Аннотация

The development and production of new functional products is a priority for the development of the food industry. At the same time, the quality and biological value of raw materials are of particular importance. From this point of view, when processing milk, the use of the process of membraneless osmosis using polysaccharides is promising. It allows to obtain dairy fractions of a high nutrition value that can be used as the main raw materials in the technology of functional products. The paper aims at developing a functional dessert based on a protein and lipid fraction (PLF) obtained by the fractionation of whole (or normalized) milk using the apple pectin manufactured in Russia. Technological parameters of milk fractionation by pectin have been studied and the conditions under which the process is most efficient have been determined. The most significant parameters were the milk pasteurization temperature (not lower than 85°С) and the concentration of pectin in the system (0.6-0.65 kg per 100 kg of milk). The recommended fractionation method is "cold" at a temperature of 4-6°C. Based on the technological parameters of fractions, depending on the conditions of the process, a method has been proposed for calculating the necessary content of the mass fraction of fat in raw materials to be regulated in PLF. As a practical implementation of the process of fractionation of normalized milk raw materials, a formulation of a new dessert that contains milk fat and protein in the native form has been developed. The functional value of the dairy dessert is provided by a complete replacement of granulated sugar with raw honey, using a starter culture with a probiotic microflora, and concentrating the product with sesame seeds. The study of the biological value of the dessert showed that it fully meets the requirements for healthy foodКлючевые слова

Pectin, raw honey, fractionation, flocculation, protein and lipid fraction, sesameВВЕДЕНИЕ

At the present time, functional products are the fastest growing segment of the food industry in the world and dairy products are in the first place among them [1, 2]. In the Russian Federation, for the majority of the population, sweet desserts are the most attractive dairy products, they are widely used and are in great demand with various groups of the population and the market of these products has been growing rapidly in recent years. The necessary sweetness of desserts is normally provided by adding refined sugar in the amount of 10–12% to the formulation of the product. The excessive use of refined sugar leads to the development of hyperglycemia, the development of diabetes, obesity, etc. It is the mentioned negative properties of sucrose that make it necessary to develop new products with a sweet functional taste, but without the negative properties of sucrose [3, 4].

The presented study aims at creating a fermented functional product with a complete replacement of sucrose with raw honey that meets the objectives of the state policy in the field of healthy nutrition. The aim of the study is the development of a functional dessert based on the protein and lipid fraction obtained by fractionation of whole (or normalized) milk by apple pectin.

To obtain the protein and lipid fraction (PLF) of milk, the membraneless fractionation of dairy raw materials was used with the help of the apple pectin manufactured in Russia. The possibility of flocculation (isolation) of casein from dairy raw materials using polysaccharides has been repeatedly proved by the studies of V. V. Molochnikov and other scientists. The main advantages of the process are low energy costs, lack of denaturing changes in the system, both fractions (the whey-polysaccharide and protein fraction) are an excellent basis for obtaining functional products [5–8].

The objectives of the study are to optimize the process of fractionation of whole milk (normalized in fat) by apple pectin, to study the physico-chemical and technological properties of the protein and lipid fraction, to select the formulation components for the production of functional desserts, to study the composition and to estimate the functional value of the product obtained.

The developed product is intended to improve the structure of the population's nutrition, contains probiotics and is enriched with vital natural minerals and vitamins. It does not contain refined sugar, the necessary sweetness is provided by raw honey and, due to its high sweetness, twice as little granulated sugar is required. Honey, in addition to the high content of monosaccharides (glucose and fructose in the amount of more than 70% of the mass of honey), contains about 400 different substances - vitamins, enzymes, proteins, minerals, therapeutic and flavoring substances. Thanks to the combination of flavor and sweetness of sugars and the acidity of the organic acids therein, honey is a good combination with dairy components [9].

The original attractive properties of the product will be provided by adding sesame to the formulation. Sesame seeds additionally enrich the cream dessert with a wide range of such mineral elements as silicon, copper, calcium, nickel, iron, phosphorus, magnesium, zinc, selenium and others, as well as polyunsaturated fatty acids, protein and vitamins [10].

The dessert will help to strengthen the health of the population, prevent the diseases caused by poor and unbalanced nutrition, its production is focused on domestic raw materials.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

Study objects are cow raw milk (GOST 31449-2013, TR TS 033/2013), whole and normalized milk with a mass fraction of fat from 0.5 to 2.0%; pectin (TU 9199-012-01014470-04 “Apple pectin, dietary food supplement”), manufactured in Belgorod region, a concentrated solution of protein and lipid fraction (PLF); raw honey (GOST R 54644-2011); sesame seeds (GOST 12095-76); the starter culture “BioMatrix-LB1” (Str. thermophilus, Lac. lactis subsp diacetilactis, Lac. acidophilus, L. plantarum, L. fermentum, L. caseisubsp rhamnosus, B. bifidum, B. longum, B. adolescentis. Bioproduct, LLC), the direct-set yoghurt starter culture YO-MIX™ (Str. thermophilus, Lac. lactissubsp. lactis, Lac. bulgaricus. Danisco), the direct-set starter culture “Sour cream vivo” (Str. Salivarius subsp. thermophilus, Lac. Lactis subsp. lactis, Lac.lactissubsp. cremoris, Lac.lactissubsp. diacetylactis. VIVO, Ukraine).

