Аннотация

Along with necessary substances for yeast, wort also contains extraneous impurities and technologically important components that affect the cells adversely. The effect of these compounds on yeast can be mitigated by adding adsorbents and stabilizers into a fermentation medium. In this article, methods of improving brewer’s yeast viability by removing phenols and high-molecular-weight proteins from wort are considered to accelerate the fermentation process and improve the final product quality. Both traditional materials (natural zeolite-containing tuffs from different fields of Siberia) and new ones (carbon-containing fibers and cyclodextrins) were suggested to transform wort composition. It has been revealed that introduction of 5% of zeolites into a mash at 70°C, or filtration of hopped wort through a mineral or carbon fiber layer at 0.10 l/min reduces haze-forming components content by 12-25%. Without significant effect on other characteristics of wort, polyphenols tend to be absorbed more than proteins. Addition of cyclodextrins in amount of 0.1-5.0% (w/v) into wort before fermentation contributes to clathrate formation with proteins and phenolic compounds. The materials used provide favorable conditions for yeast: biomass increases by an average 20%, yeast growth and extract fermentation intensify, and by-products formation decreases. This allowed us to shorten the fermentation process by 1-1.5 days, produce beer with desired organoleptic parameters, and increase its resistance to colloidal hazes formationКлючевые слова

Brewer’s yeast, adsorbents, stabilizers, polyphenols, proteins, fermentation, beerВВЕДЕНИЕ

A culture medium composition has significant effect on both the physiological state of yeast culture and its characteristics, such as yeast growth rate, fermentation activity, flocculating power, and formation of accessory substances [1, 2, 3, 4].

Apart from organic and inorganic compounds needed for yeast, wort may also contain harmful impurities and extraneous substances, such as mycotoxins, pesticides, nitrates, heavy metals, etс. They affect the culture adversely and may come into wort with raw materials (water, malt, hop, or grain unmalted materials), supporting materials, or from equipment [2, 4, 5]. This leads to brewing process breakdown and beer quality reduction. Also, wort contains substances that play a huge role in technology and, at the same time, affect yeast adversely. In particular, they include polyphenols and highmolecular-weight proteins [2, 6].

The role of phenols in beverage manufacturing, including beer, is diversified [2, 3, 6, 7]. On one hand, phenols define color, aroma, flavor, and antioxygenic properties of the product. On the other hand, their excess in beer causes haze formation, insoluble aggregates formation with proteins, and undesired changes in organoleptic properties, such as flavor and color. The important property of plant polyphenols is microorganism growth inhibition – which both extraneous microflora and microorganism cultures need for brewing. This increases the biological stability of finished beer, but has a deleterious effect on the physiological state of yeast, on culture growth, and on the fermentation process. This fact is of special importance for yeast cultures in media with high content of ethanol and extractives. The permeability of cell membranes increases and makes it possible for phenols to penetrate easily into cells with the result that fermentation slows down and yeast viability decreases. An example is high-gravity brewing technology [2, 8, 9].

In a number of cases, wort composition influences yeast mechanically. Insufficient precipitation of cold break which consists of 50% protein from wort at the stage of its clarification and cooling leads to adsorption of cold break by yeast cell walls. This makes the fermentation process complicated. Moreover, some components of the precipitation in cold wort degrade the filterability and colloidal stability of beer [2, 6, 7].

Such factors as long-time storage, incorrect storage, low quality of fermentation medium, and a number of stress factors affect the physiological and biochemical characteristics of yeast culture negatively. It is possible to increase yeast activity both at the inoculum preparation stage and during fermentation, in particular, by adjusting wort composition [1, 10, 11]. Two methods can be used for this: supplementation of the fermentation medium with needed chemical compounds and the removal of components inhibiting the culture.

It is known that removal of polyphenols from the culture medium has a favorable effect on yeast growth, and hence, on the fermentation process. Thorough wort clarification gives the same result. However, removal of more than 35% of polyphenols and 30% of polypeptides leads to degradation of such beer characteristics as foam stability, palate fullness, and taste [6, 7].

Current methods of reducing the number of polyphenols and high-molecular-weight proteins are mainly based on their adsorption at final stages of beer production using specific, expansive agents [2, 3, 6, 7].

The aim of the research was to develop methods of improving brewer’s yeast viability by removing primarily polyphenols from wort using various adsorbents and stabilizers that intensify fermentation and also improve beer quality.

As adsorbents, natural aluminum silicates (zeolitecontaining tuffs) and carbon-containing fibers were used; α-, β- and γ- cyclodextrins were suggested as stabilizing agents.

Natural zeolite-containing tuffs are promising sorbents being used in beverage production to ensure hygienic safety and improve the quality of raw materials, semi-finished, and finished products [5, 12]. Advantages of using these minerals compared to other sorbents are accessible price, availability of extraction, considerable reserves, simplicity of regeneration and utilization, ample possibilities of improvement of properties and processing, and unique properties (ionexchange, adsorption, and molecular-sieve) [5, 13]. All the properties of zeolites may be used in food industry. First of all, they are of interest as naturally-occurring filtering materials and sorbents in brewing for detoxification and improvement in quality of semifinished and finished products [5, 12, 14, 15, 16].

Natural zeolite resources in Russia amount to nearly 4.8 billion tons; more than 20 zeolite deposits are located in Siberia and in the Far East. The largest deposits in Siberia are Pegasskoe (Kemerovo region), Khonguruu (the Sakha Republic), Shivirtuyskoe (Chita region), Kholinskoe (the Buryat Republic), and Sakhaptinskoe and Pashenskoe (Krasnoyarsk Krai) [5, 17, 18].

Precursors for carbon fiber are chemical or organic materials, such as polyacrylonitrile, rayon, and pitch [19, 20]. After heat treatment, carbon fiber composes nearly 99.9% of carbon atoms; hence, it allows us to consider it a graphitized carbon material. Each strand of the fiber is 3–15 microns in diameter.

The variety of the properties of carbon fibers obtained at the present time depends on their structure that, in turn, is dictated by the nature of the precursors, their properties, and processes at different stages of fiber manufacturing. The fibers are characterized by high yield strength in tension, low thermal expansion coefficient, low specific density, high chemical inertness, high thermal resistance, and specific properties. In this connection, carbon fibers are widely used in composite materials fabrication, in electrical and radio engineering industries, for purification of liquids and gases from dispersed impurities, as catalysts in the synthesis of organic and inorganic substances, as a source of drug and biologically active substances in medicine, and as sorbents for purification of blood and other biological fluids, etc. [19–24]. The results of new researches allow the usage of carbon fibers to be expanded.

Cyclodextrins (CDs) are a special type of enzymatically modified starch that belong to nonreducing oligosaccharides. Their reactivity is dictated by the presence of one primary (C6) and two secondary (C2 and C3) hydroxyl groups which can participate in a combination reaction with formation of branched and polymeric forms of CDs, chemically modified CDs, and CDs bound covalently to different matrices [25, 26].

