Аннотация

The research featured two species of buckwheat: Fagopyrum esculentum Moench. and Fagopyrum tataricum (L.) Gaertn.The authors used 10, 20, or 30% of buckwheat flour to substitute soft wheat flour in order to obtain biscuits with improved sensory and nutritional properties.

The biscuits were tested for chemical composition, rheology, color, baking quality, sensory properties, and texture. The sample made of soft wheat flour and F. tataricum contained less protein and fat than the sample with F. esculentum. The samples with F. tataricum demonstrated greater amounts of fiber and ash while the samples made of soft wheat flour were rich in carbohydrates. The additional increment enhanced the arrival time, dough development time, dough stability, the mixing tolerance index, and weakening. Compared to the control, the samples with F. esculentum demonstrated lower peak, trough, breakdown, final, and setback viscosities. F. tataricum, on the contrary, increased the viscosity readings. The biscuits fortified with F. esculentum and F. tataricum contained more protein, fat, ash, and crude fiber the control. The control biscuits also exceeded the total carbohydrates. The experimental biscuits with F. esculentum and F. tataricum were darker in color than the control: the lightness (L*) and redness values (b*) decreased as the proportion of F. esculentum/F. tataricum rose. However, the experimental biscuits had a higher level of yellowness (a*). As the replacement levels rose, F. esculentum and F. tataricum reduced biscuit weight and volume.

According to the research results, 30% F. esculentum and 20% F. tataricum proved able to yield nutritious biscuits with outstanding physical properties. Greater proportions of F. esculentum/F. tataricum resulted in poor sensory ratings for color, taste, flavour, texture, appearance, and overall acceptability.

Ключевые слова

Fagopyrum tataricum, Fagopyrum esculentum, semolina, biscuit, chemical composition, color, baking quality, sensory evaluation, textureВВЕДЕНИЕ

Cereals products constitute an essential part of human diet. They are responsible for carbohydrates, proteins, fats, dietary fiber, B-group vitamins, and minerals. Whole grains are an essential ingredient in many processed foods [1]. In Egypt, biscuits are a popular bakery item consumed by nearly all social groups. They are affordable, nutritious, shelf-stable, and diverse in shape and taste. Bakery products are often fortified with various nutritional ingredients [2–4]. A basic biscuit formulation includes such essential primary ingredients as flour, fats, water, and sugar. Fats provide plasticity and incorporate air during dough formation. They enable the dough to withstand the baking temperatures without losing shape [5].Buckwheat is a so-called pseudocereal that derives from the genus of Fagopyrum. The common buckwheat (Fagopyrum esculentum Moench.) is the most prevalent buckwheat species [6]. Buckwheat is highly adaptable and thrives in various conditions [7]. It contains such flavonoids as quercetin, vitexin, orientin, isovitexin, and isoorientin. The flavonoid content depends on numerous factors, e.g., testa, seed size and shape, flower color, seeding time, soil placement, environment, climate, growth phases, region, etc. [8]. Buckwheat seeds are also abundant in dietary fibre, which has a beneficial physiological effect on the gastrointestinal system and facilitates the metabolism of other nutrients [9]. In addition, buckwheat seeds are gluten-free and suitable for people with celiac disease [10]. Buckwheat flour is a highly nutritional component often used in pasta, noodles, pancakes, bread, biscuits, etc. [11]. The research objective was to develop a new biscuit formulation from different combinations of the common buckwheat (F. esculentum) and the green, or Tatar, buckwheat (Fagopyrum tataricum (L.) Gaertn.), as well as to determine the effect of processing procedures on the chemistry, rheology, color, backing quality, sensory properties, and texture of the finished product.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

This research involved Fagopyrum esculentum Moench. (California) and Fagopyrum tataricum (L.) Gaertn. (Hong Kong) seeds. The samples possessed a state-certified identification label that provided the scientific, local, and English names of the species, as well as some data on germination and purity ratios. The seeds were sowed, planted, and harvested in the city of Belbies (Sharkia governorate, Egypt; coordinates: 30.4196° N, 31.5619° E) and the city of Sadat (Monofiya, Egypt; coordinates: 30.3594° N, 30.5327° E) in 2018– 2019 and 2019–2020 to evaluate the growth and quality of the buckwheat at various growing times. This research involved only hand-picked grains. After initial drying in the field for 3–4 days, they were put in a clean, shaded place for further drying and kernel separation. The soft wheat flour was supplied by South Cairo Mill Company (Giza, Egypt) and accounted for 72% of the total weight. Sugar, eggs, salt (sodium chloride), shortening, baking powder, and vanilla were purchased at a local market (Giza, Egypt).

The list of analytical reagent-grade chemicals and solvents included trichloroacetic acid, thiobarbituric acid, and DPPH (2,2-Diphenyl-1-picryl-hydrazyl). They were obtained from El-Gomhouria Co. for Trading Drugs, Chemicals, and Medical Supplies (Cairo, Egypt).Technological treatment. Preparing the flour mixes. F. esculentum and F. tataricum grains were cleaned, tempered (15% moisture), milled (Quadrumat Junior flour mill), filtered through a 40-mesh screen, and packaged in plastic bags. The blends of soft wheat flour (72% extraction) with F. esculentum and F. tataricum flour had the following ratios: 100:0, 90:10, 80:20, and 70:30 w/w.

Rheology of dough. The farinograph and rapid-viscoanalyzer tests followed the guidelines developed by the American Association of Cereal Chemists to determine the rheological qualities of the samples [12].