When carrying out a complex of physical and chemical studies and studying the properties of objects, standard and common methods were used:

– the determination of the mass fraction of moisture and solids using an infrared thermogravimetric method by means of the moisture content analyzer "Evlas-2М" and using a thermogravimetric method by means of the dryer "APS-1" Analit-Servis, and using an arbitration method - drying the weighed quantity to a constant mass in a drying cabinet at a temperature of 102–105°С;

– the determination of the content of solids in the whey-polysaccharide fraction using the refractometer "IRF-454 B2M" (Komz, JSC);

– the determination of the mass fraction of fat using the Gerber method (an acid based method);

– the determination of the mass fraction of protein according to Kjeldahl;

– the determination of the calcium content using a complexometric method;

– the determination of dynamic viscosity using an Ostwald viscometer;

– the determination of active acidity using the pHmeter/ionometer IPL-201 (MULTITEST "Semiko");

– the determination of the composition of raw and pasteurized milk using an ultrasonic analyzer "Laktan1-4" (Sibagropribor, Russia);

– the determination of titrable acidity by titration;

– the determination of the lactose content using an iodometric method;

– the organoleptic indicators of the product were determined by means of a tasting assessment of experts on a common 10-point scale.

The content of protein, vitamins, macro- and micronutrients was determined in the testing laboratory of Belgorod SAU, registered in the Russian state register that meets the requirements of GOST R ISO/IEC 17025-2006, accredited in the system of accreditation of analytical laboratories.

A 5% pectin aqueous solution prepared by dissolving pectin powder in hot water at a temperature of 70–72°C, filtered through a screen filter and cooled to a temperature of 20–25°C was used in the studies.

The content limit of pectin necessary for the flocculation of the protein and lipid fraction was determined using the whole milk pasteurized at 85°C with a pectin content from 0.2 to 0.8 g at a pitch of 0.2 g per 100 g of milk in terms of dry powder. The temperature of the components (milk and a 5% aqueous pectin solution) was 20–25°C when mixing, the mass of the mixture of each sample was 200 g. 30 cm3 of mixture were dispensed from each sample into two rows of biological test tubes (three replications). The estimation of efficiency of milk fractionation was controlled by the height of the layer of the separated whey-polysaccharide fraction (WPF) expressed as a percentage of the total height of the mixture in a test tube in two cases of process temperatures - 4–6°C and 40°C.

To estimate the effect of the pasteurization temperature and the temperature of the fractionation process, pectin was applied into the samples of the milk pasteurized at temperatures of 75, 80, 85, 90°C, cooled to a temperature of 20–25°C, based on its content of 0.65 g in 100 g of milk (on a dry basis) in the form of a 5% aqueous solution at the same temperature, the mixture was well mixed. The efficiency of flocculation of PLF was controlled according to the procedure described above in two cases of the process temperatures of 4–6°C and 40°C.

The effect of the mass fraction of fat of a normalized mixture on the fractionation process was studied as follows. Whole milk was normalized using skim milk to a mass fraction of fat of 0.5; 1.0; 1.5 and 2.0%. Further on, the samples of the same mass were pasteurized at 85–87°C without holding and cooled to 20–25°C, a 5% pectin solution at a temperature of 20–25°C was applied at the rate of 0.65% of dry powder to the mass of milk. The samples were thoroughly mixed and left for 3 hours at a temperature of 4–6°C. The WPF and PLF obtained in the field of gravitational forces were separated by decanting and the physico-chemical indicators of fractions were analyzed.

To study the process of fermentation of the protein and lipid fraction of milk using a fermented microflora, the samples were prepared according to the following pattern. Raw honey was applied into the freshly prepared PLF solution, the mixture was pasteurized at a temperature of 72–74°C with holding it for 20 seconds and cooled to the fermentation temperature appropriate for each kind of starter cultures: "BioMatrix-LB" - 38–39ºС, YO-MIX™- 40–41ºС and "Sour cream vivo" - 27–28ºС. The samples were thermostated in the same temperature conditions. The intensity of the acid formation process was determined by measuring the titrable acidity at the fixed intervals during the process of fermentation.

The proportion of components in the formulation (PLF, honey, a probiotic starter culture, sesame) was determined with a focus on the organoleptic characteristics of the product.

The biological value of cream dessert was characterized by the content of protein, fat, calcium, phosphorus, vitamins A, E, C and such micronutrients as zinc, iron and copper.

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

Technology of production, technological and physico-chemical properties of the protein and lipid fraction. The main raw material for the development of a functional dessert is the protein and lipid fraction, isolated from pasteurized milk with various fat contents with the help of apple pectin. The flocculation of PLF is based on the colloidal incompatibility of a highly hydrophilic pectin colloid with hydrophobic milk components - casein micelles, colloidal calcium phosphate and fat globules, which manifests itself in a narrow zone of low pectin concentration. The flocculation process is reversible and is not succeeded by the coalescence process (irreversible changes) - the PLF concentrate holds its homogeneous structure characteristic of solutions.

