Аннотация

Rice is now the main food for about 35 million people in Nigeria, and consumption is increasing faster than that of any other food crop in many countries in Africa. This study provided essential engineering data on the physical properties of selected varieties of local rice in Nigeria. Some selected physical properties of Igbemo, Ofada and Abakaliki rice varieties at harvest, market, and storage conditions were evaluated as a function of moisture content. The latter ranged from 12.38 to 25.69% (dry base). We also determined the physical properties of the rice samples, such as moisture content, linear dimensions, geometric mean diameter, arithmetic mean diameter, surface area, aspect ratio, sphericity, bulk density, and hundred kernel weights. A result of the linear dimensions for the major diameter was 8.4–10.3 mm, 6.4–6.55 mm, and 5.9–7.4 mm for harvested, marketed, and stored rice, respectively. The minor diameter ranged from 2.70 to 3.29 mm, 2.49 to 2.63 mm, and 2.56 to 2.74 mm, and the intermediate diameter of the rice varieties at harvest, market, and storage conditions was 1.92–2.29 mm, 1.90–2.02 mm, and 1.87–1.99 mm, respectively. Depending on the conditions and varieties, the bulk density, true density, and porosity, was observed to be between 0.59 to 0.90 g/cm³, 2.28 to 5.57 g/cm3 and 70.38 to 85.35% respectively.Ключевые слова

Rice, moisture content, surface area, aspect ratio, sphericity, bulk densityВВЕДЕНИЕ

Rice is the most widely consumed cereal after maize and sorghum in many parts of Nigeria [1]. Rice grain could be prepared in various forms. Industrially, starch could be made from broken rice which is used in laundry, pharmaceutical, cosmetics, and textile industries. The straw can be used as livestock feed, for thatching of houses, and for making mats and hats. The husk can be used as fuel [2].

The physical properties of rice, which are important in the design and selection of storage structures and processing equipment, depend on grain moisture content. Therefore, the determination and consideration of properties such as bulk density, true density, angle of internal friction, and static coefficient of friction of grain at specific moisture content are essential [3]. Sabbah et al. studied the effect of moisture content on the physical properties for three Egyptian paddy rice varieties [4]. They recorded the increase occurring in seed sphericity (S) due to the increase of moisture content. The principal axial dimensions of rye seeds are useful in selecting sieve separators and in calculating power during the rye milling process. Knowing the grain’s bulk density, true density and porosity can be useful in sizing grain hoppers and storage facilities: they can affect the rate of heat and mass transfer of moisture during the aeration and drying processes. A grain bed with low porosity will have greater resistance to water-vapour escape during the drying process, which may lead to the need for higher power to drive the aeration fans.

Cereal-grain kernel densities have been of interest in breakage susceptibility and hardness studies [5]. Researchers in [6] reported that various physical properties of green gram (Phaseulus aureus L.) were evaluated as a function of moisture content in the range of 8.39 to 33.40% d.b. The average length, width, thickness and the mass of thousand seeds were 4.21 mm, 3.17 mm, 3.8mm, and 28.19 g, respectively at moisture content of 8.39% (d.b.). Also, the geometric mean diameter increased from 3.45 mm to 3.77 mm, whereas sphericity decreased from 0.840 to 0.815. They observed that with the increase of moisture content the bulk and true densities decreased from 807 to 708 kg/m3 and from 1,363 to 1,292 kg /m3, respectively. The corresponding bulk porosity increased from 40.77 to 45.16%. The static coefficient of friction is used to determine the angle at which chutes must be positioned to achieve consistent flow of materials through the chute.

The geometric properties such as size and shape are one of the most important physical properties considered during the separation and cleaning of agricultural grains. Theoretically, agricultural seeds are assumed to be spheres or ellipse because of their irregular shapes [3]. [7] determined the physical and mechanical properties of funnel seed as a function of moisture content. They found that there was a parabolic mathematical equation for sphericity, true density, and deformation on both seed length and width sections with changes of moisture content. The shape of the rice was found to be cylindrical with three perpendicular dimensions, namely length (L), width (W), and thickness (T).

Matouk et al. developed the mathematical relationships relating the changes of the properties with the seed moisture content. The seed principal dimensions, mass of 1,000 seeds and seed projection area generally increased with the increase of seed moisture content. On the contrary, both shape-index and coefficient of contact surface decreased [8]. Thousand grain mass of rice was utilized in determining the effective diameter which can be used in the theoretical estimation of seed volume [9].

