Аннотация

Recently, there has been an increasing trend in the food and pharmaceutical industries towards using nanotechnological approaches to drug delivery and active packaging (edible coatings and films). In the food sector, nanoemulsions are the most promising technology for delivering active components and improving the barrier, mechanical, and biological properties of packaging to ensure the safety and quality of food products, as well as extend their shelf life.For this review, we used several databases (Google Scholar, Science Direct, PubMed, Web of Science, Scopus, Research Gate, etc.) to collect information about nanoemulsions and their role in edible packaging.

We searched for articles published between 2015 and 2022 and described different scientific approaches to developing active packaging systems based on nanoemulsions, as well as their high-energy and low-energy synthesis methods. We also reviewed the uses of different types of essential oil-based nanoemulsions in the packaging of food products to prolong their shelf life and ensure safety. Non-migratory active packaging and active-release packaging systems were also discussed, as well as their advantages and disadvantages.

Ключевые слова

Nanoemulsions, active packaging, essential oils, synthesis methods, shelf life, edible filmsВВЕДЕНИЕ

In recent years, there has been an increased interest in nanotechnological approaches and their applications in different areas, such as pharmaceuticals, medicine, cosmetics, rheology, polymer synthesis, drug delivery, and food industry. This interest is down to unique physical, chemical, and biological properties of nano-sized particles (with at least one dimension of 1–100 nm) and a large surface-to-volume ratio [1–11]. In the food sector, nanotechnology applications are divided into three key categories: 1) nano-structured foods, which contain nano-encapsulated or tailored nano-sized food additives or components; 2) smart food packaging, which uses nano-composite materials; and 3) materials and devices based on nanotechnologies, such as those used in nanofiltration techniques for water treatment and nanosensors for the detection of food contaminants and food safety [12, 13].

The use of nanotechnology in food applications has received significant interest, and nanoemulsions are one of the most promising techniques for encapsulating and transporting functional components [8, 12, 14]. More particularly, nanoemulsions have diverse uses in the food and pharmaceutical industries in delivering active ingredients such as drugs, micronutrients, bioactive compounds, anti-microbial agents, antioxidants, preservatives, coloring and flavoring compounds, etc. [6, 15–17].

According to the Compound Annual Growth Rate’s report (2022), the nanotechnology market is predicted to grow to USD 33.63 billion from 2021 to 2030, with applications in electronics, energy, chemicals, healthy food, and other sectors around the world [18]. In addition, the food industry demands novel technologies to improve shelf life of food and quality to gain higher consumer acceptability. Ameta et al. reported that the application of nanotechnology would mark a significant transformation in the food sectors, including production, processing, packaging, transportation, and consumption [19]. For example, according to previous studies, more than 40 000 scientists and 400 industries are using nanotechnology for developing food packaging [20, 21].In the food sector, nanoemulsions have a variety of applications. In particular, they can mask unpleasant tastes or smells of bioactive compounds and protect bioactive compounds from evaporation, undesirable chemical interactions with other ingredients, or migration in food products. Nanoemulsions are also used to control drug delivery, extend the stability of bioactive compounds during processing and storage, and enhance the bioavailability of specific food components [22–26]. Most bioactive compounds, such as specific vitamins, antioxidants, and antimicrobial agents, are susceptible to chemical degradation, e.g., through oxidative reactions during food processing. Others are volatile and sensitive to food processing conditions, while certain bioactive compounds have low bioavailability. Due to their poor water solubility and high degradability under external conditions (pH, temperature, or light), these sensitive compounds are difficult to incorporate into food matrices. Therefore, nanoemulsions are used to effectively encapsulate, protect, and release bioactive compounds [27]. In addition, they lower concentrations of each ingredient added to the food systems, thus reducing changes in the food matrix’s sensory qualities [22, 28].

Several types of nanomaterials and nano-scaled components are used to develop food packaging and improve the shelf life of fruits, vegetables, and other food products. They enhance the product’s sensory characteristics and retard microbial growth and oxidation at all stages of production, from processing to packaging, transportation, storage, safety, and quality control [25, 29].

Numerous nanostructured materials, including nanoparticles, nanocomposites, and nanoemulsions, are used in food packaging to extend shelf life [8]. These materials deliver antioxidant, anti-browning, and antimicrobial agents into food packaging systems to protect food products [30–33]. For example, Suvorov et al. described packaging materials coated in a nanofilm with bactericidal and fungicidal characteristics based on silver nanoparticles [34].

In this study, we aimed to collect information about the roles of nanoemulsions in food packaging for food preservation and shelf life extension. We reviewed their properties, types, synthesis methods (high energy, low energy, thermal, isothermal), and their advantages in food packaging. We also described the process of nanoemulsion preparation and different types of nanoemulsion-based food packaging, such as non-migratory active packaging and active release packaging.ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

For this review, we used reputable search engines such as Google Scholar, Science Direct, PubMed, Web of Science, Scopus, and Research Gate. The search was performed using keywords “nanoemulsion”, “active packaging”, “shelf life”, “essential oil”, “nanomaterials”, “synthesis”, “food packaging”, and others. The time frame was 1997 to 2023, with a focus on recent literature (2015–2022). Types of publications included review articles, research papers, book chapters, and official reports collected from reputed journals, books, conference proceedings, and official websites.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

Nanoemulsions. Nanoemulsions are nano-sized emulsions synthesized to enhance the delivery of active ingredients to food, also known as ultrafine emulsions, submicron emulsions, and mini-emulsions [35]. These are colloidal dispersions made up of oils, surfactants, and aqueous phases. They are isotropic, thermodynamically stable systems in which an emulsifying agent, such as a surfactant or a co-surfactant, combines two incompatible liquids into a single phase. Compared to thermodynamically stable microemulsions, nanoemulsions are unaffected by changes in pH or other physical or chemical factors [25, 36]. Nanoemulsions are more stable to droplet aggregation and gravitational separation than conventional emulsions, which can increase the shelf life of foods and beverages and mask the unpleasant smell of the ingredients [37]. Nanoemulsions typically have droplet sizes between 20 and 600 nm, and their transparency is due to their small size. In general, the size and shape of the particles dispersed in the continuous phase is the key difference between emulsions and nanoemulsions [25, 38–40]. As a result, nanoemulsions enhance drug delivery, improve the solubilization of poorly soluble drugs, and boost the therapeutic moiety’s bioavailability. In order to synthesize a microemulsion, a variety of non-ionic surfactants and fatty acids are frequently utilized, and they have been approved as GRAS (generally recognized as safe) [41].

Nanoemulsions are classified into three categories, namely: 1) water-in-oil (W/O), where water is dispersed in the continuous oil phase; 2) oil-in-water (O/W), where oil is dispersed in the continuous aqueous phase; and 3) bi-continuous, where micro domains of water and oil are inter-dispersed within the system [42]. Based on the amount of energy required, there are high-energy and low-energy emulsification methods to obtain nanoemulsions. Ultrasonication and high-pressure homogenization utilizing either microfluidizers or high-pressure homogenizers are examples of high-energy emulsification techniques. Low-energy emulsification techniques include the phase inversion temperature method, the solvent displacement method, and the phase inversion composition method [43–45]. These techniques have gained more interest since they are delicate and non-destructive, and they do not affect encapsulated molecules.

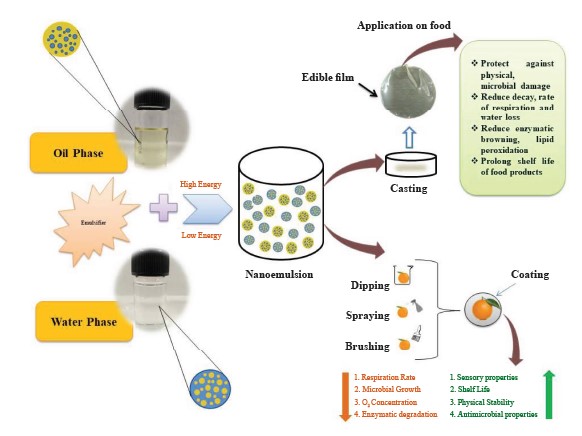

Figure 1 graphically summarizes the process of nanoemulsion synthesis. In the food sector, nanoemulsions are used to deliver nutraceuticals, antimicrobials, drugs, proteins, vitamins, as well as coloring and flavoring ingredients into food products. In addition, nanoemulsion formulations of active components are used for developing biodegradable coatings and packaging films to improve the quality, functional properties, nutritional value, and shelf life of foods [17, 36, 46]. Biodegradable edible films are being developed as an alternative to traditional packaging [47]. They can decompose into substances that are neutral to the environment under the right conditions [48]. Biodegradable packaging materials seem promising due to their safety and capacity to increase the product’s shelf life [49].