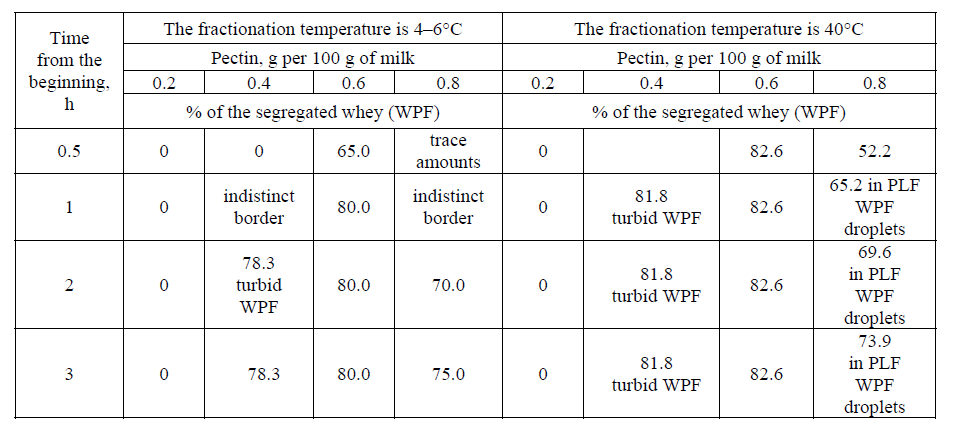

The optimal content of apple pectin of the indicated brand for an effective flocculation of PLF was determined using the whole milk pasteurized at a temperature of 85°C (without holding) with a pectin content from 0.2 to 0.8 g at a pitch of 0.2 g per 100 g of milk in terms of dry powder. Table 1 presents the effect of pectin concentration on the efficiency of fractionation of pasteurized whole milk.

As shown by the results, the effective fractionation of whole and the previously studied skim milk requires a pectin content in the range of 0.6–0.65 g per 100 g of milk in terms of the dry weight of powder. The apple pectin was applied as an aqueous solution. More technologically advanced in viscosity for industrial use is a 5% solution prepared by dissolving pectin powder in hot water at a temperature of 70 ... 72°C with continuous stirring followed by its cooling and the possibility of using it for 72 hours when stored at 4–8°C. When the pectin content is reduced to 0.4% to the mass of the mixture, the rate and efficiency of the process of PLF flocculation decreases, and fractionation completely deceases when the content is 0.2%. When the content of pectin is 0.8% in terms of dry pectin powder, two processes simultaneously proceed: the flocculation of PLF and the partial peptization of PLF concentrate with distinct WPF globules in its structure.

The technology for isolating PLF for the purpose of optimizing the process was studied using bulk whole milk. The composition of whole milk is the following: fat is 3.6 ± 0.12%, MSNF is 8.25 ± 0.05%, protein is 2.96 ± 0.05%, calcium is 146 ± 2 mg% and pH is 6.68 ± 0.04.

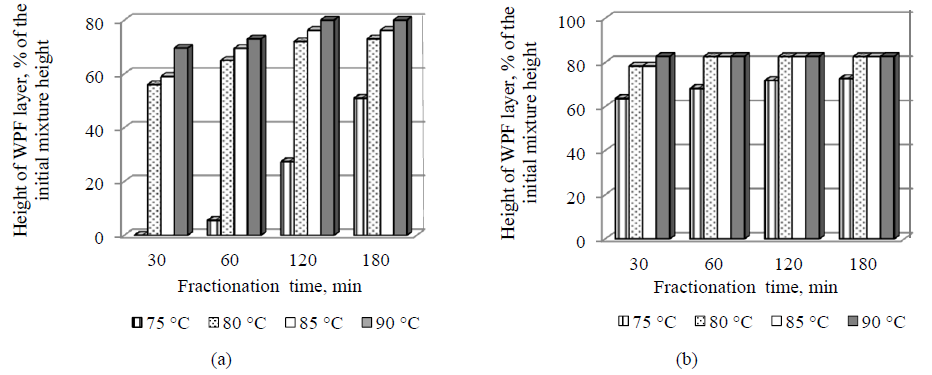

Pasteurized milk was used at temperatures in the range of 75–90°C at a pitch of 5°C. Two temperature fractionation options were studied: at a temperature of 4–6°C (in a refrigerator) and at 40°C (in a thermostat).

Fig. 1 clearly presents the results of the analysis.

It follows from the results that with an increase in the temperature of whole milk pasteurization, the efficiency of the fractionation process increases. The mode of milk pasteurization at a temperature of 75°C for the fractionation of whole milk at a temperature of 4–6°C is unacceptable (raw milk is not practically fractionated by pectin). The high-temperature pasteurization of whole milk at a temperature of more than 80°C increases the efficiency of its fractionation with the use of pectin. The observed result can be explained by the denaturation of whey proteins and the transition of part of the soluble calcium phosphate salts into a colloidal form. These processes lead to an increase in the mass of particles, to the compression of the double electrical layer of membranes and a decrease in the electrokinetic potential both of casein micelles and fat globules. It results in a decrease in the aggregative (sedimentative) and kinetic stability of these components. The fat is almost completely displaced by pectin into a protein concentrate without a boundary surface between the lipid and protein layers, a common homogeneous concentrated solution of the rich white color is formed. The process proceeds faster at a fractionation temperature of 40°C due to a decrease in the viscosity of the medium.

