. Food Chemistry. 2016;193:102–105. https://doi.org/10.1016/j.foodchem.2014.10.140

- Birkeland E, Gharagozlian S, Gulseth HL, Birkeland KI, Hartmann B, Holst JJ, et al. Effects of prebiotics on postprandial GLP-1, GLP-2 and glucose regulation in patients with type 2 diabetes: A randomised, double-blind, placebo-controlled crossover trial. Diabetic Medicine. 2021;38(10). https://doi.org/10.1111/dme.14657

- Karimi R, Azizi MH, Ghasemlouc M, Moharam V. Application of inulin in cheese as prebiotic, fat replacer and texturizer: A review. Carbohydrate Polymers. 2015;119:85–100 https://doi.org/10.1016/j.carbpol.2014.11.029

- Abd El-Gawad MAM, Hassan FAM. Manufacture of low fat soft white cheese by using fat replacers. Arab Universities Journal of Agricultural Sciences. 2000;8(1):253–261.

- Meyer D, Bayarri S, Tarrega A, Costell E. Inulin as texture modifier in dairy products. Food Hydrocolloids. 2011;25(8):1881–1890. https://doi.org/10.1016/j.foodhyd.2011.04.012

- O’Connor TP, O’Brien NM. Fat replacers. In: Kırtıl E, Öztop HM, editors. Reference Module in food science. Elsevier; 2016.

- Peng X, Yao Y. Carbohydrates as fat replacers. Annual Review of Food Science and Technology. 2017;8:331–351. https://doi.org/10.1146/annurev-food-030216-030034

- Kew B, Holmes M, Stieger M, Sarkar A. Review on fat replacement using protein-based microparticulated powders or microgels: A textural perspective. Trends in Food Science and Technology. 2020;106:457–468. https://doi.org/10.1016/j.tifs.2020.10.032

- Torres IC, Amigo JM, Knudsen JC, Tolkach A, Mikkelsen BØ, Ipsen R. Rheology and microstructure of low-fat yoghurt produced with whey protein microparticles as fat replacer. International Dairy Journal. 2018;81:62–71. https://doi.org/10.1016/j.idairyj.2018.01.004

- Torres O, Murray B, Sarkar A. Emulsion microgel particles: Novel encapsulation strategy for lipophilic molecules. Trends in Food Science and Technology. 2016;55:98–108. https://doi.org/10.1016/j.tifs.2016.07.006

- Li H, Zhang L, Jia Y, Yuan Y, Li H, Cui W, et al. Application of whey protein emulsion gel microparticles as fat replacers in low-fat yogurt: Applicability of vegetable oil as the oil phase. Journal of Dairy Science. 2022;105(12):9404–9416. https://doi.org/10.3168/jds.2022-22314

- El-Aidie S, Ghita IE, El-Dieb MS, Elgarhi H. Physicochemical, microstructural and sensory impact of fat replacers on low-fat Edam cheese manufactured from buffalo’s milk. International Journal of Advancement in Life Sciences Research. 2019;2(3):11–21. https://doi.org/10.31632/ijalsr.2019v02i03.002

- Akin MS, Kirmaci Z. Influence of fat replacers on the chemical, textural and sensory properties of low-fat Beyaz pickled cheese produced from ewe’s milk. International Journal of Dairy Technology. 2015;68(1):127–134. https://doi.org/10.1111/1471-0307.12164

- Schadle CN, Eisner P, Bader-Mittermaier S. The combined effects of different fat replacers and rennet casein on the properties of reduced-fat processed cheese. Journal of Dairy Science. 2020;103(5):3980–3993. https://doi.org/10.3168/jds.2019-17694

- Mounsey JS, O’Riordan ED. Empirical and dynamic rheological data correlation to characterize melt characteristics of imitation cheese. Journal of Food Science. 1999;64(4):701‒703. https://doi.org/10.1111/J.1365-2621.1999.TB15114.X

- Mounsey JS, O’Riordan ED. Characteristics of imitation cheese containing native starches. Journal of Food Science. 2001;66(4):586‒591. https://doi.org/10.1111/j.1365-2621.2001.tb04606.x

- Diamantino VR, Costa MS, Taboga SR, Vilamaior PSL, Franco CML, Penna ALB. Starch as a potential fat replacer for application in cheese: Behaviour of different starches in casein/starch mixtures and in the casein matrix. International Dairy Journal. 2019;89:129–138. https://doi.org/10.1016/j.idairyj.2018.08.015

- Mehanna NM, Swelam S, Ragab WA, Dawoud MA. Composition and some properties of processed cheese spread made from blends containing different quantities of the same main ingredients. Journal of Food and Dairy Sciences. 2020;11(10):285–288. https://doi.org/10.21608/jfds.2020.123932

- Abd El-Wahed EM, Hassanien MFR. Chemical, rheological and sensory characteristcs of processed cheese spread analogues. Carpathian Journal of Food Science and Technology. 2019;11(1):135–148.

