Аннотация

Persimmon juice has good nutritional composition and high antioxidant properties, however it requires more packing space because of large volume and has limited shelf-life. The research objective was to produce persimmon purée powder with prolonged shelf-life by using various concentrations of drying agents (maltodextrin and Arabic gum).The control sample was persimmon purée powder without drying agents. Experimental samples included powders with maltodextrin (40, 45, and 50%), Arabic gum (25, 30, and 35%), and the mix of maltodextrin (40%) and Arabic gum (10%). All the experimental samples contained 1% of tri-calcium phosphate as an anti-caking agent. Tests were carried out according to the standard techniques.

The samples with 45 and 50% of maltodextrin had lower moisture, ash, redness (a*), and hygroscopicity values. These powders demonstrated good yield, solubility, density, and color indices (L*, b*, C, H). The persimmon purée powders with 30 and 35% of Arabic gum showed an increase in ash content and total acidity. The samples with 30% of Arabic gum obtained the highest sensory evaluation scores.

The optimal results belonged to the samples of lyophilized persimmon purée powder with 45% of maltodextrin, which will have a longer shelf-life due to its low moisture content.

Ключевые слова

Persimmon puree powder, lyophilization, maltodextrin, Arabic gum, chemical and physical indicators, color indicatorsВВЕДЕНИЕ

Fruits and vegetables are an important component of human diet as they are known to reduce the risk of some chronic diseases [1, 2]. Persimmon (Diospyros kaki L.) has excellent sensory and nutritional properties, is a source of minerals, carbohydrates, dietary fiber, ascorbic acid, and tannins, not to mention its powerful antioxidant activity [3].

Persimmon fruit contains 76.83% of moisture; its fiber content reaches 13.5% while fats and proteins stay between 0.05% and 1.32%. In addition, 100 g of permon contains 15.60 mg of ascorbic acid [4]. Persimsimmons are a rich source of sugars (12.5 g/100 g wet weight), represented by glucose, fructose, and sucrose [5]. Unfortunately, persimmon fruits have a short shelf-life and require sophisticated preservation techniques to reduce post-harvest losses and develop new products [6]. Nevertheless, persimmons have recently become a popular subject of food science because of their antioxidant, antiatherosclerosis, and anti-tumor properties [7].

Persimmon juice powder is part of beverage formulations and can serve as a secondary ingredient in confectionary products or baby food. Contemporary studies feature a lot of fruit juice powders, e.g., concentrated apple juice [8]. Modern methods of fruit powder production, e.g., lyophilization, can open persimmon purée powder the way to the global food market.

Lyophilization is currently one of the most important drying methods because it requires low operating temperatures, which reduces thermal damage, thus preserving the flavor and color indicators of the final product [9]. Lyophilization removes water by converting it first into ice crystals and then into steam. This process includes three stages: freezing, primary drying, and secondary drying. During the freezing stage, the fruit mass turns into solid ice crystals. At the primary drying stage, the ice is removed by sublimation. The secondary drying process means removing the bound and residual water until the required moisture content [10].

Lyophilization yields dried products of high nutritional quality, which are easy to transport, consume, and store. This method maintains high standards of reliability and quality, which makes it possible to preserve vitamins and antioxidants [11].

Dubkova et al. wrote that lyophilization products can be used in a wide range of food industries and in a variety of ways; e.g., dairy powders can be part of fastsoluble sauces and desserts due to their low weight and the small size of particles [12].

Fruit powders have many economic advantages over fresh juices, e.g., low weight and volume, less packing space, easy logistics, extended shelf-life, etc. [13].

However, the complex chemical composition of fruit juices limits their powdering options. The problem is that fruit juices contain organic acids, e.g., citric acid, malic acid, tartaric acid, etc., as well as low molecular weight sugars, e.g., glucose and fructose. As a result, they have a low glass transition temperature, which leads to high viscosity, extra hygroscopicity, and low solubility of the resulting powder because viscosity directly affects its fluidity and flowability. Drying agents, such as maltodextrin and gum, can solve this problem [14].