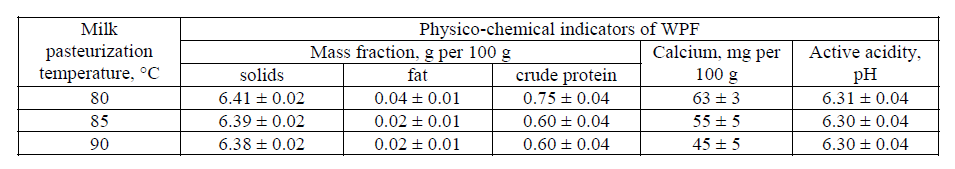

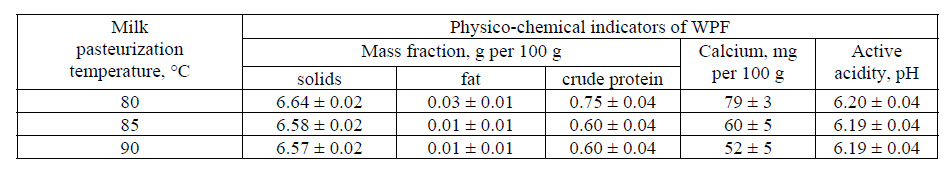

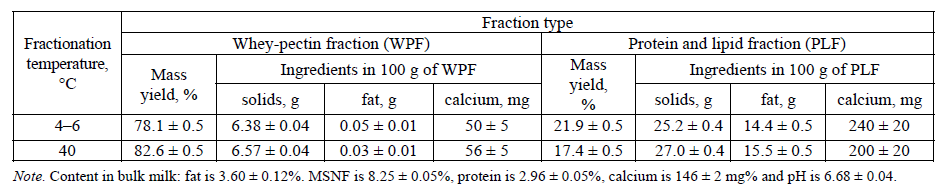

The physico-chemical characteristics of the process of fractionation of whole milk can be seen more clearly from the physico-chemical indicators of WPF. Table 2 presents the effect of the pasteurization temperature of whole milk on the physico-chemical indicators of WPF after 3 hours from the beginning of the process for the fractionation conditions at a temperature of 4–6°C. Table 3 presents the physico-chemical parameters of WPF after 3 hours from the beginning of the process for the fractionation conditions at a temperature of 4–6°C.

It can be seen from the results of Tables 2 and 3 that the fat content in WPF is independent from the fractionation temperature at a level of trace amounts. The milk pasteurization temperature and the conditions for the process of fractionating whole milk using apple pectin effect the calcium content in WPF and the pH of the medium. With an increase in the milk pasteurization temperature, the content of calcium in WPF decreases, which is a consequence of the transition of some of the soluble calcium salts and colloidal calcium hydrogen phosphate caused by a thermal effect on milk into insoluble calcium orthophosphate salt. In case of cold fractionation (the mixture temperature is 4–6°C), in comparison with raw milk (146 ± 2 mg%), the calcium content is reduced by 57–70% within the limits of milk pasteurization standards of 80–90°C. When fractionating warm milk (the temperature is 40°C), the active acidity in WPF is increased by 0.1 U pH and a larger amount of calcium remains in comparison with the WPF obtained by cold milk fractionation. It is known that even a slight acidification of the medium shifts the salt balance of milk towards soluble calcium salts, which leads to an increase in the calcium content in WPF by approximately 10 mg%.

As the pasteurization temperature rises, the residual protein content in WPF decreases, reaching the minimum threshold of 0.6%, which is 20% of the total protein content in milk. At a temperature of 85°C, the denaturation of whey proteins practically ends, which explains the same (0.6%) protein content in the WPF isolated from pasteurized milk at 85°C and at 90°C.

The technological characteristics of the fractions (WPF and PLF), isolated from whole milk with a pectin content of 0.60–0.65 g per 100 g of milk in terms of dry pectin powder, were studied for the process conditions: the milk pasteurization temperature is 85–87°C without holding, the mixing temperature of components (milk and a pectin solution) is 20–25°C, the duration of fractionation is 3 hours. With an increase in the duration of fractionation, the composition of fractions remains practically unchanged. The separation process ends when the osmotic pressure is balanced at the boundary of the layers. Table 4 presents the obtained results.

It follows from the results of Table 4: when fractionating cold (the temperature is 4–6°C) whole milk with apple pectin, the yield of PLF increases by 4.5% when the solids content is reduced by 1.8% in comparison with the fractionation of warm milk (the temperature is 40°C). The degree of fat concentration was 4 times when fractionating cold milk using pectin, and 4.3 times when fractionating warm milk. When fractionating warm milk using apple pectin (the temperature is 40°C), the calcium content in PLF decreases. The WPF indicators change: the content of calcium, the content of solids and the active acidity increase by 0.1 U pH in comparison with milk fractionation at a mixture temperature of 4–6°C. These indicators indirectly show the growth of the thermophilic microflora.

In the further studies, the milk was fractionated using apple pectin at a mixture temperature of 4–6°C. The recommended mixing temperature for milk and a pectin solution is 20–25°C, a "cold" method of fractionation method at a temperature of not higher than 8°C for 3–4 hours is used. The process termination indicators are a clear light yellow WPF solution in the upper part (the density is 1025–1026 kg/m3, the solids content is not more than 6.4–6.6%) and a bright white layer of a concentrated PLF solution, well separable by decanting, at the bottom.

