Abstract

Fermented drinks are regarded as healthy food due to their probiotic nature. Vegan consumers who choose sustainable diet and people allergic to dairy products demand alternatives for dairy products. We aimed to develop a non-dairy plant-based yogurt from peanut, oats, and coconut milk.Yogurt was formulated with addition of sugar, corn starch, pectin, and xanthan gum. Simplex-lattice mixture design was applied to optimize the composition of the yogurt and achieve the desired rheological properties, sensory attributes, and syneresis rate.

Our results revealed that the formulation containing 7.13 mL of peanut milk, 10 mL of oats milk, and 7.86 mL of coconut milk showed low syneresis rate, desired viscosity and flow behavior, as well as high overall acceptability. We found that increased amounts of peanut and oats milk improved the product’s viscosity due to high protein contents. However, coconut milk enhanced the taste and flavor of the yogurt. Flow behavior depended on viscosity and stabilizers used in accordance with the power law model. Syneresis rate was influenced by the viscosity of the yogurt. The utilization of corn starch, pectin, and xanthan gum not only improved the texture but also helped achieve the desired viscosity and flow behavior.

The nutrient composition, physicochemical properties, and high sensory characteristics of the yogurt based on peanut, oats, and coconut milk allow using it as a cow milk alterative in the diet of people with lactose intolerance.

Keywords

Plant-based yogurt alternative, peanut milk, oats milk, coconut milk, mixture designINTRODUCTION

Conventional yogurt is a product made by fermentation of milk. Bacteria ferment milk sugars and produce acid which can act on milk protein and produce textured yogurt [1]. Nowadays, many people have lactose intolerance and are allergic to dairy products. For them, plant-based yogurt is an alternative. In this work, we used oats, peanut, or coconut milk as an alternative to cow milk. These ingredients increase the nutritive value of yogurt and provides it with an honest flavor. Fermentation of plant materials using mixed cultures was found to be mutually beneficial for the human body. Mutualism was found to exist between proteolytic Lactobacillus bulgaricus and non-proteolytic Streptococcus thermophilus as the former releases free amino acids and peptides as a nitrogen source, while the latter supplies growth factors such as pyruvic acid, folic acid, formic acid, and carbon dioxide [2]. L. bulgaricus and S. thermophilus are used in yogurt as starter cultures [3].

The fermentation time determines the acidity level of yogurt. Longer fermentation produces highly acidic yogurt [4]. A low sugar content in plant milk embarrasses acid production by carboxylic acid bacteria, which requires sucrose addition. Stabilizers and gelling agents are used to improve yogurt texture and creaminess, mostly pectin, starch, gelatin, and gums. They turn into a gel when heated in the presence of liquid. They are widely utilized in jams and jellies [5]. Proper heat treatment of plant-based milk is important before fermentation for starch to gelatinize. It increases the viscosity of yogurt and helps prevent phase separation. In addition, it decreases the quantity of endogenous microbes before starter inoculation [1].

Coconut milk has a milky white color. Its nutritional content includes fat, ash, water, carbohydrate, protein, and their derivatives. The effectiveness of extraction and the composition of coconut milk rely on the processing parameters such as temperature of added water and pressing conditions. The fat content also plays an important role in the flow properties of milk [6]. According to the National Centre for Biotechnology Information, lauric acid has antifungal and antiviral properties which fight against many human diseases. Lauric acid also reduces cholesterol and triglycerides, which is helpful in treating cardiovascular diseases [7].

Oat grains are a rich source of beta-glucan, a dietary soluble fiber. They have a 5–9% lipid content and are rich in polyunsaturated fatty acids, including linoleic acid, an essential fatty acid. In addition, oats contain avenanthramide, an antioxidant, as well as tocotrienols and tocopherols, vitamin E-like compounds. Oats have cardiovascular benefits due to their cholesterol-reducing properties. They have a high content of starch (60%), protein (11–15%), and lipids (5–9%). Their essential amino acids include oleic acid (45.60 g/kg), linoleic acid (36.2–40.4%), and linolenic acid (38.4–41.6%). Thus, oats milk plays a key role in competing with numerous substitutes of dairy milk in the continuously expanding market of dairy and non-dairy products [8].