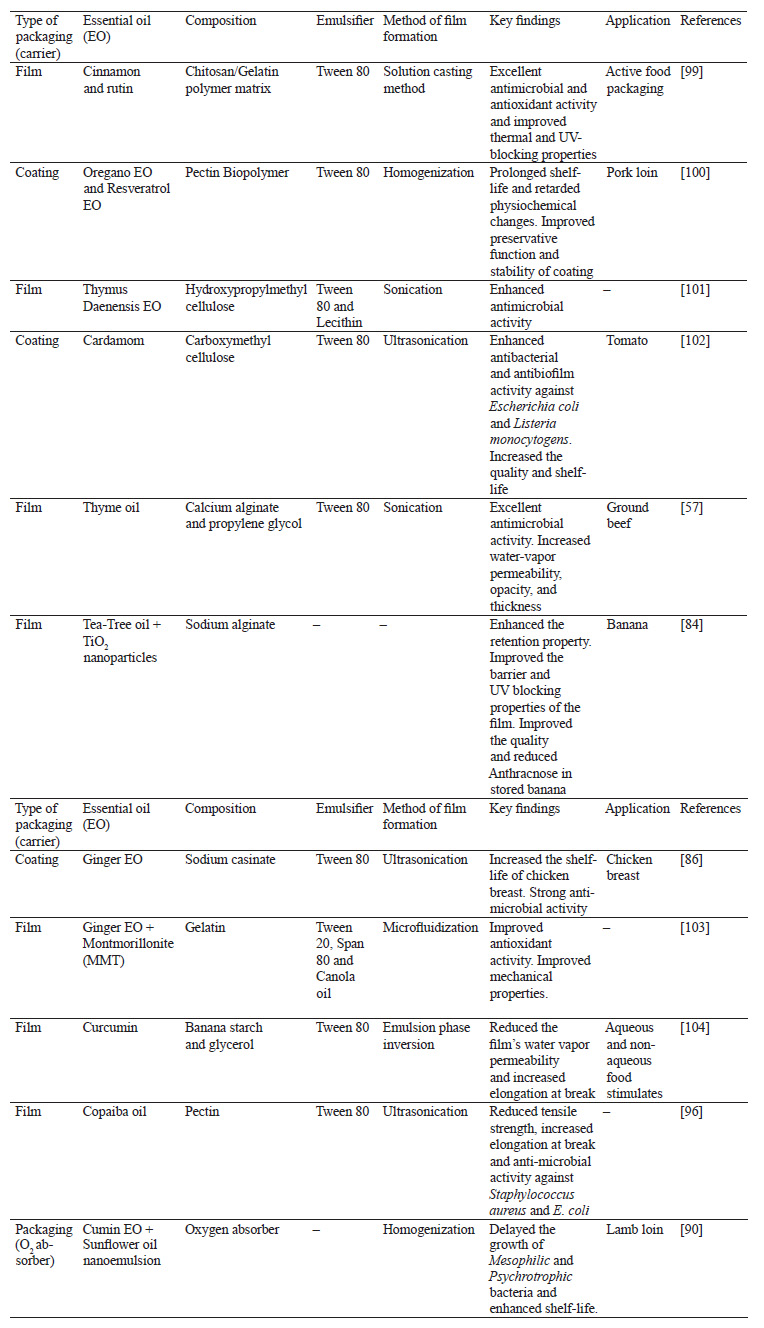

Properties and advantages of nanoemulsions. Foodgrade nanoemulsions can be used in the food packaging systems to improve their morphological, structural, and biological properties by encapsulating active agents, i.e., essential oils, plant extracts, phenolic compounds, antimicrobials, antioxidants, anti-browning agents, preservatives, flavors, coloring agents, nutraceuticals, etc. [27, 50, 51]. Furthermore, nanoemulsions incorporated into packaging may retard microbial growth, reduce color browning, and minimize lipid peroxidation, respiration rate, and water loss. This results in prolonged shelf life of food products such as fruits and vegetables [39, 52–54]. Active agents contained in nanoemulsions are incorporated in films and coatings for food packaging applications. These films and coatings comprised of biopolymer matrixes constitute the continuous phase because they are responsible for the monodispersity and stability of nanoemulsion droplets. The droplet coalescence is inversely proportional to the viscosity of the continuous phase, as the former decreases when the latter increases [22]. In comparison to other materials, biopolymer materials offer a more beneficial feature as a thermal packaging medium [55]. For example, nanoemulsions containing thyme, lemongrass, and sage essential oils were incorporated in a film comprised of sodium alginate [56]. A nanoemulsion containing antimicrobial self-microemulsifying thyme essential oil was used to develop a biopolymer film based on calcium alginate [57]. A chitosan-based film developed by incorporating a nanoemulsion with thyme oil was used as a food packaging material. This film improved packaging properties, retarded the growth of food-borne pathogens, and increased the shelf life of food [58]. Cinnamon and clove essential oils were used to increase the antioxidant and antifungal activities, as well as oxidative stability of nanocapsules containing Citrus reticulate essential oil [59]. An active nanocomposite packaging film was developed by nano-encapsulating the Cinnamodendron dinisii Schwanke essential oil, utilizing zein as a wall material and a chitosan matrix [60]. A gelatin-chitosanbased film was developed by incorporating nanoemulsions loaded with active agents: 1) canola oil; 2) α-tocopherol/cinnamaldehyde; 3) α-tocopherol/ garlic oil; or 4) α-tocopherol/cinnamaldehyde and garlic oil [61].

Synthesis of nanoemulsions. Since nanoemulsions are thermodynamically unstable systems, energy is required to develop them. Depending on the amount of energy required, nanoemulsions can be developed by high-energy or low-energy emulsification methods, as well as by some of the current techniques such as the bubble-bursting method [43, 62–64]. High-energy emulsification methods include ultrasonication and high- pressure homogenization, while low-energy emulsification methods include phase inversion temperature, solvent displacement, and phase inversion composition [35, 44, 65–66].

High-energy emulsification methods. High mechanical energy is used to generate strong disruptive forces that split up large droplets into nano-sized droplets and create nanoemulsions with high kinetic energy. High-energy methods rely on mechanical equipment to produce disruptive forces that generate high energies resulting in small oil droplets. They include high-shear stirring, ultrasonic emulsification, high-pressure homogenization, and, in particular, microfluidics and membrane emulsification [66–68]. The interior phase droplet size frequently exceeds the nanometer range when nanoemulsions are made using these methods. This is because dispersion requires a lot of energy, and there is an insufficient surfactant to completely adsorb all the droplets created during dispersion on the interface. Coalescence, which increases the average droplet size, takes place in this case [35]. Particle size, stability, rheology, and color of the emulsion can be controlled more precisely using these methods with a variety of formulation components. High-energy nanoemulsion formulation techniques for food ingredients have the benefit of lowering the risk of spoilage and inactivation of food components without affecting food safety, nutritional value, or sensory attributes [67]. High-energy methods can be used to create nanoemulsions from any type of oil. However, they are most commonly used for oils with a high molecular weight and high viscosity. This allows for easier surfactant selection and generally requires a smaller amount of the surfactant. However, these methods seem to be inconvenient for drug delivery systems due to heatsensitive ingredients [69].

High-speed stirring. High-speed stirring was found to be a very efficient technique for producing nanoemulsions. The method is rapid, economical, and suitable for mass production. Scholz & Keck created nanoemulsions with droplet sizes of 135 nm and narrow size distributions using this method [70]. The emulsions were physically stable for at least three months. This method produces an emulsion with slightly larger droplet sizes than high-pressure homogenization. Macroemulsions are usually created by high-speed stirring with rotor-stator homogenizers. According to earlier research, rotor-stator systems might create emulsions with mean droplet sizes in the lower micrometer range [71, 72].

