Аннотация

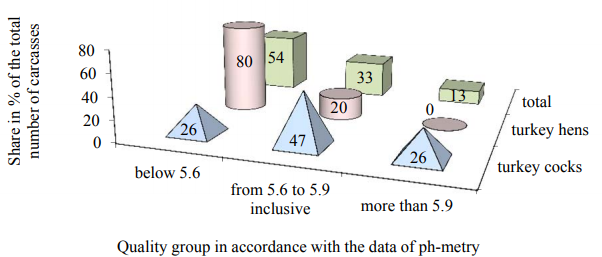

The defects in the quality of the processed meat lead to economic losses of enterprises. With an increase in the share of meat of the turkey sent to the production of meat products, the study of its technological properties becomes an urgent problem. Until now, data on the amount of domestic turkey meat with quality defects have not been collected. In this regard, the pH and microstructure of turkey meat were studied during maturation, which showed that the raw materials that goes through processing had significant quality deviations, which were based on some intravital factors. Thus, the carcasses of turkey cocks with pH20 below 5.6; from 5.6 to 5.9; above 5.9 were, respectively, 26%, 47% and 26% of their total. The carcasses of turkey hens were only divided into two groups: the carcasses with pH20 below 5.6-80%; from 5.6 to 5.9 - only 20%. The histological studies made it possible to describe in detail the nature of autolytic changes in the microstructure of the muscular tissue of pectoral and femoral muscles and confirmed the effect of poultry stress on the formation of technological properties of meat during maturation. The meat of turkey hens, especially pectoral muscles, was most susceptible to the development of quality defects. The presence of overcontraction knots and bands testified to the severity. The study showed that the problem of defects in the quality of turkey meat requires an increase in the responsible attitude towards the compliance with the technologies of poultry pre-slaughtering.Ключевые слова

Turkey meat, recyclability, muscle fibers, destructive changesВВЕДЕНИЕ

With the development of poultry farming in Russia, the enterprises of the meat industry are increasingly using poultry meat to expand the range of products. One of these relatively new types of raw materials for meat processing enterprises today is turkey meat, well known for its dietary properties [1]. However, the technological properties of turkey meat, its suitability for processing and the factors that determine the stability of the quality of this type of raw materials have not been studied sufficiently, as evidenced by the growing number of foreign and Russian publications on this subject [2].

Due to the appeal of enterprises, a scientific study was carried out, the aim of which was, first of all, the overall estimation of the technological suitability of turkey meat for processing in terms of the severity of deviations from the normal development of autolysis, as well as the estimation of the effect of sex and muscle type on the development of quality defects.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

120 carcasses of turkey cocks and 120 carcasses of turkey hens, grown in the Rostov region and brought to slaughter at the age of 6 months, were examined during the study. The poultry was stunned by electric current (the electro-stunning parameters: for turkey cocks – 98 V, 80 Hz, 12–14 s; for turkey hens – 100 V, 80 Hz, 12–14 s). The processed carcasses were randomly selected on a slaughter conveyor after inspection. The hot weight of the carcasses was: turkey cocks – from 13.26 to 18.18 kg, the average weight was 15.95 ± 1.02 kg; turkey hens – from 7.66 to 10.11 kg, the average weight – 8.81 ± 0.52 kg. During selection, the carcasses had a temperature in the thickness of pectoral muscles: turkey cocks – from 40.5 to 42.4°C (the average value is 41.55 ± 0.36°C), turkey hens – from 38.8 to 40.9°C (the average value is 39.50 ± 0.63°C). pH was measured in each carcass: pH20 – in a carcass with a hot weight immediately after slaughter and primary treatment (15–30 min post mortem); pHu – the minimum value during the cooling process and after cooling the carcasses to a temperature of 1 ± 1°C (the ultimate pH for 12 h post mortem) in the pectoral and femoral muscles; pH24 – the value after 24 h post mortem in the pectoral and femoral muscles. pH was measured using a portable pH meter "Testo 205" in the thickness of the muscle tissue at a depth of at least 15 mm from the surface of the muscles. The arithmetic mean of three parallel measurements in different muscle segments was taken as the result of pH measurement, if the discrepancy between the results of parallel measurements did not exceed 0.15 pH units. According to the results of pH measurements, the carcasses were divided into 5 groups (3 groups for turkey cocks and 2 groups for turkey hens), 2 carcasses were randomly selected from each group, of which samples of muscle tissue of pectoral and femoral muscles were isolated for histological examinations in 2, 5, 8 and 24 hours after slaughter.

