Abstract

Fruit powders possess numerous benefits compared to fresh raw materials, i.e., extended shelf-life, convenient transportation and storage, a wide range of applications, etc. Nonetheless, the storage time of fruit powders depends on such factors as storage conditions, packaging, etc.This review suggests a comprehensive analysis of articles, reviews, reports, and books indexed in Scopus, Web of Science, and eLIBRARY.RU, as well as reported at conference proceedings and other scholarly resources in 2005–2022.

Due to their high hygroscopicity, powders tend to absorb moisture from the environment and become prone to caking. Anticaking agents can prevent powders from this process. Different packaging materials also affect the compounds and properties of fruit powders. Accelerated degradation and temperature models can predict shelfp-life. This review featured the effectiveness of different anti-caking agents, as well as the impact of various packaging methods on the storage of powders. Calcium phosphate demonstrated excellent anti-caking properties, reduced hygroscopicity, and enhanced flowability. Aluminum laminated packaging proved effective in protecting powders during storage. As the storage time increased, powders demonstrated only a slight increase in moisture content. Their L* value (light to dark) and b* value (yellow to blue) decreased while the a* value (green to red) and the total color change increased. Caking increased as the flowability, pigment content, and antioxidant content went down.

The review has practical implications for developing new technologies aimed at prolonging the storage time of spray-dried fruit powders.

Keywords

Fruit powder, physico-chemical properties, anti-caking agents, kinetics, packaging, shelf-life, spray-dried productsINTRODUCTION

Stickiness and caking of food powders are one of the most important problems that the modern food industry has to solve [1]. Spray-dried powder has many water-soluble amorphous substances that are prone to caking [2, 3]. Caking can be caused by such factors as inter-particle forces that develop under moisture absorption, increased temperature, or pressure during processing, transportation, and storage [4]. Humidity caking is the most common caking phenomenon that damagees food powder. It usually occurs as bridging, agglomeration, compaction, or liquefaction [5].

Caking happens when amorphous food powders turn into an undesirable sticky material [2]. Anti-caking agents are substances that can prevent caking, clumping, and aggregation of hygroscopic powders by improving their flowability [2, 6]. An anti-caking agent competes with the host powder for moisture and acts as a moisture- protective barrier [5]. Anti-caking agents improve the powder flowability. They inhibit caking by acting as a physical surface barrier between particles. As a result, they increase the glass transition temperature (Tg) of the amorphous phase, thus or creating a moisture-protective barrier on the surface of hygroscopic particles [2]. In addition, anti-caking agents also decrease inter-particle forces and reduce stickiness [6].

Anti-caking agents are extremely important components of food production because they make it possible to obtain non-sticky and free-flowing powders [5]. Calcium phosphate, silicon dioxide, silicates, phosphates, stearic acid salts, and modified carbohydrates resolve the stickiness problem and increase the spray-dried powder yield [7]. Anti-caking agents must be effective at low concentrations, e.g., 3%. As a rule, their allowable concentration is restricted to a very low level [8]. In practice, the percentage of anti-caking agents does not exceed 1% [6, 9].

Packaging means that a product is placed in a protective container or wrapped for storage and transport [10]. Package has a three-fold function: it protects the product against heat, light, moisture, and oxygen, inhibits evaporation, and prevents microbial contamination [11]. The right selection of packaging materials is essential to maintain product quality and freshness during distribution [12]. Packaging materials affect the physicochemical profile and quality of the final product, which the consumer acceptability depends on [13].

Dehydrated fruits serve either as food or ingredients for bakery products, soups, and instant fruit powders. Spray-drying converts fruits into powder, which is a more stable product [14, 15]. Spray-drying can be applied to such exotic fruits as pineapple, papaya, cempedak (Artocarpus integer Thunb), and terung asam (Solanum ferox) [16–20]. Powder requires protection against moisture and oxygen, as well as against the loss of volatile flavorings and color [21]. High humidity and temperature conditions are not favorable for powder storage: powder starts to melt and solidify, thus decreasing in quality [4]. As a consequence, food products lose consumer attraction.

Shelf-life prediction usually relies on the data generated under accelerated storage conditions. The test measures the stability of the product under abusive storage conditions, such as high temperature and humidity [22]. The obtained data then help estimate the shelf-life value [23]. This method is fast and cheap, which makes it advantageous for food product development.

Food powders possess numerous advantages over fresh products: they have a longer shelf-life, they are easy to store and transport, and they have a wide range of application as food ingredients. However, the storage time of food powders depends on storage conditions and packaging. Thus, scientific community needs to improve storage technologies and gather data on storage conditions for food powders.

This research features different types of powders, their storage conditions, and packaging methods, with an emphasis on preventing caking and assessing their impact on the properties of spray-dried powders. The findings may aid in developing long-term storage technologies for spray-dried food powders.

STUDY OBJECTS AND METHODS

The research consisted of an exhaustive analysis that defined the anti-caking capabilities of spray-dried powders. It covered articles, reviews, reports, books, etc. published in Scopus, Web of Science, eLIBRARY.RU, conference proceedings, and other scholarly resources in 2005–2022. Such a protracted period provided a thorough comprehension of the subject matter represented in various studies, discoveries, and improvements in the field of spray-dried powder and its anti-caking properties. As a result, the review included findings and conclusions that were well-informed, reliable, and representative of the current body of knowledge on the subject.