Arabic gum is a dried exudate obtained from acacia trees. The substance owes its wide pharmaceutical and industrial uses to its emulsifying properties. Arabic gum is a complex sugar composed of molecules of calcium, magnesium, and potassium with such sugars as arabinose and galactose. It has a mild taste and no smell [15].

Maltodextrin is a product of starch degradation, which consists of β-D-glucose units. It has high solubility and a pleasant flavor. Maltodextrin is cheap and commercially available, which explains its popularity in the food industry [16, 17].

The season of persimmon fruits is as short as three months, and fresh fruits are difficult to preserve [18]. Sucrose, glucose, and fructose have low molecular weight and low glass transition temperature of 62, 32, and 5°C, respectively [19]. These properties make it difficult to convert persimmons into a powder state. This research featured different concentrations of drying agents with a high glass transition temperature and their effect on powder viscosity, productivity, and agglomeration. We also revealed the quality standards of persimmon purée powder prepared by lyophilization method.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

The study involved fresh persimmons (Diospyros kaki L.). Their chemical composition was as follows: 81.31% of moisture, 0.11% total acidity, pH 6.17, 0.72% ash, and 12.64 g total sugar (100 g wet weight). The fruits were purchased at a local market in the city of Damascus. The research was conducted at the laboratories of the Department of Food Sciences, University of Damascus, in November and December during the ripening season of 2022. Each experiment included 2 kg of persimmon fruit.

Pre-treatment. After removing damaged fruits and impurities, we washed the persimmons in plain water and peeled them with a sharp knife. The peeled fruits were mashed in an electric mixer (Starway 4550D, China) for 3 min.

The persimmon purée was divided into several samples. Sample № 1 served as control and involved pure persimmon purée without any drying agents. Sample № 2 contained persimmon purée with maltodextrin at the concentrations of 40, 45, and 50% plus 1% tri-calcium phosphate as an anti-caking agent. Sample № 3 included persimmon purée with Arabic gum at the concentrations of 25, 30, 35% plus 1% tri-calcium phosphate as an anticaking agent. Each sample was homogenized separately for 3 min using a mixer (Starway 4550D, China) [20, 21].

Freeze-drying. The persimmon purée mixes underwent drying by the freeze-drying method. After adding drying agents, each sample was frozen at –4°C, then processed in the laboratory lyophilization device at –60°C and a pressure of 0.11 mbar [22]. After that, we ground the dried samples in a mixer (Starway 4550D, China) for 3 min and stored the resulting powder in dark glass containers until further analysis.

Moisture content. The moisture content was determined in line with the method described in Article 925.09 of the Official Methods of Analysis of the Association of Official Analytical Chemists [23]. The samples were dried in a drying oven (Memmert D 91126, Germany) at 105°C until constant weight.

Ash content. We estimated the ash content in line with the method described in Article 923.03 of the Official Methods of Analysis of the Association of Official Analytical Chemists [23]. The samples were dried at 550°C until constant weight.

pH. The acidity was estimated using a pH-meter (Precisa PH-900).

Total acidity. The total acidity was measured by titration with 0.1 N sodium water in the presence of a phenolphthalein indicator [23].

Total sugars. Total sugars were defined according to the Lane-Enyon method as in [23].

Color indices. The color indices (L*, a*, b*, C, H) were mapped using a Hunter Lab tool kit (Biobase, China): L* (lightness) – the level of light to dark; a* (red to green) – positive a+ indicates red; negative a– indicates green; b* (yellow to blue) – positive b+ indicates yellow; negative b– indicates blue; C – color intensity; H (hue angle) – hue angles of 0, 90, 180, and 270° refer to pure red, pure yellow, pure green, and pure blue, respectively [24].

Process yield. The process yield, %, was determined in line with the equation described by Shuen et al. [25]:

Water solubility index. We defined the water solubility as in [26]: 1 g of persimmon purée and 10 mL of distilled water were mixed and incubated in a water bath at 37°C for 30 min, then centrifuged for 10 min. After that, we placed the floating part of the juice in Petri dishes of known weight and dried in a drying oven (Memmert D 91126, Germany) at 105°C until constant weight. The solubility of the powder was calculated as the difference in weights.