Ultrasonication. Nanoemulsions preparation by ultrasonic emulsification is a useful technique for small test samples since it reduces the mean droplet diameter size. Ultrasonication converts electrical waves into pressure waves with a reduced droplet size and increased sonication time, power, and emulsifier concentration [69]. Since this method produces more heat, it is inappropriate for heat-sensitive food components. The primary method of treatment with ultrasound is cavitation, and in liquid foods ultrasonic waves speed up chemical reactions, diffusion, and dissolving processes. Free ions produced by ultrasonic cavitation cause the ultrasonic acceleration of chemical reactions [73]. This method produces high droplet distributions with a particle size range of 150–700 nm, depending on the pre-emulsion preparation method [74]. Two mechanisms are thought to be involved in ultrasonic emulsification. First, when an acoustic field is applied, interfacial waves are created, and these waves eventually become unstable, causing the oil phase to erupt into the aqueous medium as droplets. Second, the use of low-frequency ultrasound induces acoustic cavitation, leading to the production and subsequent dissolution of micro bubbles caused by changes in sound wave pressure. Extreme levels of intensely localized turbulence are produced by each bubble collapse. The primary oil droplets of the dispersed oil are effectively broken up into droplets of a sub-micron size by turbulent micro-implosions [75, 76].

High-pressure homogenization. High-pressure homogenization is one of the high-energy mechanical processing techniques for the formation of oil-in-water nanoemulsions. It is especially well suited for the continuous synthesis of finely dispersed emulsions [77]. When compared to the nanoemulsions synthesized by spontaneous emulsification, the nanoemulsions formed by high-pressure homogenization demonstrated a reduced droplet size and enhanced in vitro release [78, 79]. This method has the advantages of rapid emulsification, a small particle size, homogeneous distribution, a stable system, and a low surfactant amount [72].

Low-energy emulsification methods. Low-energy emulsification methods use the intrinsic chemical energy (or chemical potential of its constituents) of a system for the synthesis of nanoemulsions. These methods use slow stirring (1600 rpm), which leads to lower energy consumption. Low-energy emulsification methods are categorized into two types: isothermal and thermal. For bioactive substances, which are thermally sensitive, isothermal techniques are more appropriate [64, 69]. They include phase inversion temperature, solvent displacement, phase inversion composition, spontaneous emulsification, micro-emulsion dilution, and more recently developed techniques such as D-phase emulsification [43, 44, 69].

Isothermal methods. Low-energy isothermal processes do not require temperature change or a specific homogenizer to develop small droplets. Isothermal methods have numerous benefits. They are used to prepare nanoemulsions over a wide temperature range, without the need for temperature quenching after preparation, which may result in significant energy savings. Also, they allow for the encapsulation of heat-sensitive compounds [80].

Spontaneous emulsification. Numerous physicochemical processes can lead to this method: real spontaneous emulsification occurs when two immiscible liquids come into contact and emulsify on their own without the use of heat or mechanical forces. When surfactants are present or absent, solvents might be used to speed up the process [80].

Emulsion phase inversion. In emulsion phase inversion, an aqueous phase is added to a stirring organic phase. Since this method also involves mixing water with oil, it is sometimes referred to as “catastrophic phase inversion”. The emulsion phase inversion method is quite similar to the later steps of spontaneous emulsification, which include breaking down a microemulsion into tiny oil droplets. This process is also known as “phase inversion composition” [80].

Thermal methods. Phase inversion. Phase inversion makes use of the chemical energy liberated by phase changes that occur during emulsification. Transitions from structures with a surfactant film with an average zero curvature play a key role in the formation of nanoemulsions, even though these phase transitions frequently require the inversion of the surfactant film curvature from positive to negative or vice versa. There are two methods for inducing phase transitions: phase inversion temperature and phase inversion composition. The former induces phase transition by changes in temperature, while the latter induces phase transition by changes in composition [38].

Nanoemulsion-based food packaging materials. The four primary functions of packaging are restraint, convenience, communication, and protection. Among all, protection is the key function since packaging protects food from compressive pressures, vibration, shock, dust, microbial contamination, undesirable odors, gases, water vapor, and moisture [54]. The growth of foodborne pathogens is among the most common causes of a limited shelf life. Motivated by increased consumer interest in longer shelf life and easy food handling, researchers are developing improved food packaging such as active or intelligent packaging. The term “active packaging” refers to a system in which the packaging has been modified to preserve, protect, or enhance the food’s sensory attributes, safety, and quality [81, 82]. Active packaging has become a popular way to extend the shelf life of food products, reduce product losses, and guarantee customer safety.

Active packaging can be divided into two types: non-migratory active packaging and active-release packaging. Non-migratory packaging mainly refers to scavengers or absorbers such as oxygen scavengers, moisture scavengers, and ethylene absorbers. In contrast, active-release packaging systems include carbon dioxide emitters, antimicrobial packaging, and antioxidant packaging. The use of nanoemulsions is a recent technique for providing food packaging materials with antimicrobial, antioxidant, anticancer, antiin-flammatory, and antiviral activities, as well as UV blocking, water vapor, and oxygen barrier properties [83–87].

Nanoemulsions can be integrated or incorporated into films and coatings in order to potentially be used in food packaging. Nanoemulsions containing bioactive compounds can be used to develop biodegradable films and coatings to enhance the quality, functionality, shelf life, and nutritional content. Biopolymer matrix-based films and coatings comprise the continuous phase because they provide mono dispersity and stability to nanoemulsions droplets [36].

Nanoemulsions in non-migratory active packaging. Non-migratory active packaging refers primarily to absorbers and scavengers that are meant to eliminate or absorb undesirable gaseous elements from atmosphere inside the food package without intentional migration. Also, they provide a regulated influx of desired compounds into the packing environment, which favorably affects the food product by extending its shelf life. Active ingredients are incorporated into gasabsorbent packaging materials that can react with or absorb inside gases. Of all gas scavenging technologies, the oxygen-scavenging packaging system has been the subject of most research and application [81]. This system extends the shelf life of foods while preserving their nutritional value and preventing discoloration, rancidity, oxidative browning, microbiological spoilage, and organoleptic deterioration, thus ensuring food safety [88].

Curcumin nanoemulsions were developed by high-pressure homogenization with varied surfactant (Tween 20) concentrations, and they were subsequently incorporated into the commercial milk system. Curcumin nanoemulsions exhibited efficient oxygen scavenging activity. Milk fortified with curcumin nanoemulsions showed considerably less lipid oxidation in comparison to unfortified milk, so these nanoemulsions are suitable for the beverage industry [89].Hasani-Javanmardi et al. developed an oxygen absorber packaging incorporated with a nanoemulsion containing cumin and safflower essential oils and studied its effect on the quality of lamb loins throughout a 20-day chilled storage period [90]. The treatments were performed in three stages: single, binary, and ternary. They delayed the growth of mesophilic and psychrotrophic bacteria, Enterobacteriaceae, and lactic acid bacteria. Also, they retarded the physicochemical and sensory changes, but increased the rate of metmyoglobin production, total volatile nitrogen, lipid and protein oxidation, as well as sensory and color degradation. In another study, a food-grade vitamin E acetate nanoemulsion was developed using edible mustard oil and Tween 80. The nanoemulsion exhibited high bioactivity, as well as antioxidant and antibacterial effect, indicating that it may be used to extend the shelf life of fruit juice. The presence of vitamin E acetate was thought to account for antioxidant activity. As a result, it could scavenge reactive oxygen species produced in the body when lipids were oxidized, which could harm cells [91].

Palladium nanoparticles were developed with multilayered poly (3-hydroxybutyrate) and polycaprolactone polymers, very effective oxygen scavengers, by using the electrospinning method. The resulting nanocomposites offered high oxygen-scavenging activity [92]. Ethylene scavengers are also needed in order to prolong the shelf life of fruits and vegetables. Ethylene is a well-known plant growth hormone that stimulates fruit ripening but can also cause over-ripening and even deterioration, giving fruits a restricted shelf life. Therefore, to reduce fruit waste, an ethylene scavenger can be created that is highly effective, safe, and sustainable and does not alter the physicochemical or physiological properties of the fruit.

