Аннотация

Based on perspectives of the philosophy for science of dairy and postgenomic ideas the historical aspects, an attempt has been made to formulate the paradigm of LactOmics as a logical generalization of LipidOmics, ProteOmics and GlycOmics. The depth of experience is maintained thousands years. First paper was published 400 years ago. Up-to-date concepts have been cluster formed. The technology platform of LactOmics is based on the bio- nano- electromembrane technique of the dairy industry modernization, as part of full import replacement with export orientation. This provides the national Food safety for the entire range of dairy products for the determined population groups.Ключевые слова

Dairy science, Raw milk clusters, LipidOmics, ProteOmics, GlycOmics, LactOmicsВВЕДЕНИЕ

Bearing in mind the innovative priorities to upgrade the milk industry [1–3] and in compliance with the terminology principles to be formed lately of postgenomic trends in biology science, it seems advisable to share insights on the diary science, on whole. The exclusive vision of the subject-matter related to major components (complex) of raw milk, that is carbohydrates (lactose and its derivatives); lipids (milk fat) and nitrogen-bearing components (casein and whey proteins) is clarified in our respectable journals [4–6].

The publication in the trade journal “Dairy Industry” dedicated to this topic [7] in Russian language stirred the interest and, more over, enthusiastic comments from specialists. The common suffix in terms of biology sciences – GenOmics, ProteOmics, LipidOmics, GlycOmics – afford the grounds to assume the conceptual umbrella term for the milk science – LactOmics, which consistently discords with postulates formed earlier for major components of milk raw products and diary science. Its core of essence has been formed for centuries of human civilization, and it is graphically shown in frescos of ancient Egyptians as in Fig. 1.

Definitely, LactOmics includes three logistically independent but organically associated stages:

Stage I – milk raw product obtaining;

Stage II – milk raw product processing;

Stage III – dairy products application.

First stage is traditionally the prerogative right of farming of various forms of ownership, volume and technologies from the specific owner of a cow (goat, sheep and other lactating female) to automated plants to produce marketable milk products for commercial purposes. This exceptionally labor-intensive industry, with its specifics, should be studied independently (separately) as part of LactOmics. This field has been under persistent and successful study by our respected colleagues investigators and practices in the field of established agricultural sub-sector (Agrarian and Industrial Complex) as the dairy husbandry. This is the source of raw material for our sector. That is why the dairy industry has always been objectively concerned in well-managed and developing production of marketable milk. In view of science, our task (as part of LactOmics) is to study the milk composition and properties with retaining its biocoenosis to the highest level prior to industrial processing. Criteria of interrelations with milk raw stock producers include the mutual understanding and mutually beneficial partnership within a single integrated system, for instance, a Ministry or an Association (cooperation). We would hope that the Russian Dairy Union (Russian Union of Dairy Producers) and SoyuzMoloko, as well as all trading levels and forms will come to agree to a common platform for purposes of diary science development in Russia. In terms of terminology – dairy raw processing production.

Second stage is the industrial processing (fabrication) of the milk raw stock to obtain the desired (required) range of dairy products that is the independent sector (today it is the Ministry of Agriculture of Russia as part of Agrarian and Industrial Complex) and is based on scientific accomplishments in almost all fundamental and applied sciences existing in the world. This part of LactOmics is the subject of consideration in this article as the constituent part of the investment portfolio accumulated for over 50 years of practical and academic activity. It is formalized as the diary product technology in terms of science, human resourcing and information support [8].

Third stage is the use of products (dairy and milk-containing) produced by the industrial processing of milk raw stock, that is classified as commercial, public and home food, and in terms of science, it should be reviewed culture of consumption of diary and milk-containing products, feed materials, pharmaceutical and veterinary means, as well as possible service semi-finished products. This stage of LactOmics, the same as the first stage, requires a separate (independent) study in terms of scientific and practical practice with integration of experience gained. For example, modern design and service are not involved in the dairy business at all and most often, the advertising is not positive.