Hygroscopicity. We determined the hygroscopicity according to the method described by Šavikin et al. [27]. We put 1 g of persimmon purée in a petri dish with a saturated solution of sodium chloride with a relative humidity of 75.35% and stored the samples at room temperature for 7 days. The hygroscopicity was expressed as 1 g of absorbed moisture per 100 g dry solids.

Bulk and true density. We followed Igual et al. to measure the true and bulk density by placing 2 g of powder sample in a graduated cylinder [28]. The bulk density, g/cm3, was obtained according to the following Eq. (2):

After determining the bulk density, the cylinder stayed on a vibrating device until the volume of the powder changed. The density (TRUE, g/cm3) was calculated according to the following Eq. (3):

Sensory evaluation. The sensory evaluation involved a group of panelists who used a five-point hedonic scale to evaluate the color, taste, aroma, appearance, and overall acceptability of the persimmon juice reconstituted from the powder samples [29]. The sensory tests featured only the samples with 45% of maltodextrin, 30% Arabic gum, and the mix of maltodextrin (40%) and Arabic gum (10%) because they had a better quality from a physical point of view, i.e., degree of solubility, hygroscopicity, yield, and density.

Statistical analysis. The analysis of variance involved the SPSS software, where the results were analyzed using the One-Way ANOVA test followed by the LSD test to determine the significant differences between the means at a 5% confidence level. The results were recorded as means ± standard deviation.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

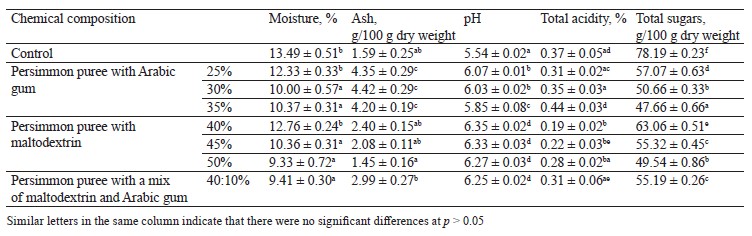

Effect of drying agents on chemical indicators of lyophilized persimmon purée powder. Table 1 demonstrates the data obtained for moisture, ash, pH, total acidity, and content of total sugars. The measurements clearly indicate a significant effect of the drying agents on the moisture content in the powder. The experimental samples with high concentrations of maltodextrin and Arabic gum showed a significant decrease in the moisture content compared to the control. The lowest total moisture values belonged to the powders with 45 and 50% of maltodextrin, 30 and 35% Arabic gum, and the mix of maltodextrin (40%) and Arabic gum (10%). The moisture contents for these samples were as low as 10.36, 9.33, 10.37, 10.00, and 9.41%, respectively. The concentration of the drying agents added to the purée before the lyophilization increased the percentage of solids, which led to a decrease in the total volume of moisture to be evaporated [30]. The results are consistent with those obtained by Cid-Ortega et al., who added Arabic gum and maltodextrin to powdered Hibiscus sabdariffa [31].

The samples with Arabic gum were significantly superior to those with maltodextrin in terms of ash content, which was in the range of 4.20–4.42 g/100 g dry weight, respectively. The ash contents in the samples with maltodextrin were from 1.45 to 2.40 g/100 g dry weight, respectively, while the indicator for the control sample was 2.99. Ali et al. reported that maltodextrin contained no minerals [32]. However, Kurniadi et al. mentioned that adding Arabic gum increased the ash content in the final product because of its high concentrations of calcium, magnesium, and potassium [33].

Table 1 also illustrates a drop in the pH of the powder with Arabic gum: the sample with 35% of Arabic gum had the lowest pH of 5.85. The samples with various concentrations of maltodextrin and the mix of maltodextrin and Arabic gum demonstrated no significant differences in pH values. In [34], Arabic gum also proved more effective in decreasing pH than maltodextrin because Arabic gum initially had a lower pH (4.64) than maltodextrin (5.16).

The total acidity was higher in the sample with 35% of Arabic gum, reaching 0.44%, while the samples with maltodextrin resulted in 0.19–0.28% total acidity, respectively.