Ghasemi et al. designed equipment for processing, sorting, sizing, and other post-harvesting equipment of agricultural products requires information about their physical properties [10]. In their study, various physical properties of rough rice cultivars were determined at a moisture content of 10% (wet basis). In the case of Sorkheh cultivar, the average thousand grain weight, equivalent diameter, surface area, volume, sphericity, aspect ratio, true density, bulk density and porosity were 21.64 g, 3.35 mm, 31.76 mm2, 20.27 mm3, 39.71%, 0.28, 1,269.1 kg/m3, 544.34 kg/m3, and 56.98%, respectively. For Sazandegi cultivar, the corresponding values were 20.52 g, 3.4 mm, 32.58 mm2, 21.06 mm3, 39.88%, 0.29, 1,193.38 kg/m3, 471.21 kg/m3, and 60.37%. For Sorkheh cultivar, the average static coefficient of fric- tion varied from 0.2899 on glass to 0.4349 on plywood, while for Sazandegi cultivar those varied from 0.2186 to 0.4279 on the same surfaces. Angle of repose values for Sorkheh and Sazandegi cultivars were 37.66° and 35.83°, respectively. Linear model for describing the mass of rough rice grain was investigated. Mass was estimated with single variable of kernel length with a determination coefficient as 0.862 for Sorkheh cultivar whereas for Sazandegi cultivar was as 0.860. These properties con siderably differ from one variety to another.

In Nigeria, there are different local varieties of rice, prominent of these varieties are, ‘Ofada’, ‘Igbemo’, and ‘Abakaliki’ rice. Ofada is a generic name for local rice produced and processed in the rice producing clusters. It originates from Ofada town and its axes including Owode and Wasimi, Ogun State South-West Nigeria. It has recently gained prominence and is fast gaining international attention. Cooked Ofada rice is usually eaten with a special kind of sauce prepared using pepper (Atarodo and Tatase), onion, locust beans, palm oil and assorted meat [11]. The growing of Igbemo rice is a primary activity among the farmers in Igbemo Ekiti, Ekiti State, where 70% are actively engaged in its production, [12]. Igbemo-Ekiti is acquiring national and international reputation for producing rice [13]. Abakaliki is known in agriculture, especially in rice production. It dates back to years before the 1960s.

Despite the popularity of these rice varieties in Nigeria, there is little or no detail of the properties of these varieties. This factor is one of the major issues affecting the development of suitable equipment/structure for the efficient storage and processing of these local rice varieties. This study, therefore, is aimed at investigating some major properties of Ofada, Igbemo, and Abakaliki rice varieties at different conditions. The study also seeks to find the effect of these conditions on the physical properties.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

1. Sample preparation. One kilogram each of the three rice grain varieties, namely Ofada, Igbemo, and Abakaliki were obtained from farmers from state of their origin, namely from Ogun, Ekiti and Ebonyi State, respectively. Each of the rice variety was divided into 10 equal parts and one part was randomly selected from each of the parts divided. The process was repeated again by mixing all the divided parts together and then separating them into another 10 equal parts. Another sample of grain was taken from each of the divided parts [14]. The process was continued until 500 g of rice were taken from each of the harvested, marketed, and stored rice varieties. The harvested grains were collected directly from the farm after harvest, while the stored and marketed rice varieties were collected from the farmer stores and market outlets respectively.

2. Determination of the physical properties of the rice varieties. We determined the following physical properties: moisture content, shape, size, 1,000 kernel weight, surface area, bulk density, true density, aspect ratio, and sphericity.

2.1 Moisture content. Oven method was adopted for moisture content determination as recommended by the ASAE standards*. The whole grains were placed on dishes for each of the varieties and conditions. After weighing the dishes and grains, dishes were placed in the oven at 105°C for 8 hours. After drying, the dishes were taken out and placed in desiccators. Then the samples were cooled and weighed with a balance. This procedure was performed in three replications for the harvested, marketed, and stored rice samples. Weight differences before and after heating were used to determine moisture content, %:

![]()

where W0 is weight of moisture dish, kg; W1 is weight of dish + sample before drying, kg; and W2 is weight of dish + sample after drying, kg.