Cyclodextrins and their derivatives are used in pharmaceutical, chemical, food processing industries, and in other industrial fields. Their ability to form complexes with different substances makes it possible to improve tastiness and rheological properties of foods, increase their food value and shelf life, stabilize flavoring agents and biologically active substances, remove unpleasant odors and tastes, enhance vitamin stability and solubility of lipophilic components, prolong the effect of drugs, reduce their harmful effect, purify wastewater from oils and toxic impurities, etc. [25]. However, the field where cyclodextrins are used most is food industry. Mixtures of β- and γ-cyclodextrins are used as a complexing agent to improve taste and aroma of juices, whisky, protein hydrolyzates, to make soft beverage powders, juice powders, in manufacture of bread, baked goods, confectionary products, pastas, in brewing (to stabilize the beer composition), etc. [25–31]. Technologies, at which cyclodextrin complexes are formed during the process, are promising [32].

The given list of natural zeolites, carbon fibers, cyclodextrins properties – mainly, the ability to sorb and bind large organic molecules – makes it possible to consider these materials showing potential for using them in brewing to adjust yeast metabolic activity and, as a consequence of this, to intensify the wort fermentation process and improve the finished beverage quality.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

The subject of the research was lager yeast of the Saccharomyces cerevisiae strain 11.

The hopped wort with the original gravity of 11 and 12% was used as a fermentation medium.

The natural zeolite-containing tuffs of different deposits of Siberia, such as kholinskiy zeolite, shivyrtuin, and pegasin, were used to remove polyphenols and high-molecular-weight nitrogenous compounds from the fermentation medium. The minerals were preliminarily washed off, dried at 120°C, and crushed into particles of 1.2–1.5 mm in size. In addition to tuffs, carbon-containing fiber in the form of non-woven fabric being obtained by pyrolysis of rayon was used as an adsorbent. In order to stabilize wort composition, chemically pure cyclodextrins («Novodex», Ufa, Russia) in the form of a mixture of homologies (α, β, γ) were used.

To study the fermentation process, yeast was added into wort (20x106 cells/ml) taking into account the number of non-viable cells. Fermentation was carried out in an enclosed vessel with a hydraulic lock at the temperature of 6–8°C. Secondary fermentation was carried out at 2–3°C for the time needed for a particular beer.

Solids content, acidity, pH, color, viscosity, bitterness, amino nitrogen, and reducing substances in the wort were determined before and after wort treatment, and during fermentation, as well as by means of widely used standard methods [33].

The ethanol content in fermenting wort was determined by distilling, after which the relative gravity of the distillate was determined. Determination of the diacetyl content was carried out spectrophotometrically using EBC technique [33]. Higher alcohols and acetaldehyde were determined by gas chromatography in the FGBU laboratory «Kemerovo Center of Standardization and Metrology».

The total concentration of polyphenols, anthocyanogens, and high-molecular-proteins were analyzed by photocolorimetry. Jerumanis method [6] based on their reaction with ferric ammonium citrate (III) in alkaline medium was used to determine the total amount of polyphenols. The anthocyanogens content was determined by Steiner-Stocker method in Pfeffer modification [6], being based on changing anthocyanogens to anthocyanidins by treating beer with the mixture of concentrated chlorohydric acid containing ferrum, and butanol. The ability of high-molecular weight proteins to react with tannin in acidic medium was used to calculate the protein A fraction [33]. The finished beer was tested for tendency of chill haze formation by measuring beer haze after 24 hours at 40°C, then at 0°C. The test characterizes the colloidal stability of beer indirectly [6].

The yeast physiology state during growth of the culture was analyzed according to the concentration of suspended cells, the number of budding cells by direct counting method, and the concentration of glycogencontaining cells using Lugol’s iodine solution [34].

The analyses were performed three of four times, and the results were processed statistically.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

At the first stage of the work, the possibility of using zeoilte-containing tuffs to remove components that affect yeast adversely with the aim of intensifying metabolic process of the culture was studied.

Zeolites have unique adsorption and cation-exchange properties due to porous structure and the ability to ion exchange. Sorption properties allow zeolite-containing tuffs to remove polyphenols and high-molecularnitrogenous substances and their compounds from a media. Using tuffs to remove these compounds is possible at various stages of wort production, such as mashing, filtration of mash, boiling of wort with hop, and сlarification of chilled hopped wort.

In the beginning of the research, zeolites were introduced into chilled hopped wort with the original extract of 11%. Wort was filtered through the layer of mineral placed in a column (75 mm in diameter, 230 mm in height). Tuff mass needed to fill column volume was 250 g for pegasin, 245 g for kholinskiy zeolite, and 255 g for shivyrtuin, respectively.