- El-Assar MA, Abou-Dawood SA, Sakr SS, Younis NM. Low-fat processed cheese spread with added inulin: Its physicochemical, rheological and sensory characteristics. International Journal of Dairy Science. 2019;14(1):12–20. https://doi.org/10.3923/ijds.2019.12.20

- Sołowiej BG, Nastaj M, Szafranska JO, Terpiłowski K, Małecki J, Mleko S. The effect of fat replacement by whey protein microcoagulates on the physicochemical properties and microstructure of acid casein model processed cheese. International Dairy Journal. 2022;131. https://doi.org/10.1016/j.idairyj.2022.105385

- Daia SF, Jiang F, Corkec H, Shaha NP. Physicochemical and textural properties of Mozzarella cheese made with konjacglucomannan as a fat replacer. Food Research International. 2018;107:691–699. https://doi.org/10.1016/j.foodres.2018.02.069

- Chatli MK, Gandhi N, Singh P. Quality of low-fat Mozzarella cheese with different fat replacers. Acta Alimentaria. 2019;48(4):441–448. https://doi.org/10.1556/066.2019.48.4.5

- Esen MK, Güzeler N. The effects of the use of whey protein as a fat replacer affected on the composition, proteolysis, textural, meltability, microstructural, and sensory properties of reduced-fat Boru-type Künefe cheese during storage. International Dairy Journal. 2023;137. https://doi.org/10.1016/j.idairyj.2022.105519

- Abd El-Gawad MAM. Quality of reduced fat Ricotta cheese made by using Dairy-Lo. Annals of Agricultural Science, Ain Shams University (Cairo). 2002;47(2):539–549.

- Rahimi J, Khosrowshahi A, Madadlou A, Aziznia S. Texture of low-fat Iranian White Cheese as influenced by Gum Tragacanth as a fat replacer. Journal of Dairy Science. 2007;90(9):4058–4070. https://doi.org/10.3168/jds.2007-0121

- Alnemr TM, Abd El-Razek AM, Hasan HMA, Massoud MI. Improving of Karish cheese by using enhanced Technological texturizing Inulin. Alexandria Journal of Agricultural Sciences. 2013;58(2):173–181.

- Alnemr T, Helal A, Hassan A, Elsaadany K. Utilizing the functions of hydrocolloids as fat mimetic to enhance the properties of low-fat Domiati cheese. Journal of Food Processing and Technology. 2016;7. https://doi.org/10.4172/2157-7110.1000637

- Rashidi H, Mazaheri-Tehrani M, Razavi SMA, Ghods-Rohany M. Improving textural and sensory characteristics of low-fat UF feta cheese made with fat replacers. Journal of Agricultural Science and Technology. 2015;17:121–132.

- Basiony MMM, El-Nimer AMM, El-Gandour AA. Effect of fat replacers on the quality of low-fat munster-like cheese. Journal of Food and Dairy Sciences. 2017;8(2):93–98. https://doi.org/10.21608/jfds.2017.37130

- Saraiva BR, Licci NM, Anjo FA, Vital ACP, da Silva JB, Bruschi ML, et al. Effects of inulin and canistel addition in the physical characteristics of fat-reduced processed cheese. Research, Society and Development. 2020;9(11). https://doi.org/10.33448/rsd-v9i11.9917

- Kadpe BB, Patange DD, Yadav MM, Kamble DK, Memane CV, Kamble SS. Process development of low fat Quarg cheese using fat replacer. International Journal of Food and Fermentation Technology. 2019;9(2):139–148. https://doi.org/10.30954/2277-9396.02.2019.11

- Aini N, Prihananto V, Sustriawan B, Romadhon D, Ramadhan RN. The formulation of cheese analogue from sweet corn extract. International Journal of Food Science. 2019;2019. https://doi.org/10.1155/2019/8624835

- Giha V, Ordonez MJ, Villamil RA. How does milk fat replacement influence cheese analogue microstructure, rheology, and texture profile? Journal of Food Science. 2021;86(7):2802–2815. https://doi.org/10.1111/1750-3841.15799

- Sharaf S, Nateghi L, Eyvazzade O, Ebrahimi MTA. The physicochemical, texture hardness and sensorial properties of Ultrafiltrated low- fat cheese containing galactomannan and novagel gum. Acta Scientiarum Polonorum, Technologia Alimentaria. 2020;19(1):83–100. https://doi.org/10.17306/J.AFS.2020.0685