The microstructure of the samples was studied in accordance with the generally accepted methods (GOST 19496-13). For this purpose, at least 2 pieces of muscle tissue measuring 2.0 x 1.5 x 0.5 cm were taken from each sample. The pieces were placed in a 10% aqueous solution of neutral formalin for 72 hours at room temperature. They were then washed with cold running water for 12 hours. The washed material was put into molds, which were then filled with 12.5%, and then 25% gelatin, and placed in a thermostat at 37°C for 12 and 24 hours for impregnation, respectively. The obtained piece was placed in a freezing chamber of a microtome-cryostat "MIKROM-HM525" (Carl Zeiss, Germany) on a stage. It was frozen at a temperature of –20°C for 15–20 minutes and sections were made with a thickness of 20 μm. The sections were stained with Ehrlich's hematoxylin and additionally with a freshly prepared 1% aqueous-alcoholic eosin solution, then put under cover slips in glycerin-gelatin. The histological specimens were studied and photographed using an AxioImaiger A1 light microscope (Carl Zeiss, Germany) with an x340 magnification using an AxioCam MRc 5 video camera. The images were processed using a computerized image analysis system "AxioVision 4.7.1.0", adapted for histological studies. After 24 hours of autolysis, the muscle tissue of pectoral muscles was characterized by straight or slightly wavy muscle fibers with distinct cross striation, the length of sarcomeres was 2.5–2.7 μm. The boundaries between the fibers were clearly distinguishable, the cores of the fibers took on a rod or oval shape. The destructive changes were detected in the form of microcracks or cross cracks with an integral sarcolemma. The destructive changes in the structure of muscle fibers was characteristic for this stage of maturation of muscle tissue. The samples of muscle tissue of femoral muscles were characterized by less pronounced dynamics of microstructural changes for the same time after the slaughter. Thus, the first signs of post-mortem contraction of muscle fibers were only noted 5 hours after the slaughter of fowl. The muscle fibers took on a wavy or folded shape. As a result of the unstable process of contraction of myofibrils, the longitudinal striation of fibers intensified. The length of sarcomeres was 1.9–2.0 μm. The muscle fibers lay loosely in relation to each other. The muscle tissue was at the initial stage of rigor. 8 hours after the slaughter, the muscle fibers took on a slightly wavy or straight shape. The longitudinal striation was expressed in the bulk of the fibers. The length of sarcomeres decreased to 1.7–1.9 μm. According to the microstructural parameters, muscle tissue was in a state of rigor. After 24 hours of autolysis, the muscle tissue was characterized by straight muscle fibers, the cross striation was distinct, the length of a sarcomere was 2.7–2.9 μm. Separate muscle fibers showed destructive changes in the form of microcracks that indicated post rigor and the beginning of the maturation stage. The STATISTICA program (version 10) was used for the statistical processing of experimental data.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

The carcasses of turkey cocks had the values of pH20 ranging from 5.21 to 6.19, turkey hens – from 5.08 to 5.84. At the same time, there was no correlation between the values of pH20, body weight and body temperature (the correlation test showed that the absolute value of the correlation coefficients was not more than 0.2220). According to the results of pH20 measurement, the selected carcasses were conditionally divided into 3 quality groups (Fig. 1).

The analysis of the obtained carcass division depending on pH20 showed that, among the carcasses of turkey cocks, the proportion of meat presumably with PSE signs (pH from 5.6 to 5.9) was 47%. The rest of the carcasses was equally presented by two quality groups: 26% had pH values below 5.6 and, accordingly, were turkey meat with PSE properties; and 26%, on the contrary, had pH values above 5.9. The latter group of carcasses could be both meat with the signs of DFD, and meat with normal autolysis.

Among the carcasses of turkey hens, there was a different pattern of distribution among the quality groups: the carcasses with the value of pH from 5.6 to 5.9 were only 20%; the carcasses with pH20 below 5.6–80%. The carcasses with pH20 above 5.9 were not detected during the study. This confirmed the fact that turkey hens are more susceptible to stress than turkey cocks [2], and therefore the quality stability and producibility of the meat obtained from turkey hens is lower than the turkey meat obtained from turkey cocks.

Thus, even by measuring pH20 it was found that a significant part of carcasses of turkey cocks and turkey hens had some deviations in the development of autolytic processes, and, consequently, in quality. Moreover, the influence of sex on the autolytic changes in meat was significant: the number of carcasses from turkey cocks with a non-critically low level of pH20 (from 5.6 inclusive and higher) was 3.7 times higher than that from turkey hens (respectively, 47%, + 26% and 20%). In general, of the total number of the studied carcasses, only 13%, according to ph20 measurement, were close to the normal course of autolysis, 33% did not have strongly pronounced deviations from the norm and 54% were meat raw materials with the pronounced properties of PSE, which is hardly suitable for use in meat processing due to low functional and technological properties.