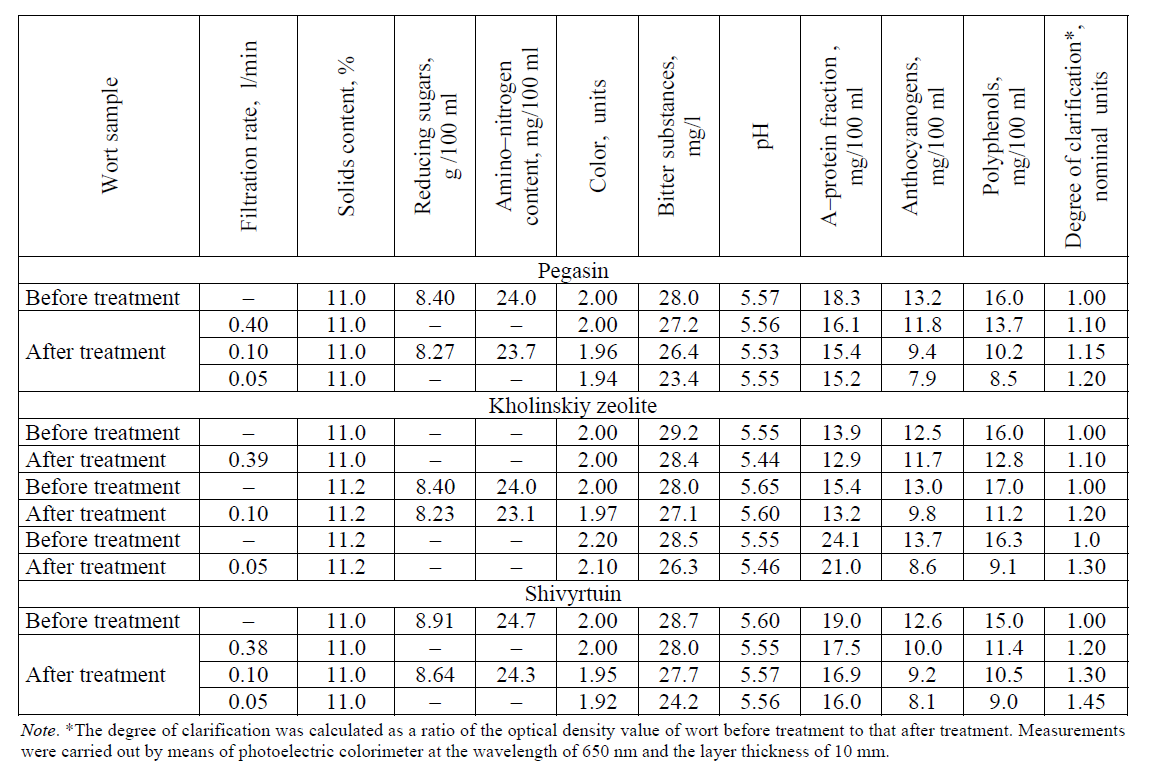

Filtration was carried out at different rates (l/min): 0.05, 0.10, and the maximum, where wort flowed under gravity (0.40 for pegasin, 0.39 for kholinskiy zeolite, and 0.38 for shivyrtuin, respectively). Rate was regulated with a clip; the head of the wort supply into the column was constant. The wort temperature was 8–10°C. The wort volume for filtration was 1 liter; five samples (each of 200 ml) were taken during the filtering and evaluated according to main quality factors. The results are in Table 1.

Filtration of hopped wort through the zeolite layer leads to removal of phenols and polypeptides. The lower the filtration rate, the greater the number of removing substances; however, other characteristics of the medium do not change considerably.

Depending on the mineral used, the minimum filtration rate ensures the reduction of highmolecular-weight proteins amount by 16–21%, polyphenols by 39–51%, and anthocyanogens by 36–40% in comparison to the initial value, while at the maximum rate the number of these components decreases by only 10–12%, 15–37%, and 10–20%, respectively. The filtration rate in the 1.10–0.05 l/min range ensures better clarification of wort as well.

It should be noted the negative effect of zeolites on such important characteristic as bitterness. When filtering wort using tuffs of different deposits, the amount of bitter substances decreases by 2–3% at the maximum filtration rate and by 16% at the minimum rate compared to the initial value.

Among the studied minerals, pegasin and kholinskiy zeolite have demonstrated the highest adsorptive capacity to proteins and polyphenols due to high content of clinoptilolite, which has the sufficient number of active centers acting on large polar molecules [5, 18]. On the other hand, shivyrtuin has a considerable impact on wort clarification; it is because the mineral contains more than 50% of the clay fraction – montmorillonite – which is able to be easily dispersed as extremely small-sized particles in an aqueous medium.

In order to remove the sufficient amount of polypeptides and polyphenols (about 20%), samples of hopped wort were passed through columns filled with the minerals at the rate of 0.10 l/min. Then, the samples obtained were subjected to fermentation. Zeoliteuntreated hopped wort was used as a control sample.

The analysis of the data presented in Table 2 shows that yeast in the study samples grew so rapidly that the maximum number of cells was reached 24 hours sooner than in the control sample. In comparison with the control sample, the greatest increase in biomass was observed in wort treated with pegasin (by 33%) and kholinskiy tuff (by 14%), which contains polyphenols and high–molecular–weight proteins in small amounts.

It should be noted that concentration of suspended yeast in the study samples of green beer by the end of fermentation was lower by a factor of 1.1–1.6 than in the control variant. This fact had a positive effect on the degree of beer clarification and, in a sequel, would allow the service life of filters to be prolonged.

The intensive growth of yeast in study samples led to the increase of fermentation rate of wort by an average of 20% in comparison to the control sample that made it possible to reduce fermentation duration by 24 hours.

Stimulation of yeast metabolic processes has influenced other characteristics of the fermentation medium as well. The study samples of wort are characterized by intensive acid formation and reduction of pH that create favorable conditions for precipitation of proteins and protein–phenolic complexes that, in turn, increase the beverage colloidal stability.

It is seen from table 3 that physical and chemical parameters in finished beer samples changed more significantly than those in the control sample (Table 3). The content of high–molecular–weight proteins and polyphenols in study samples is higher than in the control that indirectly indicates the beer colloidal stability. Beer obtained using tuffs contains less volatile components (which affect taste and favor of beer negatively) than the test.

The revealed dependencies of studied medium parameters from different minerals arise from properties and composition of used tuffs. Tuffs not only reduce the amount of polyphenols in wort but also probably adsorb some other (foreign) components which came from raw materials [5, 12, 17].

In addition, it should be taken into account ion–exchange properties of zeolite–containing tuffs [5, 13, 14, 18]. The minerals differ in content of silicon dioxide, calcium, magnesium, potassium, sodium, iron, and other chemical elements. Potassium and sodium in kholinskiy zeolite and shivyrtuin, and calcium and magnesium in pegasin play a dominant role among exchangeable ions [5, 17, 18]. Consequently, they will take part in ion exchange with ions in the yeast culture medium and have an influence on enzyme activity, yeast growth, and their ability to flocculate which was reflected in the results obtained. In addition to basic elements, cuprum, plumbum, zinc, cobalt, molybdenum, vanadium, strontium, beryllium, and others are presented in the tuffs of different deposits.

Micro– and macro elements in natural minerals are in quite available form. Some minerals perform structural function in a cell while others are able to influence the activity of enzyme system [1, 2, 4].

In particular, magnesium and potassium ions enhance fermentation of maltose and maltotriose and relate to fermentation rate. Calcium and zinc cations which activate many enzymes (especially alcoholic fermentation enzymes), have an effect on yeast growth, prevent the culture from degeneration, and take part in the cell flocculation process [1, 2, 3, 4]. An importance of potassium for reducing oxalate content in wort which increases the beer colloidal stability should be noted [6, 7].

Sodium, along with enzyme activation, plays a significant role in transportation of substances through a cell wall.

Manganese enhances the fermentation activity of yeast and, along with calcium and magnesium cations, stimulates sterol formation [4] which has a positive effect on cell membranes structure and penetration of nutrients into the cell.

Being in small quantities in the fermentation medium, iron and cuprum exert a favorable effect on the yeast budding. Cobalt contributes to better assimilation of proteins by yeast and the increase of culture fermentation activity. As the main structural component of natural zeolites is silicon dioxide, this fact allows us to assume that it has an effect on the mineral composition of the fermentation medium. Silicon is present in yeast cell membranes, accelerates carbohydrate metabolism, contributes to better assimilation of nitrogenous substances by yeast, including amino acids [1, 2, 4].

Thus, removal of endo– and exogenous substances inhibiting the yeast culture by the zeolite–containing tuffs allows us to optimize micro– and macro–elements content in the medium. It can be considered as a means to adjust and improve the mineral composition of semi–processed materials and finished beverages.

The use of zeolites is possible not only at the clarification stage but also in mashing. The latter appears advisable in order to optimize the polyphenols content, high–molecular–weight proteins content, and bitter principles content, and to preserve components necessary for yeast feeding.