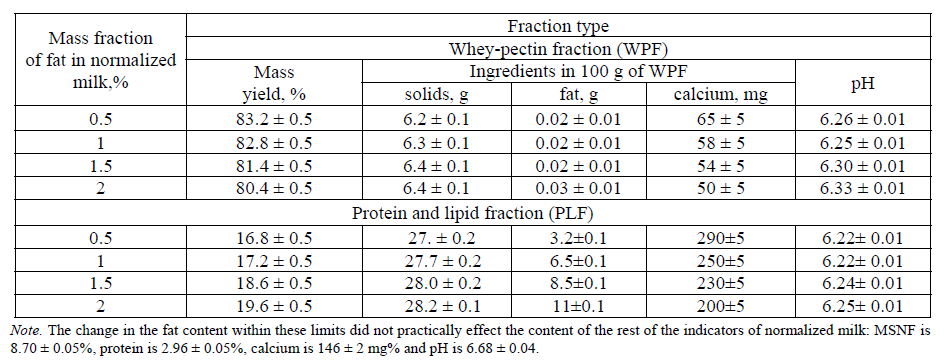

A study has been carried out on the effect of the normalizable mass fraction of milk fat in the range from 0.5 to 2% at a pitch of 0.5% on the technological and physico-chemical indicators of PLF when fractionating it with apple pectin in the conditions of the parameters specified above.

Table 5 presents the effect of the normalizable mass fraction of milk fat on the technological and physico-chemical indicators of PLF and WPF. The parameters of the fractionation process are the following: the titrable acidity of milk is 16–18°T, the milk pasteurization temperature is 85–87°C, the pectin content is 0.65% in terms of dry powder, the fractionation temperature is 4–6°C and the fractionation duration is 3 hours.

When comparing the results of the study of the presented paper with the earlier studies on the fractionation of skim milk using apple pectin of the same grade, some facts come under notice. The optimal content of pectin per 100 g of milk, regardless of the mass fraction of fat, is 0.6–0.7 g (based on dry pectin powder). The mass of the protein and lipid fraction isolated from 100 g of milk with fat is less (16.8–19.6 g) than the mass of the natural casein concentrate (NCC) isolated from 100 g of skim milk (20–22 g). That is, the fat phase promotes the displacement of water from the PLF layer and an increase in the content of solids therein. The content of solids is 27-28% in PLF and 23–25% in NCC.

Since pectin attracts the aquatic environment and keeps it well, there is a reason to assume that the process of concentrating of the hydrophobic components of milk during the fractionation of milk using pectin proceeds in a similar way to the process of removal of moisture from milk mixtures during canning. To calculate the degree of fat concentration during the fractionation of pasteurized milk with a normalized fat content, we calculated the fat content in 100 g of solid matter in PLF and the fat content in the solid matter of normalized milk. Taking into account that milk fat almost completely transits from milk to PLF, the degree of fat concentration (n) can be determined using the ratio of these indicators (n = FsmPLF / Fsmmilk).

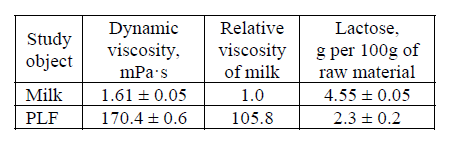

With regard to choosing the type of functional product based on PLF, the ability to whip, the viscosity and the lactose content to identify the possibility of ripening was studied in addition to the normalization of the fat content in PLF. The studies were carried out using the PLF isolated from whole pasteurized milk at a temperature of 87°C with apple pectin. The conditions and parameters of the fractionation process are the same as in the studies above.

The ability of PLF for whipping was checked after preliminary holding it for 10–12 hours at a temperature of 4–6°C in order to stabilize the structure of proteins and fat and for the subsequent absorption of air bubbles when whipping. An effect of the disperser rotations of 500, 1000 and 2000 rpm on PLF was studied, the temperature of the PLF solution was 4–6°C. It should be noted that, in contrast to the natural casein concentrate obtained from skim milk, PLF does not have the ability to whip and foam regardless of the mass fraction of fat (1.5–11%). There is a process of aggregation of fat globules, like whipping cream into butter. We assume that the cause is the dehydration of fat globule membranes caused by pectin and the process of fat hardening within fat globules, leading to the deformation of phospholipid and protein membranes and the displacement of a part of the liquid fraction through the emerged microcracks of mebranes. If combined, it results in the absence of foam and the formation of small particles plastic by touch in the structure of PLF when whipping. The observed effect excludes a possibility of creating a whipped product based on PLF.

Table 6 presents the dynamic viscosity of PLF and the lactose content therein in comparison with raw milk.

The results indicate a high viscosity of the PLF solution, which is important for the development of structured products, and the sufficient lactose content necessary for the production of fermented product variants.