Peanut milk and its products have high dietary benefits for all age groups due to a high content of protein, essential fatty acids (linoleic and oleic acids), and minerals. Peanut milk also contains hexanal, an important component responsible for its undesirable beany flavor which is entirely eliminated by fermentation or cooking. The stability of peanut milk and its products is highly enhanced by heating at 66–87°C for about 15–20 min and homogenization. This increase in stability is caused by the solubility of proteins [9].

We aimed to formulate a plant-based yogurt, optimize its ingredients and process conditions, as well as analyze its physicochemical, rheological, and nutritive qualities.

STUDY OBJECTS AND METHODS

Raw peanut, coconut, and oats were procured from the local market in Erode, India. We used the Vegan Greek Yogurt Starter Culture (Alla’s Posh Flavors, Uttar Pradesh, India) that contained live cultures of Lactobacillus bulgaricus and Streptococcus thermophilus stored in a freezer at –18°C. Xanthan gum, pectin, and corn starch were of the Urban Platter brands.

Peanut milk was prepared by immersing raw peanuts in potable water for about 8–10 h at room temperature. Then, the soaked peanuts were blended using a food processor with an adequate amount of water and filtered with cheesecloth/muslin or a strainer. The supernatant was collected.

Coconut milk was prepared from fresh and matured coconut endosperm which was cut into pieces and blended using a food processor with an adequate amount of water and filtered with cheesecloth/muslin or a strainer. The supernatant was collected.

Oats milk was prepared by soaking freshly bought oats in water for about 30 min until they absorbed enough moisture for milk extraction. Then, they were blended and filtered using cheesecloth/muslin. The milk was extracted by ensuring enough beta-glucan was present in the supernatant.

To prepare a cow milk yogurt alternative, the milk samples were pasteurized at an optimum temperature of 72°C for 20 min by a double boiling method to avoid gelatinization. This method uses the steam from the simmering water to warm the milk in the bowl gently with indirect heat. Then, the milk was cooled to 45°C. The starter cultures (L. bulgaricus and S. thermophilus) were added as 0.4% of the milk mixture weight. After inoculation, 10% of sucrose was added to the milk mixture to optimize the growth of lactic acid bacteria. To strengthen the gel network of the yogurt, we added corn starch (5%) at above 60°C, xanthan gum (0.15%) at above 70°C under continuous stirring, and pectin (0.75%) at above 25°C. The milk was incubated at 41°C for 18 h to maintain the humidity and temperature in favorable conditions for the growth of microorganisms. The formed yogurt was cooled to a room temperature of 27°C and stored in a refrigerator at 4°C for 1 h.

The physiochemical properties of the yogurt were analyzed using the AOAC method, 1995. They included pH, titratable acidity, moisture content, total solids, fat, ash, protein, and carbohydrates.

Viscosity was measured using a Brookfield DV-III Ultra rheometer, with a CPE 40 spindle. The samples were measured at different RPM at different shear rates. Particularly, we measured the shear rate, shear stress, viscosity, and torque. The shear rate was kept constant for all the trials to measure changes in viscosity.

The flow behavior was determined by plotting the shear rate versus viscosity and the n-value was determined from the power equation. The power equation was generated by a power line in a trendline model graph. The n-value was determined from the negative power value in the equation. The n-value was estimated to be less than 1 to determine the flow behavior of the yogurt [10].

The centrifugal acceleration test was performed to determine the syneresis rate of the yogurt. In a test tube, 5 g of a yogurt sample was placed and centrifuged at 1.200×g for 0, 3, 6, 9, 12, and 15 min at room temperature. To estimate the initial syneresis rate, the volume of the serum separated from the samples was measured at each time interval, which was expressed as milliliters of serum released per gram of sample per unit of time. To evaluate the syneresis rate for that day, the average of 5 tests (except 0) was calculated [11].

The cups containing 100 mL of a yogurt sample at 10°C were provided for sensory analysis. Each sample was assessed in three repetitions for flavor, texture, appearance, color, and overall acceptability on a nine-point hedonic scale, where 1 = the least/lowest; 9 = the most/highest. The panelists were trained about the sensory attributes before the sensory analysis.