Bio-based ethylene scavenger films were produced using paper towel microfibers coated with Zein – Artemisia sphaerocephala Krasch. Gum (ASKG) nanoparticles with core-shell structures were developed via electrospraying, and bananas coated with these films showed reduced browning, increased firmness, and extended shelf life [93]. Novel nanocomposites based on polyolefin elastomer were developed, including nano-silica and nano clay impregnated with KMnO4. In comparison to neat polyolefin films, the resulting nanocomposites showed improved mechanical characteristics, a higher ethylene absorption, and a reduced water vapor permeability. Furthermore, the enhanced nanocomposite coatings could improve the shelf life of bananas by up to 15 days under ambient conditions [94]. The application of nanoemulsion coatings on apricot fruit had a significant impact on its quality characteristics. The nanoemulsion suppressed ascorbic acid and carotenoid contents, as well as decay rate, weight loss, and antioxidant activity. Similarly, it helped reduce the overall number of psychrophilic bacteria, yeast, and mold [95].

Nanoemulsions in active-release packaging. Activerelease packaging systems release the required gases into the package environment to preserve product quality and freshness and lengthen shelf life. They are highly demanded to ensure food quality and safety. Active ingredients, such as antioxidants and antimicrobials, are incorporated into the packaging systems rather than added to the food itself so that the migration of these compounds can enrich the product.

There has been a great deal of interest in the systems’ antimicrobial and antioxidant activities, as well as their water vapor and oxygen barrier properties. For example, a neem oil nanoemulsion in a pectin matrix exhibited enhanced mechanical attributes, diminished stiffness and water vapor permeability, increased extensibility, and showed excellent antifungal activity against Aspergillus flavus and Penicillium citrinum [97].

A clove essential oil nanoemulsion was incorporated into a chitosan coating to preserve fresh Tremella fuciformis. The coating exhibited high antibacterial activity against Burkholderia gladioli and increased the shelf-life of T. fuciformis to 9 days [97]. A bilayer film was developed based on a sodium alginate/tea tree essential oil nanoemulsion and containing TiO2 nanoparticles to improve the postharvest losses of banana fruit and reduce the fungal disease (anthracnose). The addition of a specific amount of TiO2 to sodium alginate significantly improved the film’s UV blocking, water vapor, and oxygen barrier properties [84]. A bionanocomposite was developed in which different concentrations of a pracaxi oil nanoemulsion were incorporated into a xylitol pectin matrix. This bionanocomposite efficiently improved the shelf life and stability of butter against the oxidation process [85]. Clove- and cinnamon-based nanoemulsions were created via ultrasonication with varying concentrations of soy lecithin as a surfactant. The resulting nanoemulsions exhibited antioxidant activity, and the coated muffins maintained their texture and had lower weight loss, density, and moisture content. Additionally, the nanoemulsion-based coating helped extend the shelf life of the ingredients by up to 6 days without any quality loss, which made them more useful as functional components [98]. In another study, films were developed with gelatin-chitosan (4:1) that included nanoemulsions loaded with various active substances, such as canola oil, tocopherol/cinnamaldehyde, tocopherol/garlic oil, tocopherol/cinnamaldehyde, and garlic oil. The nanoemulsions were synthesized in a microfluidizer using the casting method with biopolymers and glycerol as a plasticizer. The films loaded with nanoencapsulated active compounds showed strong antioxidant activity and were particularly effective against Pseudomonas aeruginosa. These active films could be used as packaging materials to extend the shelf life of foods [61].

Advantages and disadvantages of nanoemulsions in packaging. Researchers in the fields of food science, food technology, and food microbiology are all concerned about food safety due to the amount of food that is wasted after its shelf life has expired [105]. Food scientists have been fascinated by the development of more efficient nanotechnology-based methods in food packaging, along with significant progress in biotechnology in a broad range of industries, including cosmetic, agricultural, and pharmaceutical fields [54]. Many approaches can improve food packaging systems and reduce waste. For example, the use of essential oils can remove the limitations of conventional food packaging while lowering environmental risks [106, 107]. With the substantial growth of nanotechnology, there is an increasing interest in the use of nanoemulsion-based packaging systems for the real-time monitoring of food products [108]. They provide opportunities to streamline targeted compound distribution to large surface areas to improve stability, biodegradability, anti-oxidation, and antimicrobial qualities. There is a variety of methods for producing nanoemulsions.In recent years, nanoemulsions have helped in food preservation, as well as in the development of stable, conventional food packaging systems. In addition, some edible coatings based on nanoemulsions containing essential oils have been created for food preservation. For example, a coating for strawberries was incorporated with a nanoemulsion based on pullulan and cinnamon essential. This coating retarded senescence and inhibited the decay of strawberry fruits during storage more efficiently than the control and pure pullulan coatings [105]. Strawberry cartilage and grey mold rot were controlled using a nanoemulsion made of cinnamon essential oil, which had antifungal properties. This nanoemulsion can replace chemical fungicides to minimize strawberry fruit post-harvest lesions [109].

Edible coatings provide food products with a glossy finished surface but one of their major advantages is that they are environmentally safe and, therefore, can replace plastic packaging to reduce waste and protect the environment. Natural coatings provide similar protection against oxygen, light, bacteria, and moisture as modified-environment packaging does by extending the shelf life of food products [110]. Recently developed active edible coatings are used to encapsulate active compounds in the form of nanoemulsions that play an important role in increasing the functionality of edible packaging [111]. Nanoemulsions mixed with ground meat or fish products help uniformly distribute bioactive compounds throughout the product, while dipping or coating with nanoemulsions helps in preventing spoilage [105, 112].

Nanoemulsions that contain active components, such as antimicrobial agents and antioxidants, are incorporated into packaging films and coatings. The major application of these packaging systems is to protect the food against microbes, oxidation, denaturation, and changes in pH. However, they can also help control the release of active ingredients into the food. Active agents are incorporated into the packaging systems instead of being added directly to food. However, when added in a non-encapsulated form, these bioactive substances have an adverse effect on the optical and transparency properties of the films. Several disadvantages can also be seen throughout the film’s development such as weak miscibility, phase separation, and the chemical or thermal degradation of bioactive compounds [113]. Moreover, the synthesis of nanoemulsions requires high-tech, expensive equipment, which may raise the total cost of the packaging system. High concentrations of emulsifiers used to develop nanoemulsions can prove to be highly toxic, inflicting serious harm to the human body, if consumed, and to the environment, if discarded.

Unless the most stable emulsifying conditions are used to develop nanoemulsions, instability in the form of flocculation or coalescence often occurs during storage. Nanoemulsions that are stored for a long time may become unstable, and their stability may also be affected by changes in pH and temperature [114]. Some processes reduce the interfacial area that occurs in them over time. The following processes lead to emulsion breakdown: 1) flocculation, which is the sticking together of dispersed phase droplets; 2) coalescence, which is the fusion of droplets; 3) sedimentation (creaming), which is the directed motion of particles (downward or upward); and 4) Ostwald ripening, also known as isothermal distillation, which is the transfer of material from smaller to larger droplets due to the difference in drop curvature radii [115, 116].

ВЫВОДЫ

Nanoemulsions as a nanotechnological approach are gaining more attention due to their applications in the pharmaceutical, cosmetic, and food sectors to improve the stability of carrier agents. Their application in packaging systems is promising in terms of improving the packaging’s physical, mechanical, barrier, and other functional properties, as well as extending the shelf life of fruits, vegetables, and other food categories. Furthermore, high-energy emulsification methods for preparing nanoemulsions, such as high-pressure homogenizers, ultrasonication, and others, are preferred to low-energy emulsification methods. The high-pressure homogenizer method has the best potential for improving the stability of nanoemulsions by reducing the particle size. In addition, different types of essential oils used as active components in nanoemulsion-based coatings and films improve their antimicrobial and antioxidant properties. They also help reduce post-harvest losses of fruits and vegetables by retarding their water and gas transpiration throughout the storage period. However, further research is needed to investigate the effects that essential oils may have on the stability of nanoemulsions and the retention of their volatile compounds on the surface of fruits and vegetables.

Вклад авторов

Jaishankar Prasad: Conceptualization, methodology, investigation, resources, and writing (original draft, review, and editing). Aishwarya Dixit: Writing (original draft, review, and editing). Sujata Pandit Sharma: Supervision and writing (review and editing). Anjelina William Mwakosya: Writing (review and editing). Anka Trajkovska Petkoska: Writing (review and editing). Ashutosh Upadhyay: Writing (review and editing). Nishant Kumar: Conceptualization, methodology, formal analysis, visualization, and writing (original draft, review, and editing).

КОНФЛИКТ ИНТЕРЕСОВ

The authors declare no conflict of interest.