The increasing concentration of both drying agents decreased the values for total sugars. Grabowski et al. reported a similar effect of maltodextrin on the total sugars in sweet potato powder [35].

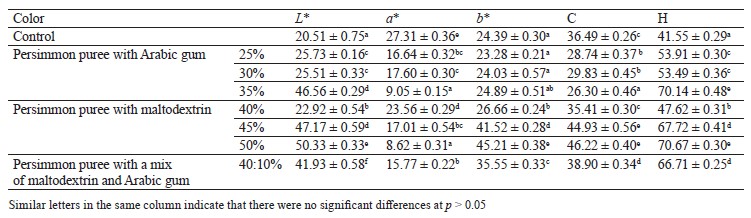

Effect of drying agents on color indicators of lyophilized persimmon purée powder. Table 2 sums up the obtained values of color indicators. Lightness index L* increased together with the concentration of the drying agent. The samples with high amounts of the drying agents, namely the powders with 50% of maltodextrin and 35% of Arabic gum demonstrated the highest lightness values, 50.33 and 46.56, respectively. The powders with maltodextrin had superior lightness values compared to those with Arabic gum because maltodextrin is white [36]. The obtained results for the lightness value were consistent with those reported by Suravanichnirachorn et al. [37].

As for indicator a* (red to green), Table 2 shows a significant decrease in the samples with high concentrations of the drying agents. In the sample with 50% maltodextrin, a* equaled 8.62 whereas the sample with 35% of Arabic gum had 9.05. Such results could be explained by the low concentration of persimmon purée [38].

The value of indicator b* (yellow to blue) increased together with the concentration of maltodextrin: its highest value reached 45.21 in the sample with 50% maltodextrin. No significant differences in the b* values were recorded for the samples with Arabic gum compared to the control.

Color intensity C increased following the concentration of maltodextrin, its highest value was in the sample with 50% ramaltodextrin (46.22). The C values decreased as the concentration of Arabic gum rose. The results are similar to those reported in [37].

Hue index H increased together with the concentration of the drying agent. The increase in the color gradient angle indicated that the red color of the powders turned yellow. The results were similar to those obtained by Shishir et al., who reported an increase in the hue value at higher concentrations of maltodextrin [39].

Effect of drying agents on some physical parameters of lyophilized persimmon purée powder. The physical properties of powders depend on many factors, i.e., the drying method used, the drying temperature, and the type and concentration of the agent [40].

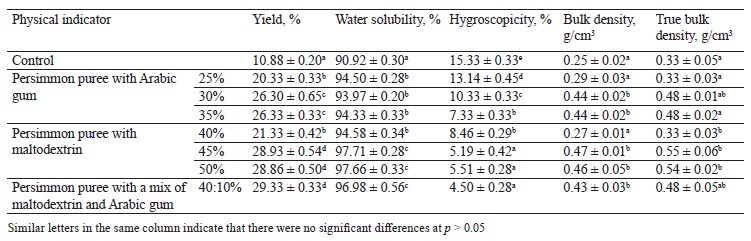

Table 3, which sums up the physical profiles of the persimmon powders, shows that a higher concentration of the drying agent caused a significant increase in the yield of persimmon purée powder. The highest yield belonged to the sample with 45 and 50% of maltodextrin: 28.93 and 28.86%, respectively. The sample with the mix of maltodextrin and Arabic gum reached a similar value of 29.33. Adetoro et al. also reported that maltodextrin had a greater effect on the yield rate than Arabic gum [41]. In general, powder yield is one of the most important physical indicators in terms of production process and economic efficiency [42].

The solubility index is an important property of powders because it is used as a standard to determine the solubility of a powder in water [43].

The solubility index of the powders rose together with the concentration of the drying agent. Its value increased from 90.92% in the control powder sample to 97.71 and 97.66% in the samples with 45 and 50% of maltodextrin, respectively. The samples with maltodextrin had a greater solubility compared to those with Arabic gum because maltodextrin is highly soluble in water [37].

Hygroscopicity is the ability of powder to attract water molecules from the environment. Fruit powders are highly hygroscopic because they contain glucose and fructose, which have polar ends. This property allows them to interact with water molecules, which increases the hygroscopicity of the product. Low hygroscopicity is important to maintain because it increases the stability of the final product [44].