RESULTS AND DISCUSSION

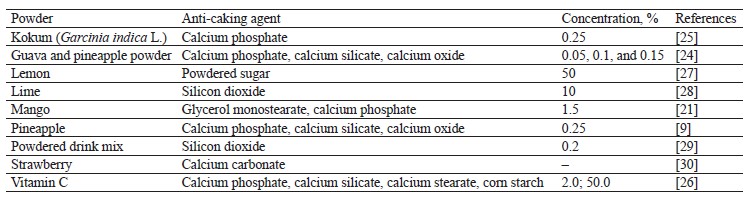

Types of anti-caking agents and their effect on powder properties. Table 1 shows different types of anti-caking agents that are incorporated into fruit powders. Calcium phosphate and calcium silicate proved to be the main anti-caking agents [9, 21]. The percentage range of anti-caking agents in food formulations was 0.05–0.25% [24, 25]. However, Lipasek et al. described some extreme cases when the share of an anti-caking agent was as high as 50% [26].

Fruit powder producers use different anti-caking agents. Pui et al. studied calcium silicate, silicon dioxide, and calcium phosphate incorporated into cempedak powder: 0.66% of calcium phosphate demonstrated the best results in hygroscopicity reduction [31]. On the other hand, Addo et al. reported calcium stearate to be the most effective anti-caking agent in improving the flowability of jujube powder, as compared to magnesium stearate and silicon dioxide [32].

Calcium phosphate. Calcium phosphate (E341) is a calcium salt of phosphoric acid. Its chalky texture makes it a useful free-flowing agent as it can take up to 10% of its weight in moisture [33]. Calcium phosphate inhibits caking in cases when a lot of multiwall bags are stacked on top of each other [34].

Jaya & Das reported the optimal requirement of 0.015 kg calcium phosphate and glycerol monostearate per 1 kg mango solid [7]. The degree of caking decreased when the concentration of the anti-caking agents increased. Calcium phosphate also proved effective in hygroscopicity reduction [7]. Nayak & Rastogi added 0.25% of calcium phosphate to Garcinia indica L. powder, while Phanindrakumar et al. incorporated the same concentration into pineapple powder [9, 25]. Tricalcium phosphate also reduced hygroscopicity in crystalline coconut sugar [35].

Calcium silicate. Calcium silicate (E552) is made from chalk, limestone, or diatomaceous earth. It serves as an anti-caking agent in dry products [8]. Due to its extensive surface area, calcium silicate can draw up quite a lot of moisture [34]. Phanindrakumar et al. incorporated 0.25% of calcium silicate into pineapple powder, while Lipasek et al. used as many as 2% in vitamin C powder [9, 26]. However, other studies reported a much lower concentration of calcium silicate in guava and pineapple powder, namely 0.05–0.15% [24].

Silicon dioxide. Silicon dioxide (E551), also known as silica, is the oxide of silicon. It absorbs water and improves the flowability of dry products [8]. Silicon dioxide is known to attract and soak up moisture in seasoning blends. However, after silicon dioxide reached its moisture limit, it stopped inhibiting moisture caking [34].

Castro et al. applied 0.2% of silicon dioxide to a powder drink mix [29]. Nortuy et al. calculated the optimal percentage of 0.73% silicon dioxide for instant date powder [36]. On the other hand, Rostapour et al. came up with a much higher optimal concentration of 10% for lime powder [28]. The maximal limit of silicon dioxide was 2% because higher doses gave powder a sandy texture [8].

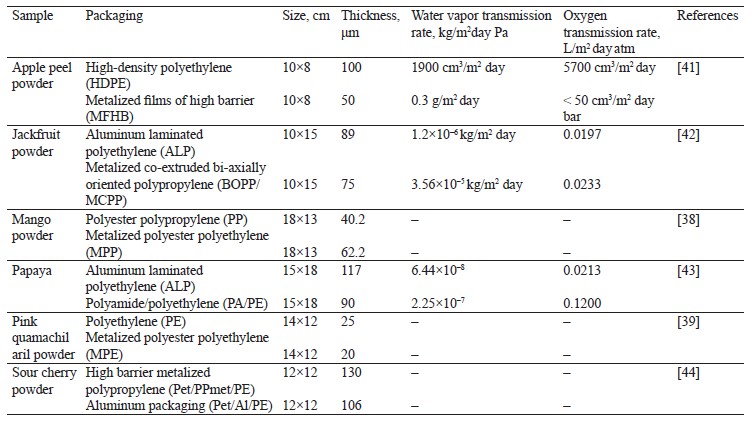

Packaging materials. Table 2 describes different storage packaging materials for different powders. Quite a few popular packaging materials can be applied to food powders, e.g., polyethylene and polypropylene. Pouches with a metalized barrier are another type of powder packaging, e.g., metalized co-extruded bi-axially-oriented polypropylene, metalized polyester polyethylene, and aluminum foil laminated polyethylene [37–40].

New powder packaging materials appear in scientific publications every day. For instance, Kardile et al. used low density polyethylene and coextruded laminated pouches to store instant puran powder [45]. Ding et al. studied black garlic powder stored in polyethylene tetraphtalate bottles, kraft paper bags, and aluminum laminated polyethylene bags [46]. Kuchi et al. determined the quality of Burfi banana packaged in aluminium foil, butter paper, and polyethylene film [47]. Varastegani et al. used low density polyethylene to store Nigella sativa instant beverage powder [48].

The thickness of these packaging is usually 90– 100 μm [40, 41, 43]. However, metalized films of high barrier can be as thin as 50 μm; they are used as packaging for apple peel powder [41]. Rao et al. studied polyethylene and metalized polyester polyethylene with a thickness of 25 and 20 μm, respectively [39].