2.2 Size. 100 grains selected randomly from 500 g were used, and the basic dimensions of the seed (major, minor, and intermediate) were measured using a digital micrometer (Mitutoyo Digital Micrometer, Series) with accuracy 0.001 mm. The arithmetic and geometric average diameters of rice for each of the varieties and conditions were calculated using equations suggested by K. Shkelqim and M. Joachim [16]:

![]()

![]()

where AMD is arithmetic mean diameter, mm; GMD is geometric mean diameter, mm; L is length, mm; W is width, mm; and T is thickness, mm

2.3 Surface area. Surface area is an important property of grain. It helps the designer in estimating the hopper, processing chamber and the chute. The surface area was found by analogy with a sphere of some geometric mean diameter using the expression cited by Amin et al. [17]:

![]()

where S is surface area (mm2) and Dg stands for geometric mean diameter (mm) respectively.

2.4 Sphericity. The sphericity was calculated using the equation reported by [18]:

![]()

where Ø is sphericity; L is the major diameter; W is the minor diameter; and T is the intermediate diameter.

2.5 True density, bulk density and porosity. The bulk density was determined by filling a container of known mass and volume to the brim with each variety of rice and condition for three replicate each. The net mass of rice was obtained by subtracting the mass of the container from the mass of the rice. To achieve uniformity in bulk density, the container was tapped 10 times in the same manner in all measurements to consolidate as reported by Aderinlewo et al. [18]. This experiment was carried out in three replicates. The bulk density was then calculated using the equation:

![]()

where Ms is the mass of sample in the container, g; V0 is the volume occupied, cm3.

The true density and porosity were calculated as follow:

![]()

![]()

2.6 1,000 kernel weight. 1,000 kernel weight was measured by counting 1,000 grains and weighted them on an electronic balance to an accuracy of 0.001 g. This experiment was carried out in three replicates.

2.7 Aspect ratio. Aspect ratio relates the width of a grain to its length which is indicative of its tendency towards being oblong in shape [19]. The aspect ratio R was estimated using the equation reported by Aderinlewo et al. [18]:

![]()

where W is the minor diameter; L is the major diameter. This experiment was conducted for 100 replicates for the width and length.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

1. Moisture content.Table 1 shows the moisture content in the Igbemo, Ofada, and Abakaliki rice at different conditions. The moisture content in the marketed and stored samples was lesser (12.72 and 12.63%) compared with the harvested sample (25.64%). The moisture content of Ofada rice was 20.25%, 12.44%, and 13.41% at harvest, storage, and market conditions, respectively. The Abakaliki rice had the moisture content of 12.85%, 13.20%, and 13.40% for harvested, stored, and marketed samples, respectively.

A one can see in Table 1, the increase in moisture content of the Abakaliki rice occurred after harvest. The rice would have absorbed moisture after harvest unlike the Igbemo and Ofada rice that had a decrease in their moisture content. The Abakaliki rice was usually allowed to dry before harvesting in September with 85% humidity. This led to lower moisture content in the harvested sample when compared to the other rice varieties.

The results are in agreement with [20] that stated that the optimum moisture content of stored grains was 12–13%, while that for harvested grains ideally was 20–25% (wet basis). It also referred to rice as hygroscopic material, which explains why the Abakaliki rice had decreased moisture at harvest condition but increased moisture at market and storage conditions.