Design Expert software (version 13.0) was used to optimize the development of a plant-based yogurt. The response surface methodology (RSM) explored the relationship between explanatory variables and one or more response variables. The mixture simplex-lattice design was used to find the optimum combination of constituents in the range between 5 and 10. The values of sugars and stabilizers were taken as constant. Time and temperature of incubation were also taken as constant for improved product quality. The mixture consisted of peanut milk, coconut milk, and oats milk in 14 combinations (Table 1).

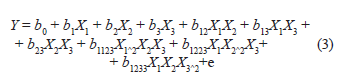

Statistical and data analysis. To represent the fitted response value, the linear, special cubic, and special quartic models (Eqs. (1) – (3)) were used. To make predictions about the response for given levels of each factor, the equations could be used in terms of coded factors. The statistical significance of each equation was determined by variance analysis (ANOVA).

![]()

![]()

For Simple Quartic, X1, X2 and X3 are the proportions of each number grade; b0 is the constant, b1, b2 and b3 are the coefficients of linear terms; b12, b13 and b23 are the coefficients of two-term interactions; b1123, b1223 and b1233 are the coefficients of special three-term interactions.

RESULTS AND DISCUSSION

Fitting for the best model. Table 2 shows the results of mixture design studies. The independent and dependent variables were fitted to linear, cubic, and special quartic models and the residuals plots were formulated to check the goodness of model fit. Low standard deviation, low predicted sum of squares, and high predicted R-squared were the parameters for the best model [13]. The linear model was found to be best fitted for sensory analysis and viscosity. The special cubic model was best fitted for the response flow behavior. The special quartic model was found to be best fitted for syneresis.

The linear and the quadratic models were used to relate the response to the operating factors of the experiment design. The fit of the polynomial models was analyzed using the coefficient of determination R2 and the adjusted R2, with statistical significance tested by the F-test. A large value specified that variations in the response could be revealed by the regression equation. To point out the statistical significance, the desired larger F-value was tested by the P-value. The model that showed a confidence interval greater than 95% (prob > [t] < 0.05) by the probability test was regarded as statistically significant. The Prob > F-value for the linear model was less than 0.0032 R2 and the adjusted R2 was found to have a maximum of 0.6474 and 0.5833, respectively. Although the cubic model was found to be aliased, the linear model was selected for further analysis of viscosity.

The ANOVA results for the model fitted for viscosity are shown in Table 3. As we can see, the linear effects of coconut (X3), oats (X1), and peanut (X2) milk on the yogurt viscosity were found to be significant. Considering the significant factors, equation (4) represents the model developed for viscosity.

![]()

The interaction effect of the process parameters was studied using response surface plots, which helped predict the optimal levels of each parameter to achieve maximum viscosity. Figure 1a shows the influence of three parameters on viscosity. According to Table 2, runs 5, 9, and 14 show greater viscosity. This means that viscosity increased with an increase in peanut and oats milk, but decreased with an increase in coconut milk.

The optimum region was determined by setting the maximum viscosity as the goal. In a study by Ye et al., the increase in viscosity was due to a higher protein content in peanut and oats milk [14]. Brückner- Gühmann et al. suggested that due to a high content of protein, oats could be used as a plant-based gelling agent even at temperatures below the temperature of denaturation [15]. The addition of pectin and xanthan gum also influenced the viscosity range. Figure 1b shows that viscosity ranged from 48.000 to 58.000 P.

Our results showed that peanut and oats milk, as well as stabilizers, had a greater effect on the viscosity of the plant-based yogurt than other components, such as coconut milk or sucrose.

The cubic model was used to relate the response to the operating factors of the experiment design. The fit of the polynomial models was analyzed using the coefficient of determination R2, the adjusted R2, with statistical significance tested by the F-test. A large value specified that response variations could be revealed by the regression equation. To point out the statistical significance, the desired larger F-value was tested by the P-value. The model that showed a confidence interval greater than 95% (prob > [t] < 0.05) by the probability test was regarded as statistically significant. The Prob > F-value for the special cubic model was less than 0.0135 R2 and the adjusted R2 was found to have a maximum of 0.8467 and 0.7154, respectively. The cubic model was selected for further analysis of flow behavior.