It should be noted that according to foreign literature data [3, 4], in order to achieve the optimal technological characteristics of turkey meat, it is necessary to ensure that the bulk of carcasses (over 85%) should have a pH value not lower than 6.2 and not higher than 6.7 20 minutes after the slaughter. With such pH values, it can be expected 20 minutes after the slaughter that the matured meat will have a pH value from 5.7 to 5.9 inclusive and the best organoleptic and technological characteristics.

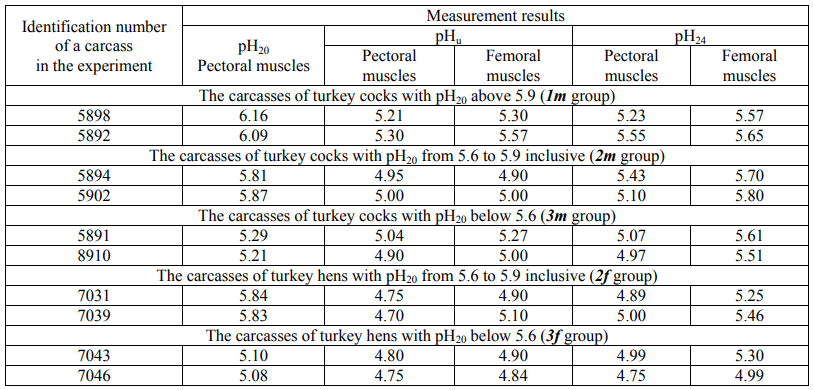

For a histological study, two carcasses from each quality group (10 carcasses in total) were selected. Table 1 shows the data on the determination of pH20, pHu and pH24 for the selected samples.

The results of 24-hour pH measurement in the carcasses of turkey cocks showed that the lowest decrease in pHu in 1m group was recorded 5 hours after slaughter and was 5.2–5.3 for pectoral muscles and 5.3–5.6 for femoral muscles. After 24 hours, there were no significant changes in pH in the pectoral muscles, or there was an insignificant increase in pH (0.13 on average). In the femoral muscles, there was an increase in pH24 in comparison with pHu on average by 0.25. 2m group was characterized by a decrease in the value of pHu to 4.9–5.0 both in the pectoral and femoral muscles. Then the pH24 measurement showed significant differences during the autolysis between the pectoral (5.1–5.4) and femoral (5.7–5.8) muscles. In 3m group, pH20 and pHu remained in the same interval, the upper value of which did not exceed 5.3. Moreover, in the pectoral muscles, the low values of pH remained unchanged after 24 hours, and in the femoral muscles pH24 increased to 5.50–5.65.

The following changes in pH were characteristic of the carcasses of turkey hens of 2f group: during the first 2 hours after the slaughter there was already a sharp decrease and pHu was 4.7–4.8 for pectoral muscles and 4.9–5.1 for femoral muscles; after 24 hours, pH did not increase in pectoral muscles, but it increased to 5.2–5.6 in femoral muscles. 3f group showed the extremely low values of pH for 24 hours, while pH24 was not higher than 5.3 even for femoral muscles.

It should be noted that the pattern of a change in pH that was noted during the study was not typical for turkey meat, and indicated the pronounced effect of intravital stress factors on the course of autolysis [2, 5, 6, 7, 8, 9].

The histological studies of the muscle tissue samples taken in 2, 5, 8 and 24 hours aimed at studying the nature of development of autolytic processes depending on the sex and type of poultry muscles. In this study, two types of muscles were selected: pectoral and femoral muscles as those that contain, respectively, the largest and smallest number of glycolytic "white" muscle fibers. In the samples studied, they were on average 74.6 ± 3.5% and 64.0 ± 2.5%, respectively, in the pectoral and femoral muscles. Such a number was small and was explained by the genetics of fowl (according to the literature data [7], their number is up to 99.8% and 87.5% in pectoral muscles).