Consideration of the milk raw stock lactOmics would be desirable to start with the tractate of Fabrizio Bertolletti [9], the inquisitive Italian monk who divided the milk into three components back in 1615 (the time of the great Leonardo da Vinci) as follow: Butyrum (fat); Serum (whey) and Caseus (protein). At our justifiable request and during the personal meeting, Saverio Mannino, the respected Professor of the Milan University, the well-known nanotechnologist, made photo-copies of pages of this unique scientific work (kept in the manuscript department of the University of Florence), with the fragment shown in Fig. 2 just for reference.

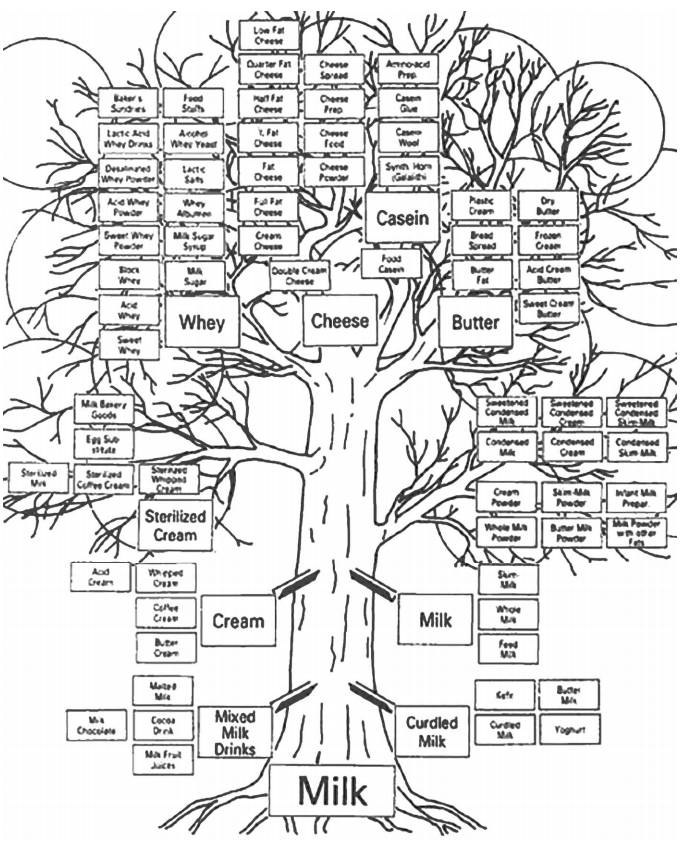

It is notable that only three components are identified in milk, two of which turned out to be the base for industrial and home production of milk products as the sweet butter – Butyrum and cheese (cottage cheese) – Caseus. By the way, F. Bertolletti used to evaporate (condense) the Serum (milk whey – curd) just being concerned to obtain the "manna"(pasty mass) that became the harbinger of lactose (milk sugar). In the "milk tree" by Wygand (cited as per I.G. Zadow) [10], as shown in Fig. 3, dozens of milk components can be identified as well as dairy products.

As per modern concepts [11], about 2000 components have been identified in milk, which include more than 100,000 molecular structures, which is impressive and requires a constant study of this unique product provided to the humans by nature ("amazing food" by our compatriot I. P. Pavlov, the Acad., Nobel Laureate) for the purpose of its rational (effective) use. This postulate is the purpose and content of the proposed science of LactOmics. At the same time, it is necessary to pay attention to the ethical component of LactOmics – milk fabrication is "blessed by the Almighty", and the cow-nurse in all nations is "poetized".

For example, the hymn of the Sumerians, that given below solely for the respect to the postulate of evidence of LactOmics life affirmation:

“Our force is cows!

Cows feed us!

We hope for cows!

We win thanks to our cows!”