БЛАГОДАРНОСТИ

The authors are grateful to their institutions for providing facility and infrastructural support.

СПИСОК ЛИТЕРАТУРЫ

- Wang L, Dong J, Chen J, Eastoe J, Li X. Design and optimization of a new self-nanoemulsifying drug delivery system. Journal of Colloid and Interface Science. 2009;330(2):443–448. https://doi.org/10.1016/j.jcis.2008.10.077

- Wu X, Guy RH. Applications of nanoparticles in topical drug delivery and in cosmetics. Journal of Drug Delivery Science and Technology. 2009;19(6):371–384. https://doi.org/10.1016/s1773-2247(09)50080-9

- Shah P, Bhalodia D, Shelat P. Nanoemulsion: A pharmaceutical review. Systematic Reviews in Pharmacy. 2010;1(1):24–32. https://doi.org/10.4103/0975-8453.59509

- Cheng CJ, Tietjen GT, Saucier-Sawyer JK, Saltzman WM. A holistic approach to targeting disease with polymeric nanoparticles. Nature Reviews Drug Discovery. 2015;14(4):239–247. https://doi.org/10.1038/nrd4503

- Singh Y, Meher JG, Raval K, Khan FA, Chaurasia M, Jain NK, et al. Nanoemulsion: Concepts, development and applications in drug delivery. Journal of Controlled Release. 2017;252:28–49. https://doi.org/10.1016/j.jconrel.2017.03.008

- Salem MA, Ezzat SM. Nanoemulsions in food industry. In: Milani J, editor. Some new aspects of colloidal systems in foods. IntechOpen; 2019. https://doi.org/10.5772/intechopen.79447

- Fytianos G, Rahdar A, Kyzas GZ. Nanomaterials in cosmetics: Recent updates. Nanomaterials. 2020;10(5). https://doi.org/10.3390/nano10050979

- Nile SH, Baskar V, Selvaraj D, Nile A, Xiao J, Kai G. Nanotechnologies in food science: Applications, recent trends, and future perspectives. Nano-Micro Letters. 2020;12(1). https://doi.org/10.1007/s40820-020-0383-9

- Rolland M, Truong NP, Parkatzidis K, Pilkington EH, Torzynski AL, Style RW, et al. Shape-controlled nanoparticles from a low-energy nanoemulsion. JACS Au. 2021;1(11):1975–1986. https://doi.org/10.1021/jacsau.1c00321

- Mohammadi Z, Jafari SM. Detection of food spoilage and adulteration by novel nanomaterial-based sensors. Advances in Colloid and Interface Science. 2020;286. https://doi.org/10.1016/j.cis.2020.102297

- Zhang Z, Qiu C, Li X, McClements DJ, Jiao A, Wang J, et al. Advances in research on interactions between polyphenols and biology-based nano-delivery systems and their applications in improving the bioavailability of polyphenols. Trends in Food Science and Technology. 2021;116:492–500. https://doi.org/10.1016/j.tifs.2021.08.009

- Yalçınöz Ş, Erçelebi E. Potential applications of nano-emulsions in the food systems: An update. Materials Research Express. 2018;5(6). https://doi.org/10.1088/2053-1591/aac7ee

- Huang J-Y, Li X, Zhou W. Safety assessment of nanocomposite for food packaging application. Trends in Food Science and Technology. 2015;45(2):187–199. https://doi.org/10.1016/j.tifs.2015.07.002

- Liu K, Chen Y-Y, Pan L-H, Li Q-M, Luo J-P, Zha X-Q. Co-encapsulation systems for delivery of bioactive ingredients. Food Research International. 2022;155. https://doi.org/10.1016/j.foodres.2022.111073

- Goindi S, Kaur A, Kaur R, Kalra A, Chauhan P. Nanoemulsions: an emerging technology in the food industry. In: Grumezescu AM, editor. Emulsions. Nanotechnology in the agri-food industry, volume 3. A volume in nanotechnology in the agri-food industry. Academic Press; 2016. pp. 651–688. https://doi.org/10.1016/b978-0-12-804306-6.00019-2

- Abbasian Chaleshtari Z, Zhou M, Foudazi R. Nanoemulsion polymerization and templating: Potentials and perspectives. Journal of Applied Physics. 2022;131(15). https://doi.org/10.1063/5.0081303

- Tan C, Zhu Y, Ahari H, Jafari SM, Sun B, Wang J. Sonochemistry: An emerging approach to fabricate biopolymer cross-linked emulsions for the delivery of bioactive compounds. Advances in Colloid and Interface Science. 2022;311. https://doi.org/10.1016/j.cis.2022.102825

- Nanotechnology for Food Packaging Market: Segmented By Application; By Technology and Region – Global Analysis of Market Size, Share & Trends for 2019–2020 and Forecasts to 2030 CAGR 2022 [Internet]. [cited 2022 Dec 20]. Available from: https://reports.valuates.com/request/sample/ALLI-Manu-S71/Nanotechnology_Market

- Ameta SK, Rai AK, Hiran D, Ameta R, Ameta SC. Use of nanomaterials in food science. In: Ghorbanpour M, Bhargava P, Varma A, Choudhary DK, editors. Biogenic nano-particles and their use in agro-ecosystems. Singapore: Springer Nature; 2020. pp. 457–488. https://doi.org/10.1007/978-981-15-2985-6_24

- Neethirajan S, Jayas DS. Nanotechnology for the food and bioprocessing industries. Food and Bioprocess Technology. 2011;4(1):39–47. https://doi.org/10.1007/s11947-010-0328-2

- Cerqueira MÂPR, McClements DJ, Pastrana-Castro LM. Nutrition, health and well-being in the world: The role of food structure design. In: Cerqueira MÂPR, Pastrana-Castro LM, edutors. Food structure engineering and design for improved nutrition, health and well-being. Academic Press; 2023. pp. 3–15. https://doi.org/10.1016/B978-0-323-85513-6.00015-3

- Artiga-Artigas M, Acevedo-Fani A, Martín-Belloso O. Effect of sodium alginate incorporation procedure on the physicochemical properties of nanoemulsions. Food Hydrocolloids. 2017;70:191–200. https://doi.org/10.1016/j.foodhyd.2017.04.006

- Azmi NAN, Elgharbawy AAM, Motlagh SR, Samsudin N, Salleh HM. Nanoemulsions: Factory for food, pharmaceutical and cosmetics. Processes. 2019;7(9). https://doi.org/10.3390/pr7090617

- Nedovic V, Kalusevic A, Manojlovic V, Levic S, Bugarski B. An overview of encapsulation technologies for food applications. Procedia Food Science. 2011;1:1806–1815. https://doi.org/10.1016/j.profoo.2011.09.265

- McClements DJ. Advances in edible nanoemulsions: Digestion, bioavailability, and potential toxicity. Progress in Lipid Research. 2021;81. https://doi.org/10.1016/j.plipres.2020.101081

- Reis DR, Ambrosi A, Luccio MD. Encapsulated essential oils: A perspective in food preservation. Future Foods. 2022;5. https://doi.org/10.1016/j.fufo.2022.100126

- McClements DJ, Decker EA, Weiss J. Emulsion-based delivery systems for lipophilic bioactive components. Journal of Food Science. 2007;72(8):R109–R124. https://doi.org/10.1111/j.1750-3841.2007.00507.x

- McClements DJ. Edible nanoemulsions: fabrication, properties, and functional performance. Soft Matter. 2011;7(6):2297–2316. https://doi.org/10.1039/c0sm00549e

- Nanotechnology in the food industry: a short review [Internet]. [cited 2022 Dec 20]. Available from: https://www.food-safety.com/articles/5193-nanotechnology-in-the-food-industry-a-short-review

- Cha DS, Chinnan MS. Biopolymer-based antimicrobial packaging: A review. Critical Reviews in Food Science and Nutrition. 2004;44(4):223–237. https://doi.org/10.1080/10408690490464276

- Weiss J, Takhistov P, McClements DJ. Functional materials in food nanotechnology. Journal of Food Science. 2006;71(9):R107–R116. https://doi.org/10.1111/j.1750-3841.2006.00195.x

- Sharma N, Kaur G, Khatkar SK. Optimization of emulsification conditions for designing ultrasound assisted curcumin loaded nanoemulsion: Characterization, antioxidant assay and release kinetics. LWT. 2021;141. https://doi.org/10.1016/j.lwt.2021.110962