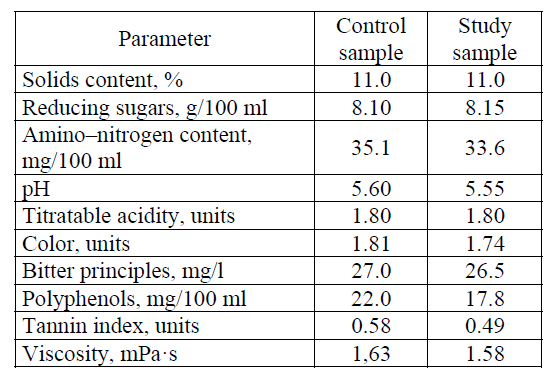

Based on the above, in our research we used pegasin to make wort. For this, infusion mashing using 100% pale malt was used to make wort in laboratory setting. The mineral in the amount of 5% to cereal product mass (the optimum parameters were determined in earlier researches [5]) was added at the saccharification stage at the temperature of 70°C. Wort made without pegasin was used as the control sample. Samples obtained were subjected to hopping under identical conditions. The parameters of study and control samples of hopped cooled wort are presented in Table 4.

It is revealed that the zeolite adsorbs proteins and polyphenols from wort so that their content is by 18% less than in the control sample. Additionally, the study sample had lower viscosity and contained less phenols which affect wort and beer color as well as color index of the medium. The amino nitrogen content also decreases (by 4%). Bitter principles were found to be the same in both of samples.

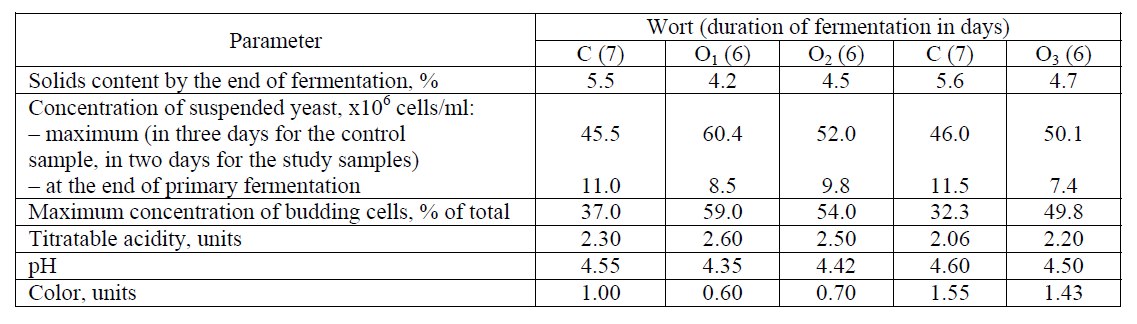

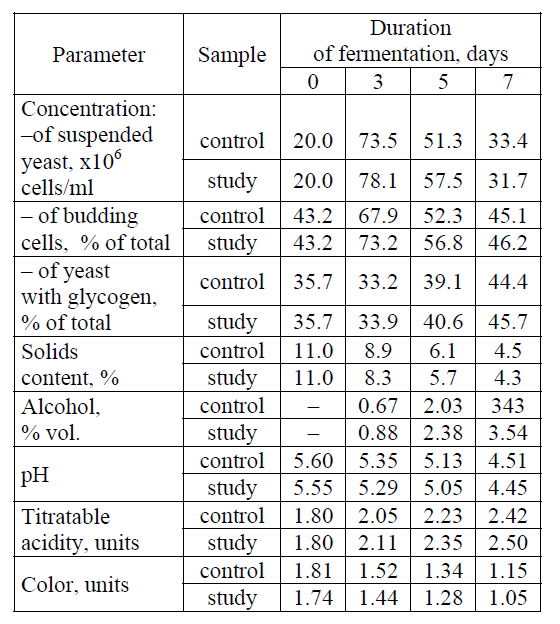

Hopped, cooled 11% wort was subjected to fermentation. The parameters characterizing the primary fermentation process are presented in Table 5.

It is seen from the data obtained that in wort made using the zeolite at the mashing stage, intensive yeast growth during the fermentation process occurred. The maximum amount of budding cells was achieved by the third day of fermentation; however, the value in the study sample was 8% greater than in the control one.

Basic parameters of the fermentation medium (color, pH, titratable acidity, extractives content, and ethanol) in the study sample change faster than that in the control one. The amount of the visible extract in the study sample is 4% lower, and the ethanol content is 3% higher than in the control one.

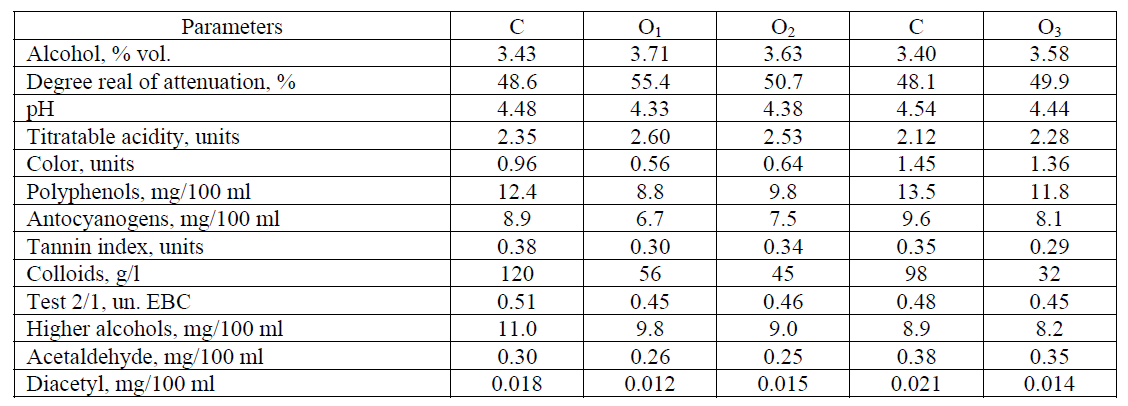

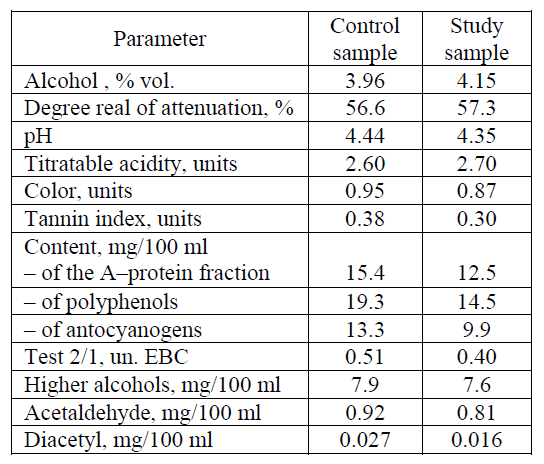

After primary fermentation, green beer was subjected to secondary fermentation. According to the data from Table 6, the study beverage is characterized by higher degree of attenuation, increased ethyl alcohol content, and lower concentration of diacetyl and acetaldehyde that has a favorable effect on its flavor and aroma.