A cow is idealised and idolize (India and other countries) by a range of ethnic groups. To note, as a food product, the milk (as the animals are domesticated) by F. Engels ("Dialectic of nature"), is at least treated as the meat food and associated with formation of the homo sapiens of today. The motto – "Back to apes with no milk" was claimed at the 6th International Conference of Milk Whey (USA, 2011) [12] by health care professionals.

Let's enlarge upon the second stage of LactOmics – industrial fabrication of milk raw stock.

First, it should be stated nowadays in compliance with LactOmics postulates that milk and all milk raw materials (cream, skim milk, buttermilk, whey, ultrafiltrates and casein-free phase) are the most complex and naturally synthesized – and thus, of specific value – bio-technologically pure ecosystem (BTES). This statement is claimed by our colleagueslive stock breeders [13] and fully corresponds to the science gradation in Category "Live Systems". It is methodologically justified in the system analysis, for example, in the unique works by the Academician of the Russian Academy of Sciences V.A. Panfilov [14, 15].

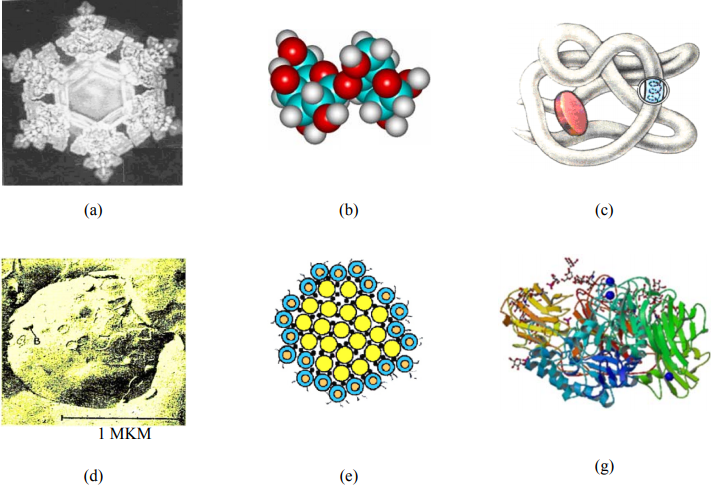

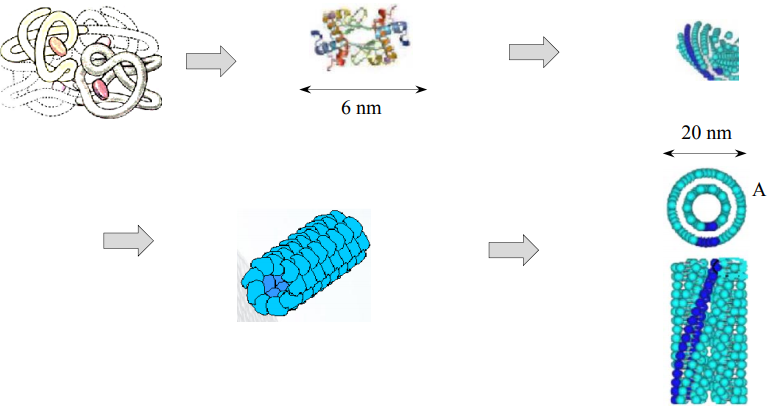

Second, based on BTES postulates, all the milk raw stock components should be considered as natural CLUSTERS – lipid (fat), nitrogen-containing (proteins), carbohydrate (lactose), mineral (salts), BAS and water. The Figure 4 shows the milk LactOmics clusters in the integrated llustrations exclusively for the visual verification of BTES.