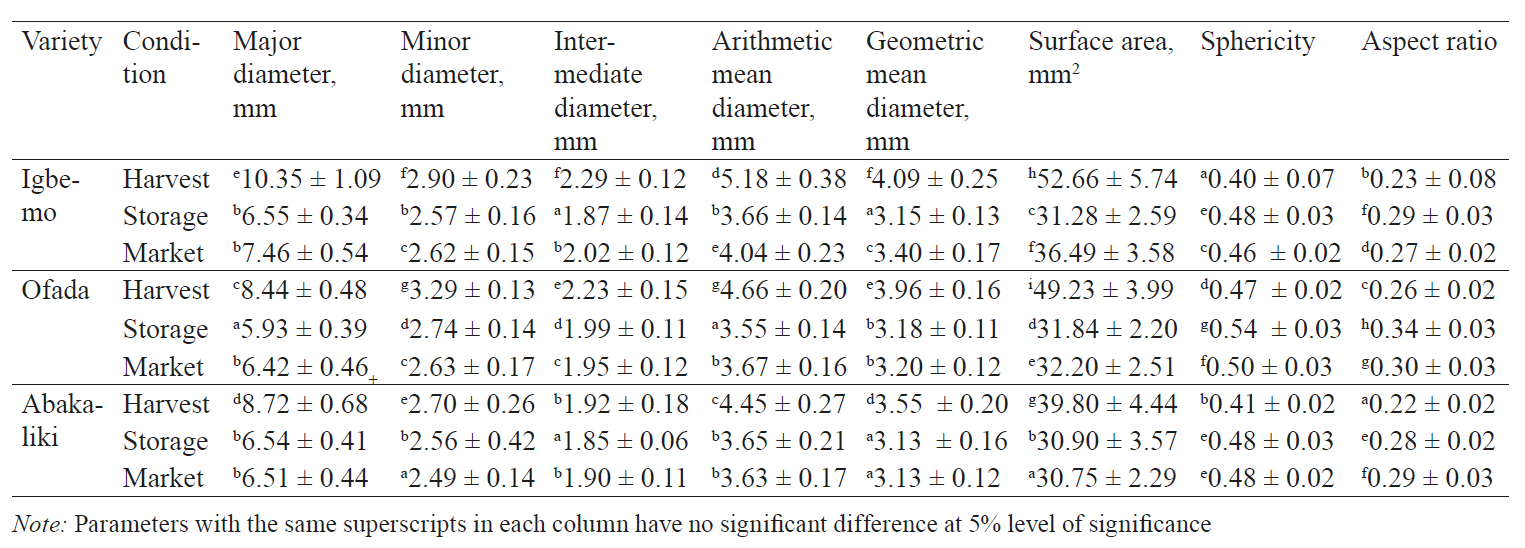

2. Geometric properties. The axial dimensions, arithmetic mean, geometric mean diameter, surface area, sphericity, and aspect ratio of the Igbemo, Abakaliki, and Ofada rice at different conditions are presented in Table 2.

2.1 Axial dimension. Table 2 summarizes axial properties of the Igbemo, Ofada and Abakaliki rice at harvest, storage, and market conditions.

Major diameter. We found that the major diameter of the Igbemo, Ofada, and Abakaliki rice was 10.35; 8.44; and 8.73 mm respectively at harvest conditions; 6.55; 5.93; and 6.54 mm at storage condition; and 7.46; 6.42; and 6.51 mm at market conditions. Statistical analysis with t-test revealed that there was no significant difference in the major diameter between the three varieties at market condition and Abakaliki rice at storage condition.

Minor diameter. The minor diameter for the Igbemo, Ofada, and Abakaliki rice was 2.90; 3.29; and 2.70 mm respectively at harvest condition; 2.57; 2.74; and 2.56 mm at storage condition; and 2.62; 2.63; and 2.49 at market conditions. The result in Table 2 also showed that there was a significant difference between the minor diameter in all the varieties and conditions, except for the stored Igbemo and Ofada rice that had no significant difference (p < 0.05). This is also the case for the market condition of Igbemo and Abakaliki rice.

Intermediate diameter. According to Table 2, the intermediate diameter of the Igbemo, Ofada, and Abakaliki rice was 2.29; 2.23; and 1.92 mm respectively in harvested samples; 1.87; 1.99; and 1.85 mm in stored samples; and 2.02; 1.95; and 1.90 mm were marketed rice. The t-test result revealed the rice varieties and conditions whose intermediate diameters are significant at 5% level of significance. At storage and market conditions, the intermediate diameters of Igbemo and Abakaliki rice were observed not to have any significant difference. Besides, the harvested and marketed Abakaliki rice were also observed not to differ significantly in their intermediate diameter.

2.2 Arithmetic mean diameter. Table 2 also contains the arithmetic mean diameter of the Igbemo, Ofada, and Abakaliki rice under different conditions. The arithmetic mean diameters were 5.18; 4.66; and 4.45 mm, respectively, in the harvested samples; 3.66; 3.55; and 3.65 mm in the stored samples; and 4.04; 3.67 mm; and 3.63 mm in the marketed samples. Further analysis revealed that there was no significant difference in the arithmetic mean diameters among the stored Igbemo rice, the marketed Ofada rice, and the stored and marketed Abakaliki rice.