- Jiang T, Charcosset C. Encapsulation of curcumin within oil-in-water emulsions prepared by premix membrane emulsification: Impact of droplet size and carrier oil on the chemical stability of curcumin. Food Research International. 2022;157. https://doi.org/10.1016/j.foodres.2022.111475

- Suvorov ОA, Volozhaninova SYu, Balandin GV, Frolova YuV, Kozlovskaya AE, Fokina EN, et al. Antibacterial effect of colloidal solutions of silver nanoparticles on microorganisms of cereal crops. Foods and Raw Materials. 2017;5(1):100–107. https://doi.org/10.21179/2308-4057-2017-1-100-107

- Koroleva MYu, Yurtov EV. Nanoemulsions: the properties, methods of preparation and promising applications. Russian Chemical Reviews. 2012;81(1):21–43. https://doi.org/10.1070/rc2012v081n01abeh004219

- Aswathanarayan JB, Vittal RR. Nanoemulsions and their potential applications in food industry. Frontiers in Sustainable Food Systems. 2019;3. https://doi.org/10.3389/fsufs.2019.00095

- Choi SJ, McClements DJ. Nanoemulsions as delivery systems for lipophilic nutraceuticals: Strategies for improving their formulation, stability, functionality and bioavailability. Food Science and Biotechnology. 2020;29(2):149–168. https://doi.org/10.1007/s10068-019-00731-4

- Solans C, Izquierdo P, Nolla J, Azemar N, Garcia-Celma MJ. Nano-emulsions. Current Opinion in Colloid and Interface Science. 2005;10(3–4):102–110. https://doi.org/10.1016/j.cocis.2005.06.004

- Jaiswal M, Dudhe R, Sharma PK. Nanoemulsion: an advanced mode of drug delivery system. 3 Biotech. 2014;5(2):123–127. https://doi.org/10.1007/s13205-014-0214-0

- Patel RB, Patel MR, Thakore SD, Patel BG. Nanoemulsion as a valuable nanostructure platform for pharmaceutical drug delivery. In: Grumezescu AM, editor. Nano- and microscale drug delivery systems. Design and fabrication. Elsevier; 2017. pp. 321–341. https://doi.org/10.1016/b978-0-323-52727-9.00017-0

- Patravale V, Dandekar P, Jain R. Nanoparticulate systems as drug carriers: the need. In: Patravale V, Dandekar P, Jain R, editors. Nanoparticulate drug delivery. Perspectives on the transition from laboratory to market. A volume in woodhead publishing series in biomedicine. Woodhead Publishing; 2012. pp. 1–28. https://doi.org/10.1533/9781908818195.1

- Gurpret K, Singh SK. Review of nanoemulsion formulation and characterization techniques. Indian Journal of Pharmaceutical Sciences. 2018;80(5):781–789. https://doi.org/10.4172/pharmaceutical-sciences.1000422

- Gupta PK, Bhandari N, Shah HN, Khanchandani V, Keerthana R, Nagarajan V, et al. An update on nanoemulsions using nanosized liquid in liquid colloidal systems. In: Koh KS, Wong VL, editors. Nanoemulsions – properties, fabrications and applications. IntechOpen; 2019. https://doi.org/10.5772/intechopen.84442

- Simonazzi A, Cid AG, Villegas M, Romero AI, Palma SD, Bermúdez JM. Nanotechnology applications in drug controlled release. In: Grumezescu AM, editor. Drug targeting and stimuli sensitive drug delivery systems. William Andrew; 2018. pp. 81–116. https://doi.org/10.1016/b978-0-12-813689-8.00003-3

- Hashemnejad SM, Badruddoza AZM, Zarket B, Ricardo Castaneda C, Doyle PS. Thermoresponsive nanoemulsion-based gel synthesized through a low-energy process. Nature Communications. 2019;10(1). https://doi.org/10.1038/s41467-019-10749-1

- Rehman A, Tong Q, Jafari SM, Korma SA, Khan IM, Mohsin A, et al. Spray dried nanoemulsions loaded with curcumin, resveratrol, and borage seed oil: The role of two different modified starches as encapsulating materials. International Journal of Biological Macromolecules. 2021;186:820–828. https://doi.org/10.1016/j.ijbiomac.2021.07.076

- Bykov DE, Eremeeva NV, Makarova NV, Bakharev VV, Demidova AV, Bykova TO. Influence of plasticizer content on organoleptic, physico-chemical and strength characteristics of apple sauce-based edible film. Foods and Raw Materials. 2017;5(2):5–14. https://doi.org/10.21603/2308-4057-2017-2-5-14

- Asyakina LK, Dolganyuk VF, Belova DD, Peral MM, Dyshlyuk LS. The study of rheological behavior and safety metrics of natural biopolymers. Foods and Raw Materials. 2016;4(1):70–78. https://doi.org/10.21179/2308-4057-2016-1-70-78

- Giro TM, Beloglazova KE, Rysmukhambetova GE, Simakova IV, Karpunina LV, Rogojin AA, et al. Xanthan-based biodegradable packaging for fish and meat products. Foods and Raw Materials. 2020;8(1):67–75. https://doi.org/10.21603/2308-4057-2020-1-67-75

- Chime SA, Kenechukwu FC, Attama AA. Nanoemulsions – Advances in formulation, characterization and applications in drug delivery. In: Sezer AD, editor. Application of nanotechnology in drug delivery. IntechOpen; 2014. https://doi.org/10.5772/58673

- Nirmala MJ, Durai L, Gopakumar V, Nagarajan R. Preparation of celery essential oil-based nanoemulsion by ultrasonication and evaluation of its potential anticancer and antibacterial activity. International Journal of Nanomedicine. 2020;15:7651–7666. https://doi.org/10.2147/IJN.S252640

- Donsi F. Applications of nanoemulsions in foods. In: Jafari SM, McClements DJ, editors. Nanoemulsions. Formulation, applications, and characterization. Cambridge: Academic Press; 2018. pp. 349–377. https://doi.org/10.1016/B978-0-12-811838-2.00011-4

- Che Marzuki NH, Wahab RA, Abdul Hamid M. An overview of nanoemulsion: Concepts of development and cosmeceutical applications. Biotechnology and Biotechnological Equipment. 2019;33(1):779–797. https://doi.org/10.1080/13102818.2019.1620124

- Ahari H, Naeimabadi M. Employing nanoemulsions in food packaging: Shelf life enhancement. Food Engineering Reviews. 2021;13:858–883. https://doi.org/10.1007/s12393-021-09282-z

- Shershneva EG. Biodegradable food packaging: Benefits and adverse effects. IOP Conference Series: Earth and Environmental Science. 2022;988(2). https://doi.org/10.1088/1755-1315/988/2/022006

- Acevedo-Fani A, Salvia-Trujillo L, Rojas-Graü MA, Martín-Belloso O. Edible films from essential-oil-loaded nanoemulsions: Physicochemical characterization and antimicrobial properties. Food Hydrocolloids. 2015;47:168–177. https://doi.org/10.1016/j.foodhyd.2015.01.032

- Almasi L, Radi M, Amiri S, McClements DJ. Fabrication and characterization of antimicrobial biopolymer films containing essential oil-loaded microemulsions or nanoemulsions. Food Hydrocolloids. 2021;117. https://doi.org/10.1016/j.foodhyd.2021.106733

- Elshamy S, Khadizatul K, Uemura K, Nakajima M, Neves MA. Chitosan-based film incorporated with essential oil nanoemulsion foreseeing enhanced antimicrobial effect. Journal of Food Science and Technology. 2021;58(9):3314–3327. https://doi.org/10.1007/s13197-020-04888-3

- Mahdi AA, Al-Maqtari QA, Mohammed JK, Al-Ansi W, Cui H, Lin L. Enhancement of antioxidant activity, antifungal activity, and oxidation stability of Citrus reticulata essential oil nanocapsules by clove and cinnamon essential oils. Food Bioscience. 2021;43. https://doi.org/10.1016/j.fbio.2021.101226

- Xavier LO, Sganzerla WG, Rosa GB, da Rosa CG, Agostinetto L, Veeck APDL, et al. Chitosan packaging functionalized with Cinnamodendron dinisii essential oil loaded zein: A proposal for meat conservation. International Journal of Biological Macromolecules. 2021;169:183–193. https://doi.org/10.1016/j.ijbiomac.2020.12.093