Aluminum is a good barrier to oxygen, water vapor, and light. Barrier properties can be measured by the oxygen and water vapor permeation [49]. However, the permeability of plastic films to gases and water vapor varies according to the type and thickness of the plastic used [50].

Pua et al. described the high-water vapor transmission rate and oxygen transmission rate of 3.56×10–5 kg/m2 day Pa and 0.0233 L/m2 day atm, respectively [42]. On the other hand, aluminum foil laminated polyethylene had a lower water vapor transmission rate of 1.58× 10–8 kg/m2 day Pa [51]. Udomkum et al. reported oxygen transmission rate value of 0.12 L/m2 day atm for polyamide/polyethylene [43].

Aluminum laminated polyethylene. The barrier properties are the main requirement in choosing a high-performance packaging material. A good packaging material prevents oxygen, water, light, flavor, and grease from entering or leaving the package [49]. Aluminum foil laminates have a wide application in food packaging. Table 2 demonstrates quite clearly that aluminum laminated polyethylene is a better packaging material than aluminum foil laminated polyethylene in terms of water vapor permeability [37, 43, 51].

Powder packed in aluminum laminated polyethylene retains more nutrients and catches less moisture. Yu et al. reported that powder packaged in polyethylene terephthalate pouches gained more moisture than that in aluminum laminated polyethylene pouches [51]. Aluminum laminated polyethylene had a lower water vapor transmission rate than metalized co-extruded biaxially oriented polypropylene.

Pua et al. reported that jackfruit powder packaged in aluminum laminated polyethylene exhibited a lower moisture uptake and had a higher kinetic constant for the total color [42]. In addition, spray-dried bovine colostrum powder packaged in aluminum laminated polyethylene had a longer shelf-life than that packaged in polyethylene terephthalate pouches [51]. Zorić et al. studied marasca powder preserved with laminated packaging [52].

Loo & Pui reported that aluminum laminated polyethylene pouches were more effective than polyethylene terephthalate pouches in retaining moisture content, water solubility, carotenoid content, flowability, and hygroscopicity [53]. Dried carrots packaged in aluminum laminated pouches and stored under refrigerated conditions showed a minimal increase in moisture content, water activity, pH, and sugar. The carrots also retained the highest amounts of carotenoids, total phenolics, and antioxidants [54].

Phahom et al. also reported that aluminum laminated polyethylene was more effective that polyester poly in storing Thunbergia laurifolia L. leaves: it had a smaller decrease in hue angle and a smaller increase in total color difference [55]. Suhag & Nanda studied honey powder stored in aluminum laminated polyethylene [56]. The sample had better antioxidant properties and minimal hygroscopicity as compared to those stored in highdensity polyethylene. According to Barooah et al., spraydried ripe banana powder stored in aluminum laminated polyethylene was sensory acceptable even after one year of storage, while metalized polyester pouches were able to preserve its qualities for three months only [57].

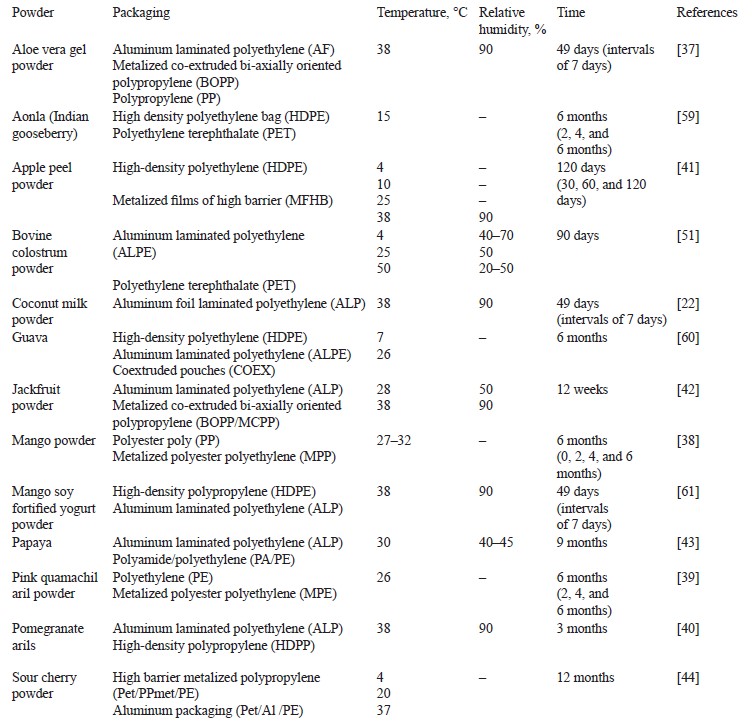

Accelerated storage of powder. Table 3 summarizes the storage conditions for different powders. Accelerated storage tests usually include high relative humidity and temperature. Accelerated storage at 90% relative humidity and 38 ± 1°C can be applied to model moisture adsorption and storage time relationships [58].

Some publications report models that predict variations in food quality and shelf-life, e.g., for aloe vera gel powder and apple peel powder [37, 41, 62]. Kinetic modeling based on the Arrhenius principle relates temperature to shelf-life. For dried products, their shelf-life can be calculated from their critical moisture content [63, 64].