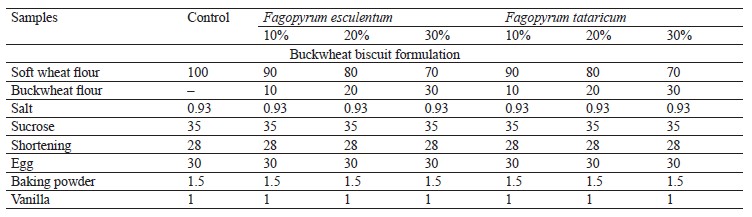

Preparing the biscuits. We mixed 200 g of soft wheat flour with 10, 20 and 30% of F. esculentum or F. tatari- cum. The biscuits were cooked according to the formulation recommended by The Association of Official Analytical Chemists with some modifications (Table 1) [13]. The dry ingredients (flour, sugar, salt, and baking powder) were thoroughly mixed in a bowl by hand for 3 min. Then, egg was added and kneaded in. The dough was rolled and sliced with a five-millimeter biscuit cutter. The biscuits were baked on trays at 200°C for 25 min. After that, they were cooled, packaged in plastic bags, and stored at 28 ± 2°C before the analytical and sensory assessment.

Baking quality. The weight, volume, specific volume, diameter, thickness, and spread ratio were measured in triplicates.

Color attributes. The color of both mixes and biscuits were measured using a Spectro-Colorimeter (Tristimulus Color Machine) with a CIE lab color scale (Hunter, Lab Scan XE, Reston VA.) calibrated using a white Hunter Lab color standard tile (LXNO. 16379): X = 77.26, Y = 81.94, and Z = 88.14. The Hunter-Scotfield’s equation was used to measure the color difference (E) using Hunter a, b, and L scales:

where 0 stood for the control color.

The hue angle and saturation index were calculated in line with the procedure described by Sapers & Douglas [14].

Sensory evaluation. The sensory evaluation relied on the method developed by Hussein et al. [15]. Each formulation was analyzed by twenty panelists. Each panelist gave the product a score between 0 and 20 based on its color, smell, taste, texture, appearance, and general acceptability.

Texture analysis. The biscuit samples underwent a texture analysis using a texturometer (Brookfield, CT3- 10 kg, USA) with a cylinder probe (TA. AACC36). The hardness, stickiness, resilience, cohesion, springiness, gumminess, and chewiness were measured using the method of texture profile analysis, which was programmed for two cycles of measurements to generate a two- bit texture profile curve. The trigger load was 9.00 N g, and the test speed was 2.5 mm/s.

Analytical methods. Chemical composition. The ash, crude fiber, fat, and protein levels were calculated using the standards developed by The Association of Official Analytical Chemists [13]. The carbohydrate content was determined as follows:

Statistical analysis. The obtained results were evaluated statistically using the analysis of variance reported by McClave & Benson [16].

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

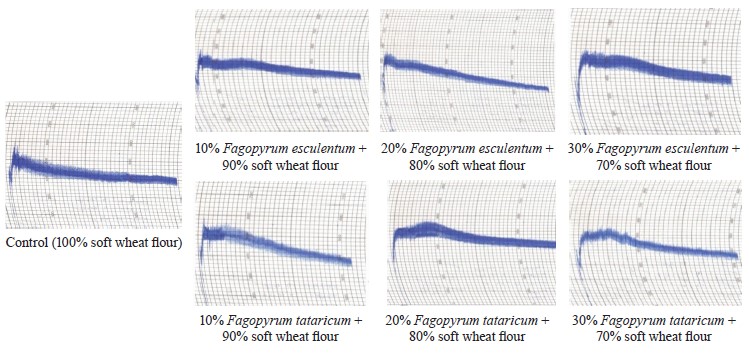

Chemical composition of raw materials. The soft wheat flour, Fagopyrum tataricum (L.) Gaertn., and Fa- gopyrum esculentum Moench. were analyzed for moisture, ash, crude protein, lipid, crude fiber, and carbohydrates. Table 2 displays the acquired values for the chemical composition of soft wheat flour, F. tataricum, and F. esculentum. The soft wheat flour had the most effective moisture content (11.65%), followed by F. esculentum (9.17%) and F. tataricum (8.78%). F. esculentum had higher protein and fat concentrations (14.90 and 2.18%) than soft wheat flour (11.81 and 1.57%) and F. tataricum (11.32 and 1.66%). F. tataricum contained more fiber and ash than F. esculentum (12.51 and and 2.58%) and soft wheat flour (0.79 and 0.81%), respectively (22.08 and 2.85%). Soft wheat flour had a more significant proportion of total carbohydrates than F. tataricum and F. esculentum. The results obtained were consistent with those published elsewhere [17–21].