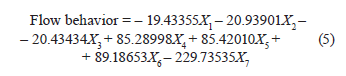

The ANOVA results for the model fitted for the flow behavior are shown in Table 4. As can be seen, the cubic effects of coconut (X3), oats (X1), and peanut (X2) milk on the flow behavior were found to be significant. Considering the significant factors, equation (5) represents the model developed for the flow behavior.

where X4= oats milk + peanut milk, X5 = oats milk + + coconut milk, X6 = peanut milk + coconut milk, X7 = oats milk + peanut milk + coconut milk.

The interaction effect of the process parameters was studied using response surface plots, which helped to predict the optimal levels of each parameter for achieving maximum flow behavior. Figure 2a shows the influence of three parameters on the flow behavior. The flow behavior depends on viscosity and the shear rate. This was determined by the power law model. The power law does not consider yield stress since it is a non-Newtonian fluid model. The relationship between viscosity and the shear rate in the power law model is defined as η = mγn–1, where η is apparent viscosity, γ is the shear rate, and m and n are the power law constants [16].

Figure 2b shows that the n-value of the flow behavior ranged from 0 to 0.14. Yogurt is a thixotropic fluid with n < 1, where n is the flow behavior index (dimensionless) indicating the non-Newtonian or Newtonian character. According to Ghica et al., n < 1 determines a non- Newtonian pseudo plastic fluid, n > 1 determines a non-Newtonian dilatant fluid, and n = 1 determines a Newtonian fluid [10]. Table 2 shows changes in the flow behavior with respect to viscosity and the composition of milk. The lesser the viscosity, the greater the flow behavior. This was due to the influence of stabilizers and the composition of milk.

The linear model was used to relate the response to the operating factors of the experiment design. The fit of the polynomial models was analyzed using the coefficient of determination R2 and the adjusted R2, with statistical significance tested by the F-test. A large value specified that variations in the response could be revealed by the regression equation. To point out the statistical significance, the desired larger F-value was tested by the P-value. The model with a confidence interval greater than 95% (prob > [t] < 0.05) by the probability test was regarded as statistically significant. The Prob > F-value for the linear model was less than 0.0001 R2 and the adjusted R2 was found to have a maximum of 0.9222 and 0.9080, respectively. Although the cubic model was found to be aliased, the linear model was selected for further analysis of sensory evaluation.

The ANOVA results for the model fitted for sensory evaluation are shown in Table 5. As we can see, the linear effects of coconut (i>X3), oats (i>X1), and peanut (i>X2) milk were found to be significant on sensory attributes. Considering the significant factors, equation (6) represents the model developed for sensory evaluation.

![]()

The interaction effect of the process parameters was studied using response surface plots, which helped predict the optimal levels of each parameter to achieve maximum sensory values. Figure 3a shows the influence of three parameters on sensory evaluation. We found a decrease in sensory values with higher contents of peanut milk. However, higher contents of coconut and oats milk provided maximum sensory values. This was due to the nutty flavor of peanut producing off-flavor.

Ye et al. noted that the application of flavoring agents improved the sensory and overall acceptability of peanut milk-based yogurt [14]. This confirmed earlier reports that adding flavoring agents and fruits to yogurt increased the product range, as well as consumers’ liking of the product [17].

Figure 3b shows that the overall acceptance ranged from 6 to 8. According to Table 2, runs 1, 6, and 13 showed higher sensory values in the formulations with a lower quantity of peanut milk compared to oats and coconut milk. Therefore, the flavor problem in peanut milk yogurt could be corrected or improved by applying commercial flavoring agents.