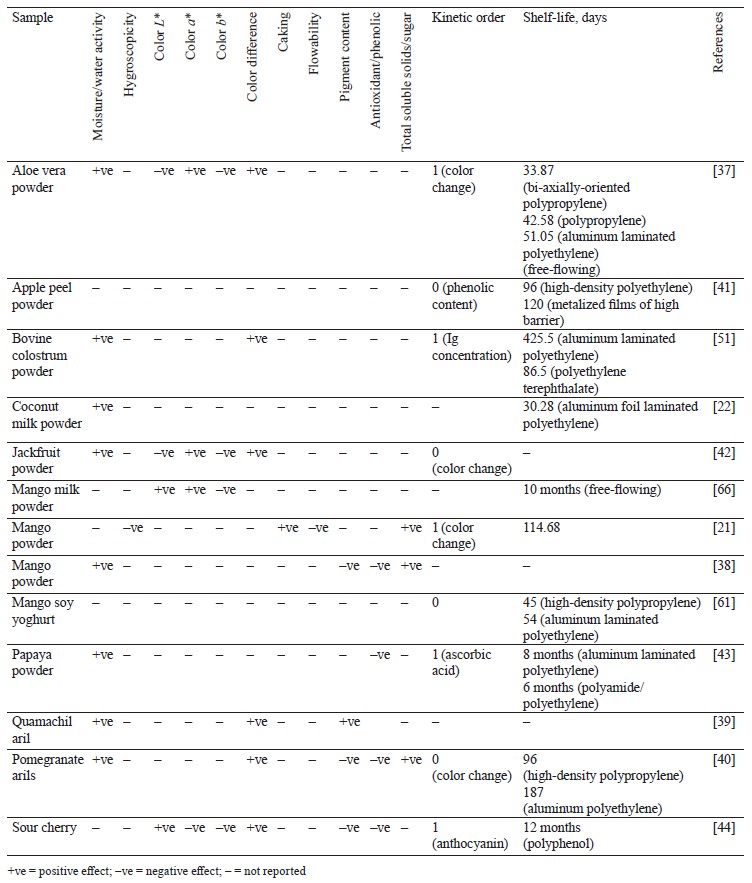

Table 4 illustrates the effects of storage stability on the properties and shelf-life of powders. Generally, the moisture content in packaged powder increases together with storage time. Sornsomboonsuk et al. reported that extended storage under elevated temperature increased the water activity, moisture content, bulk density, and tapped density of bael fruit powder [65]. Apart from storage time, relative humidity, and temperature, the packaging material also affected the moisture gain in jackfruit powder because water vapor migrated from the storage environment into the packaging material [42].

An increased oisture content deteriorates the physical, chemical, and technological properties of the product [67]. Jaya & Das studied mango powder and reported that accelerated storage time decreased the flowability and increased caking [21].

Color is an important attribute as it is the first property noticed by the consumer [68]. Hence, color retention is a predictor of food deterioration rate [69]. Nonenzymatic browning during storage depends on temperature, moisture, water activity, oxygen, and chemical composition [70].

Table 3 shows that total color change increases together with storage period temperature and relative humidity, as well as the type of packaging. Kumar & Mishra studied the total color change in yogurt powder fortified with mango soy and stored under accelerated storage conditions [61]. Packaged powders lost their pigment content and total phenolic content (Table 4) under the effect of temperature, acidity, light, and oxygen exposure caused by the porosity of the packaging.

In addition, a higher moisture uptake eventually leads to degradation of phenolic compounds [71]. Li et al., who studied plum powder, reported that phenolic components were stable for 40 days at room temperature and decreased slightly to 85% after 60 days of storage [72]. Pereira et al. managed to preserve the bioactive compounds in juçara powder for 103 days [73]. Zhang et al. reported that cranberry powder retained its phenolic content after 12 weeks of storage at 25°C [74]. Food quality requires a minimal retention of 50% initial phenolics. Loss of phenolics may result from the excessive gas permeability of the packing material [75].Kinetic modeling is essential to predict food changes during storage [62]. Most studies in Table 4 reported losses in food quality by zero or first-order degradation reaction kinetics [61, 76, 77].

According to Singh, the zero-order rate was useful in describing such reactions as enzymatic degradation, non-enzymic browning, and lipid oxidation, which cause rancidity [77]. On the other hand, food deterioration reactions showing first-order losses indicated vitamin and protein losses, as well as microbial growth.

Syamila et al. reported reaction kinetics and halflife based on carotenoid content for spray-dried spinach powder [78]. Muzzafar & Kumar assessed the storage stability of spray-dried tamarind powder [79]. They found that the color change followed the zero-order reaction kinetics. The zero-order kinetics was also observed for L* and a* parameters, moisture content, ascorbic acid, and total sugar in Khodifad et al., who studied custard apple powder [80]. Similarly, Chang et al. reported that total color difference in soursop powder was also caused by a zero-order kinetic reaction [81].

Different specific models can predict product shelflife [82]. The shelf-life of a food product ends when the product is no longer sensory stable or safe, or when its nutrients have degraded [83]. According to Entrup et al., the actual shelf-life depends on the formulation, processing, packaging, and storage conditions [80].

Table 4 shows that powders packaged in aluminum laminated polyethylene had a longer shelf-life, which ranged from 30.28 to 425.5 days. This shelf-life determination is commonly based on the free-flow properties of the powder. In Ramachandra & Rao, aloe vera powder packaged in aluminum laminated polyethylene had a shelf-life of 51.05 days [37]. However, Kumar & Mishra reported a shelf-life of 54 days for mango soy yogurt powder packaged in aluminum laminated polyethylene [61].

Some powders have a shelf-life of 6–12 months when subjected to lower storage temperature, which is another basis for shelf-life determination, e.g., polyphenol content [44]. Instant puran powder had a predicted shelflife of 13.41 months while the predicted shelf-life for soursop powder was 242 days [45, 85].