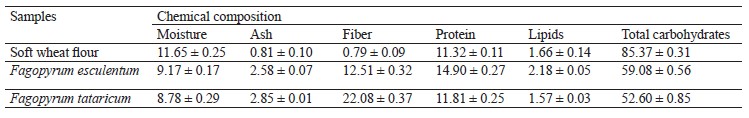

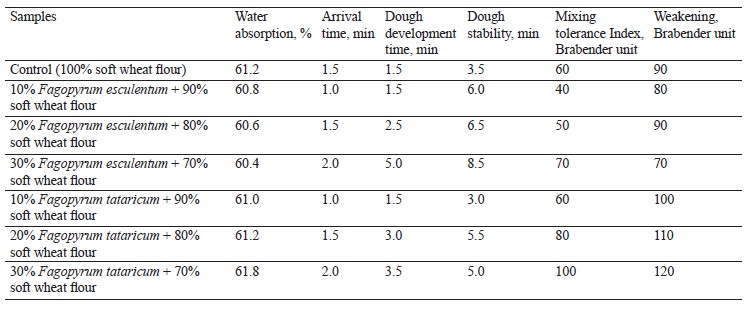

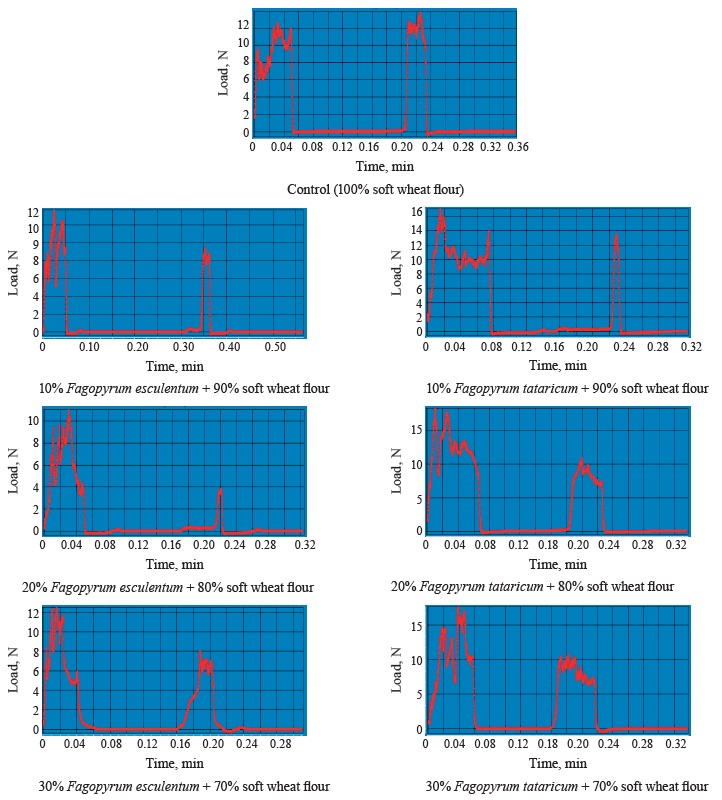

Rheological parameters. Farinograph parameters. Table 3 and Fig. 1 illustrate the effects of 10, 20, and 30% F. esculentum/F. tataricum on the farinograph test parameters. The findings demonstrated the effect of combining F. esculentum/F. tataricum at 10, 20, and 30% with soft wheat flour on such farinograph parameters as water absorption, arrival time, dough development time, dough stability, and dough deterioration. The water absorption value of the soft wheat flour sample was 61.2%. Its combinations with different proportions of F. esculentum/F. tataricum resulted both in a progressive decline and an increase. In tandem with the extra increase, the arrival time, dough development time, dough stability, mixing tolerance index, and weakening went down, compared to the control. The increased dough development time and stability may have been induced by a slower water hydration rate and gluten formation due to the increased fiber content. The higher mixing tolerance and extension value might have resulted from the interactions between gluten and fiber [3]. As gluten diluted in the flour samples, it could not interact with starch, thus resulting in a greater mixing tolerance index [22, 23].