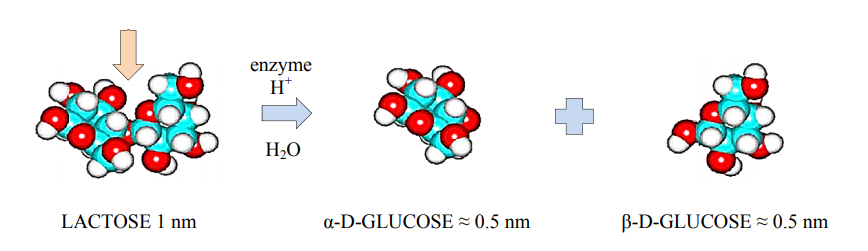

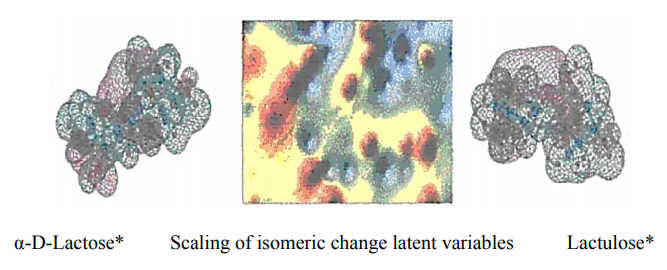

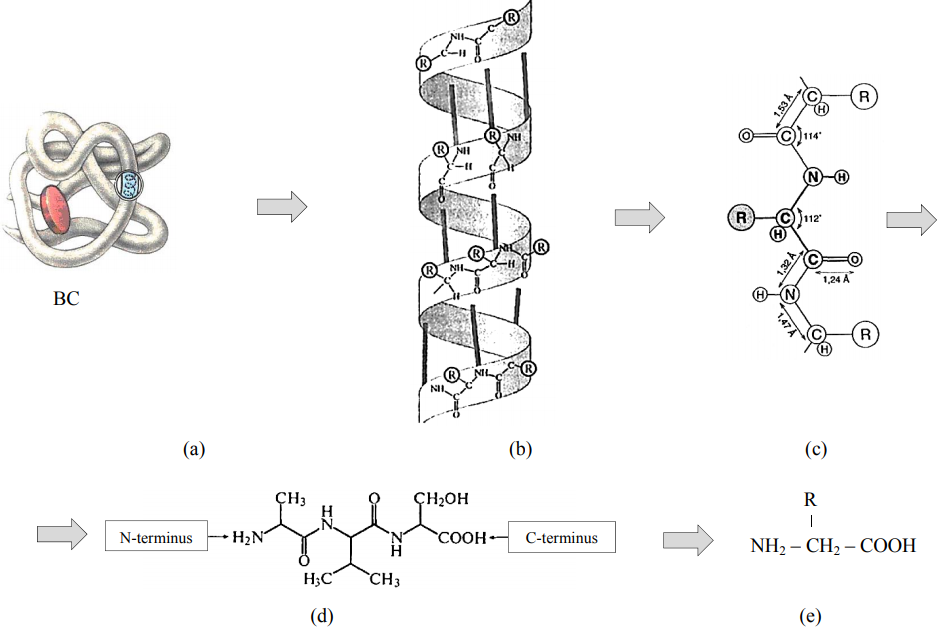

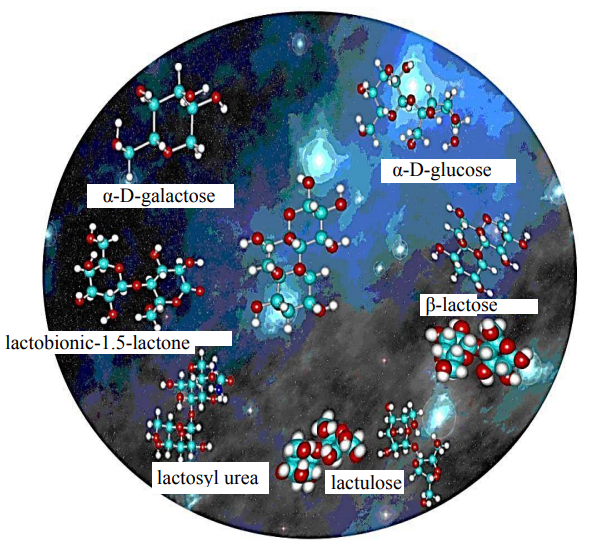

It should be noted that each cluster is polymorphic, is of interest by itself and is considered in detail in our articles: fats (LipiOmics) [5] proteins (ProteOmics, PeptidOmics) [6], lactose (GlycOmics) [4]. At that, the size of certain clusters is idealized in terms of nanotechnology concepts – lactose anomers are shown in Fig. 5; mineral saults; water – they are heterogenetic for the molecular sieve effect-based separation (membrane technology) and subjectively (as "live systems") correspond to biotechnology postulates (bio-membrane technology).