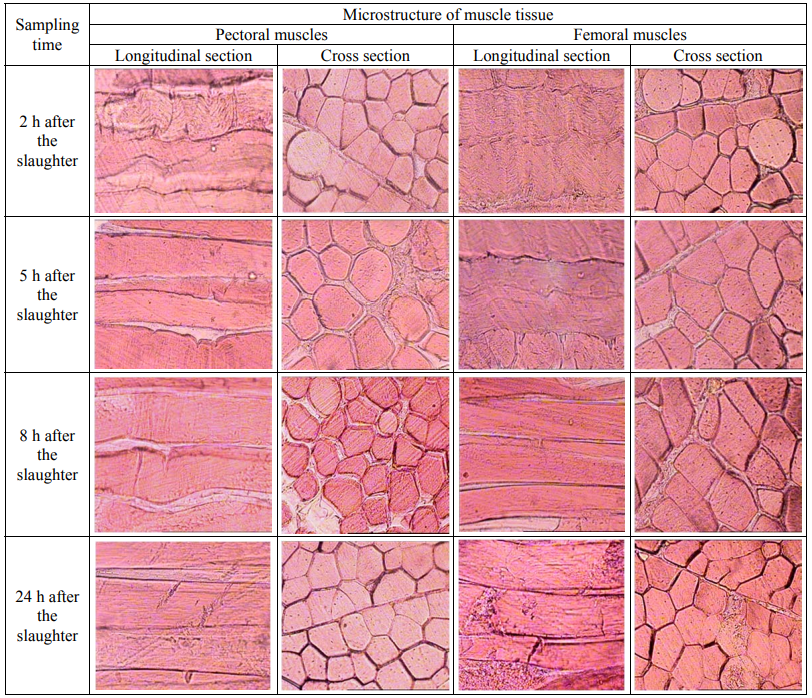

1m group. During the microstructural study of the muscle tissue of pectoral muscles, muscle fibers of a wavy or convoluted shape were noted 2 hours after the slaughter. The boundaries between the fibers were clearly distinguishable. The cores of the fibers had a round or oval shape. The muscle tissue was characterized by fine cross striation. The length of sarcomeres was 1.8–2.0 μm. Separate fibers were characterized by increased longitudinal striation. The cross section of the muscle fibers had a polygonal shape. The connective-tissue layers were wavy. The change in the shape of muscle fibers, the shortening of the length of sarcomeres, the increase in longitudinal striation and the decrease in cross striation of fibers indicated the beginning of post mortem rigor (rigor).

Five hours after the slaughter, the changes characteristic for rigor were detected in the bulk of the fibers. The longitudinal striation increased, the length of sarcomeres decreased to 1.5–1.7 microns. The muscle fibers took on a straight shape due to the uniform contraction of myofibrils throughout the sample. 8 hours after the slaughter, there was some swelling of muscle fibers and an increase in the diameter of a fiber and the length of sarcomeres (1.9–2.2 μm) in muscle tissue. There was a restoration of cross striation and a decrease in longitudinal striation. The noted microstructural changes were characteristic for the post-slaughter resolution stage (postrigor).

After 24 hours of autolysis, the muscle tissue of pectoral muscles was characterized by straight or slightly wavy muscle fibers with distinct cross striation, the length of sarcomeres was 2.5–2.7 μm. The boundaries between the fibers were clearly distinguishable, the cores of the fibers took on a rod or oval shape. The destructive changes were detected in the form of microcracks or cross cracks with an integral sarcolemma. The destructive changes in the structure of muscle fibers was characteristic for this stage of maturation of muscle tissue.

The samples of muscle tissue of femoral muscles were characterized by less pronounced dynamics of microstructural changes for the same time after the slaughter. Thus, the first signs of post-mortem contraction of muscle fibers were only noted 5 hours after the slaughter of fowl. The muscle fibers took on a wavy or folded shape. As a result of the unstable process of contraction of myofibrils, the longitudinal striation of fibers intensified. The length of sarcomeres was 1.9–2.0 μm. The muscle fibers lay loosely in relation to each other. The muscle tissue was at the initial stage of rigor. 8 hours after the slaughter, the muscle fibers took on a slightly wavy or straight shape. The longitudinal striation was expressed in the bulk of the fibers. The length of sarcomeres decreased to 1.7–1.9 μm. According to the microstructural parameters, muscle tissue was in a state of rigor. After 24 hours of autolysis, the muscle tissue was characterized by straight muscle fibers, the cross striation was distinct, the length of a sarcomere was 2.7–2.9 μm. Separate muscle fibers showed destructive changes in the form of microcracks that indicated post rigor and the beginning of the maturation stage.

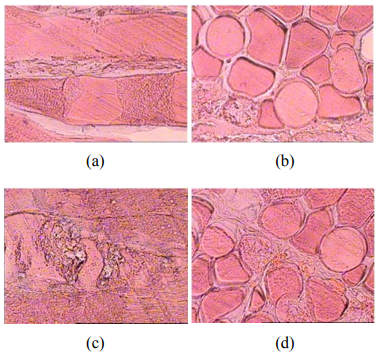

The nature of microstructural changes in the carcasses of 1m group was the closest to the changes that take place during the normal course of autolysis. Table 2 presents the photos that show these changes. However, there were still some separate segments of myofibril overcontraction in the microstructure of muscle tissue samples (mainly in the pectoral muscle of carcass No. 5889), usually found in PSE meat, but their pronouncement was insignificant in comparison with the samples of other groups.