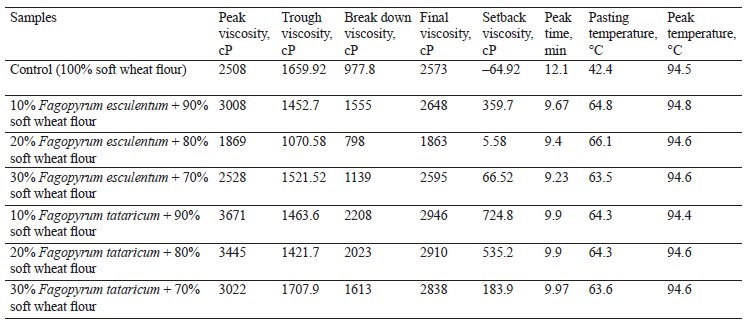

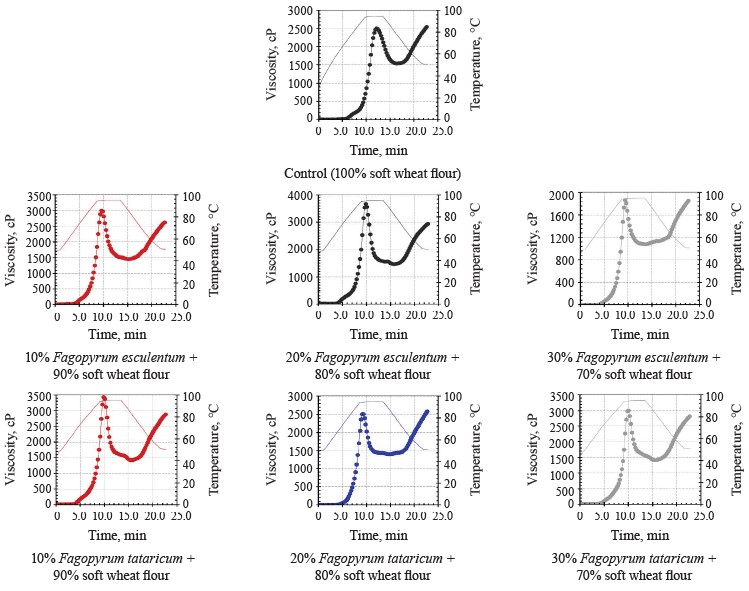

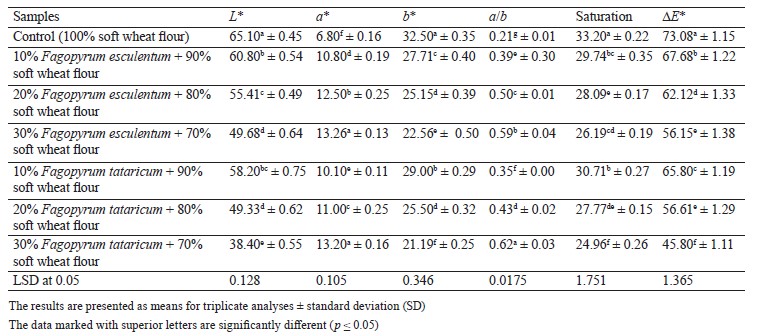

Pasting profile. Table 4 and Fig. 2 demonstrate the pasting properties of the flour mixes. The control sample with soft wheat flour showed the following pasting viscosities: peak viscosity – 2508 сP, trough viscosity – 1659.92 сP, breakdown viscosity – 977.8 сP, final viscosity – 2573 сP, setback viscosity – 64.92 сP. The sample with F. esculentum reduced the peak, trough, breakdown, final, and setback viscosities of soft wheat flour from 2508 to 1869 сP, 1659.92 to 1070.58 сP, 977.8 to 798 сP, and 2573 to 1863 сP, respectively. In contrast, the samples with F. tataricum enhanced all the viscosity parameters: peak viscosity – 3022 сP, trough viscosity – 1707.9 сP, breakdown viscosity – 1613 сP, final viscosity – 2838 сP, setback viscosity – 183.9 сP. The thermal data for both F. esculentum and F. tataricum samples were as follows: peak time – 9.23–9.97 min, pasting temperature – 66.1–63.5°C, peak temperature – 94.6–94.8°C. According to Hallen et al., the degradation of the pasting profile might occur as a result of the fact that less starch is available for gelatinization [24]. Symons & Brennan reported similar findings [25]. They replaced wheat starch with 5% barley b-glucan fiber fractions, and the peak viscosity went down because less starch was available for gelatinization and less water was available for the first swelling of the starch granule. Adebowale et al. linked the pasting temperature with the water-binding capacity [26]. In other studies [24, 27], the pasting profile of flour samples also revealed that flour blends had lower viscosities and pasting temperature. Gluten-free flour proved able to alter the amylose/amylopectin ratios of starches and the gluten content [28, 29].

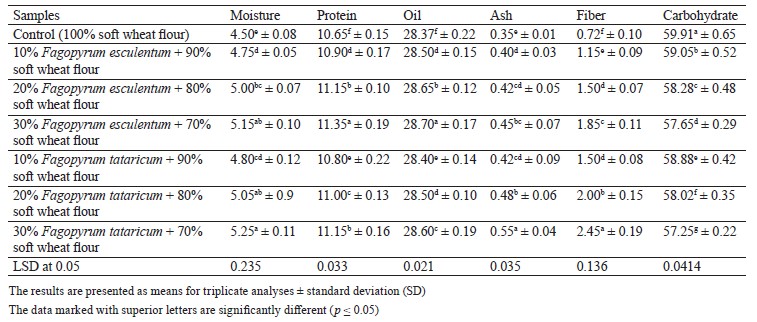

Chemical composition of biscuit samples. This research stage featured the effect of adding 10, 20, and 30% F. esculentum/F. tataricum to soft wheat flour. The biscuits fortified with F. esculentum/F. tataricum contained more protein, fat, ash, and crude fiber than the control sample fortified with soft wheat flour (Table 5). The biscuits with 72% soft wheat flour had more carbohydrates than total carbohydrates. F. esculentum and F. tataricum were rich in iron, copper, and magnesium, which could be responsible for the increased ash concentration [30]. The rise in the moisture content may be attributed to the higher protein content. Mustafa et al. demonstrated that the moisture content of bread rose as the protein level increased [31]. The fat content of the biscuit samples with F. esculentum and F. tataricum was higher than that of the biscuits with soft wheat flour because buckwheat flour tends to retain oil during baking [32–34]. Higher oil retention improves the texture and flavor retention of biscuits. The protein content in the biscuits increased together with the concentration of F. esculentum/F. tataricum, probably, because soft wheat flour was low-protein.

Color parameters. Color is a crucial sensory element that directly affects customer choice for any product, especially bakery items. We analyzed the color properties of the biscuits using a Hunter laboratory colorimeter (Table 6). The Hunter L scale spanned from 0 black to 100 white, whereas Hunter b scale ranged from negative blue to positive yellow. The biscuits with F. esculentum/F. tataricum were darker than the control. The lightness (L*) and redness (b*) values decreased as the percentage of F. esculentum/F. tataricum increased. The yellowness (a*) increased together with the share of F. esculentum/F. tataricum. Both F. esculentum and F. tataricum flours were darker (lower L*) than soft wheat flour. Naturally, the biscuits with F. esculentum/ F. tataricum were darker in color. These results concurred with other publications [35–37]. The Maillard browning and sugar caramelization during baking are believed to cause brown pigments [38]. These browning events depend on several variables, including water activity, pH, temperature, sugars, and the type and proportion of amino compounds [39, 40]. Sugar caramelization and the Maillard processes also cause browning in high-sugar biscuit formulations [41].