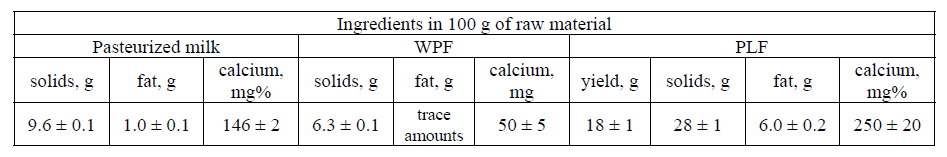

Development of the formulation and technology of the functional product "Cream-dessert" with honey and sesame. To produce PLF, pasteurized milk with the following composition was used at a temperature of 87°C without holding: the mass fraction of fat is 1%. MSNF is 8.6%, protein is 3.1%, pH is 6.72 (16–17°T), calcium is 146 mg% and apple pectin in the form of a 5% aqueous solution. The components were mixed at a temperature of 20–25°C, the amount of pectin to the milk mass was 0.65%, in terms of dry powder. The mixture was left for 3 hours at a temperature of 4–6°C, there was a distinct fractionation during this period: WPF is the whey portion of the mixture in the upper part of the tank and PLF is a concentrated white solution in the bottom of the tank.

We have made an attempt to determine the possible fat content in PLF by calculation. Based on the previous calculations (Table 5), a fact was revealed that the degree of fat concentration in the solid matter of PLF relative to fat in the solid matter of normalized milk (n = FsmPLF / Fsmmilk) during the fractionation of milk by 0.65% apple pectin (in terms of dry powder) is 2.0–2.2 times.

To calculate the possible fat content in PLF, a degree of fat concentration n = 2.1 has been set. The real composition of the milk used: 1% of fat and 9.6% of solids. The average content of solids in PLF on the basis of numerous studies is 28%. The fat content of the obtained liquid form of PLF should be equal to 6.1% as per calculation. The above calculation was confirmed experimentally, therefore, it is possible to normalize the fat content in raw materials and in the product. To develop the formulation, a use of PLF with a mass fraction of fat of 6% was assumed.

Table 7 presents the technological parameters of raw materials for a dessert with a mass fraction of fat of 6%.

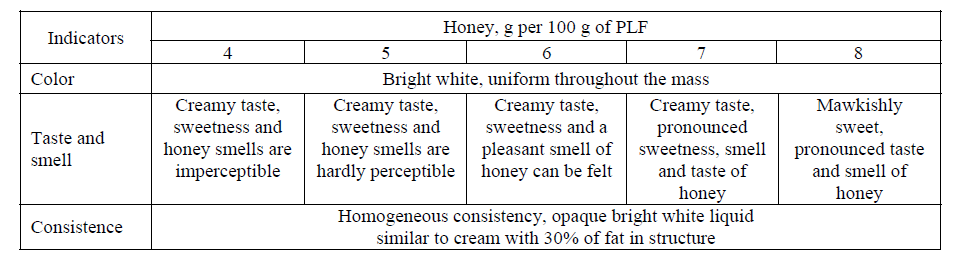

To replace sugar in dessert with raw honey, the possible limits of its content in PLF with a mass fraction of fat of 6% have been determined. The sweetness and structure of the compositions that contain raw honey in the amount from 4 to 8 g of honey per 100 g of PLF at a pitch of 1 g was studied. The honey was kept in a thermostat at a temperature of 40-45°C for plasticity and was dissolved in PLF when stirring. Taking into account the high water-binding properties of carbohydrates and proteins, the obtained compositions for stabilizing the structure were held in the refrigerator at a temperature of 4–6°C for 12 hours. On expiration, the samples were left for 30 minutes at room temperature and were organoleptically estimated. Table 8 presents the organoleptic indicators of PLF with a different honey content.

A mixture with a mass fraction of honey of 7% had the best organoleptic characteristics.

The organoleptic properties of PLF, the high viscosity and sufficient lactose content served as an argument for choosing the type of product - "Creamdessert" with honey and sesame fermented using a starter culture with probiotic microorganisms. The components of the product formulation were chosen taking into account its functional focus and organoleptic characteristics. The use of starter cultures that contain probiotic microorganisms is the most expedient and convenient way of enriching a dairy product. Probiotics, in case of the natural mode of administration, have beneficial effects on the physiological functions and biochemical reactions of the human body by optimizing its microbiological status [11, 12]. The addition of a plant supplement in the form of sesame to the protein and lipid milk basis allows to increase the nutritional value of the final product, to improve its mineral composition and to enrich it with valuable components [13].

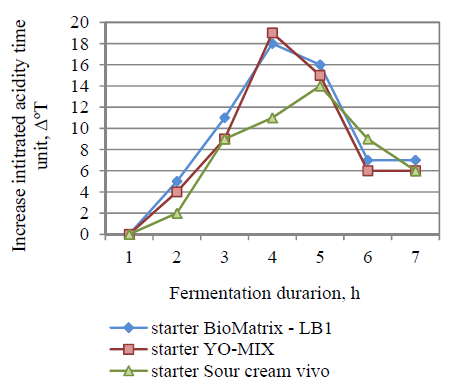

The honey was applied in the amount of 7% to the mass of PLF in the process of gentle heat treatment of the freshly obtained PLF (72–74°C with holding for 20 sec). Two factors served as a basis for choosing a mode of heat treatment: the pre-heating of milk to a temperature of 87°C before the process of fractionation using pectin leads to the complete destruction of lipase and is complete for pasteurization efficiency; secondly, the effect of high temperatures is undesirable for retaining the natural properties of honey. Further on, PLF with honey was cooled to the fermentation temperature and a direct-set starter culture was applied. Fig. 2 presents the dynamics of fermentation using the starter cultures "BioMatrix - LB1", the yoghurt starter culture YO-MIX and "Sour cream vivo".