The simple cubic and quadratic models were used to relate the response to the operating factors of the experiment design. The fit of the polynomial models was analyzed using the coefficient of determination R2 and the adjusted R2, with statistical significance tested by the F-test. A large value specified that variations in the response could be revealed by the regression equation. The P-value was used to test whether F-value was large enough to point out statistical significance. The model with a confidence interval greater than 95% (prob > [t] < 0.05) by the probability test was regarded as statistically significant. The Prob > F-value for the special quartic model was less than 0.0300 R2 and the adjusted R2 was found to have a maximum of 0.9083 and 0.7616, respectively. Although the cubic model was found to be aliased, the special quartic model was selected for further analysis of syneresis.

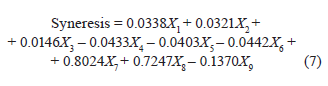

The ANOVA results for the model fitted for syneresis are shown in Table 6. As can be seen, the quartic effects of coconut (i>X3), oats (i>X1), and peanut (i>X2) milk were found to be significant on syneresis. Considering the significant factors, equation (7) represents the model developed for syneresis.

where X4 = oats milk + peanut milk, X5 = oats milk + coconut milk, X6 = peanut milk + coconut milk, X7 = oats milk2 + peanut milk + coconut milk, X8 = oats milk + peanut milk2 + coconut milk, X9= oats milk + peanut milk + coconut milk2.

The interaction effects of the process parameters were studied using response surface plots, which helped predict the optimal levels of each parameter to achieve minimum syneresis rate values. Figure 4a shows the influence of three parameters on syneresis. We found that syneresis was minimum when viscosity was maximum, i.e., syneresis decreased as viscosity increased. Figure 4b represents the syneresis values ranging from 0.01 to 0.04.

According to Table 2, runs 4, 5, 9, and 14 had minimum syneresis with maximum viscosity values. This was due to the binding of molecules in higher viscosity that holds the water during syneresis. In a study by Dönmez et al., the interaction with casein micelles in conventional yogurt influenced the strength of the casein network and the stabilized yogurt structure, increasing the consistency by reducing the syneresis rate at certain concentrations [18]. The syneresis value also depends on the composition of the stabilizers used.

Optimization of component proportion. We solved the equations to yield the average values of each independent variable in order to obtain the optimal yogurt. This allowed us to find a desirable combination of oats, coconut, and peanut milk (Table 7). Then, we analyzed the optimized yogurt for viscosity, sensory evaluation, flow behavior, and syneresis rate. The optimized yogurt consisted of 7.134 mL of peanut milk, 10 mL of oats milk, and 7.866 mL of coconut milk. Its predicted values of syneresis, viscosity, flow behavior, and sensory evaluation were 0.0138081, 53.4733, 0.0648189, and 7.20565, respectively, with a desirability value of 0.717.

Physiochemical analysis of raw milk and optimized yogurt. The optimized plant-based yogurt and raw milk were exposed to nutritional analysis to compare the predicted and actual values (Table 8). This ensured adequate nutritional values in the developed yogurt.

CONCLUSION

Our results showed the effectiveness of the mixture simplex-lattice design approach for optimizing yogurt based on plant milk. According to our experimental results and counter plots, an increase in peanut and oats milk improved the viscosity and reduced the flow behavior and syneresis rate. The samples with higher contents of peanut milk received low sensory values. This indicates that peanut milk has to be used in minimum amounts with stabilizers, such as corn starch, pectin, and xanthan gum, to ensure optimum texture properties. The plant-based yogurt with an optimized composition was found to have high sensorial acceptance. The physiochemical analysis of raw milk and the optimized yogurt showed adequate amounts of nutrients.Contribution

The authors were equally involved in the writing of the manuscript and are equally responsible for any potential plagiarism.CONFLICTS OF INTEREST

The authors declare no conflict of interest.ACKNOWLEDGEMENTS

We thank the management of Kongu Engineering College, Perundurai, Erode, India for their support with our work.REFERENCES

- Montemurro M, Pontonio E, Coda R, Rizzello CG. Plant-based alternatives to yogurt: State-of-the-art and perspectives of new biotechnological challenges. Foods. 2021;10(2). https://doi.org/10.3390/foods10020316

- Tangyu M, Muller J, Bolten CJ, Wittmann C. Fermentation of plant-based milk alternatives for improved flavour and nutritional value. Applied Microbiology and Biotechnology. 2019;103(23–24):9263–9275. https://doi.org/10.1007/s00253-019-10175-9

- Irkin R, Eren UV. A research about viable Lactobacillus bulgaricus and Streptococcus thermophilus numbers in the market yoghurts. World Journal of Dairy and Food Sciences. 2008;3(1):25–28.