CONCLUSION

Prolonged storage time makes powders prone to caking. This review featured various anti-caking agents, e.g., calcium phosphate, calcium stearate, silicon dioxide, etc., in fruit powders, as well as different packaging materials used to preserve spray-dried powders. Aluminum laminated polyethylene, polypropylene, polyethylene, polyethylene terephthalate, and metalized films proved to be the most common packaging materials adopted for spray-dried powders. The review also included storage conditions for different fruit powders, as well as the effects of storage stability on their roperties and shelf-life. Most powders stored in aluminum laminated polyethylene followed zero- or first-order kinetics with predicted powder shelf-life ranging from 51 to 425 days, deding on the storage temperature.

Contribution

All the authors were equally involved in the research analysis and manuscript writing.

CONFLICTS OF INTEREST

The authors declare no conflict of interest regarding the publication of this article.

REFERENCES

- Özkan N, Walisinghe N, Chen XD. Characterization of stickiness and cake formulation in whole and skim milk powders. Journal of Food Engineering. 2002;55(4):293–303. https://doi.org/10.1016/S0260-8774(02)00104-8

- Aguilera JM, del Valle JM, Karel M. Caking phenomena in amorphous food powders. Trends in Food Science and Technology. 1995;6(5):149–155. https://doi.org/10.1016/S0924-2244(00)89023-8

- Hartmann M, Palzer S. Caking of amorphous powders – Material aspects, modelling and applications. Powder Technology. 2011;206(1–2):112–121. https://doi.org/10.1016/j.powtec.2010.04.014

- Rahman MS. Glass transition and state diagram of foods. In: Rahman MS, editor. Handbook of food preservation. Boca Raton: CRC Press; 2007. https://doi.org/10.1201/9781420017373

- Barbosa-Canovas GV, Ortega-Rivas E, Juliano P, Yan H. Food powders. Physical properties, processing, and functionality. New York: Kluwer Academic/Plenum Publishers; 2005. 388 p.

- Peleg M, Hollenbach AM. Flow conditioners and anticaking agents. Food Technology. 1984;38(3):93–102.

- Jaya S, Das H. Effect of maltodextrin, glycerol monostearate and tricalcium phosphate on vacuum dried mango powder properties. Journal of Food Engineering. 2004;63(2):125–134. https://doi.org/10.1016/S0260-8774(03)00135-3

- Code of federal regulations Title 21, Volume 3. Part 172 Subpart E. Food and Drug Administration; 2011.

- Phanindrakumar HS, Radhakrishna K, Mahesh S, Jagannath JS, Bawa AS. Effect of pretreatments and additives on the thermal behavior and hygroscopicity of freeze-dried pineapple juice powder. Journal of Food Processing and Preservation. 2005;29(5–6):307–318. https://doi.org/10.1111/j.1745-4549.2005.00030.x

- Sibley DO. Container for the storage, preservation, identification, tracking and transport of a federally controlled substance. Patent US20160107796A1. 2016.

- Vaclavik VA, Elizabeth WC. Food preservation and processing. In: Vaclavik VA, Christian EW, editors. Essentials of food science. New York: Springer; 2008. pp. 425–446. https://doi.org/10.1007/978-0-387-69940-0_17

- Fellows P, Axtell B. Packaging materials. In: Fellows P, Axtell BL, editors. Appropriate food packaging: Materials and methods for small businesses. ITDG Publishing; 2002. pp. 25–77.

- Ranadheera CS, Evans CA, Adams MC, Baines SK. Production of probiotic ice cream form goat’s milk and effect of packaging materials on product quality. Small Rumin Research. 2013;112(1–3):174–180. https://doi.org/10.1016/j.smallrumres.2012.12.020

- Chew S-C, Tan C-H, Pui L-P, Chong P-N, Gunasekaran B, Lin NK. Encapsulation technologies: A tool for functional foods development. International Journal of Innovative Technology and Exploring Engineering. 2019;8(5S):154–160.

- Pui LP, Saleena LAK. Effects of spray-drying parameters on physicochemical properties of powdered fruits. Foods and Raw Materials. 2022;10(2):235–251. https://doi.org/10.21603/2308-4057-2022-2-533

- Pui LP, Karim R, Yusof YA, Wong CW, Ghazali HM. Optimization of spray-drying parameters for the production of “Cempedak” (Artocarpus integer) fruit powder. Journal of Food Measurement and Characterization. 2020;14:3238–3249. https://doi.org/10.1007/s11694-020-00565-3

- Gopinathan M, Yusof YA, Pui LP. Effects of different drying methods on the physicochemical and antioxidant content of “cempedak” (Artocarpus integer L.) powder. Journal of Food Processing and Preservation. 2020;44(12). https://doi.org/10.1111/jfpp.14966

- Wong CW, Pui LP, Ng JML. Production of spray-dried Sarawak pineapple (Ananas comosus) powder from enzyme liquefied puree. International Food Research Journal. 2015;22(4):1631–1636.

- Chang LS, Tan YL, Pui LP. Production of spray-dried enzyme-liquefied papaya (Carica papaya L.) powder. Brazilian Journal of Food Technology. 2020;23. https://doi.org/10.1590/1981-6723.18119

- Chang LS, Eau Yong SM, Pui LP. Production of Spray-dried “Terung Asam” (Solanum lasiocarpum Dunal) powder. Walailak Journal of Science and Technology. 2021;18(1). https://doi.org/10.48048/wjst.2021.6922

- Jaya S, Das H. Accelerated storage, shelf life and color of mango powder. Journal of Food Processing and Preservation. 2005;29(1):45–62. https://doi.org/10.1111/j.1745-4549.2005.00012.x

- Jena S, Das H. Shelf life prediction of aluminum foil laminated polyethylene packed vacuum dried coconut milk powder. Journal of Food Engineering. 2012;108(1):135–142. https://doi.org/10.1016/j.jfoodeng.2011.06.036

- Hernandez RJ, Giacin JR. Factors affecting permeation, sorption and migration processes in package-product systems. In: Taub IA, Singh RP, editors. Food storage stability. Boca Raton: CRC Press; 1998.