2m group. Two hours after the slaughter, the muscle fibers of pectoral muscles were characterized by a folded or straight shape. The longitudinal striation was distinct, the cross striation was reduced and was not uniform. The length of sarcomeres was 1.6–2.0 μm. The muscle fibers lay loosely in relation to each other. 5 hours after the slaughter, the fibers took on a straight shape, the longitudinal striation was sharply strengthened in the bulk of the fibers, the cross striation was connivent, the length of a sarcomere was 1.3–1.5 μm. In the structure of muscle tissue, separate overcontraction knots of a rectangular shape and cross bands were revealed in varying degrees of pronouncement. The muscle tissue was at the stage of post mortem rigor. 8 hours after the slaughter, the muscle fibers became straight or slightly wavy, the cross striation was restored, the length of sarcomeres was 1.9–2.0 μm, which is typical for the post rigor stage. Twenty-four hours after the slaughter, the muscle fibers had a straight shape, the cross striation was clearly pronounced in the bulk of the fibers, the length of sarcomeres was 2.0–2.5 μm. In the structure of muscle fibers, separate cross cracks were detected, peculiar to the beginning of the maturation stage.

The microstructure of muscle tissue of the femoral muscles 2 hours after the slaughter was characterized by straight or wavy muscle fibers. The cross striation was reduced and was not uniform, the length of sarcomeres was 1.9–2.5 μm. The longitudinal striation was strengthened in the straight-lying fibers. In the structure of the fibers, overcontraction knots of a rectangular shape and cross bands were detected. The muscle tissue was at the initial stage of postmortem contraction. The longitudinal striation increased in 5 hours after the slaughter. The fibers became straight. The cross striation was non-uniform and fine. The muscle fibers lay loosely in relation to each other. The length of sarcomeres was 1.9–2.3 μm. The muscle tissue was at the stage of rigor development. 8 hours after the slaughter, the muscle fibers had a straight shape, the longitudinal striation was pronounced in the bulk of the fibers, the length of sarcomeres decreased to 1.7–2.0. According to the microstructural parameters, muscle tissue was in a state of rigor. 24 hours after the slaughter, the muscle fibers lay in a straight line, the boundaries between them were well pronounced. The cross striation was clearly revealed, the length of sarcomeres was 2.2–2.7 μm. The destructive changes were detected in the form of microcracks and separate cross cracks without the violation of integrity of the sarcolemma.

The microstructure of muscle tissue samples from the carcasses of 2m group was characterized by a more pronounced formation of multiple overcontraction knots both in the pectoral and femoral muscles. According to the results of histological studies, the carcasses of this group were classified as turkey meat with moderately prominent signs of PSE.

3m group. Two hours after the slaughter, the muscle fibers of the pectoral muscles were straight and lay loosely in relation to each other. The nonuniform cross striation was clearly pronounced in the bulk of the fibers, the length of sarcomeres was 1.5 to 2.6 μm. In the structure of muscle tissue, there were multiple homogeneous overcontraction bands or knots characterized by ruptures of myofibrils and sarcolemma in the adjacent segments of the fibers and the destruction of the myofibrillar substance to a fine-grained protein mass. The nuclei in the fibers were well distinguishable.

In the subsequent terms of sampling after the slaughter, the muscle fibers did not change their configuration, the length of sarcomeres did not differ significantly either, which was a characteristic microstructural indicator of meat with a PSE defect. Twenty-four hours after the slaughter, multiple cross cracks were formed in the structure of the muscle fibers, which indicated the maturation of the meat.

In the femoral muscles, the microstructural signs of meat with a PSE defect were less distinct, but there were also multiple overcontraction cross sections with an integral sarcolemma. Two hours after the slaughter, the muscle fibers were characterized by a straight or slightly wavy shape, the cross striation was clearly pronounced, the length of sarcomeres was 2.3–2.7 μm. In the structure of the fibers, overcontraction bands were noted, which remained throughout the entire maturation period. After 5 and 8 hours of autolysis, there was an increase in longitudinal striation in separate muscle fibers, the cross striation was distinct, the length of sarcomeres varied from 2.0 to 2.5 microns. The post rigor stage was observed after 8 hours of autolysis. The signs of the maturation stage were noted 24 hours after the slaughter of the poultry in the form of multiple cross cracks.

According to the results of histological studies, the carcasses of 3m group were classified as turkey meat with the pronounced signs of PSE – the formation of multiple overcontraction bands and knots (in the pectoral and femoral muscles), sarcolemma ruptures in the knot formation segments, the destruction of myofibrils in the segments adjacent to the contraction knots and the dynamics of a change in the length of sarcomeres. Table 3 presents the photos that describe the microstructure of the samples of this group.