- Trachoo N. Yogurt: The fermented milk. Songklanakarin Journal of Science and Technology. 2002;24(4):727–738.

- Arioui F, Ait Saada D, Cheriguene A. Physicochemical and sensory quality of yogurt incorporated with pectin from peel of Citrus sinensis. Food Science and Nutrition. 2017;5(2):358–364. https://doi.org/10.1002/fsn3.400

- Alyaqoubi S, Abdullah A, Samudi M, Abdullah N, Addai ZR, Musa KH. Study of antioxidant activity and physicochemical properties of coconut milk (Pati santan) in Malaysia. Journal of Chemical and Pharmaceutical Research. 2015;7(4):967–973.

- Patil U, Benjakul S. Coconut milk and coconut oil: Their manufacture associated with protein functionality. Journal of Food Science. 2018;83(8):2019–2027. https://doi.org/10.1111/1750-3841.14223

- Paul AA, Kumar S, Kumar V, Sharma R. Milk analog: Plant based alternatives to conventional milk, production, potential and health concerns. Critical Reviews in Food Science and Nutrition. 2020;60(18):3005–3023. https://doi.org/10.1080/10408398.2019.1674243

- Diarra K, Nong ZG, Jie C. Peanut milk and peanut milk based products production: A review. Critical Reviews in Food Science and Nutrition. 2005;45(5):405–423. https://doi.org/10.1080/10408390590967685

- Ghica MV, Hîrjău M, Lupuleasa D, Dinu-Pîrvu C-E. Flow and thixotropic parameters for rheological characterization of hydrogels. Molecules. 2016;21(6). https://doi.org/10.3390/molecules21060786

- Dönmez Ö, Mogol BA, Gökmen V. Syneresis and rheological behaviors of set yogurt containing green tea and green coffee powders. Journal of Dairy Science. 2017;100(2):901–907. https://doi.org/10.3168/jds.2016-11262

- Nikzade V, Tehrani MM, Saadatmand-Tarzjan M. Optimization of low-cholesterol–low-fat mayonnaise formulation: Effect of using soy milk and some stabilizer by a mixture design approach. Food Hydrocolloids. 2012;28(2):344–352. https://doi.org/10.1016/j.foodhyd.2011.12.023

- Cornell JA. Experiments with mixtures: Designs, models, and the analysis of mixture data. John Wiley & Sons; 2011. 680 p.

- Ye M, Ren L, Wu Y, Wang Y, Liu Y. Quality characteristics and antioxidant activity of hickory-black soybean yogurt. LWT – Food Science and Technology. 2013;51(1):314–318. https://doi.org/10.1016/j.lwt.2012.09.027

- Brückner-Gühmann M, Kratzsch A, Sozer N, Drusch S. Oat protein as plant-derived gelling agent: Properties and potential of modification. Future Foods. 2021;4. https://doi.org/10.1016/j.fufo.2021.100053

- Pratumwal Y, Limtrakarn W, Muengtaweepongsa S, Phakdeesan P, Duangburong S, Eiamaram P, et al. Whole blood viscosity modeling using power law, Casson, and Carreau Yasuda models integrated with image scanning U-tube viscometer technique. Songklanakarin Journal of Science and Technology. 2017;39(5):625–631. https://doi.org/10.14456/sjst-psu.2017.77

- Mohameed HA, Abu-Jdayil B, Al-Shawabkeh A. Effect of solids concentration on the rheology of labneh (concentrated yogurt) produced from sheep milk. Journal of Food Engineering. 2004;61(3):347–352. https://doi.org/10.1016/S0260-8774(03)00139-0

- Dönmez Ö, Mogol BA, Gökmen V. Syneresis and rheological behaviors of set yogurt containing green tea and green coffee powders. Journal of Dairy Science. 2017;100(2):901–907. https://doi.org/10.3168/jds.2016-11262