- Moy JH. Vacuum puff freeze-drying of tropical fruit juices. Journal of Food Science. 1971:36(6):906–910. https://doi.org/10.1111/j.1365-2621.1971.tb15557.x

- Nayak CA, Rastogi NK. Effect of selected additives on microencapsulation of anthocyanin by spray drying. Drying Technology. 2010;28(12):1396–1404. https://doi.org/10.1080/07373937.2010.482705

- Lipasek RA, Taylor LS, Mauer LJ. Effects of anticaking agents and relative humidity on the physical and chemical stability of powdered vitamin C. Journal of Food Science. 2011;76(7):C1062–C1074. https://doi.org/10.1111/j.1750-3841.2011.02333.x

- Sharma SK, Kaushal BBL, Sharma PC. Effect of cation exchange resin treatment and addition of anti-caking agent on non-enzymatic browning of lemon juice powder during storage. Journal of Scientific and Industrial Research. 2009;68:611–616.

- Roustapour OR, Hosseinalipour M, Ghobadian B. An experimental investigation of lime juice drying in a pilot plant spray dryer. Drying Technology. 2006;24(2):181–188. https://doi.org/10.1080/07373930600559035

- Castro IA, Motizuki M, Murati H, Chui MC, Silva RSSF. Effect of anticaking agent addition and headspace reduction in the powdered-drink mix sensory stability. Journal of Food Quality. 2006;29(3):203–215. https://doi.org/10.1111/j.1745-4557.2006.00067.x

- Krishnan JR. Development of spray dried strawberry juice powder. Thesis. Malaysia: University Malaysia Pahang; 2008. 89 p.

- Pui LP, Karim R, Yusof YA, Wong CW, Ghazali HM. Anti-caking agent effects on the properties of spray-dried “cempedak” fruit powder. Pertanika Journal of Tropical Agricultural Science. 2020;43(4):621–635. https://doi.org/10.47836/pjtas.43.4.15

- Addo KA, Bi J, Chen Q, Bhandari B, Lyu J, Wu X, et al. Assessment of anticaking agent on caking behavior of jujube amorphous powder via glass transition and state diagram. Food and Bioprocess Technology. 2020;13:1588–1599. https://doi.org/10.1007/s11947-020-02493-y

- Tricalcium phosphate for food formulations [Internet]. [cited 2023 Feb 20]. Available from: https://knowledge.ulprospector.com/297/tricalcium-phosphate-food-formulations

- Tainter DR, Grenis AT. Spices and seasonings: A food technology handbook. New York: John Wiley & Sons; 2001. 256 p.

- Nurhadi B, Sukri N, Saputra RA, Wandhani FI, Nurlita AI. Physical characteristics of amorphous and crystalline coconut sugar powder with the addition of tricalcium phosphate (TCP) as an anticaking agent. International Journal of Food Science. 2020;2020. https://doi.org/10.1155/2020/5320173

- Nortuy N, Suthapakti K, Utama-ang N. Effects of maltodextrin and silicon dioxide added as anticaking agents on the properties of instant date palm (Phoenix dactylifera L.) powder using spray drying. Journal of Advanced Agricultural Technologies. 2018;5(2):86–92. https://doi.org/10.18178/joaat.5.2.86-92

- Ramachandra CT, Rao PS. Shelf-life and colour change kinetics of aloe vera gel powder under accelerated storage in three different packaging materials. Journal of Food Science and Technology. 2011;50(4):747–754. 10.1007/s13197-011-0398-9

- Hymavathi TV, Khader V. Carotene, ascorbic acid and sugar content of vacuum dehydrated ripe mango powders stored in flexible packaging material. Journal of Food Composition and Analysis. 2005;18(2–3):181–192. https://doi.org/10.1016/j.jfca.2004.03.028

- Rao GN, Nagender A, Satyanarayana A, Rao DG. Preparation, chemical composition and storage studies of quamachil (Pithecellobium dulce L.) aril powder. Journal of Food Science and Technology. 2010;48(1):90–95. https://doi.org/10.1007/s13197-010-0135-9

- Dak M, Sagar VR, Jha SK. Shelf-life and kinetics of quality change of dried pomegranate arils in flexible packaging. Food Packaging and Shelf Life. 2014;2(1):1–6. https://doi.org/10.1016/j.fpsl.2014.04.005

- Henríquez C, Córdova A, Lutz M, Saavedra J. Storage stability test of apple peel powder using two packaging materials: High-density polyethylene and metalized films of high barrier. Industrial Crops and Products. 2013;45:121–127. https://doi.org/10.1016/j.indcrop.2012.11.032

- Pua CK, Hamid NSA, Tan CP, Mirhosseini H, Rahman RA, Rusul G. Storage stability of jackfruit (Artocarpus heterophyllus) powder packaged in aluminum laminated polyethylene and metallized co-extruded biaxially oriented polypropylene during storage. Journal of Food Engineering. 2008;89(4):419–428. https://doi.org/10.1016/j.jfoodeng.2008.05.023