In our case, the hygroscopicity index decreased when the concentration of the drying agent increased. It dropped to 5.19 and 5.51% in the samples with 45 and 50%

of maltodextrin, respectively, and to 4.50% in the mix of maltodextrin and Arabic gum, compared to the control, where it was 15.33%. The powders with maltodextrin had lower hygroscopicity values compared to those with Arabic gum, because maltodextrin has a higher glass transition temperature [41]. In addition, Arabic gum contains free hydroxyl groups that can bind water molecules more easily [45].

Bulk density is one of the most important physical properties for storage, packaging, and transportation of food powders. Powders with high density are more commercially advantageous because they reduce shipping and storage costs [19].

The drying agents had a significant effect on the bulk density of the persimmon powders. The samples with 45 and 50% of maltodextrin had the highest bulk density values, which amounted to 0.47 and 0.46 g/cm, respectively. No significant differences in the bulk density were registered between the samples with 30 and 35% of Arabic gum, 45 and 50% of maltodextrin samples, and the mix of maltodextrin and Arabic gum. The results are consistent with those obtained by Nthimole et al. [43].

Table 3 demonstrates a significant effect of the drying agents on the true density values of the persimmon powders. The samples with 45 and 50% of maltodextrin showed the highest true density values.

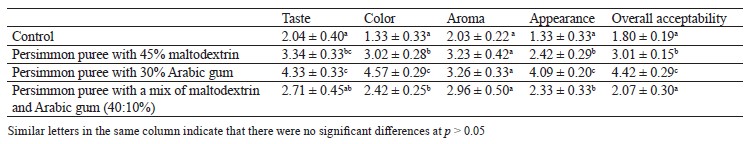

Effect of drying agents on sensory properties of lyophilized persimmon purée powder. Table 4 summarizes the results of the sensory evaluation of persimmon juice reconstituted from the lyophilized powders. The type of drying agent had a significant effect on the taste of the final product. The juice prepared from the powder with 30% of Arabic gum had the best score for taste, followed by juice samples prepared from the maltodextrin samples. The lowest score belonged to the samples prepared from the powder with the mix of maltodextrin and Arabic gum and the control sample. In terms of color, appearance, and overall acceptability, the juice prepared from powder with 30% of Arabic gum achieved the highest scores for acceptance, followed by the sample with 45% of maltodextrin. The scores for aroma demonstrated no significant differences between the control and the experimental samples: the drying agents had no aroma which could affect the sensory profile of the final product [46].

ВЫВОДЫ

Drying agents with a high glass transition temperature proved effective in the production of high-quality persimmon purée powder.

The lyophilized powders with 45 and 50% of maltodextrin had a much lower moisture content, redness (a*), and hygroscopicity, as well as greater color indicators L*, b*, C, and H. These samples also demonstrated good yield rate, solubility index, and true and apparent density. The samples with 30% of Arabic gum had a high ash content and better sensory characteristics compared to the other samples.

Maltodextrin at a concentration of 45% with 1% anticaking agent could be recommended for commercial use because it improved the physical properties of persimmon purée powder and reduced its moisture content, thus increasing its shelf-life.

Вклад авторов

All authors participated equally to the research and the manuscript.КОНФЛИКТ ИНТЕРЕСОВ

The authors declare no conflict of interests regarding the publication of this article.ФИНАНСИРОВАНИЕ

This research is part of a PhD thesis prepared at Damascus University, Syria, which supplied raw materials and laboratory equipment. The study received no support from any funding agencies.СПИСОК ЛИТЕРАТУРЫ

- Ghinea C, Leahu A. Valorisation of apple (Malus domestica) wastes. In: Ramadan MF, Farag MA, editors. Mediterranean fruits bio-wastes: Chemistry, functionality and technological applications. Cham: Springer; 2022. pp. 325–348. https://doi.org/10.1007/978-3-030-84436-3_13

- Leahu A, Ghinea C, Ropciuc S, Oroian M-A, Damian C. Polyphenol-rich smoothies: Sensory and chemical characterization. Studia Universitatis Vasile Goldis Arad. Seria Stiintele Vietii. 2019;29(1):37–45.