2.3 Geometric mean diameter. The geometric mean diameters under harvest condition were 4.09; 3.96; and 3.55 mm for the Igbemo, Ofada, and Abakaliki rice, respectively. These values for the stored samples were 3.15; 3.18; and 3.13 mm, and the marketed samples had he geometric mean diameters 3.40; 3.20; and 3.13 mm. Statistical analysis revealed that there was no significant difference between the geometric mean diameters of the stored Igbemo rice and the stored and marketed samples of the Abakaliki rice. In addition, there was no significant difference between the geometric mean diameters of Ofada rice at market and storage conditions. This result implies that a multi-variety screen can be used to clean, sort, or grade Igbemo and Abakaliki rice at storage conditions, Ofada rice at storage and market conditions, and Abakaliki rice at storage and market conditions. This will not be appropriate for the other samples because the discrepancy in their GMD will not allow the use of a screen with a particular diameter. The only possible solution is to have a screen with adjustable size or to replace the screens in the machines when the rice is to be changed.

2.4 Surface area. The surface area of the Igbemo, Ofada, and Abakaliki rice was 52.66; 49.23; 39.80 mm2; respectively in the harvested samples; 31.28; 31.84; and 30.90 mm2in the stored samples; and 36.49; 32.20; and 30.75 mm2in the marketed samples. The result also showed that there was no significant difference between the surface area of each condition across the rice varieties (p > 0.05). Without varying the air speed or the water pressure in a multi-variety or multi-condition aerodynamic or hydrodynamic applications of these rice varieties, the efficiency will be affected.

2.5 Sphericity. Acording to Table 2, sphericity of the Igbemo, Ofada, and Abakaliki rice was 0.40; 0.47; and 0.48, respectively, at harvest condition; 0.48; 0.54; and 0.48 at storage condition; and 0.46; 0.50; and 0.48 at market condition. In line with the result of GMD, statistical analysis revealed that there was no significant difference in sphericity between the stored Igbemo rice and the samples of the stored and marketed Abakaliki rice. It should be noted that the mean values of sphericity for all the three investigated varieties, which ranged between 0.40 and 0.54, decreased to 0.32–1.00 for most of agricultural products [3].

2.6 Aspect ratio. The aspect ratio of the Igbemo, Ofada, and Abakaliki rice was 0.23; 0.26; and 0.22 for the harvested samples; 0.29; 0.34; and 0.28 for the stored samples; and 0.27; 0.30; and 0.29 for the marketed samples (Table 2). This result did not indicated any significant difference among all the varieties and conditions (p > 0.05), except the stored Igbemo rice and the marketed Abakaliki sample.