- Udomkun P, Nagle M, Argyropoulos D, Mahayothee B, Latif A, Müller J. Compositional and functional dynamics of dried papaya as affected by storage time and packaging material. Food Chemistry. 2016;196:712–719. https://doi.org/10.1016/j.foodchem.2015.09.103

- Zorić Z, Pedisic S, Kovačević DB, Ježek D, Dragović-Uzelac V. Impact of packaging material and storage conditions on polyphenol stability, colour and sensory characteristics of freeze-dried sour cherry (Prunus cerasus var. Marasca). Journal of Food Science and Technology. 2015;53(2):1247–1258. https://doi.org/10.1007/s13197-015-2097-4

- Kardile NB, Nema PK, Kaur BP, Thakre SM. A comparative study of suitability of low-density polyethylene and coextruded laminate pouches for storage stability and shelf life prediction of instant puran powder. Journal of Packaging Technology and Research. 2019;3(3):223–233. https://doi.org/10.1007/s41783-019-00071-y

- Ding Y, Jiang Y, Deng Y, Zhao Y. Effect of packaging materials and storage temperature on water status, mechanical and thermal properties of black garlic. Food Packaging and Shelf Life. 2020;24. https://doi.org/10.1016/j.fpsl.2020.100507

- Kuchi VS, Kabir J, Bouri FK, Gupta R, Dhua RS. Influence of packaging materials on quality of banana burfi during storage. International Journal of Current Microbiology and Applied Sciences. 2017;6(7):118–127. https://doi.org/10.20546/ijcmas.2017.607.014

- Varastegani B, Lubowa M, Teixeira JA, Easa AM. Storage stability of spray dried Nigella sativa (Ranunculaceae family) instant beverage powder: effect of carrier agents on the physicochemical, phenolic compounds and antioxidant properties. Current Research in Nutrition and Food Science. 2019;7(3):648–661. https://doi.org/10.12944/CRNFSJ.7.3.05

- Ebnesajjad S. Plastic films in food packaging: Materials, technology and applications. William Andrew; 2012. 384 p.

- Thompson AK. Controlled atmospheric storage of fruits and vegetables. CAB International; 1998. 278 p.

- Yu H, Zheng Y, Li Y. Shelf life and storage stability of spray-dried bovine colostrum powders under different storage conditions. Journal of Food Science and Technology. 2013;52(2):944–951. https://doi.org/10.1007/s13197-013-1046-3

- Zorić Z, Pelaić Z, Pedisić S, Garofulić IE, Kovačević DB, Dragović-Uzelac V. Effect of storage conditions on phenolic content and antioxidant capacity of spray dried sour cherry powder. LWT – Food Science and Technology. 2017;79:251–259. https://doi.org/10.1016/j.lwt.2017.01.049

- Loo YY, Pui LP. Storage stability of kuini powder in two packaging aluminum laminated polyethylene and polyethylene terephthalate. Malaysian Journal of Analytical Sciences. 2020;24(5):657–669.

- Kumar P, Thakur NS, Sharma KD, Hamid, Thakur A. Effect of type and permeability behaviour of packaging material on the quality characteristics of dried carrot roundels during storage. Current Journal of Applied Science and Technology. 2020;39(7):83–92. https://doi.org/10.9734/cjast/2020/v39i730579

- Phahom T, Kerr WL, Pegg RB, Phoungchandang S. Effect of packaging types and storage conditions on quality aspects of dried Thunbergia laurifolia leaves and degradation kinetics of bioactive compounds. Journal of Food Science and Technology. 2017;54(13):4405–4415. https://doi.org/10.1007/s13197-017-2917-9

- Suhag Y, Nanda V. Degradation kinetics of ascorbic acid in encapsulated spray-dried honey powder packaged in aluminium laminated polyethylene and high-density polyethylene. International Journal of Food Properties. 2017;20(3):645–653. https://doi.org/10.1080/10942912.2016.1174939

- Barooah N, Das P, Barooah MS, Seth DK, Dutta P. Storage studies on spray dried ripe banana powder produced by response surface methodology. International Journal of Current Microbiology and Applied Sciences. 2018;7(6):1922–1933. https://doi.org/10.20546/ijcmas.2018.706.228

- Potter NN. Food Science, 3rd ed. The AVI Publishing Company, Inc.; 1978.

- Sumitha N, Tiwari RB, Patil RA. Suitability of packaging and storage conditions for osmo-air dried aonla segments. Proceedings of the National Academy of Sciences, India Section B: Biological Sciences. 2015;85(1):203–209. https://doi.org/10.1007/s40011-013-0276-5

- Kumar PS, Sagar VR. Effect of packaging materials and storage temperature on quality of osmo-vac dehydrated guava slices during storage. Proceedings of the National Academy of Sciences, India Section B: Biological Sciences. 2016;86(4):869–876. https://doi.org/10.1007/s40011-015-0545-6

- Kumar P, Mishra HN. Storage stability of mango soy fortified yoghurt powder in two different packaging materials: HDPP and ALP. Journal of Food Engineering. 2004;65(4):569–576. https://doi.org/10.1016/j.jfoodeng.2004.02.022

- van Boekel MAJS. Kinetic modeling of food quality: A critical review. Comprehensive Reviews in Food Science and Food Safety. 2008;7(1):144–158. https://doi.org/10.1111/j.1541-4337.2007.00036.x

- Robertson GL. Food quality and indices of failure. In: Robertson GL, editor. Food packaging and shelf life. Boca Raton: CRC Press; 2009. https://doi.org/10.1201/9781420078459

- Labuza TP, Roboh D. Theory and application of Arrhenius kinetics to the prediction of nutrient losses in foods. Food Technology. 1982;36:66–74.