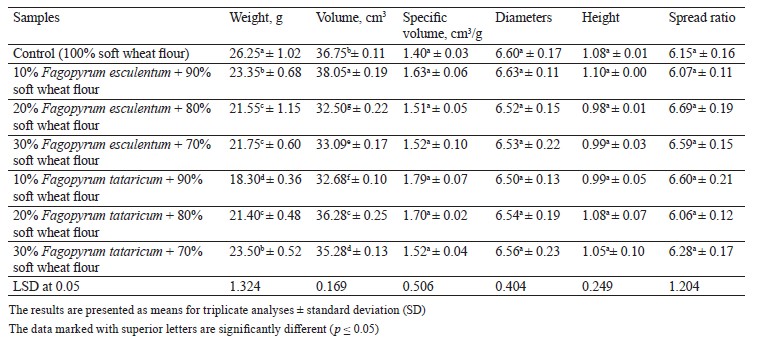

Baking quality. Table 7 describes the following baking parameters of biscuits: weight (g), volume (cm3), specific volume (v/w), diameter (cm), thickness (cm), and spread ratio (%). The diameter of the F. esculentum/F. tataricum biscuits decreased slightly with increasing the substitution percentage compared to control biscuits. The samples with 10% F. esculentum had the biggest diameter (6.63 cm), while the samples with 20% F. esculentum had a small diameter (6.52 cm). However, the height of F. esculentum/F. tataricum biscuits decreased relative to the control sample, except for the sample with 10% F. esculentum. The spread ratio normally corresponds to the diameter-to-height ratio, which serves as a quality indicator. Therefore, premium biscuits should have a high spread ratio [42]. F. esculentum/F. tataricum proved to enhance the spread ratio, although the sample with 20% F. tataricum had the lowest spread ratio value of 6.06 cm. The rise in spread ratio may be due to the dilution of gluten caused by the increased proportion of F. esculentum/F. tataricum in the formulation. The samples with F. esculentum/F. tataricum had a greater protein and dietary fiber content, which reduced the spread ratio because these ingredients have a greater water-binding capacity. As a result, they reduced the amount of water available to dissolve sugars and prevented the biscuits from spreading [43, 44]. As the gluten protein diluted and the fiber and gluten interacted, the extra fiber added to wheat flour together with F. esculentum/F. tataricum had a decisive impact on the devement of gluten networks [43, 45]. F. esculentum/F. tataricum decreased the weight and volume of biscuits as the replacement levels rose. The formulation of biscuits often depends on the quality of the components employed [46]. Thus, the specific volume has a significant effect on the quality of the finished product.

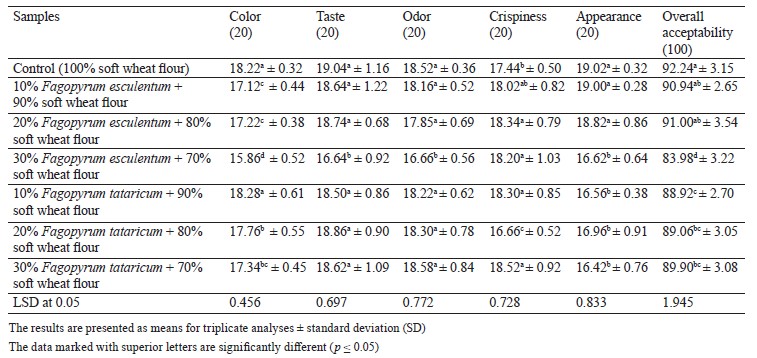

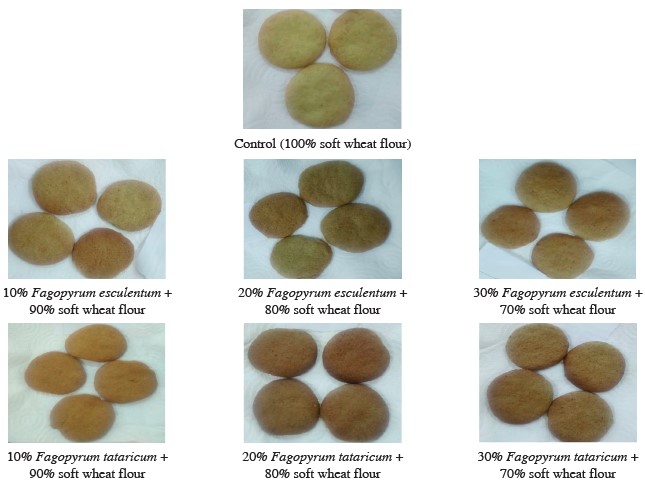

Sensory properties. Sensory properties affect the purchase decision. Sensory evaluation of biscuits usually includes such parameters as color, taste, smell, crispiness, and overall acceptability. Table 8 and Fig. 3 demonstrate the sensory properties of the experimental biscuits. The increasing level of F. esculentum/F. tataricum in the biscuit formulation affected the color of all biscuit samples compared to the control, but there was no significant difference between the color of the biscuit control sample and biscuit with 10% F. tataricum (Table 8). Also, the increasing level of F. esculentum/F. tataricum did not affected significantly on the taste and odor of the biscuit compared to the control sample except 30% F. esculentum. As for crispiness, all tested samples had slight differences. There was no significant difference in the appearance of 10 and 20% F. esculentum compared to the control sample. Also, there was no significant differences between the 30% F. esculentum buiscit and all the samples with F. tataricum, while all they significantly decreased compared to the control sample. The same trend between appearance and overall acceptability was noticed. Also, these results were confirmed by the results of the physical properties of biscuits.