In general, the process of fermentation of PLF using starters of lactic acid cultures proceeds in a similar way to the fermentation of any other dairy raw material. The presence of the lag phase, the period of active growth of microflora and the phase of extinction of a culture is typical. The formation of a dense curd for a yogurt starter culture and "BioMatrix-LB1" begins on average in 3.5 hours after the fermentation begins. For the starter culture "Sour cream vivo" the curd was formed 4 hours after the fermentation had begun. However, to get a more pronounced sour-milk taste, the duration of fermentation should be increased by 2–3 hours for all the crops. According to the results of the organoleptic estimation, the fermented milk product obtained using the starter culture "BioMatrix-LB1" had the most attractive taste.

The honey performs several functions in the obtained product: a natural effective sweetener, gives the product a special taste and smell, enriches the product with valuable ingredients inherent only in raw honey, and the fructose contained promotes the growth and preservation of the viability of bifidobacteria in the chosen probiotic starter culture.

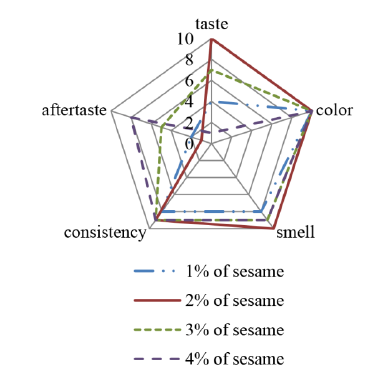

The mass fraction of sesame was selected for the formulation of the product using a tasting assessment made by experts with respect to 5 approved descriptors: color, taste, consistency, aftertaste and smell. The descriptors were graded on a 10-point scale (Fig. 3).

The sesame was heat treated at 105–105°C for 5 minutes and was applied into the fermented protein and lipid base with honey in a cooled state. The product was stirred for 5 minutes and sent for ripening at a temperature of 4–6°C to provide the final formation of its structure and taste characteristics. The organoleptic estimation of the finished "Cream-dessert" was carried out at a temperature of 20–22°C. It has been found that the sample with a sesame content of 2% to the mass of PLF had the most attractive organoleptic indicators.

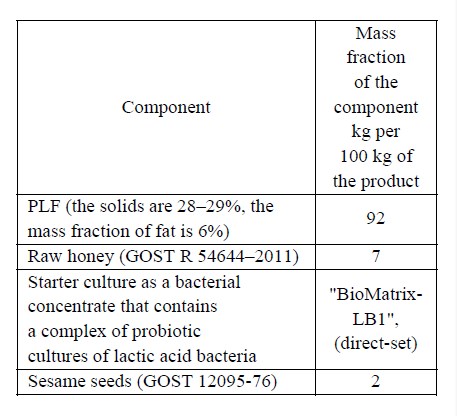

The production technology of "Cream-dessert" in production consists of the following operations. The derivation of a protein and lipid fraction: the normalization of whole milk to a mass fraction of 1% fat, the pasteurization at 87°C without holding, cooling to 20–25°C, applying a 5% pectin solution at a temperature of 20–25°C based on its content of 0.65% to the mass of milk on a dry basis, stirring for 15 minutes, cooling to 4–6°C and fractionating for 3 hours. The indicator of completion of the fractionation process is: a transparent WPF solution with a density in the range of 1025–1026 kg/m3 and the content of solids in the range of 6.4–6.6%. The process of production of "Cream-dessert": the separation of PLF by decanting from the bottom of the tank, applying honey in the amount of 7% to the mass of PLF, the heat treatment of mixture at a temperature of 72–74°C with holding for 20 seconds, cooling to a fermentation temperature of 35–38°C, applying the starter culture "BioMatrix - LB1", the fermentation to a titrable acidity of 90–100°T, cooling to 20°C, applying sesame in the amount of 2% into the mass of mixture, product packing, biochemical and physical ripening at a temperature of 6–8°C for 12 hours, the technical and chemical control of the composition, quality and safety of the product, organoleptic estimation and implementation.

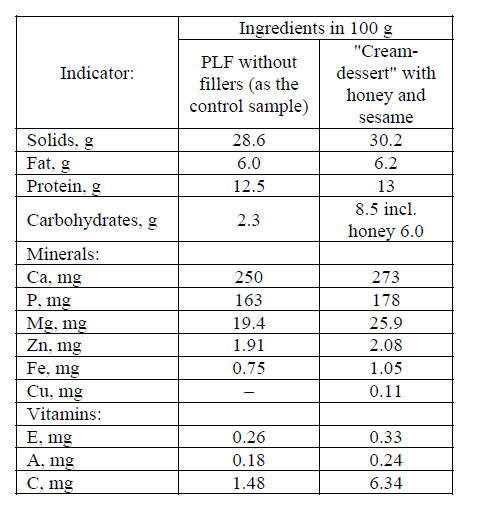

Based on the results of the organoleptic, physicochemical and microbiological studies of the product, a shelf life is determined to be 10 days at a storage temperature of 6–8°C. Table 9 presents the resulting formulation of "Cream-dessert" with honey and sesame. Table 10 presents the characteristics of the composition "Cream-dessert" with honey and sesame.

As can be seen from the data obtained, the use of honey and sesame allows to enrich the product additionally with macro- and micronutrients and vitamins.