Breakthrough researches by I. T. Smykov [16] conducted on the national level obviously verify the statements above, while the synthesis of nantubes of whey proteins (fat substitutes) [17] makes them "reassuring" as part of LactOmics sciencce (Fig. 6).

As it was repeated again and again [3, 8], the classic example of bio-, nanotechnology principle implementation is the controlled hydrolysis of lactose (milk sugar) to glucose monosaccharides and galactose (Fig. 7), protein cleavage to peptides and amino acids (Fig. 8), as well as the controlled lactose transformation to lactulose (Fig. 9) and other derivatives (over 100 titles).

Third, the range of LactOmics diary products formed traditionally is great and may satisfy needs of any consumer, from birth to extreme ages "in sickness and in health". The list of cheese only includes over 10000 items [18]. The scientific support for dairy product technology is justified by our outstanding predecessors (I dare to mention only a few fellow citizens): by basics – D.I. Mendeleev, I.P. Pavlov, I.I. Mechnikov, N.V. Vereshchagin, N.V. Parashchuk, G.A. Kuk, G.S. Inikhov, Ya.S. Zaykovsky, S.А. Korolev, N.N. Lipatov, P.F. Dyachenko; by separate product line groups: butter making industry – М.М. Kazansky, G.V. Tverdokhlyob, V.I. Sirik; cheese making industry – A.I. Chebotaryov, P.F. Krasheninin, А.М. Shalygina; canned milk – М.S. Kovalenko, V.V. Strakhov, N.V. and L.V. Chekulaeva. The laid basis for LactOmics has been actively and purposefully developed by creative teams, among which the schools by the Academician of the Russian Academy of Sciences V.D. Kharitonov (All-Russia Dairy Research Institute, Russia) are recognized at the national level – whole milk products and canned milk; schools by Professor F.A. Vyshemirsky (All-Russia R&D Institute of Butter and Cheese Industry, Russia) – butter industry; schools by Professor L.А. Ostroumov (Kemerovo Technological Institute of Food Industry (University), Russia); by the Academician of the RAS Yu.Ya. Sviridenko (All-Russia R&D Institute of Butter and Cheese Making, Russia), by the Prof. А.А. Mayorov (Siberian Scientific Research Institute of Cheesemaking Industry, Russia), – cheesemaking; as well as the scientific school 7510.2010.4, now NCFU (North Caucasus Federal University – co-supervisors: the Acad. of the Russian Academy of Sciences A.G. Khramtsov and Prof. I.A. Evdokimov) – secondary milk raw processing. It should be emphasized that lots of creative teams, outstanding researchers and practitioners in this industry, research institutes, universities and commercial organizations are involved in scientific researches in the field of dairy science, including dairy technology. The work they are engaged in is noble and demanded. The scope of the publication does not allow mentioning them. In addition to hundreds of national research organizations and companies, the International Dairy Federation (IDF) has been operating for more than 100 years that represents LactOmics as the integrated science in a worthy manner.

Conceptual part of Technological Platform [19–21] of LactOmics, in terms of diary product technology and its implementation and, in our opinion, it should lean on three pillars:

– the full use of the milk raw stock components with modification thereof, standardization (regulation), structuring and enriching (filling mixtures);

– the extraction of single components or groups of components producing the commercial product;

– the fabrication (synthesis) of derivative components of milk raw stock producing the commercial product, including pharmaceuticals and veterinary drugs.