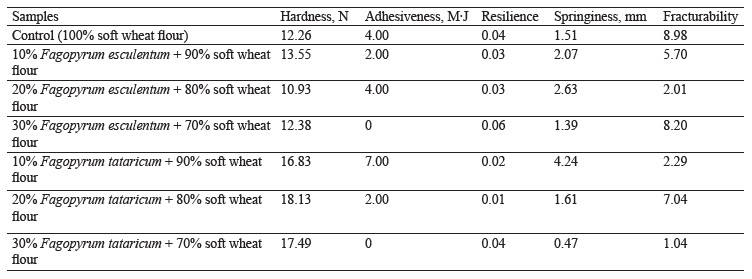

Texture profile analysis. Table 9 and Fig. 4 illustrates the texture values for the biscuit samples. Hardness is known to depend on the compressive strength of biscuits. The instrumental hardness test revealed that hardness increased together with the quantity of F. esculentum/F. tataricum. The immediate increase in hardness was from 12.26 N for the control biscuits to 17.49 N for the samples with 30% F. tataricum. The increase in hardness might have been caused by the increased dietary fiber content with its high water-absorbing capacity. The initial region of negative force produced by the bite quantified the adhesion. In this study, adhesiveness was the negative force area for the first bite. The samples with 20% F. esculentum and 10% F. tataricum demonstrated the maximal adhesiveness values of 4.0 and 7.0 g/cm, respectively.

Springiness reflects the strength of internal links and the degree to which it may be deformed without breaking F. esculentum/F. tataricum enhanced the springiness of the experimental samples compared to control except 30% F. esculentum and 30% F. tataricum. The sample with 10% F. tataricum had the highest springiness (4.24%). These experimental results contradicted those reported in [34, 47].

All the experimental biscuit samples exhibited a slight drop in resilience scores, depending on the F. esculentum/F. tataricum concentrations. Resilience measures the speed and force with which a sample recovers from deformation. In our study, the sample with 30% F. esculentum showed the maximal resilience value of 0.06.

ВЫВОДЫ

Wheat flour biscuits fortified with buckwheat flour had an improved nutritional value. According to the obtained results, the overall acceptability of all the experimental biscuits fell within a suitable range but the biscuits with buckwheat flour up to 20% demonstrated the highest quality. Higher concentrations of Fagopyrum esculentum Moench. or Fagopyrum tataricum (L.) Gaertn. adversely affected the baking quality, color, and texture of the experimental biscuits. However, the samples with 10% F. esculentum or F. tataricum demonstrated no significant changes in the sensory profile. Finally, we can recommend to use 10% buckwheat to improve biscuit quality and alleviate shortages of raw wheat materials.Вклад авторов

The authors were equally involved in the research and are equally responsible for any potential cases of plagiarism.КОНФЛИКТ ИНТЕРЕСОВ

The authors declare that there is no conflict of interests regarding the publication of this article.СПИСОК ЛИТЕРАТУРЫ

- Okarter N, Liu RH. Health benefits of whole grain phytochemicals. Critical Reviews in Food Science and Nutrition. 2010;50(3):193–208. https://doi.org/10.1080/10408390802248734

- Gandhi A-P, Kotwaliwale N, Kawalkar J, Srivastav DC, Parihar VS, Nadh PR. Effect of incorporation of defatted soyflour on the quality of sweet biscuits. Journal of Food Science and Technology. 2001;38(5):502–503.

- Sudha ML, Vetrimani R, Leelavathi K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chemistry. 2007;100(4):1365–1370. https://doi.org/10.1016/j.foodchem.2005.12.013

- Ibrahim GE, Bahgaat WK, Hussein AMS. Egyptian kishk as a fortificant: Impact on the quality of biscuit. Foods and Raw Materials. 2021;9(1):164–173. https://doi.org/10.21603/2308-4057-2021-1-164-173

- Lee H, Yuan C, Hammet A, Mahajan A, Chen ES-W, Wu M-R, et al. Diphosphothreonine-specific interaction between an SQ/TQ cluster and an FHA domain in the Rad53-Dun1 kinase cascade. Molecular Cell. 2008;30(6):767–778. https://doi.org/10.1016/j.molcel.2008.05.013

- Verma KC. Biochemical constituents of buckwheat (Fagopyrum esculentum Moench) collected from different geographical regions of Himachal Pradesh. Molecular Biology Reports. 2018;45:2681–2687. https://doi.org/10.1007/s11033-018-4437-8

- Ahmed A, Khalid N, Ahmad A, Abbasi NA, Latif MSZ, Randhawa MA. Phytochemicals and biofunctional properties of buckwheat: A review. The Journal of Agricultural Science. 2014;152(3):349–369. https://doi.org/10.1017/S0021859613000166

- Rauf M, Yoon H, Lee S, Hyun DY, Lee M-C, Oh S, et al. Evaluation of Fagopyrum esculentum Moench germplasm based on agro-morphological traits and the rutin and quercetin content of seeds under spring cultivation. Genetic Resources and Crop Evolution. 2020;67:1385–1403. https://doi.org/10.1007/s10722-020-00899-3

- Halbrecq B, Romedenne P, Ledent JF. Evolution of flowering, ripening and seed set in buckwheat (Fagopyrum esculentum Moench): Quantitative analysis. European Journal of Agronomy. 2005;23(3):209–224. https://doi.org/10.1016/j.eja.2004.11.006

- Skerritt JH. Molecular comparison of alcohol-soluble wheat and buckwheat proteins. Cereal Chemistry. 1986;63(4):365–369.