Moreover, the study sample of beer contains less high–molecular–weight proteins (by 19%) as well as polyphenols and antocyanogens (by 25 and 26%, respectively) that obviously will ensure the great stability of beer against colloidal hazes formation.

The parameter called «test 2/1» gives more accurate information about the colloidal stability of beer and its tendency to form hazes. The value is 22% less in the test sample than in the control.

As for organoleptic parameters, beer made using the zeolite at the mashing stage had intense hoppy flavor and pure malty taste.

Therefore, the use of natural zeolite–containing tuffs both at the mashing stage and at the clarification allows polyphenols and high–molecular–weight nitrogenous substances to be removed partially from the medium. As a result, the yeast culture growth intensifies, biomass grows, and the uptake of the extract accelerates. This makes it possible to reduce the primary fermentation duration by 24 hours and to improve the beer quality at the same time.

Along with nature minerals, we used carbon fiber obtained by pyrolysis of rayon as an adsorbing agent to remove components inhibiting the yeast growth from the fermentation medium. Carbon–containing fiber in the form of non–woven fabric was placed between Zeiss filter plates. Filtration of hopped cooled wort was carried out at different rates.

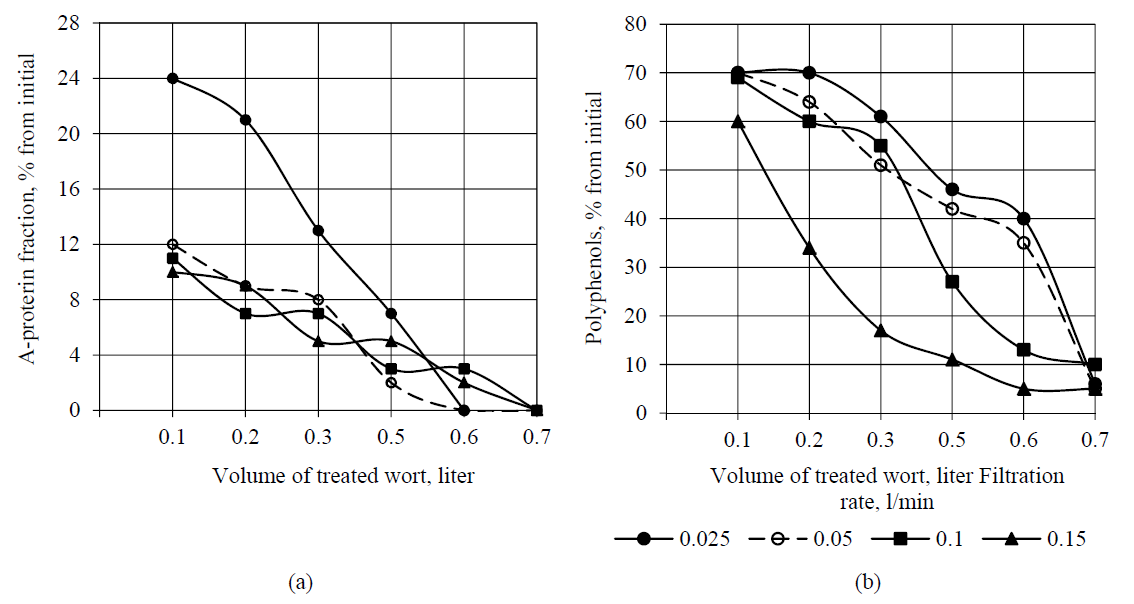

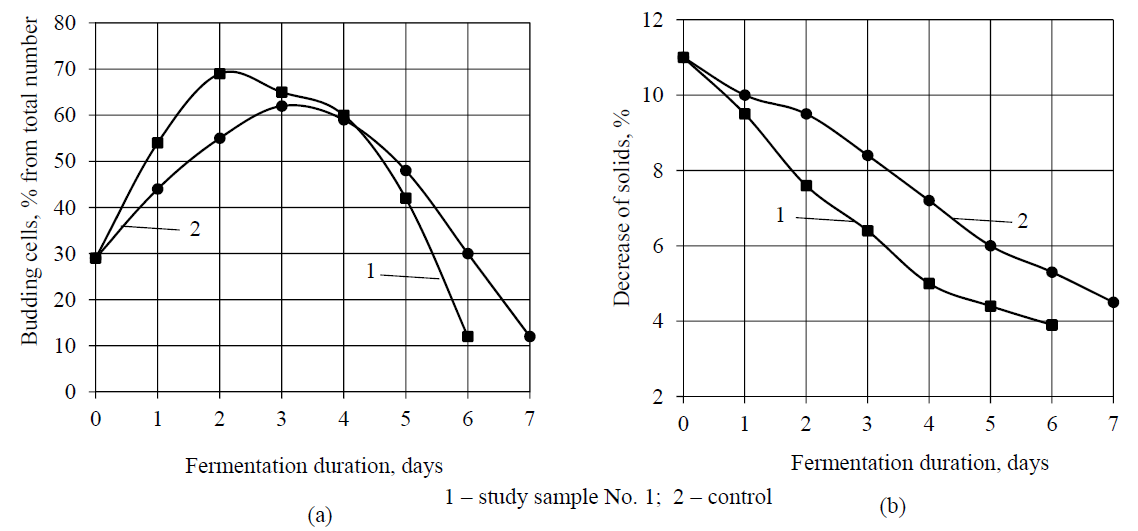

During filtration, several samples of wort were taken (0.1 liter in volume); the total volume of treated wort was 0.7 liter. For each filtration rate, a new filtering material was used. The mass of fiber was 0.22 g (the parameter was determined in previous researches as the optimum one). The results are in Fig. 1.

The amount of polyphenols removed from wort is greater by a factor 2.0–2.5 than that of proteins. A characteristic feature of carbon–fiber adsorbents is high sorption activity due to the presence of microscopic pores in their top surface, which play a dominant role in the molecular adsorption process. Carbon–containing fiber is able to arrest coarse particles as well [19, 20, 22, 23, 24].

The reduction of filtration rate from 0.15 up down 0.025 l/min leads to the increase in the amount of removed substances (from 6 up to 16% for polypeptides and from 27 up to 54% for phenolic substances.

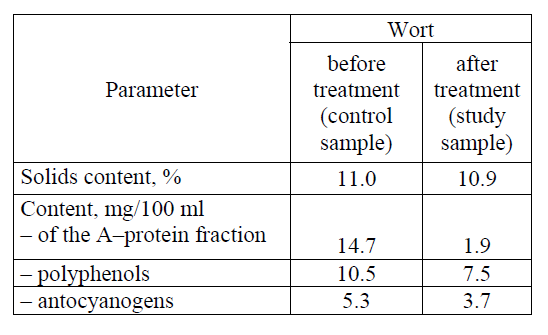

The adsorption of the studied substances is maximal at the filtration rate of 0.025–0.10 l/min and wort volume of 0.4–0.5 litеr; then the degree of their removal from the medium decreases. Some parameters of wort after the treatment with carbon fiber at the rate of 0.10 l/min are given in table 7.