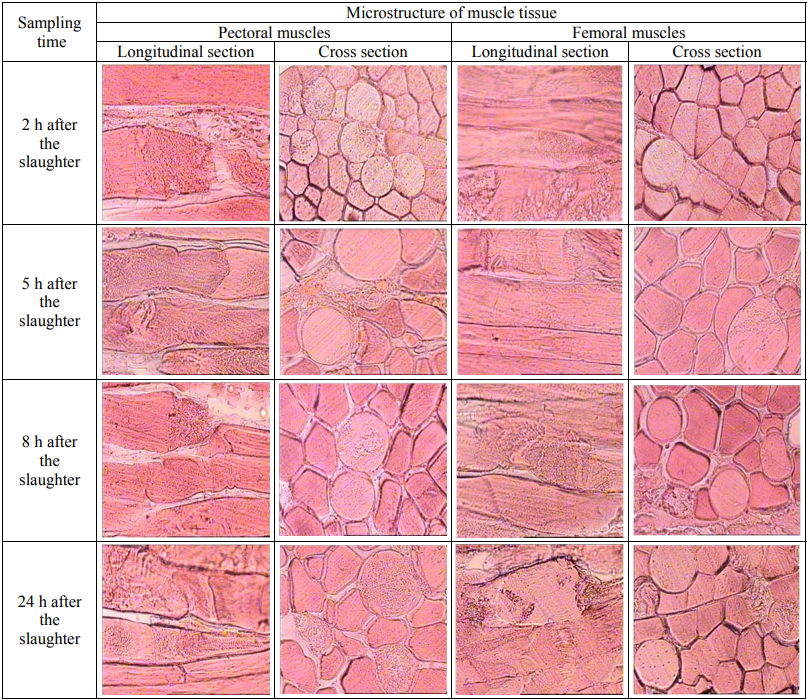

Groups 2f and 3f. The samples of muscle tissue from the carcasses of turkey hens had the same microstructural characteristics as the samples from the carcasses of turkey cocks of the groups 2m and 3m, respectively. However, in turkey hens, the signs of PSE meat and muscle fiber overcontraction were much more pronounced than in turkey cocks (Fig. 2). This fact was consistent with the foreign studies on the effect of turkey sex on the development of quality defects in meat. It is believed that turkey cocks are less susceptible to stress factors than turkey hens.

The microstructural study of the samples from the pectoral muscles of the carcasses of 2f group showed that 5 hours after the slaughter, the muscle fibers were predominantly of a straight shape. The non-uniform longitudinal striation was only in part of the fibers, the cross striation was reduced. The length of sarcomeres was 1.9–2.0 μm. The muscle fibers lay loosely in relation to each other. In some segments, some overcontraction bands or knots of the myofibrillar substance 0.6–0.8 mm in length were revealed without the violation of the integrity of sarcolemma. Muscle fibers of various (round or polygonal) shapes, as well as wavy connective-tissue layers were noted in cross sections. After 24 hours of storage, the muscle fibers took on a straight shape, the cross striation was clearly pronounced in the bulk of the fibers and the length of a sarcomere was 2.0–2.2 μm. In the structure of muscle fibers separate cross cracks were detected, characteristic of the beginning of the maturation stage.

Muscle fibers of a straight or slightly wavy shape were noted in the tissue of femoral muscles 5 hours after the slaughter. The cross striation was distinct. The longitudinal striation was strengthened in separate fibers. The overcontraction segments were mainly found in the form of narrow cross bands or separate rectangular knots without the violation of the integrity of sarcolemma. In 24 hours of autolysis, the muscle fibers took on a straight shape, the cross striation was restored, the longitudinal striation was not pronounced, the length of a sarcomere was 2.0–2.3 μm. The destructive changes that characterized the stage of maturation of muscle tissue were detected in the form of microcracks or cross cracks.

The microstructure of the samples of muscle tissue of the pectoral and femoral muscles of the carcasses of 3f group 5 hours after the slaughter was characterized by straight muscle fibers lying loosely relative to each other, the cross striation was non-uniform and distinct in the bulk of the fibers, the length of sarcomeres varied within a considerable range – from 1.3 to 2.9 μm. In the structure of the muscle tissue, multiple overcontraction knots with the violation of the integrity of sarcolemma, the ruptures of myofibrils in the adjacent segments of the fibers and the destruction of the myofibrillar substance to a fine-grained protein mass were noted. In cross sections, the muscle fibers had in some places a round shape, which was due to the formation of multiple overcontraction knots and bands. The connective-tissue layers were folded or wavy in shape. After 24 h of autolysis, microcracks or cross cracks characteristic of the maturation stage of muscle tissue were detected in separate muscle fibers.