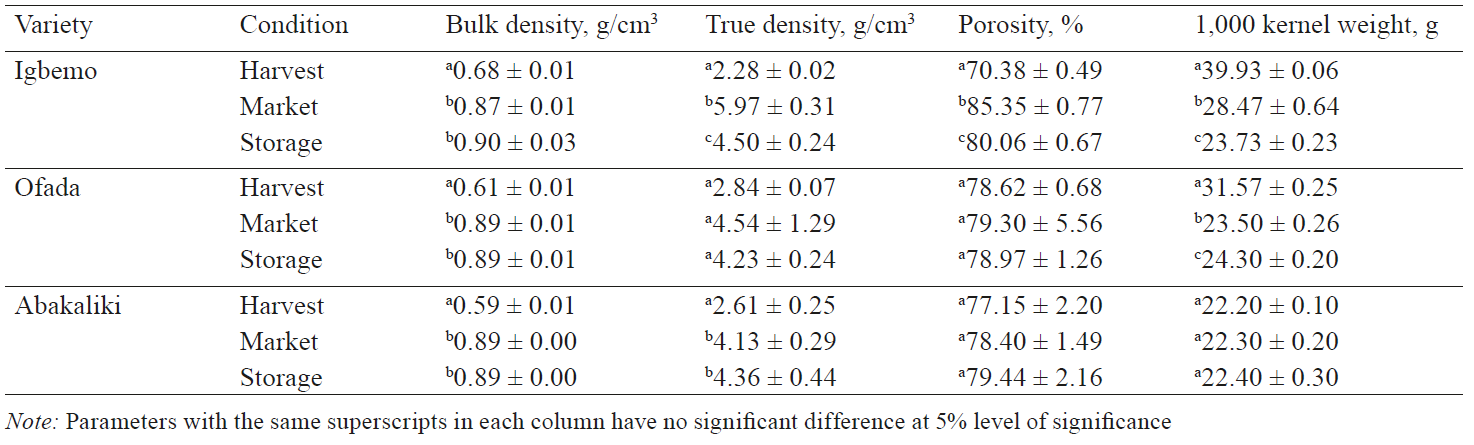

3. Gravimetric properties. Table 3 presents the bulk density, true density, porosity and 1,000 kernel weight of the three selected local varieties of rice in Nigeria at different conditions.

3.1 Bulk density. As one can see in Table 3, bulk density of the harvested samples was 0.68; 0.61; and 0.58 g/cm3 for Igbemo, Ofada, and Abakaliki rice, respectively. There was not observed any significant differences at 5% level of significance. The values for the stored and marketed samples were 0.90; 0.89; and 0.89 g/cm3 and 0.87; 0.89; and 0.89 g/cm3, respectively. The samples did not show a considerable difference in the bulk density values.

3.2 True density. True density values are also presented in Table 3. In the harvested samples of the Igbemo, Ofada, and Abakaliki rice, the true density was observed to be 2.28; 2.84; and 2.61 g/cm3, respectively. The values of true density were 5.67; 4.54; and 4.13 g/cm3 in the marketed rice and 4.50; 4.23; and 4.36 g/cm3 in the stored rice. The stored samples showed a significant difference unlike the other samples which did not differ considerably.

3.3 Porosity. According to Table 3, porosity of the Igbemo, Ofada, and Abakaliki rice samples was 70.38; 78.62; and 77.15%, respectively, at harvest condition. They did not show a significant difference at 5% level of significance. In the marketed samples, porosity values were 85.35; 79.30; and 78.40% for the Igbemo, Ofada, and Abakaliki rice, respectively. There was no significant difference between the marketed Ofada and Abakaliki rice. In the stored samples, the porosity was 80.06; 78.97; and 79.44%. Similar to market conditions, no significant difference existed between the stored Ofada and Abakaliki rice.

3.4 1,000 kernel weight. This parameter was 39.93; 31.57; and 22.20 g for the stored Igbemo, Ofada, and Abakaliki rice, respectively. The samples did not demonstrate any significant difference at 5% level of significance. For the marketed rice, the 1,000 kernel weight was 28.47; 23.50; and 22.30 g for Igbemo, Ofada, and Abakaliki rice respectively. There was no significant difference existed between the Ofada and Igbemo rice. At storage conditions, the 1,000 kernel weight was 23.73; 24.30; and 22.40 g. Similar to market condition, no significant difference exist between the stored Ofada and Igbemo rice samples.

ВЫВОДЫ

An investigation was carried out to determine and compare the physical properties of Igbemo, Abakaliki, and Ofada rice at harvest, storage, and market conditions. The values of the major diameter, minor diameter, intermediate diameter, arithmetic mean diameter, geometric mean diameter, surface area, sphericity, aspect ratio, bulk density, true density, porosity and 1,000 kernel weights were presented for each variety at the three conditions. Depending on the condition, the moisture content of the Igbemo, Ofada and Abakaliki rice varied from 12.63–25.64, 12.44–20.25 and 12.85–13.40% respectively. The rice condition (or moisture content) influenced some of the axial dimensions, other geometrical properties, and gravimetric properties, likewise the variety. The result presented can be of use in the design of multi-variety or multi-condition separators, pneumatic conveyors, bins, etc. for these three major local rice varieties in Nigeria.

КОНФЛИКТ ИНТЕРЕСОВ

The authors declare no conflict of interests.СПИСОК ЛИТЕРАТУРЫ

- Odenigbo A.M., Ngadi M., Danbaba N., and Manful J. Starch fraction profiles in selected rice varieties cultivated in Nigeria. International Journal of Food Sciences and Technology, 2013, vol. 48, no. 12, pp. 2535–2540. DOI: https:// doi.org/10.1111/ijfs.12246.