- Pérez-Córdoba LJ, Norton IT, Batchelor HK, Gkatzionis K, Spyropoulos F, Sobral PJA. Physico-chemical, antimicrobial and antioxidant properties of gelatin-chitosan based films loaded with nanoemulsions encapsulating active compounds. Food Hydrocolloids. 2018;79:544–559. https://doi.org/10.1016/j.foodhyd.2017.12.012

- Gupta A, Eral HB, Hatton TA, Doyle PS. Nanoemulsions: formation, properties and applications. Soft Matter. 2016;12(11):2826–2841. https://doi.org/10.1039/c5sm02958a

- Nejatian M, Abbasi S. Application of bio-based emulsifiers in the formulation of food-grade nanoemulsions. In: Abd-Elsalam KA, Murugan K, editors. Bio-based nanoemulsions for agri-food applications. A volume in nanobiotechnology for plant protection. Elsevier; 2022. pp. 311–327. https://doi.org/10.1016/B978-0-323-89846-1.00021-8

- Nain A, Tripathy DB, Gupta A, Dubey R, Kuldeep, Singh A. Nanoemulsions: Nanotechnological approach in food quality monitoring. In: Sharma A, Vijayakumar PS, Prabhakar EPK, Kumar R, editors. Academic Press; 2023. pp. 223–238. https://doi.org/10.1016/B978-0-323-85791-8.00020-3

- Jasmina H, Džana O, Alisa E, Edina V, Ognjenka R. Preparation of nanoemulsions by high-energy and lowenergy emulsification methods. CMBEBIH 2017. Proceedings of the International Conference on Medical and Biological Engineering. 2017;62:317–322. https://doi.org/10.1007/978-981-10-4166-2_48

- Chircov C, Grumezescu AM. Nanoemulsion preparation, characterization, and application in the field of biomedicine. In: Grumezescu AM, editor. Nanoarchitectonics in biomedicine. William Andrew; 2019. pp. 169–188. https://doi.org/10.1016/b978-0-12-816200-2.00019-0

- Kumar M, Bishnoi RS, Shukla AK, Jain CP. Techniques for formulation of nanoemulsion drug delivery system: A review. Preventive Nutrition and Food Science. 2019;24(3):225–234. https://doi.org/10.3746/pnf.2019.24.3.225

- Islam F, Saeed F, Afzaal M, Hussain M, Ikram A, Khalid MA. Food grade nanoemulsions: promising delivery systems for functional ingredients. Journal of Food Science and Technology. 2023;60(5):1461–1471. https://doi.org/10.1007/s13197-022-05387-3

- Safaya M, Rotliwala YC. Nanoemulsions: A review on low energy formulation methods, characterization, applications and optimization technique. Materials Today: Proceedings. 2020;27:454–459. https://doi.org/10.1016/j.matpr.2019.11.267

- Scholz P, Keck CM. Nanoemulsions produced by rotor–stator high speed stirring. International Journal of Pharmaceutics. 2015;482(1–2):110–117. https://doi.org/10.1016/j.ijpharm.2014.12.040

- Zhang A, Wang L, Song T, Yu H, Wang X, Zhao X. Effects of high pressure homogenization on the structural and emulsifying properties of a vegetable protein: Cyperus esculentus L. LWT. 2022;153. https://doi.org/10.1016/j.lwt.2021.112542

- Shi Y, Zhang M, Chen K, Wang M. Nano-emulsion prepared by high pressure homogenization method as a good carrier for Sichuan pepper essential oil: Preparation, stability, and bioactivity. LWT. 2022;154. https://doi.org/10.1016/j.lwt.2021.112779

- Bredihin SA, Andreev VN, Martekha AN, Schenzle MG, Korotkiy IA. Erosion potential of ultrasonic food processing. Foods and Raw Materials. 2021;9(2):335–344. https://doi.org/10.21603/2308-4057-2021-2-335-344

- Modarres-Gheisari SMM, Gavagsaz-Ghoachani R, Malaki M, Safarpour P, Zandi M. Ultrasonic nano-emulsification – A review. Ultrasonics Sonochemistry. 2019;52:88–105. https://doi.org/10.1016/j.ultsonch.2018.11.005

- Kentish S, Wooster TJ, Ashokkumar M, Balachandran S, Mawson R, Simons L. The use of ultrasonics for nanoemulsion preparation. Innovative Food Science and Emerging Technologies. 2008;9(2):170–175. https://doi.org/10.1016/j.ifset.2007.07.005

- Abbas S, Hayat K, Karangwa E, Bashiri M, Zhnag X. An overview of ultrasound-assisted food-grade nanoemulsions. Food Engineering Reviews. 2013;5:139–157. https://doi.org/10.1007/s12393-013-9066-3

- Ruiz-Montañez G, Ragazzo-Sanchez JA, Picart-Palmade L, Calderón-Santoyo M, Chevalier-Lucia D. Optimization of nanoemulsions processed by high-pressure homogenization to protect a bioactive extract of jackfruit (Artocarpus heterophyllus Lam). Innovative Food Science and Emerging Technologies. 2017;40:35–41. https://doi.org/10.1016/j.ifset.2016.10.020

- Sharma S, Sahni JK, Ali J, Baboota S. Effect of high-pressure homogenization on formulation of TPGS loaded nanoemulsion of rutin – pharmacodynamic and antioxidant studies. Drug Delivery. 2014;22(4):541–551. https://doi.org/10.3109/10717544.2014.893382

- Hidajat MJ, Jo W, Kim H, Noh J. Effective droplet size reduction and excellent stability of limonene nanoemulsion formed by high-pressure homogenizer. Colloids and Interfaces. 2020;4(1). https://doi.org/10.3390/colloids4010005

- Komaiko JS, McClements DJ. Formation of food-grade nanoemulsions using low-energy preparation methods: A review of available methods. Comprehensive Reviews in Food Science and Food Safety. 2016;15(2):331–352. https://doi.org/10.1111/1541-4337.12189

- Ahmed MW, Haque MA, Mohibbullah M, Khan MSI, Islam MA, Mondal MHT, et al. A review on active packaging for quality and safety of foods: Current trends, applications, prospects and challenges. Food Packaging and Shelf Life. 2022;33. https://doi.org/10.1016/j.fpsl.2022.100913

- Yildirim S, Röcker B, Pettersen MK, Nilsen-Nygaard J, Ayhan Z, Rutkaite R, et al. Active packaging applications for food. Comprehensive Reviews in Food Science and Food Safety. 2017;17(1):165–199. https://doi.org/10.1111/1541-4337.12322

- Lopes AT, Figueiredo BL, Michelon M, Chura SSD, de Souza AL, Teixeira LMC, et al. Use of essential oil-loaded nanoemulsions in active food packaging. In: Abd-Elsalam KA, Murugan K, editors. Bio-based nanoemulsions for agri-food applications. A volume in nanobiotechnology for plant protection. Elsevier; 2022. pp. 363–386. https://doi.org/10.1016/b978-0-323-89846-1.00024-3

- Yang Z, Li M, Zhai X, Zhao L, Tahir HE, Shi J, et al. Development and characterization of sodium alginate/tea tree essential oil nanoemulsion active film containing TiO2 nanoparticles for banana packaging. International Journal of Biological Macromolecules. 2022;213:145–154. https://doi.org/10.1016/j.ijbiomac.2022.05.164

- Candido GS, Natarelli CVL, Carvalho EEN, Oliveira JE. Bionanocomposites of pectin and pracaxi oil nanoemulsion as active packaging for butter. Food Packaging and Shelf Life. 2022;32. https://doi.org/10.1016/j.fpsl.2022.100862

- Noori S, Zeynali F, Almasi H. Antimicrobial and antioxidant efficiency of nanoemulsion-based edible coating containing ginger (Zingiber officinale) essential oil and its effect on safety and quality attributes of chicken breast fillets. Food Control. 2018;84:312–320. https://doi.org/10.1016/j.foodcont.2017.08.015

- Espitia PJP, Fuenmayor CA, Otoni CG. Nanoemulsions: Synthesis, characterization, and application in bio-based active food packaging. Comprehensive Reviews in Food Science and Food Safety. 2018;18(1):264–285. https://doi.org/10.1111/1541-4337.12405