- Torbica A, Hadnađev M, Dapčević T. Rheological, textural and sensory properties of gluten-free bread formulations based on rice and buckwheat flour. Food Hydrocolloids. 2010;24(6–7):626–632. https://doi.org/10.1016/j.foodhyd.2010.03.004

- Approved methods of the American association of cereal chemists. AACC; 2000. 1200 p.

- Official methods of analysis. 17th Edition. Gaithersburg: AOAC; 2000.

- Sapers GM, Douglas Jr FW. Measurement of enzymatic browning at cut surfaces and in juice of raw apple and pear fruits. Journal of Food Science. 1987;52(5):1258–1285. https://doi.org/10.1111/j.1365-2621.1987.tb14057.x

- Hussien AMS, Badr AN, Naeem MA. Innovative nutritious biscuits limit aflatoxin contamination. Pakistan Journal of Biological Sciences. 2019;22(3):133–142. https://doi.org/10.3923/pjbs.2019.133.142

- McClave JT, Benson PG, Sincich T. Statistical for business and economics. Prentice Hall; 1998. 1067 p.

- Sindhu R, Khatkar BS. Composition and functional properties of common buckwheat (Fagopyrum esculentum Moench) flour and starch. International Journal of Innovative Research and Advanced Studies. 2016;3(7):154–159.

- Ahmad M, Ahmad F, Dar EA, Bhat RA, Mushtaq T, Shah F. Buck wheat (Fagopyrum esculentum) – A neglected crop of high altitude cold arid regions of ladakh: Biology and nutritive value. International Journal of Pure and Applied Bioscience. 2018;6(1):395–406. https://doi.org/10.18782/2320-7051.6001

- Babu S, Yadav GS, Singh R, Avasthe RK, Das A, Mohapatra KP, et al. Production technology and multifarious uses of buckwheat (Fagopyrum spp.): A review. Indian Journal of Agronomy. 2018;63(4):118–130.

- El-Shenawy M, Hussien AMS, Fouad MT. Production of biscuits from mixture of tiger nut flour, milk permeate and soft wheat flour. Asian Food Science Journal. 2020;18(2):11–21. https://doi.org/10.9734/afsj/2020/v18i230212

- Hussein AS, Bahgaat WK, Ibraheim GE. Impact of Jameed fortification on physicochemical, antioxidant and volatile compounds of snacks. Egyptian Journal of Chemistry. 2022;65(5):1–11.

- Chen H, Rubenthaler GL, Schanus EG. Effect of apple fiber and cellulose on the physical properties of wheat flour. Journal of Food Science. 1988;53(1):304–305. https://doi.org/10.1111/j.1365-2621.1988.tb10242.x

- Ogunsina BS, Radha C, Indrani D. Quality characteristics of bread and cookies enriched with debittered Moringa oleifera seed flour. International Journal of Food Sciences and Nutrition. 2011;62(2):185–194. https://doi.org/10.3109/09637486.2010.526928

- Hallén E, İbanoğlu Ş, Ainsworth P. Effect of fermented/germinated cowpea flour addition on the rheological and baking properties of wheat flour. Journal of Food Engineering. 2004;63(2):177–184. https://doi.org/10.1016/S0260-8774(03)00298-X

- Symons LJ, Brennan CS. The effect of barley β‐glucan fiber fractions on starch gelatinization and pasting characteristics. Journal of Food Science. 2006;69(4):FCT257–FCT261. https://doi.org/10.1111/j.1365-2621.2004.tb06325.x

- Adebowale YA, Adeyemi IA, Oshodi AA. Functional and physicochemical properties of flours of six Mucuna species. African Journal of Biotechnology. 2005;4(12).

- Muralikrishna G, Nirmala M. Cereal α-amylases – An overview. Carbohydrate Polymers. 2005;60(2):163–173. https://doi.org/10.1016/j.carbpol.2004.12.002

- van Hung P, Maeda T, Morita N. Dough and bread qualities of flours with whole waxy wheat flour substitution. Food Research International. 2007;40(2):273–279. https://doi.org/10.1016/j.foodres.2006.10.007

- Renzetti S, Arendt EK. Effect of protease treatment on the baking quality of brown rice bread: From textural and rheological properties to biochemistry and microstructure. Journal of Cereal Science. 2009;50(1):22–28. https://doi.org/10.1016/j.jcs.2009.02.002

- de Francischi MLP, Salgado JM, Leitao RFF. Chemical, nutritional and technological characteristics of buck wheat and non-prolamine buckwheat flours in comparison of wheat flour. Plant Foods for Human Nutrition. 1994;46:323–329. https://doi.org/10.1007/BF01088431

- Mustafa AI, Al-Wessali MS, Al-Basha OM, Al-Amir RH. Utilization of cowpea flour and protein isolate in bakery products. Cereal Foods World. 1986;31(10):756–759.

- Rufeng N, Enqi L, Chuangji C, Jiangping Z. A study of the production of healthy biscuit made with tartary buckwheat grown in North China. Current advances in buckwheat research. 1995:861–865.

- Baljeet SY, Ritika BY, Roshan LY. Studies on functional properties and incorporation of buckwheat flour for biscuit making. International Food Research Journal. 2010;17:1067–1076.

- Kaur M, Sandhu KS, Arora A, Sharma A. Gluten free biscuits prepared from buckwheat flour by incorporation of various gums: Physicochemical and sensory properties. LWT – Food Science and Technology. 2015;62(1):628–632. https://doi.org/10.1016/j.lwt.2014.02.039

- Kim YS, Ha TY, Lee SH, Lee HY. Effect of rice bran dietary fiber on flour rheology and quality of wet noodles. Korean Journal of Food Science and Technology. 1997;29(1):90–95.