It is seen from the data obtained that high–molecular–weight nitrogenous substances fraction and the total content of phenols and antocyanogens have decreased by 12% and by a factor of 1.4 respectively.

The next step of the research was the study of the fermentation process of wort treated with carbon fiber. According to the data presented in Figure 2, the use of hopped cooled wort filtered through the carbon fiber layer made it possible to intensify yeast growth due to partial removal of polyphenols. As a result of that, the maximum number of budding cells in the study sample was achieved 24 hours sooner than in the control. The study sample was characterized by higher growth of yeast cells (by 20%) and higher assimilation rate of extractives from the medium in comparison to the control sample. All this allowed us to reduce the fermentation time without deterioration of the finished beer quality (Fig. 3).

The results presented in Figure 3 demonstrate the improved beer stability against colloidal hazes; this is due to lower content of phenolic compounds which are able to react with proteins. This is the reason why removal of antocyanogens, which play a dominant role in the haze formation, has more influence on beer shelf life than that of proteins.

Apart from that, the content of higher alcohols and diacetyl in the study beer is lower (by 19 and 45%, respectively) than in the control sample that allowed organoleptic parameters of beverage to be improved.

The results obtained allow us to consider carbon fiber as promising material for removing haze–forming components from wort to create favorable conditions for yeast viability and fermentation process.

Along with adsorbents, we proposed to use stabilizing agents (α–, β– and γ– cyclodextrins) to adjust the medium composition, stimulate metabolic processes, and improve the beer attenuation process.

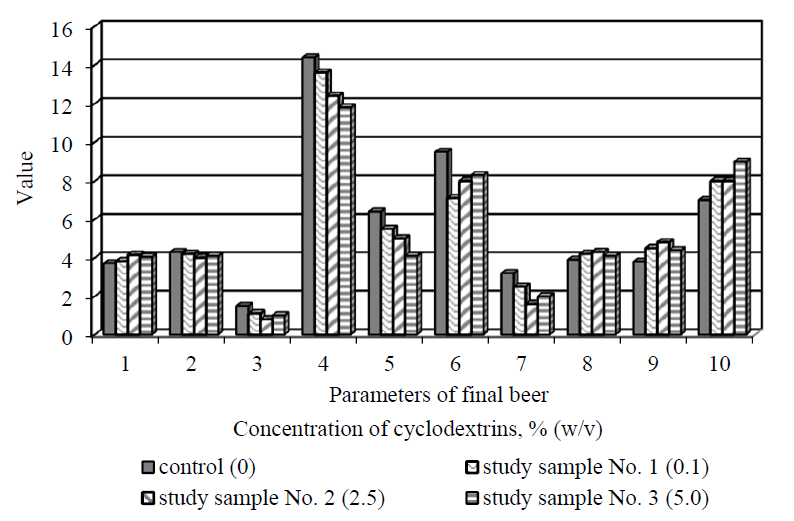

The cyclodextrins (0.1–5.0%, w/v) were introduced into hopped cooled wort, then yeast was added, after which wort was subjected to fermentation. The cyclodextrin concentrations were chosen on the basis of preliminary researches.

The mixture of the α–, β– and γ–cyclodextrins (0.1; 2.5; 5%, w/v) was added into the study samples. In the control sample, cyclodextrins were not used.

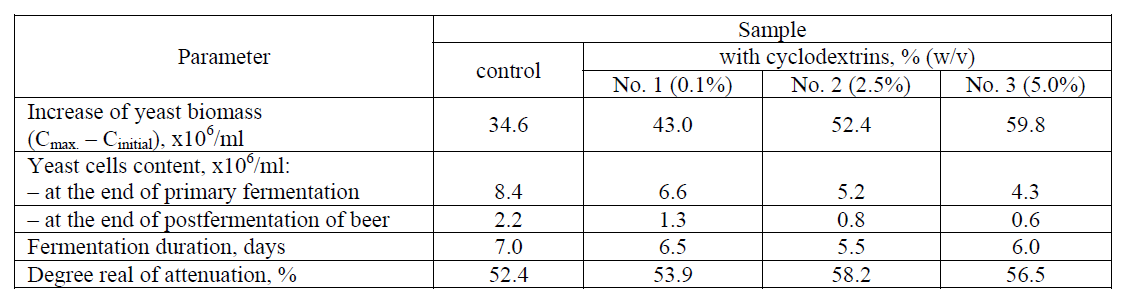

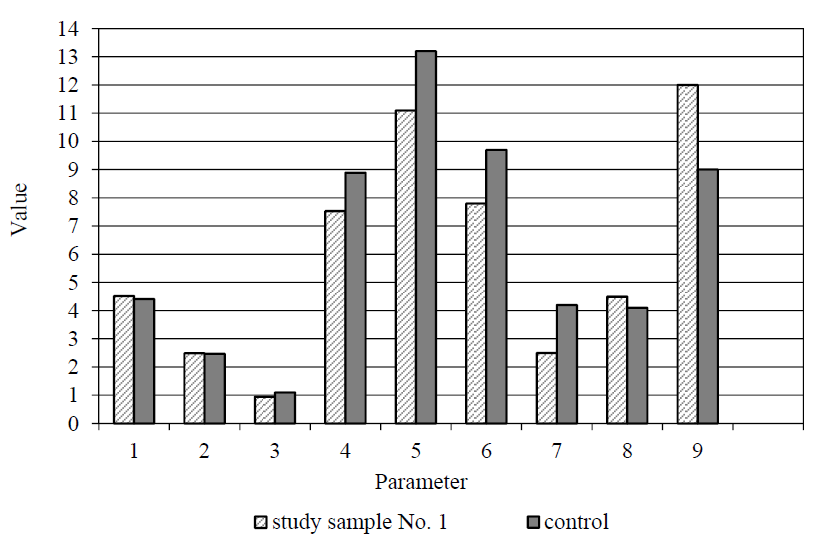

Basic parameters of the fermentation process are presented in Table 8. Figure 4 shows quality parameters of the finished beer.

According to the data from Table 8, addition of the cyclodextrins into wort leads to yeast growth; the values of biomass increase in three study samples were 14; 32, and 28% higher than in the control variant. Apart from that, at the end of primary fermentation the concentration of suspended yeast in experimental samples were 21; 38, and 49% lower than in the control beer, which contributes to better beer clarification. The real degree of fermentation value was 3–8% higher in the study samples and was achieved 0.5–1.5 days sooner than in the control variant.