Thus, the turkey meat from 2f and 3f groups was assigned to the meat with pronounced PSE properties, moreover, the presence of strongly pronounced destructive changes in the form of overcontraction knots and bands was especially characteristic for these groups. According to the literature data [10], such segments are formed as a result of conformational changes in actin myofilaments in the area of A-disks (zigzag folding). In this case, myosinous myofilaments diverge and become deformed. In the overcontraction segments, muscle fiber proteins such as myosin, actin, C-protein, tropomyosin, troponin, a-actinin, desmin and other proteins aggregate, forming a densified protein complex. The linear dimensions of sarcomeres decrease by 2–3 times, their diameter increases by nearly the same factor.

Overcontraction bands and knots are a negative factor that has a negative effect on the functional and technological properties of meat raw materials [11]. The presence of multiple overcontraction knots in muscle tissue leads to the rupture of sarcolemma, the denatural changes in proteins and a decrease in their functional properties, in particular, the ability to retain water. The formation of contraction knots and bands in muscle tissue was an additional factor in reducing the hydrophilicity of proteins, since some of the free bonds are used to form a densified protein complex with the aggregation of its structures. At the same time, the moisture that is not bound in the overcontraction segments leaves the muscle fibers through the damaged sarcolemma, and the structure of the densified protein complex is not subjected to any significant changes even in the process of prolonged autolysis.

Since such overcontraction knots and bands are not relaxed in the process of autolysis and also under any technological effects (salting, heat treatment, etc.), their presence adversely affects the formation of the technological properties of meat raw materials during maturation, and then the organoleptic characteristics of the finished product [11].

It should be noted that there were microcolonies of predominantly coccal microorganisms between the fibers, in the segments of sarcolemma rupture and in the connective-tissue layers in all the samples of muscle tissue 5–8 hours after the slaughter. The penetration and spread of microorganisms in the muscle tissue was a consequence of a decrease in the permeability of the intestinal walls as a result of the stress of fowl, as well as destructive changes in the muscle tissue as a result of deviation from the normal development of autolysis.

In recent years, similar defects in the microstructure of muscle tissue in farm animals and poultry (from a partially visually imperceptible change in the structural elements of a muscle fiber in a separate muscle to the deep lysis of muscle cells in an anatomically integral muscle group, manifested dependently or independently of the rate of autolysis) have been associated with the intensification of reproduction, rearing, fattening of animals, as well as other intravital and post-mortem factors, including those with the progressive diseases of muscles in mammals, birds and human [12–16].

On the one hand, the overcontraction of muscle fibers is characteristic of PSE meat and is explained by a distinct reaction to the formation of lactic acid in the process of rapid glycolysis. Overcontraction knots are the histological evidence of the increased stress sensitivity of turkey, especially of female turkey. Overcontraction can be caused by intravital factors – the violation of keeping and fattening technology (myopathy, the violation of calcium metabolism), a breed or stunning conditions [17, 18, 19]. In the presented study such destructive changes were less characteristic for the femoral muscles than for the pectoral muscles. This means that, first of all, it is necessary for the personnel to pay attention to correct fowl pre-slaughtering and the observation of the conditions of its transportation. The observed deviations in the quality of turkey meat are not the norm for this type of raw materials, but are directly related to non-compliance with requirements for fowl pre-slaughter preparation and transportation.

ВЫВОДЫ

The problem of the quality of meat products is complex, as its quality is formed in a living organism that grows and develops according to the biological programs embedded therein that are self-correcting depending on internal and external factors. The deep destructive changes in the structure of muscle tissue are the result of the effect of a whole complex of consequences that are as a result of the intensifications and technological solutions used in specific production conditions on the living organism. Their presence today results in the loss of the quality of meat and meat products, the loss of its functional, technological and consumer properties, and, ultimately, in a decrease in the economic efficiency of livestock product processing.

As shown by the studies carried out, special attention should be paid to the study of the conditions for the formation of quality of the turkey meat obtained as a result of the slaughter of turkey hens, in particular, when the delivery of the thoracic part of the carcass to further processing is of primary interest.

The characteristics of the structure of muscle tissue are of primary importance for the quality and safety of meat and meat products. In the technological practice of output from the raw materials of unstable quality, all the undesirable changes in the structure of muscle tissue are compensated by the use of food supplements and ingredients. Reasonable limitations in the use of food supplements in the production of both functional and traditional meat products should be based on the further study and use of mechanisms of formation, including intravital formation, and the stabilization of meat quality.

СПИСОК ЛИТЕРАТУРЫ

- Gasilina V.A. and Tatarina L.I. Indicies of turkey white and red meat chemical composition in the industrial conditions of Krasnoyarsk region. Bulletin of Krasnoyarsk State Agrarian University, 2010, no. 9, pp. 143-147. (In Russian).