- AI-Bedrani DIJ, Hasan ST, Altaee AA, Alqotbi AA. Improving low-fat soft cheese quality properties made from reconstituted skim milk by using whey protein concentrate as a fat replacer. IOP Conference Series: Earth and Environmental Science. 2021;910. https://doi.org/10.1088/1755-1315/910/1/012040

- Mefleh M, Pasqualone A, Caponio F, de Angelis D, Natrella G, Summo C, et al. Spreadable plant-based cheese analogue with dry-fractioned pea protein and inulin–olive oil emulsion-filled gel. Journal of the Science of Food and Agriculture. 2022;102(12):5478–5487. https://doi.org/10.1002/jsfa.11902

- Basiony M, Hassabo R. Composition and quality of low-fat Halloumi cheese made using modified starch as a fat replacer. Starch – Stärke. 2022;74(3–4). https://doi.org/10.1002/star.202100211

- Mahdian E, Karazhian R. Effects of fat replacers and stabilizers on rheological, physicochemical and sensory properties of reduced-fat ice cream. Journal of Agricultural Science and Technology. 2013;15(6):1163–1174.

- Salem SA, Hamad EM, Ashoush IS. Effect of partial fat replacement by whey protein, oat, wheat germ and modified starch on sensory properties, viscosity and antioxidant activity of reduced fat ice cream. Food and Nutrition Sciences. 2016;7(6):397–404. https://doi.org/10.4236/fns.2016.76041

- Babu AS, Parimalavalli R, Mohan RJ. Effect of modified starch from sweet potato as a fat replacer on the quality of reduced-fat ice creams. Journal of Food Measurement and Characterization. 2018;12:2426–2434. https://doi.org/10.1007/s11694-018-9859-4

- Warren MM, Hartel RW. Effects of emulsifier, overrun and dasher speed on ice cream microstructure and melting properties. Journal of Food Science. 2018;83(3):639–647. https://doi.org/10.1111/1750-3841.13983

- Hatipoğlu A, Türkoğlu H. A research on the quality features of ice cream produced using some fat substitutes. Journal of Food Science and Engineering. 2020;10:1–10. https://doi.org/10.17265/2159-5828/2020.01.001

- El-Shafei SMS. Manufacture of functional and healthy probiotic frozen goat's yoghurt using chia flour. Pakistan Journal of Biological Sciences. 2020;23(6):753–768. https://doi.org/10.3923/pjbs.2020.753.768

- Abdou SM, Shenana ME, El Nagar GF, Abd Elatif RG. Improving the quality of low-fat ice cream using some fat replacers. 5 th International Conference on Biotechnology Applications in Agriculture; 2021; Egypt. Egypt: Benha University; 2021.

- Silantjeva K, Zagorska J, Galoburda R. Physicochemical and rheological properties of non-fat ice cream. Proceedings of the Latvian Academy of Sciences. Section B. 2022;76(1):138–144. https://doi.org/10.2478/prolas-2022-0021

- Hamad MN-EF, Abbas HM, El-sayed El-Sabea NBF. Preparation of functional frozen-yoghurt using fat replacer and sweetener substitutes. Egyptian Journal of Chemistry. 2022;65(4):185–195.

- Shahein MR, Elkot WF, Albezrah NKA, Abdel-Hafez LJM, Alharbi MA, Massoud D, et al. Insights into the microbiological and physicochemical properties of bio-frozen yoghurt made with probiotic strains in combination with Jerusalem artichoke tubers powder. Fermentation. 2022;8(8). https://doi.org/10.3390/fermentation8080390

- Atallah AA, Morsy OM, Gemiel DG. Characterization of functional low-fat yogurt enriched with whey protein concentrate, Ca-caseinate and spirulina. International Journal of Food Properties. 2020;23(1):1678–1691. https://doi.org/10.1080/10942912.2020.182340

- Abd El-Galeel AA, Atwaa EH, Abdelwahed EM. Improving properties of non-fat yoghurt using fat replacers. Zagazig Journal of Agricultural Research. 2017;44(2):583–590. http://dx.doi.org/10.21608/zjar.2017.53878

- Aydinol Sonmez P, Ozcan T. Assessment of structure and sensory characteristics of reduced fat yoghurt manufactured with carob bean gum polysaccharides. Food Science and Technology. 2022;42. https://doi.org/10.1590/fst.61220

- Zbikowska A, Szymańska I, Kowalska M. Impact of inulin addition on properties of natural yogurt. Applied Sciences. 2020;10(12). https://doi.org/10.3390/app10124317