- María Roberta A. Oxygen scavenging films and coating of biopolymers for food application. In: de Moraes MA, da Silva CF, Vieira RS, editors. Biopolymer membranes and films. Health, food, environment, and energy applications. Elsevier; 2020. pp. 535–551. https://doi.org/10.1016/b978-0-12-818134-8.00022-5

- Joung HJ, Choi M-J, Kim JT, Park SH, Park HJ, Shin GH. Development of food-grade curcumin nanoemulsion and its potential application to food beverage system: Antioxidant property and in vitro digestion. Journal of Food Science. 2016;81(3):N745–N753. https://doi.org/10.1111/1750-3841.13224

- Hasani-Javanmardi M, Fallah AA, Abbasvali M. Effect of safflower oil nanoemulsion and cumin essential oil combined with oxygen absorber packaging on the quality and shelf-life of refrigerated lamb loins. LWT. 2021;147. https://doi.org/10.1016/j.lwt.2021.111557

- Dasgupta N, Ranjan S, Mundra S, Ramalingam C, Kumar A. Fabrication of food grade vitamin E nanoemulsion by low energy approach, characterization and its application. International Journal of Food Properties. 2015;19(3):700–708. https://doi.org/10.1080/10942912.2015.1042587

- Cherpinski A, Szewczyk PK, Gruszczyński A, Stachewicz U, Lagaron JM. Oxygen-scavenging multilayered biopapers containing palladium nanoparticles obtained by the electrospinning coating technique. Nanomaterials. 2019;9(2). https://doi.org/10.3390/nano9020262

- Fan X, Rong L, Li Y, Cao Y, Kong L, Zhu Z, et al. Fabrication of bio-based hierarchically structured ethylene scavenger films via electrospraying for fruit preservation. Food Hydrocolloids. 2022;133. https://doi.org/10.1016/j.foodhyd.2022.107837

- Ebrahimi A, Zabihzadeh Khajavi M, Mortazavian AM, Asilian-Mahabadi H, Rafiee S, Farhoodi M, et al. Preparation of novel nano–based films impregnated by potassium permanganate as ethylene scavengers: An optimization study. Polymer Testing. 2021;93. https://doi.org/10.1016/j.polymertesting.2020.106934

- Gull A, Bhat N, Wani SM, Masoodi FA, Amin T, Ganai SA. Shelf life extension of apricot fruit by application of nanochitosan emulsion coatings containing pomegranate peel extract. Food Chemistry. 2021;349. https://doi.org/10.1016/j.foodchem.2021.129149

- Norcino LB, Mendes JF, Natarelli CVL, Manrich A, Oliveira JE, Mattoso LHC. Pectin films loaded with copaiba oil nanoemulsions for potential use as bio-based active packaging. Food Hydrocolloids. 2020;106. https://doi.org/10.1016/j.foodhyd.2020.105862

- Wang H, Ma Y, Liu L, Liu Y, Niu X. Incorporation of clove essential oil nanoemulsion in chitosan coating to control Burkholderia gladioli and improve postharvest quality of fresh Tremella fuciformis. LWT. 2022;170. https://doi.org/10.1016/j.lwt.2022.114059

- Prastuty, Kaur P, Singh A. Shelf life extension of muffins coated with cinnamon and clove oil nanoemulsions. Journal of Food Science and Technology. 2022;59(5):1878–1888. https://doi.org/10.1007/s13197-021-05202-5

- Roy S, Rhim J-W. Fabrication of bioactive binary composite film based on gelatin/chitosan incorporated with cinnamon essential oil and rutin. Colloids and Surfaces B: Biointerfaces. 2021;204. https://doi.org/10.1016/j.colsurfb.2021.111830

- Xiong Y, Li S, Warner RD, Fang Z. Effect of oregano essential oil and resveratrol nanoemulsion loaded pectin edible coating on the preservation of pork loin in modified atmosphere packaging. Food Control. 2020;114. https://doi.org/10.1016/j.foodcont.2020.107226

- Moghimi R, Aliahmadi A, Rafati H. Antibacterial hydroxypropyl methyl cellulose edible films containing nanoemulsions of Thymus daenensis essential oil for food packaging. Carbohydrate Polymers. 2017;175:241–248. https://doi.org/10.1016/j.carbpol.2017.07.086

- Das SK, Vishakha K, Das S, Chakraborty D, Ganguli A. Carboxymethyl cellulose and cardamom oil in a nanoemulsion edible coating inhibit the growth of foodborne pathogens and extend the shelf life of tomatoes. Biocatalysis and Agricultural Biotechnology. 2022;42. https://doi.org/10.1016/j.bcab.2022.102369

- Alexandre EMC, Lourenço RV, Bittante AMQB, Moraes ICF, Sobral PJA. Gelatin-based films reinforced with montmorillonite and activated with nanoemulsion of ginger essential oil for food packaging applications. Food Packaging and Shelf Life. 2016;10:87–96. https://doi.org/10.1016/j.fpsl.2016.10.004

- Sanchez LT, Pinzon MI, Villa CC. Development of active edible films made from banana starch and curcumin-loaded nanoemulsions. Food Chemistry. 2022;371. https://doi.org/10.1016/j.foodchem.2021.131121

- Tripathi AD, Sharma R, Agarwal A, Haleem DR. Nanoemulsions based edible coatings with potential food applications. International Journal of Biobased Plastics. 2021;3(1):112–125. https://doi.org/10.1080/24759651.2021.1875615

- Kamrul Hasan SM, Ferrentino G, Scampicchio M. Nanoemulsion as advanced edible coatings to preserve the quality of fresh‐cut fruits and vegetables: A review. International Journal of Food Science and Technology. 2019;55(1):1–10. https://doi.org/10.1111/ijfs.14273

- Zubair M, Shahzad S, Hussain A, Pradhan RA, Arshad M, Ullah A. Current trends in the utilization of essential oils for polysaccharide- and protein-derived food packaging materials. Polymers. 2022;14(6). https://doi.org/10.3390/polym14061146

- Korotkaya EV. Biosensors: Design, classification, and applications in the food industry. Foods and Raw Materials. 2014;2(2):161–171. https://doi.org/10.12737/5476

- Koroleva MYu, Yurtov EV. Ostwald ripening in macro- and nanoemulsions. Russian Chemical Reviews. 2021;90(3):293–323. https://doi.org/10.1070/rcr4962

- Valencia-Chamorro SA, Palou L, del Río MA, Pérez-Gago MB. Antimicrobial edible films and coatings for fresh and minimally processed fruits and vegetables: A review. Critical Reviews in Food Science and Nutrition. 2011;51(9):872–900. https://doi.org/10.1080/10408398.2010.485705

- Krishnamoorthy C, Chatterjee P, Paul U, Banerjee S, Kumar L, Chidambaram R. Nanoencapsulation of antimicrobial agents and antimicrobial effect of silver nanoparticles. In: Sharma A, Vijayakumar PS, Prabhakar EPK, Kumar R, editors. Nanotechnology applications for food safety and quality monitoring. Academic Press; 2023. pp. 435–456. https://doi.org/10.1016/B978-0-323-85791-8.00023-9

- Gennadios A, Hanna MA, Kurth LB. Application of edible coatings on meats, poultry and seafoods: A review. LWT – Food Science and Technology. 1997;30(4):337–350. https://doi.org/10.1006/fstl.1996.0202

- Yousefi M, Ehsani A, Jafari SM. Lipid-based nano delivery of antimicrobials to control food-borne bacteria. Advances in Colloid and Interface Science. 2019;270:263–277. https://doi.org/10.1016/j.cis.2019.07.005

- Dasgupta N, Ranjan S. Food nanoemulsions: Stability, benefits and applications. In: Dasgupta N, Ranjan S, editors. An introduction to food grade nanoemulsions. Singapore: Springer; 2018. pp. 19–48. https://doi.org/10.1007/978-981-10-6986-4_2

- Naserzadeh Y, Mahmoudi N, Pakina E. Antipathogenic effects of emulsion and nanoemulsion of cinnamon essential oil against Rhizopus rot and grey mold on strawberry fruits. Foods and Raw Materials. 2019;7(1):210–216. https://doi.org/10.21603/2308-4057-2019-1-210-216

- Yüzer MO, Gençcelep H. Sesame seed protein: Amino acid, functional, and physicochemical profiles. Foods and Raw Materials. 2023;11(1):72–83. https://doi.org/10.21603/2308-4057-2023-1-555