- Corrêa JLG, Lopes FJ, de Mello Júnior RE, de Jesus Junqueira JR, de Mendonça KS, Macedo LL, et al. Drying of persimmon fruit (Diospyros kaki L.) pretreated by different osmotic processes. Journal of Food Process Engineering. 2021;44(10). https://doi.org/10.1111/jfpe.13809

- Ayoub A, Singh J, Sharma S. Physico-chemical analysis of fresh persimmon (Diospyros kaki L) fruit pulp from Jammu Region India. International Journal of Plant and Soil Science. 2022;34(22):1028–1034. https://doi.org/10.9734/IJPSS/2022/v34i2231464

- Choudhary R, Singh A, Upadhyay A, Singh R, Thangalakshmi S, Dar AH, et al. Exotic god fruit, persimmon (Diospyros kaki): Pharmacological importance and human health aspects. eFood. 2023;4(1). https://doi.org/10.1002/efd2.52

- Matheus JRV, de Andrade CJ, Miyahira RF, Fai AEC. Persimmon (Diospyros kaki L.): Chemical properties, bioactive compounds and potential use in the development of new products – A review. Food Reviews International. 2022;38(4):384–401. https://doi.org/10.1080/87559129.2020.1733597

- González CM, Gil R, Moraga G, Salvador A. Natural drying of astringent and non-astringent persimmon “Rojo Brillante”. Drying kinetics and physico-chemical properties. Foods. 2021;10(3). https://doi.org/10.3390/foods10030647

- Qadri T, Naik HR, Hussain SZ, Naseer B, Bhat T, Wani FJ. Spray dried apple powder: Qualitative, rheological, structural characterization and its sorption isotherm. LWT. 2022;165. https://doi.org/10.1016/j.lwt.2022.113694

- Delshadi R, Bahrami A, Tafti AG, Barba FJ, Williams LL. Micro and nano-encapsulation of vegetable and essential oils to develop functional food products with improved nutritional profiles. Trends in Food Science and Technology. 2020;104:72–83. https://doi.org/10.1016/j.tifs.2020.07.004

- Voroshilin RA, Kurbanova MG, Ostapova EV, Makhambetov EM, Petrov AN, Khelef MEA. Effect of gelatin drying methods on its amphiphilicity. Foods and Raw Materials. 2022;10(2):252–261. https://doi.org/10.21603/2308-4057-2022-2-534

- Artyukhova SI, Kozlova OV, Тolstoguzova ТТ. Developing freeze-dried bi-oproducts for the Russian military in the Arctic. Foods and Raw Materials. 2019;7(1):202–209. https://doi.org/10.21603/2308-4057-2019-1-202-209

- Dubkova NZ, Kharkov VV, Vakhitov MR. Using Jerusalem artichoke powder in functional food production. Foods and Raw Materials. 2021;9(1):69–78. https://doi.org/10.21603/2308-4057-2021-1-69-78

- Tan SL, Sulaiman R, Rukayadi Y, Ramli NS. Physicochemical properties of spray-dried cantaloupe powder and rheological behaviour of cake icing. International Food Research Journal. 2022;29(2):385–396. https://doi.org/10.47836/ifrj.29.2.16

- Gawałek J, Domian E. Tapioca dextrin as an alternative carrier in the spray drying of fruit juices – A case study of chokeberry powder. Foods. 2020;9(8). https://doi.org/10.3390/foods9081125

- Tiamiyu QO, Adebayo SE, Yusuf AA. Gum Arabic edible coating and its application in preservation of fresh fruits and vegetables: A review. Food Chemistry Advances. 2023;2. https://doi.org/10.1016/j.focha.2023.100251

- Hu W, Zhang W, Zhang Z, Shen S, Lu G, Wu W. Effect of maltodextrin on the physicochemical properties and cooking performance of sweet potato starch noodles. Foods. 2022;11(24). https://doi.org/10.3390/foods11244082