Thus, the developed "Cream-dessert" has attractive organoleptic properties. It has a moderate titrable acidity (not higher than 100°T). It is characterized by a high content of milk protein, which provides the ratio of casein and whey proteins necessary for intake. Its content of carbohydrates is low for a sweet dessert, since the necessary sweetness is compensated by a high content of monosaccharides in honey (glucose and fructose). The portion of 200 g of the product provides 50% of the recommended daily intake of calcium and 34% of phosphorus for a person aged 25–50 [14].

ВЫВОДЫ

The presented paper describes an innovative technology of protein dessert. Protein and fat raw material is concentrated simultaneously being effected by the normalized milk of apple pectin, while the bulk of the calcium of fresh milk is concentrated and transits into PLF, and therefore remains in the product. In the classical protein dessert obtained on the basis of cottage cheese, the bulk of calcium salts transits into whey effected by fermentation lactic acid, and micellar calcium casein phosphate remains practically only within the product.

The protein and lipid fraction is enriched with protein and milk fat in their natural (native) form. The previous high temperature of milk pasteurization (87–90°C) provides the enrichment of casein and fat globules with whey proteins, which significantly increases the protein efficiency ratio (PER). The selective flocculation of milk components by pectin enriches the content of macronutrients in raw materials (calcium, phosphorus and magnesium), micronutrients (zinc, iron and copper) and vitamins A, E and C. The product is additionally enriched with an appreciable quantity of micronutrients and vitamins due to applying raw honey and sesame seeds into it.

СПИСОК ЛИТЕРАТУРЫ

- Siró I., Kápolna E., Kápolna B., and Lugasi A. Functional food. Product development, marketing and consumer acceptance - A review. Appetite, 2008, vol. 51, no. 3, pp. 456-467. DOI: 10.1016/j.appet.2008.05.060.

- Zakharova L. Development and Introduction of New Dairy Technologies. Food and Raw Materials, 2014, vol. 2, no. 2, pp. 68-74. DOI: 10.12737/5462.

- Kudryavtseva N.N., Bondar N.P., and Kovalenko I.L. Effect of positive and negative social experiences on sucrose solution intake by male mice. I.P. Pavlov Journal of Higher Nervous Activity, 2009, vol. 59, no. 2, pp. 192-198. (In Russian).

- Babenyshev S.P., Emelyanov S.A., Zhidkov V.E., Mamay D.S., and Utkin V.P. Main aspects of producing whey beverages with the addition of plant polysaccharides based on the use of ultrafiltration. Food Processing: Techniques and Technology, 2015, vol. 38, no. 3, pp. 5-10. (In Russian).

- Trukhachev V.I., Molochnikov V.V., and Khramtsov A.G. Innovative component of biomembrane technology for production of dairy products. Bulletin of the Russian Agricultural Science, 2015, no. 5, pp. 3-7. (In Russian).

- Trukhachev V.I., Molochnikov V.V. and Emelyanov S.A. Nekotorye aspekty otsenki radioprotektornoy aktivnosti molochnykh produktov tekhnologii «Bio-ton» [Some aspects of evaluation of radioprotective activity of dairy products of the technology "Bio-ton"]. Fundamental and Applied Studies in the Pacific and Atlantic Oceans Countries The 1st International Academic Congress, 2014, pp. 554-557.

- Molochnikov V.V., Orlova T.A., and Moreno V.V. Novyy vzglyad na pererabotku moloka [A new insight into milk processing]. Food processing industry, 2009, no. 6, pp. 30-31. (In Russian).

- Molochnikov V.V., Khramtsov A.A., Orlova T.A., et al. Fractionation of the milk raw materials with the aid of polysaccharides. Dairy Industry, 2008, no. 12, pp. 47-48. (In Russian).

- Danikov N.V. Tselebnyy med [Healing honey]. Moscow: Eksmo-Press Publ., 2012. 256 p.

- Klyuchnikova D.V., Ismailova A.I., Kuznetsova A.A., and Tarasova A.V. Functional dairy products, enriched with non-traditional botanicals. International Research Journal, 2016, no. 6-2 (48), pp. 72-74. DOI: 10.18454/IRJ.2016.48.175. (In Russian).

- Casarotti S.N., Monteiro D.A., Moretti M.M.S., and Penna A.L.B. Influence of the combination of probiotic cultures during fermentation and storage of fermented milk. Food Research International, 2014, vol. 59, pp. 67-75. DOI: 10.1016/j.foodres.2014.01.068.

- Evdokimov I.A., Volodin D.N., Misyura V.A., Zolotorevа М.S., and Shramko М.I. Functional fermented milk desserts based on acid whey. Foods and Raw Materials, 2015, vol. 3, no. 2, pp. 40-48. DOI: 10.12737/13116.

- Katserikova N.V., Solopova A.N., and Lipatova Yu.S. Development of the cottage cheese gerodietary products with sesame. Food Processing: Techniques and Technology, 2011, vol. 22, no. 3, pp. 97-101. (In Russian).

- Kodentsova V.M., Vrzhesinskaya O.A., Spirichev V.B., and Shatnyuk L.N. Substantation of vitamins and minerals level in fortified foodstuffs. Problems of Nutrition, 2010, vol. 79, no. 1, pp. 23-33. (In Russian).