- Sornsomboonsuk S, Junyusen T, Chatchavanthatri N, Moolkaew P, Pamkhuntod N. Evaluation of physicochemical properties of spray dried bael fruit powder during storage. International Journal of Food Engineering. 2019;5(3):209–213. https://doi.org/10.18178/ijfe.5.3.209-213

- Chauhan AK, Patil V. Effect of packaging material on storage ability of mango milk powder and the quality of reconstituted mango milk drink. Powder Technology. 2013;239:86–93. https://doi.org/10.1016/j.powtec.2013.01.055

- Korotkiy IA, Neverov EN, Vladimirov AA, Neverova OA, Proskuryakova LA. Thermophysical characteristics of tropical fruits in milk powder products. Food Processing: Techniques and Technology. 2021;51(2):220–231. (In Russ.). https://doi.org/10.21603/2074-9414-2021-2-220-231

- Saénz M, Buraĉas GT, Boynton GM. Global feature-based attention for motion and color. Vision Research. 2003;43(6):629–637. https://doi.org/10.1016/S0042-6989(02)00595-3

- Shin S, Bhowmik SR. Thermal kinetics of color changes in pea puree. Journal of Food Engineering. 1995;24(1):77–86. https://doi.org/10.1016/0260-8774(94)P1609-2

- Korbel E, Attal E-H, Grabulos J, Lluberas E, Durand N, Morel G, et al. Impact of temperature and water activity on enzymatic and non-enzymatic reactions in reconstituted dried mango model system. European Food Research and Technology. 2013;237:39–46. https://doi.org/10.1007/s00217-013-2026-6

- Sablani SS. Drying of fruits and vegetables: Retention of nutritional/functional quality. Drying Technology. 2006;24(2):123–135. https://doi.org/10.1080/07373930600558904

- Li Y, Tang B, Chen J, Lai P. Microencapsulation of plum (Prunus salicina Lindl.) phenolics by spray drying technology and storage stability. Food Science and Technology. 2018;38(3):530–536. https://doi.org/10.1590/1678-457X.09817

- Pereira DCdS, Beres C, Gomes FdS, Tonon RV, Cabral LMC. Spray drying of juçara pulp aiming to obtain a “pure” powdered pulp without using carrier agents. Drying Technology. 2020:38(9):1175–1185. https://doi.org/10.1080/07373937.2019.1625363

- Zhang J, Zhang C, Chen X, Quek SY. Effect of spray drying on phenolic compounds of cranberry juice and their stability during storage. Journal of Food Engineering. 2020;269. https://doi.org/10.1016/j.jfoodeng.2019.109744

- Sacchetti G, Cocci E, Pinnavaia GG, Mastrocola D, Rosa MD. Influence of processing and storage on the antioxidant activity of apple derivatives. International Journal of Food Science and Technology. 2008;43:797–804. https://doi.org/10.1111/j.1365-2621.2007.01518.x

- Ávila IMLB, Silva CLM. Modelling kinetics of thermal degradation of colour in peach puree. Journal of Food Engineering. 1999;39(2):161–166. https://doi.org/10.1016/S0260-8774(98)00157-5

- Singh RP. Scientific principles of shelf-life evaluation. In: Man CMD, Jones AA, editors. Shelf-life evaluation of foods. New York: Springer; 1994. pp. 3–26. https://doi.org/10.1007/978-1-4615-2095-5_1

- Syamila M, Gedi MA, Briars R, Ayed C, Gray DA. Effect of temperature, oxygen and light on the degradation of β-carotene, lutein and α-tocopherol in spray-dried spinach juice powder during storage. Food Chemistry. 2019;284:188–197. https://doi.org/10.1016/j.foodchem.2019.01.055

- Muzaffar K, Kumar P. Quality assessment and shelflife prediction of spray dried tamarind pulp powder in accelerated environment using two different packaging materials. Journal of Food Measurement and Characterization. 2017;11:265–271. https://doi.org/10.1007/s11694-016-9393-1

- Khodifad BC, Kumar N, Bhatt HG, Vyas DM. Effect of packaging material on colour kinetics and biochemical parameters of custard apple powder during storage. Journal of Packaging Technology and Research. 2018;2:223–232. https://doi.org/10.1007/s41783-018-0040-7

- Chang LS, Karim R, Sabo Mohammed A, Chai KF, Ghazali HM. Moisture sorption isotherm and shelf-life prediction of anticaking agent incorporated spray-dried soursop (Annona muricata L.) powder. Journal of Food Process Engineering. 2019;42(5). https://doi.org/10.1111/jfpe.13134

- Corradini MG, Peleg M. Shelf-life estimation from accelerated storage data. Trends in Food Science and Technology. 2007;18(1):37–47. https://doi.org/10.1016/j.tifs.2006.07.011

- Hough G. Sensory shelflife estimation of food products. Boca Raton: CRC Press; 2010. 264 p. https://doi.org/10.1201/9781420092943

- Lütke Entrup M, Günther H-O, van Beek P, Grunow M, Seiler T. Mixed-Integer Linear Programming approaches to shelf-life-integrated planning and scheduling in yoghurt production. International Journal of Production Research. 2005;43(23):5071–5100. https://doi.org/10.1080/00207540500161068

- Chang LS, Karim R, Abdulkarim SM, Yusof YA, Ghazali HM. Storage stability, color kinetics and morphology of spray-dried soursop (Annona muricata L.) powder: effect of anticaking agents. International Journal of Food Properties. 2018;21(1):1937–1954. https://doi.org/10.1080/10942912.2018.1510836