- Onwueme I.C. and Sinha T.D. Field Crop Production in Tropical Africa. Netherlands, Wageningen: CTA Technical Publ., 1991. 480 pp.

- Mohsenin N. Physical properties of plant and animal materials. New York: Gorden and Breach Sci. Publ., 1986. 159–165 pp.

- Sabbah M.A., Soliman S.N., and Yehia M.O. Physical properties of Egyptian paddy rice related to steeping process.Misr Journal of Agricultural Engineering, 1994, vol. 11, no. 1, pp. 248–260.

- Chang C.S. Measuring Density and Porosity of Grain Kernels Using a Gas Pycnometer. Cereal Chemistry, 1988, vol. 65, no. 1, pp. 13–15.

- Nimkar P.M. and Chattopadhyay P.K. PH—Postharvest Technology: Some physical properties of green gram. Journal of Agricultural Engineering Research, 2001, vol. 80, no. 1, pp. 183–189. DOI: https://doi.org/10.1006/jaer.2000.0664.

- Mollazade K., Ahmadi H., Khorshidi J., Mohtasebi S.S., and Rajabipour A. Some physical and mechanical properties of fennel seed (Foeniculum vulgare). Journal of Agricultural Science, 2009, vol. 1, no. 1, pp. 66–75. DOI: https://doi. org/10.5539/jas.v1n1p66.

- Matouk A.M., Abd El-latiff S.M., and Tharwt A. Aerodynamic and mechanical properties of some oil crops. Journal of Agricultural Science Mansoura University, 2008, vol. 33, no. 6, pp. 4195–4211.

- Ogunjimi L.A.O., Aviara N.A., and Aregbesola O.A. Some engineering properties of locust bean seed. Journal of Food Engineering, 2002, vol. 55, no. 2, pp. 95–99. DOI: https://doi.org/10.1016/S0260-8774(02)00021-3.

- Ghasemi H., Mobli H., Jafari A., et al. Some physical properties of rough rice (Oryza Sativa L.) grain. Journal of Ce- real Science, 2008, vol. 47, no. 3, pp. 496–501. DOI: https://doi.org/10.1016/j.jcs.2007.05.014.

- CMDG 2006. Draft Report on Project Delicacy (Ofada Rice Attributes Evaluation Study) submitted to PrOpCom. Abuja: Research Group Limited Publ., 2006.

- Basorun J.O. and Fasakin J.O. Factors influencing rice production in Igbemo-Ekiti Region of Nigeria. Journal of Ag- riculture, Food and Environmental Sciences, 2012, vol. 5, no. 1, pp. 23–29.

- Longtau S.R. Multi-Agency Partnership in West African Agriculture: A review and description of rice production system in Nigeria. Jos, Nigeria: Eco-system Development Organization Publ., 2000. 47pp.

- Adewumi B.A. Physical and Mechanical properties of rice varieties in Ondo State. Applied Tropical Agriculture, 1996, vol. 1, no. 1, pp. 24–28.

- ASAE S352.1. Moisture measurement-grains and seeds. 1982.

- Shkelqim K. and Joachim M. Determination of physical, mechanical and chemical properties of seeds and kernels of Jatropha curcas L. Industrial Crops and Products, 2010, vol. 32, no. 2, pp. 129–138. DOI: https://doi.org/10.1016/j. indcrop.2010.04.001.

- Amin M.N., Hossain M.A., and Roy K.C. Effects of moisture content on some physical properties of lentil seeds. Journal of Food Engineering, 2004, vol. 65, no. 1, pp. 83–87. DOI: https://doi.org/10.1016/j.jfoodeng.2003.12.006.

- Aderinlewo A.A., Raji A.O., and Olayanju T.M.A. Effect of moisture content on some physical properties of cowpea(Vigna Unguiculata). Journal of Natural Sciences, Engineering and Technology, 2011, vol. 10, no. 2, pp. 133–145.

- Omobuwajo T.O., Akande E.A., and Sanni L.A. Selected physical, mechanical andaerodynamic properties of Africa breadfruit (Treculia Africana) seeds. Journal of Food Engineering, 1999, vol. 40, no. 4, pp. 241–244. DOI: https://doi. org/10.1016/S0260-8774(99)00060-6.

- IRRI 2010. The International Research Institute. Available at: www.knowledgebank.irri.org. (accessed 12 June 2018).