The study variants of finished beer are characterized by high ethanol content, good composition of flavoring agents (higher alcohols, diacetyl), and components ensuring the colloidal stability of the beer (antocyanogens, of the A–protein fraction) (Fig. 4).

The changes can be explained as follows.

It is known that phenolic substances (antocyans, chlorogenic acids, resveratrol, etc.) are able to form complexes with cyclodextrins [35, 36, 37]. In particular, antocyans, being in semi–acetal form, form stable complexes with cyclodextrins, and their stability decreases with the increase of glycosidic radical. In addition, the ability of cyclodextrins to cooperate with gluten proteins is used in baking industry: they enhance the gas retaining ability of dough and improve its adhesive properties [32].

Cyclodextrins are able to form clathrates with both phenolic substances and high–molecular protein fraction as well as with polyphenols–protein complexes of the fermentation medium, and, thereby, reduce a negative impact of these components on yeast. As a result, fermentation time reduces, and the finished beer quality improves due to smaller amount of by–products formation.

The change in color of the study samples were 36–47% in comparison to the control variants should be noted. According to the research results presented in the literature, both the reduction and the improvement of the color stability occur [38]; the latter is due to the complex formation of cyclodextrins with cyanidine and pelargonidin [29]. The changes depend on the type of cyclodextrins (α–, β– or γ–), the complex forming mechanism, and the complex strength.

It is seen from Figure 4, the foaming ability of the study beer samples increases as well. Most likely, cyclodextrins being used as stabilizing agents prevent foam bubbles from coalescence; in other words, they decrease surface tension and contribute to foam formation.

Polyphenols, lipids, and a number of other substances are able to reduce the head retention [2, 3, 7]; therefore, their binding to cyclodextrins during the process has a favorable effect on the foam stability.

The formation of complexes from high–molecular nitrogenous compounds and cyclodextrins prevent the cleavage of proteins which stimulate foam formation by proteolytic enzymes (proteolysis), in particularly, by A–protease. The proteolysis occurs when using a weakened yeast culture or under unfavorable conditions for the fermentation process and beer maturation [1, 2, 3, 4, 7].

The carbon dioxide concentration in the study beer sample was higher than that in the control sample. Taking into account the physical–and–chemical theory of binding carbonic acid, it can be suggested that cyclodextrins themselves and their complexes with high–molecular–weight proteins as well work as «a protector», which covers CO2 bubbles with adsorption films and does not allow them to form larger aggregates followed by deflocculation.

On the other hand, from the standpoint of the chemical bond theory, dissolved carbon dioxide can form with OH–groups of cyclodextrins mono- and diesters of carbonic acid. The latter has a high chemical stability.

Addition of cyclodextrins into wort at the fermentation stage can reduce the haze–forming components content – high–molecular–weight proteins and antocyanogens – thereby increasing the finished beer colloidal stability. In our research, the study samples of unpasteurized beer remained clear at 20°C by 1–2 days longer than the control beer.

Not only does a colloidal aspect have a stability effect on the beer but also a biological aspect. It is known that the use of antimicrobial/antioxidant complexes with cyclodextrins increase the microbiological stability of foods, which increases their shelf life [27, 39]. Compared to pure cyclodextrins, their complexes with preservatives/antioxidants are able to increase their activity, the compound solubility, the stability of chemical reagents, and the pH range of the medium where the complexes can be used. This allows us to make a conclusion that preservatives/antioxidants are able to protect foods from enzymic degradation, photochemical reactions, and physical factors (such as temperature and pressure).

Beer contains substances having bacteriostatic and antioxidant properties, such as ethanol, acids, carbon dioxide, polyphenols, hop resins, tanning substances, reductones, melanoidins, etc. It may be assumed that the presence of cyclodextrins in the fermentation medium strengthens their effects on both microorganisms and easily oxidizable compounds.

Beer made using cyclodextrins has mild flavor, slight hop bitterness, and pleasant aroma. Obviously, this is due to the ability of cyclodextrins to hold volatile components forming during fermentation and maturation.

Addition of cyclodextrins in an amount of less than 0.1% (w/v) did not reduce fermentation duration. Addition of more than 5% (w/v) of cyclodextrins caused adverse changes in organoleptic and physical–and–chemical parameters of beer.

Therefore, the results have demonstrated the possibility of application of cyclodextrins to intensify the fermentation process by means of adjusting the medium composition in order to create favorable conditions for yeast viability and improve the beer quality.

ВЫВОДЫ

The use of natural adsorbing and stabilizing agents (such as zeolite–containing tuffs, carbon fiber, and cyclodextrins) for partial removal of inhibiting yeast components from the fermentation medium stimulates metabolic processes of the yeast culture, which makes it possible to reduce fermentation time by 1–1.5 days and improve the beer quality. The methods of beer wort fermentation with the use of carbon fiber and cyclodextrins are patented in the Russian Federation [22, 30].

СПИСОК ЛИТЕРАТУРЫ

- Zhvirblyanskaya А.Yu. and Isaeva V.S. Drozhzhi v pivovarenii [Yeast in brewing]. Moscow: Pishchevaya promyshlennost’ Publ., 1979. 246 p.

- Nartsiss L. Kratkiy kurs pivovareniya [Short course in brewing]. St. Petersburg: Professija Publ., 2007. 640 p.

- Back W. Ausgewählte Kapitel der Brauereitechnologie. Nürnberg: Hans Carl -Fachverlag, 2008. 392 р.

- Annemyuller G., Manger G., and Litz P. Drozhzhi v pivovarenii [Yeast in brewing]. St. Petersburg: Professija Publ., 2015. 428 p.

- Khorunzhina S.I. and Poznyakovskiy V.M. Prirodnye tseolity v proizvodstve napitkov [Natural zeolites in beverage production]. Kemerovo: Кuzbassvuzizdat Publ., 1994. 239 p.

- Pokrovskaya N.V. and Kadaner Ya.D. Biologicheskaya i kolloidnaya stoykost’ piva [Biological and colloidal stability of beer]. Moscow: Pishchevaya promyshlennost’ Publ., 1978. 272 p.

- Meledina T.V., Dedegkaev А.Т., and Аfonin D.V. Kachestvo piva: stabil’nost’ vkusa i aromata, kolloidnaya stoilost’, degustatsiya [Beer quality: stability of taste and aroma, colloidal stability, degustation]. St. Petersburg: Professija Publ., 2011. 220 p.

- Filimonova Т.I., Borisenko О.А., Ryzhova Т.P., and Kobelev К.V. Problems of dense brewing. Beer and beverages, 2006, no. 3, pp. 26-27. (In Russian).

- Yu Z., Zhao M., Li H., et al. A comparative study on physiological activities of lager and ale brewing yeasts under different gravity conditions. Biotechnology and Bioprocess Engineering, 2012, vol. 17, no. 4, pр. 818-826. DOI: 10.1007/s12257-011-0658-6.