- Siccama JW, Pegiou E, Zhang L, Mumm R, Hall RD, Boom RM, et al. Maltodextrin improves physical properties and volatile compound retention of spray-dried asparagus concentrate. LWT. 2021;142. https://doi.org/10.1016/j.lwt.2021.111058

- Méndez DA, Fabra MJ, Falcó I, Sánchez G, Aranaz P, Vettorazzi A, et al. Bioactive extracts from persimmon waste: influence of extraction conditions and ripeness. Food and Function. 2021;12(16):7428–7439. https://doi.org/10.1039/D1FO00457C

- Pui LP, Saleena LAK. Effects of spray-drying parameters on physicochemical properties of powdered fruits. Foods and Raw Materials. 2022;10(2):235–251. https://doi.org/10.21603/2308-4057-2022-2-533

- Du J, Ge Z-Z, Xu Z, Zou B, Zhang Y, Li C-M. Comparison of the efficiency of five different drying carriers on the spray drying of persimmon pulp powders. Drying Technology. 2014;32(10):1157–1166. https://doi.org/10.1080/07373937.2014.886259

- Kamtekar AR, Pujari KH, Masal MS, Kambekar PH. Effect of maltodextrin and tricalcium phosphate on quality attributes of jamun juice powder. Bulletin of Environment, Pharmacology and Life Sciences. 2017;6(2):51–55.

- Gopinathan M, Yusof YA, Pui LP. Effects of different drying methods on the physicochemical and antioxidant content of “cempedak” (Artocarpus Integer L.) powder. Journal of Food Processing and Preservation. 2020;44(12). https://doi.org/10.1111/jfpp.14966

- Official Methods of Analysis of the Association of Official Analytical Chemists, 17 th Ed. Association of Official Analytical Chemists; 2005.

- Ramashia SE, Mamadisa FM, Mashau ME. Effect of Parinari curatellifolia peel flour on the nutritional, physical and antioxidant properties of biscuits. Processes. 2021;9(8). https://doi.org/10.3390/pr9081262

- Shuen GW, Yi LY, Ying TS, Yu Von GC, Yusof YAB, Phing PL. Effects of drying methods on the physicochemical properties and antioxidant capacity of Kuini powder. Brazilian Journal of Food Technology. 2021;24. https://doi.org/10.1590/1981-6723.08620

- Loo YY, Pui LP. Storage stability of kuini powder in two packaging aluminum laminated polyethylene and polyethylene terephthalate. Malaysian Journal of Analytical Sciences. 2020;24(5):657–669.

- Šavikin K, Nastić N, Janković T, Bigović D, Miličević B, Vidović S, et al. Effect of type and concentration of carrier material on the encapsulation of pomegranate peel using spray drying method. Foods. 2021;10(9). https://doi.org/10.3390/foods10091968

- Igual M, Cebadera L, Cámara RM, Agudelo C, Martínez-Navarrete N, Cámara M. Novel ingredients based on grapefruit freeze-dried formulations: Nutritional and bioactive value. Foods. 2019;8(10). https://doi.org/10.3390/foods8100506

- Feguš U, Žigon U, Petermann M, Knez Ž. Effect of drying parameters on physiochemical and sensory properties of fruit powders processed by PGSS-, Vacuum- and Spray-drying. Acta Chimica Slovenica. 2015;62(2):479–487. https://doi.org/10.17344/acsi.2014.969

- Hajiaghaei M, Sharifi A. Physicochemical properties of red beetroot and quince fruit extracts instant beverage powder: Effect of drying method and maltodextrin concentration. Journal of Food Quality. 2022;2022. https://doi.org/10.1155/2022/7499994

- Cid-Ortega S, Guerrero-Beltran JA. Lyophilized powder of Hibiscus sabdariffa (Roselle) extracts using Arabic gum and maltodextrin as carrier agents. Journal of Food Research. 2022;11(2):1–15. https://doi.org/10.5539/jfr.v11n2p1

- Ali DY, Sunarharum WB, Dyatmika WP. The effect of filler type and concentration on physicochemical properties and organoleptic of mushroom broth powder. IOP Conference Series: Earth and Environmental Science. 2022;1063. https://doi.org/10.1088/1755-1315/1063/1/012003