- Lesiów T. and Kijowski J. Impact of PSE and DFD meat on poultry processing - A Review. Polish journal of food and nutrition sciences, 2003, vol. 12/53, no. 2, pp. 3-8.

- Fernandez X., Sante-Lhoutellier V., Baeza E., et al. Effects of the rate of muscle post mortem pH fall on the technological quality of turkey meat. British poultry science, 2002, vol. 43, no. 2, pp. 245-252. DOI: 10.1080/00071660120121463.

- Molette C., Remignon H., and Babile R. Effect of rate of pH fall on turkey breast meat quality. British Poultry Science, 2003, vol. 44, no. 5, p. 787-788.

- Mitchell M.A. and Sandercock D.A. Spontaneous and stress induced myopathies in modern meat birds: a cause for quality and welfare concerns. Proceedings of the Australian Poultry Science Symposium, 2004, pp. 100-107.

- Fedyuk V.V. and Yagodka Yu.V. Influence of pre-slaughter factors on quality of meat of the turkey. Bulletin of Don State Agrarian University, 2016, no. 4-1(22), pp. 42-48. (In Russian).

- Punkt K. Fiber types in skeletal muscles. Series Advances in Anatomy, Embryology and Cell Biology. Springer, Berlin, Heidelberg, 2002, vol. 162. 112 p. DOI: 10.1007/978-3-642-59399-4.

- Fraqueza M.J., Cardoso A.S., Ferreira M.C., and Barreto A.S. Incidence of pectoralis major turkey muscles with light and dark color in a Portuguese slaughterhouse. Poultry Science, 2006, vol. 85, no. 11, pp. 1992-2000. DOI: 10.1093/ps/85.11.1992.

- Opalka J.R., Wicke M., Gellerich F.N., et al. Mitochondrial function in utrkey skeletal muscle--impact on meat quality. British Poultry Science, 2004, vol. 45, no. 3, pp. 367-379. DOI: 10.1080/00071660410001730860.

- Sosnicki A.A. Focal Myonecrosis Effects in Turkey Muscle Tissue. MUSCLE BIOCHEMISTRY. Proceedings of the 46th Reciprocal Meat Conference, 1993, pp. 97-102.

- Çelen M.F., Söğüt B., Zorba Ö., Demirulus H., and Tekeli A. Comparison of normal and PSE turkey breast meat for chemical composition, pH, color, myoglobin, and drip loss. Revista Brasileira de Zootecnia, 2016, vol. 45, no. 8, pр. 441-444. DOI: 10.1590/S1806-92902016000800003.

- Averos A., Martin S., Riu M., et al. Stress response of extensively reared yong bulls being transported to growing - finishing farm under Spanish summer commercial condition. Livestock Science, 2008, vol. 119, pp. 174-182. DOI: 10.1016/j.livsci.2008.04.002.

- Chulayo A.Y., et al. Beef quality and creatin kinase activities as affected by animal - related factors and season. 60 International Congress of Meat Science and Technology. Punta Del Este, Uruguay, 2014. n.p.

- Kalhovde J.M., Jerkovic R., Sefland I., et al. “Fast” and “slow” muscle fibers in hind limb muscles of adult rats regenerate from intestinally different satellite celle. The Journal of Physiology, 2005, vol. 562, no. 3, pp. 847-857. DOI: 10.1113/jphysiol.2004.073684.

- Zyryanova T.Yu. Investigation of molecular mechanisms regulating skeletal muscle fiberphenotype as a theoretical approach of myopathy treatment. Vestnik of saint petersburg university. Medicine, 2014, no. 1, pp. 221-235. (In Russian).

- Khrabrova L.A. Inheritable defects of horses: diagnosis and prevention. Farm Animals, 2014, no. 2, pp. 80-91. (In Russian).

- Boukhris H., Najar T., Damergi C., Samet A. Sensibilite au transport: evolution de la qualite de la viande de dinde - Caracterisation et frequences des viandes PSE. 15èmes Journées Sciences du Muscle et Technologies des Viandes, Clermont-Ferrand, 2014, р. 109-110.

- Medvedskiy V.A. and Medvedeva D.V. Hygienic features of raising turkey males and females for meat. Scientific Notes of Educational Establishment "Vitebsk State Academy of Veterinary Medicine", 2016, vol. 52, no. 3, pp. 144-149. (In Russian).

- Canato M., Scorzito M.,Giacomello M., et al. Massive alterations of sarcoplasmic reticulum free cflcium in skeletal muscle fibres lacking calseqvestrin revealed by genetically encoded probe. Proceedings of the National Academy of Sciences of the United States of America, 2010, vol. 107 (51), pp. 22326-22331. DOI: 10.1073/pnas.1009168108.