- Permyakova L.V. Classification of preparatiopns to promote yeast vital activity. Food Processing: Techniques and Technology, 2016, vol. 42, no. 3, pp. 46-55. (In Russian).

- Karpenko D.V., Gernet М.V., and Mokhammed Amin Fayz. Use of biosorbent to intensify primary fermentation stage in brewing. Mir piva, 1996, no. 5, pp. 20-22. (In Russian).

- Pushmina I.N., Khorunzhina S.I., and Permyakova L.V. Use of Siberian zeolites in beverage production. Beer and beverages, 2009, no. 3, pp. 18-20. (In Russian).

- Breck D.W. Zeolites molecular sieves. New York: A Viley-Interecience publication, 1974. 771 p.

- Auerbach S.M., Carrado K.A., and Dutta P.K. Handbook of Zeolite Science and Technology. New York-Basel: Marcel Dekker, Inc., 2003. 1024 р.

- Zemskov V.I. and Kharchenko G.М. Properties of filter baffle plates made of natural zeolite. Bulletin of Altai State Agricultural University, 2014, no. 4, pp. 148-152. (In Russian).

- Pritul’ska N.V. and Bondarenko S.V. Research of prospects for using zeolites in the food industry. Eastern- European Journal of Eenterprise Technologies, 2015, vol. 5, no. 11, pp. 4-9. DOI: 10.15587/1729-4061.2015.51067. (In Ukrainian).

- Savchenkov М.F. Zeolities of Siberia and the Far East: Ecological-hygienic aspects. Siberian Medical Journal (Irkutsk), 2009, vol. 85, no. 2, pp. 15-18. (In Russian).

- Kolodeznikov К.Е. Tseolitonosnye provinchii vostoka Sibirskoy platform [Zeolite-bearing east province of the Siberian platform]. Yakutsk: Publishing House SB RAS, 2003. 224 p.

- Varshavskiy V.Ya. Uglerodnye volokna [Carbon fibers]. Мoscow: VINITI RAS Publ., 2007. 500 p.

- Podkopaev S.A. Struktura, svoystva i tekhnologiya polucheniya uglerodnykh volokon [Structure, properties and technology of carbon fibers]. Chelyabinsk: CSU Publ., 2006. 217 p.

- Permyakova L.V. and Khorunzhina S.I. Sposob stabilizathii piva [Method of stabilization of beer]. Patent RF, no. 2527072, 2014.

- Permyakova L.V. and Khorunzhina S.I. Sposob sbrazhivaniya pivnogo susla [Method of wort fermentation]. Patent RF, no. 2527071, 2014.

- Aslauski А.I. and Smatryn S.М. Absorbtive and adsorbtive capacities of carbon absorbent materials to biological fluids. Journal of the Grodno State Medical University, 2012, no. 3, pp. 25-28. (In Russian).

- Generalova K.N., Minkova A.A., and Olontsev V.F. The isotherm of adsorption of bacteria’s non-growing cell on carbon materials. PNRPU Bulletin. Chemical Technology and Biotechnology, 2014, no. 3, pp. 55-66. (In Russian).

- Abelyan V.А. Tsiklodekstriny: poluchenie i primenenie [Cyclodextrins: production and application]. Erevan: “Van- Ar’yan” Publ., 2001. 519 p.

- Fenyvesi É., Vikmon M., and Szente L. Cyclodextrins in food technology and human nutrition: benefits and limitations. Critical Reviews in Food Science and Nutrition, 2016, vol. 56, no. 12, pр. 1981-2004. DOI: 10.1080/10408398.2013.809513.

- Zhao M., Wang H., Yang B., and Tao H. Identification of cyclodextrin inclusion complex of chlorogenic acid and its antimicrobial activity. Food Chemistry, 2010, vol. 120, no. 4, pр. 1138-1142. DOI: 10.1016/j.foodchem.2009.11.044.

- Fedorova P.Yu., Anderson R.К., Alekhin Е.К., and Usanov N.G. Natural cyclic oligosaccharides - cyclodextrins, in drug delivery systems. Bashkortostan Medical Journal, 2011, vol. 6, no. 4, pp. 125-131. (In Russian).

- Howard L.R., Brownmiller C., Prior R.L., and Mauromoustakos A. Improved stability of chokeberry juice anthocyanins by β-cyclodextrin addition and refrigeration. Journal of Agricultural and Food Chemistry, 2013, vol. 61, no. 3, pp. 693-699. DOI: 10.1021/jf3038314.

- Permyakova L.V., Romanov А.S., Usanov N.G., et al. Sposob sbrazhivaniya pivnogo susla [Method of wort fermentation]. Patent RF, no. 2053263, 1996.

- Permyakova L.V., Romanov А.S., Usanov N.G., et al. Sposob sbrazhivaniya pivnogo susla [Method of wort fermentation]. Patent RF, no. 2053287, 1996.

- Romanov А.S. Tsiklodekstriny - polifunktsional’nye pishchevye dobavki [Cyclodextrins - multifunctional nutrient additives]. Kemerovo: KemIFST Publ., 1998. 147 p.

- Ermolaeva G.А. Spravochnik rabotnika laboratorii pivovarennogo predpriyatiya [Reference book for laboratory workers of beer factory]. St. Petersburg: Professija Publ., 2004. 536 p.

- Kachmazov G.S. Drozhzhi brodil’nykh proizvodstv [Brewing yeast]. St. Petersburg: Lan’ Publ., 2012. 224p.

- Anisimovich I.P., Deyneka V.I., and Deyneka L.А. Investigation of supramolecular complexes of chlorogenic acids with β-cyclodextrin. Belgorod State University Scientific Bulletin. Natural sciences, 2011, vol. 15, no. 9-2, pp. 226-233. (In Russian).

- Lapshova M.S., Deyneka V.I., and Deyneka L.А. Investigation of inclusion complexes of some anthocyanins with hydroxypropyl-β-cyclodextrin. Chemistry of plant raw material, 2014, no. 4, pp. 139-146. DOI: 10.14258/jcprm.201404187 (In Russian).

- Wang J., Cao Y., Sun B., and Wang Ch. Characterisation of inclusion complex of trans-ferulic acid and hydroxypropyl-β-cyclodextrin. Food Chemistry, 2011, vol. 124, no. 3, pр. 1069-1075. DOI: 10.1016/j.foodchem.2010.07.080.

- Dangles O. and Brouillard R. A spectroscopic method based on the anthocyanin copigmentation interaction and applied to the quantitative study of molecular complexes. Journal of the Chemical Society, Perkin Transactions 2, 1992, vol. 2, pр. 247-257. DOI: 10.1039/P29920000247.

- Smit R.Т. Povyshenie stabil’nosti napitka pri khranenii konpleksami s rastvorimym ligandom [Improvement of beverage stability using complexes with soluble RANK ligand]. Patent RF, no. 2465790, 2012.