- Kurniadi M, Parnanto NHR, Saputri MW, Sari AM, Indrianingsih AW, Herawati ERN, et al. The effect of kappa-carrageenan and gum Arabic on the production of guava-banana fruit leather. Journal of Food Science and Technology. 2022;59(11):4415–4426. https://doi.org/10.1007/s13197-022-05521-1

- Tuan Azlan TNN, Hamzah Y, Mohd Abd Majid HA. Effect of gum Arabic (Acacia senegal) addition on physicochemical properties and sensory acceptability of roselle juice. Food Research. 2020;4(2):449–458.

- Grabowski JA, Truong V-D, Daubert CR. Nutritional and rheological characterization of spray dried sweetpotato powder. LWT – Food Science and Technology. 2008;41(2):206–216. https://doi.org/10.1016/j.lwt.2007.02.019

- Nitteranon V. Effects of wall materials on the physicochemical and antioxidant properties of microwave-assisted encapsulation of Basella rubra fruit extract. Food and Applied Bioscience Journal. 2021;9(2):40–52.

- Suravanichnirachorn W, Haruthaithanasan V, Suwonsichon S, Sukatta U, Maneeboon T, Chantrapornchai W. Effect of carrier type and concentration on the properties, anthocyanins and antioxidant activity of freeze-dried mao [Antidesma bunius (L.) Spreng] powders. Agriculture and Natural Resources. 2018;52(4):354–360. https://doi.org/10.1016/j.anres.2018.09.011

- Wilkowska A, Ambroziak W, Adamiec J, Czyżowska A. Preservation of antioxidant activity and polyphenols in chokeberry juice and wine with the use of microencapsulation. Journal of Food Processing and Preservation. 2017;41(3). https://doi.org/10.1111/jfpp.12924

- Shishir MR, Taip FS, Saifullah M, Yong SY, Aziz NA, Talib RA. Changes in quality attributes of pink guava (Psidium guajava) powder with respect to different drying techniques and maltodextrin concentrations. International Food Research Journal. 2018;25(4):1625–1632.

- Hadree J, Shahidi F, Mohebbi M, Abbaspour M. Evaluation of effects of spray drying conditions on physicochemical properties of pomegranate juice powder enriched with pomegranate peel phenolic compounds: modeling and optimization by RSM. Foods. 2023;12(10). https://doi.org/10.3390/foods12102066

- Adetoro AO, Opara UL, Fawole OA. Effect of carrier agents on the physicochemical and technofunctional properties and antioxidant capacity of freeze-dried pomegranate juice (Punica granatum) powder. Foods. 2020;9(10). https://doi.org/10.3390/foods9101388

- Gawałek J. Effect of spray dryer scale size on the properties of dried beetroot juice. Molecules. 2021;26(21). https://doi.org/10.3390/molecules26216700

- Nthimole CT, Kaseke T, Fawole OA. Micro-encapsulation and characterization of anthocyanin-rich raspberry juice powder for potential applications in the food industry. Processes. 2022;10(5). https://doi.org/10.3390/pr10051038

- Vladić J, Nastić N, Janković T, Šavikin K, Menković N, Lončarević I, et al. Microencapsulation of Sideritis raeseri Boiss. & Heldr. subsp. raeseri extract using spray drying with maltodextrin and whey protein. Periodica Polytechnica Chemical Engineering. 2022;66(2):229–238. https://doi.org/10.3311/PPch.19060

- Jović T, Garofulić IE, Čulina P, Pedisić S, Dobroslavić E, Cegledi E, et al. The effect of spray-drying conditions on the characteristics of powdered Pistacia lentiscus leaf extract. Processes. 2023;11(4). https://doi.org/10.3390/pr11041229

- Featherstone S. Ingredients used in the preparation of canned foods. In: Featherstone S, editors. A complete course in canning and related processes. Volume 2: Microbiology, packaging, HACCP and ingredients. A volume in Woodhead publishing series in food science, technology and nutrition. Woodhead Publishing; 2015. pp. 147–211. https://doi.org/10.1016/B978-0-85709-678-4.00008-7