The theoretical justification of each LactOmics thesis of diary science on whole and the technology of dairy products in particular, practical implementation thereof require fundamental approaches to be developed, as A.M. Osintsev [22] attempted under the guidance of the Professor L.A. Ostroumov. However, it's not the end. The milk tree continuously grows and crops.

The conceptual part implementation of LactOmics of dairy product technology by the product line groups as above allows creating an alternative approach to the procedure of industrial processing of raw milk, under conditions of economic reforms and globalization of the dairy market, based on principles of non-waste and robotic technology in the complete and even captive manufacture with no draining wastes. A vast and continuously expanding range of dairy and milkcontaining products, beverages, feed, pharmaceutical and veterinary agents, as well as commercial semifinished products is worth to be listed in the Guinness Book of World Records.

The Technological platform (TP) of industrial processing (fabrication) of the milk raw stock, based on LactOmics principles, should be started from its conditioning phase. This problem is addressed as system issues in trade journals [23, 24] and requires specific development for widespread scaling in the industry [25–27]. The essential condition for the TP implementation is harmonization of biotechnological impact on the raw material system minimizing intramolecular alterations and retaining the system integrity, so called "steamed milk", as the high level of LactOmics in the biocenosys of the Earth.

Implementation of advanced innovative (high) bionanoelectro-membrane technologies [28–30] in line with the doctrine that we suggest [31] and upgrading logistics [32] will afford to ensure Food Safety in the Russian Federation [34], within the new technological wave [33] in terms of irreplacable food of functional purpose, that is, milk and dairy products.

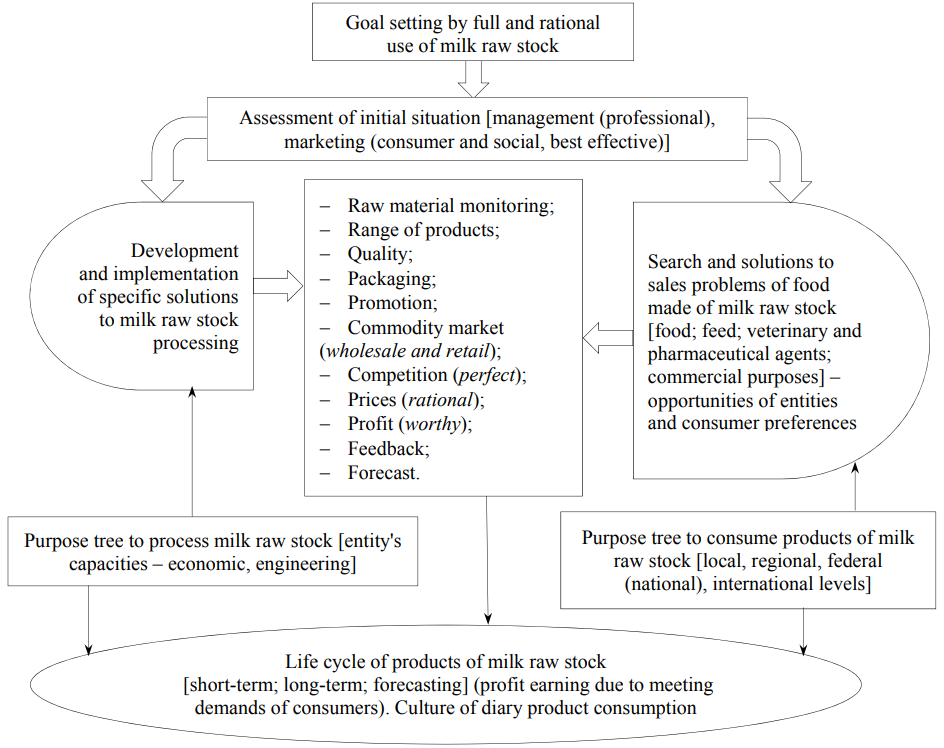

The logistic scheme of LactOmics market concept as terms is shown in Fig. 10 in respect to diary product technology.