- Hussein AMS, Saber MM, Daoud EM, Alshafei MM, Ziada YM, Gamal A, et al. Formulation and evaluation of biscuits from functional flour mixture to enhance of antioxidants reflecting on nutrition in -patients. Egyptian Journal of Chemistry. 2022;65(5):455–466.

- Ramy A, Salama MF, Shouk AA. Pollards a potential source of dietary fiber for pasta manufacture. Egyptian Journal of Food Science. 2002;30(2):313–330.

- Laguna L, Salvador A, Sanz T, Fiszman SM. Performance of a resistant starch rich ingredient in the baking and eating quality of short-dough biscuits. LWT – Food Science and Technology. 2011;44(3):737–746. https://doi.org/10.1016/j.lwt.2010.05.034

- Stojceska V, Ainsworth P, Plunkett A, İbanoğlu Ş. The effect of extrusion cooking using different water feed rates on the quality of ready-to-eat snacks made from food by-products. Food Chemistry. 2009;114(1):226–232. https://doi.org/10.1016/j.foodchem.2008.09.043

- Sharma P, Gujral HS. Extrusion of hulled barley affecting β-glucan and properties of extrudates. Food and Bioprocess Technology. 2013;6:1374–1389. https://doi.org/10.1007/s11947-011-0777-2

- Sharma P, Gujral HS. Cookie making behavior of wheat-barley flour blends and effects on antioxidant properties. LWT – Food Science and Technology. 2014;55(1):301–307. https://doi.org/10.1016/j.lwt.2013.08.019

- Miller RA, Hoseney RC. Factors in hard wheat flour responsible for reduced cookie spread. Cereal Chemistry. 1997;74(3):330–336. https://doi.org/10.1094/CCHEM.1997.74.3.330

- Arshad MU, Anjum FM, Zahoor T. Nutritional assessment of cookies supplemented with defatted wheat germ. Food Chemistry. 2007;102(1):123–128. https://doi.org/10.1016/j.foodchem.2006.04.040

- Ganorkar PM, Jain RK. Effect of flaxseed incorporation on physical, sensorial, textural and chemical attributes of cookies. International Food Research Journal. 2014;21(4):1515–1521.

- Wang N, Hou GG, Kweon M, Lee B. Effects of particle size on the properties of whole-grain soft wheat flour and its cracker baking performance. Journal of Cereal Science. 2016;69:187–193. https://doi.org/10.1016/j.jcs.2016.03.010

- Kuchtová V, Minarovičová L, Kohajdová Z, Karovičová J. Effect of wheat and corn germs addition on the physical properties and crackers sensory quality. Potravinarstvo. 2016;10(1):543–549. https://doi.org/10.5219/598

- Gujral HS, Mehta S, Samra IS, Goyal P. Effect of wheat bran, coarse wheat flour, and rice flour on the instrumental texture of cookies. International Journal of Food Properties. 2003;6(2):329–340. https://doi.org/10.1081/JFP-120017816

- Hunter RS. Scales for the measurements of color difference. In: Hunter RS, editor. The measurement of appearance. New York: Willy; 1975. pp. 133–140.

- Krishnaswamy GG, Parameshwari S. A concise review on buckwheat materials based ready to serve and ready to eat food products. Materials Today: Proceedings. 2022;66:783–788. https://doi.org/10.1016/j.matpr.2022.04.284

- Sofi SA, Ahmed N, Farooq A, Rafiq S, Zargar SM, Kamran F, et al. Nutritional and bioactive characteristics of buckwheat, and its potential for developing gluten‐free products: An updated overview. Food Science and Nutrition. 2022;11(5):2256–2276. https://doi.org/10.1002/fsn3.3166

- Hassona MM, Hussein AS, Morsy N, Abd El-Aal HA. Chemical, rheological, sensorial and functional properties buckwheat semolina flour composite pasta. Egyptian Journal of Chemistry. 2023. https://doi.org/10.21608/ejchem.2023.172021.7137

- Silav-Tuzlu G, Tacer-Caba Z. Influence of chia seed, buckwheat and chestnut flour addition on the overall quality and shelf life of the gluten-free biscuits. Food Technology and Biotechnology. 2021;59(4):463–474. https://doi.org/10.17113/ftb.59.04.21.7204

- Farzana T, Hossain FB, Abedin MdJ, Afrin S, Rahman SS. Nutritional and sensory attributes of biscuits enriched with buckwheat. Journal of Agriculture and Food Research. 2022;10. https://doi.org/10.1016/j.jafr.2022.100394

- Constantino ABT, Garcia‐Rojas EE. Proteins from pseudocereal seeds: Solubility, extraction, and modifications of the physicochemical and techno‐functional properties. Journal of the Science of Food and Agriculture. 2022;102(7):2630–2639. https://doi.org/10.1002/jsfa.11750

- Sofi SA, Ahmed N, Farooq A, Rafiq S, Zargar SM, Kamran F, et al. Nutritional and bioactive characteristics of buckwheat, and its potential for developing gluten‐free products: An updated overview. Food Science and Nutrition. 2022;11(5):2256–2276. https://doi.org/10.1002/fsn3.3166

- di Cairano M, Condelli N, Caruso MC, Cela N, Tolve R, Galgano F. Use of underexploited flours for the reduction of glycaemic index of gluten-free biscuits: Physicochemical and sensory characterization. Food and Bioprocess Technology. 2021;14:1490–1502. https://doi.org/10.1007/s11947-021-02650-x