- Godoy-Garcia L, Abadia-Garcia L, Cruz-Aldaco K, Castano-Tostado E, Murua-Pagola B, Amaya-Llano SL. Addition of glycomacropeptide as fat replacer in sugar-reduced Greek-style yoghurt. International Journal of Dairy Technology. 2020;73(4):718–725. https://doi.org/10.1111/1471-0307.12717

- Costa MP, Rosario AIS, Silva VLM, Vieira CP, Conte-Junior CA. Rheological, physical and sensory evaluation of low-fat cupuassu goat milk yogurts supplemented with fat replacer. Food Science of Animal Resources. 2022;42(2):210–224. https://doi.org/10.5851/kosfa.2021.e64

- Subroto E, Indiarto R, Djali M, Rosyida HD. Production and application of crosslinking modified starch as fat replacer: A review. International Journal of Engineering Trends and Technology. 2020;68(12):26–30. https://doi.org/10.14445/22315381/IJETT-V68I12P205

- Míčková K, Čopíková J, Synytsya A. Determination of polydextrose as a fat replacer in butter. Czech Journal of Food Sciences. 2007;25(1):25–31. https://doi.org/10.17221/738-CJFS

- Iftikhar SA, Dutta H. Use of raw and physically modified rice starches as fat replacer in whipping cream. Current Research in Nutrition and Food Science. 2020;8(1):122–130. https://doi.org/10.12944/CRNFSJ.8.1.11

- Ahmadi P, Tabibiazar M, Roufegarinejad L, Babazadeh A. Development of behenic acid-ethyl cellulose oleogel stabilized Pickering emulsions as low calorie fat replacer. International Journal of Biological Macromolecules. 2020;150:974–981. https://doi.org/10.1016/j.ijbiomac.2019.10.205

- Palla CA, Wasinger MF, Carrín ME. Monoglycerideoleogels as fat replacers in filling creams for sandwich cookies. Journal of the Science of Food and Agriculture. 2021;101(6):2398–2405. https://doi.org/10.1002/jsfa.10863

- Schädle CN, Sanahuja S, Bader-Mittermaier S. Influence of fat replacers on the rheological, tribological, and aroma release properties of reduced-fat emulsions. Foods. 2022;11(6). https://doi.org/10.3390/foods11060820

- Schädle CN, Bader-Mittermaier S, Sanahuja S. Characterization of reduced-fat mayonnaise and comparison of sensory perception, rheological, tribological, and textural analyses. Foods. 2022;11(6). https://doi.org/10.3390/foods11060806

- Bayat E, Moslehishad M, Homapour M. Fat replacement with mero (Salvia macrosiphon) and chia (Salvia hispanica L.) seed gum on physicochemical, rheological and sensory characteristics of low-fat whipped creams. Iranian Journal of Nutrition Sciences and Food Technology. 2022;17(3):87–98. https://doi.org/20.1001.1.17357756.1401.17.3.7.1

- Cui XT, Saleh ASM, Yang S, Wang N, Wang P, Zhu M, et al. Oleogels as animal fat and shortening replacers: Research advances and application challenges. Food Reviews International. 2022;39(8):5233–5254. https://doi.org/10.1080/87559129.2022.2062769

- Kim M, Hwang H-S, Jeong S, Lee S. Utilization of oleogels with binary oleogelator blends for filling creams low in saturated fat. LWT. 2022;155. https://doi.org/10.1016/j.lwt.2021.112972

- Onsri N, Hudthagosol C, Sanporkha P. Effect of inulin and whey protein concentrate on the physicochemical properties and shelf life of reduced‐fat cream puffs. Journal of Food Processing and Preservation. 2022;46(12). https://doi.org/10.1111/jfpp.16955

- Jiang X, Shekarforoush E, Muhammed MK, Whitehead KA, Arneborg N. Risbo J. Lactic acid bacteria as structural building blocks in non-fat whipping cream analogues. Food Hydrocolloids. 2023;135. https://doi.org/10.1016/j.foodhyd.2022.108137

- Suriaini N, Arpi N, Syamsuddin Y, Supardan MD. Characteristics of palm oil-based oleogel and its potency as a shortening replacer. South African Journal of Chemical Engineering. 2023;43:197–203. https://doi.org/10.1016/j.sajce.2022.11.003

- You S, Huang Q, Lu X. Development of fat-reduced 3D printed chocolate by substituting cocoa butter with water-in-oil emulsions. Food Hydrocolloids. 2023;135. https://doi.org/10.1016/j.foodhyd.2022.108114