The scheme above previously adapted to consumer's milk on international level, and to milk whey and secondary milk raw materials on national level reveals the entire complexity of the hierarchy of interrelations of a dairy enterprise in the cycle of turnover. The infinity of LactOmics on the Earth may be figuratively depicted (Fig. 11) against the galaxy as the family of lactose derivatives.

In conclusion, emphasizing once again that this article is prepared to raise an issue for discussion and possible development of LactOmics provisions at all three interrelated levels, and I would hope that the dairy business in Russia will always stay the forefront in the great dairy Empire.

СПИСОК ЛИТЕРАТУРЫ

- Khramtsov A.G. Nauchno-tekhnicheskie osnovy modernizatsii molochnoy promyshlennosti АPK Rossii [Research and development basics of diary industry upgrading of the Russian Agrarian Science and Technology]. Stavropol: SKFU Publ., 2013. 82 p.

- Khramtsov A.G. Innovatsionnye prioritety i praktika tekhnologicheskoy platformy modernizatsii molochnoy otrasli APK [Innovative priorities and practice of technological platform of modernization of dairy industry of agrarian and industrial complex of Russia]. Volgograd: Volgograd Scientific Publ., 2013.148 p.

- Khramtsov A.G. Innovatsionnye prioritety i praktika tekhnologicheskoy platformy modernizatsii molochnoy otrasli APK [Innovative priorities and practice of technological platform of modernization of dairy industry of agrarian and industrial complex]. Voronezh: VSUET Publ., 2015. 260 p.

- Khramtsov A.G. Glycoomics clusters of lactose and its derivatives in nanotechnology of living cultures. Foods and Raw Materials, 2015, vol. 3, no. 1, pp. 3-12. DOI: 10.12737/11168.

- Khramtsov A.G. An epistemological background on paradigm formation of lipidomics of dairy industry. Foods and Raw Materials, 2016, vol. 4, no. 1, pp. 79-89. DOI: 10.21179/2308-4057-2016-1-79-89.

- Khramtsov A.G. Scientific and technical justification of conceptual provisions of proteomics of dairy business. Foods and Raw Materials, 2016, vol. 4, no. 2, pp. 16-31. DOI: 10.21179/2308-4057-2016-2-16-31.

- Khramtsov A.G. Laltoomika as the science of milk. Modernization of our ideas. Dairy Industry, 2011, no. 6, pp. 45-48. (In Russian).

- Gavrilova N.B. and Shchetinin M.P. Tekhnologiya moloka i molochnykh produktov: traditsii i innovatsii [Milk and diary product technology: traditions and innovations]. Moscow: KolosS Publ., 2012. 544 p.

- Bartoletus F. Enziklopedia hermеtiko-dogmatika. Bologna, 1619. 168 р.

- Zadow J.G. (ed.). Whey and Lactose processing. Chapter 10: Lactose hydrolysis. London - New York: Elsevier applied science, 1992. XVI, 489 p.

- Tepel A. Khimiya i fizika moloka [Chemistry and physics of milk]. St. Petersburg: Professija Publ., 2012. 832 p.

- Khramtsov A.G. International summit on milk whey: innovative priorities. Dairy Industry, 2014, no. 1, pp. 60-61. (In Russian).

- Khramtsov A.G. Innovatsionnye prioritety realizatsii biotekhnologicheskikh sistem produktov pitaniya novogo pokoleniya [Innovative priorities of implementation of bio-technological systems of new generation food products]. Materialy Mezhdunarodnogo nauchno-prakticheskogo kongressa fakul'teta biotekhnologii, tovarovedeniya i ehkspertizy tovarov «Biotekhnologicheskie sistemy i innovatsionnye tekhnologii proizvodstva produktov pitaniya kak odin iz instrumentov realizatsii «Gosudarstvennoy programmy razvitiya sel'skogo khozyaystva i regulirovaniya rynkov sel'skokhozyaystvennoy produktsii, syr'ya i prodovol'stviya na 2008-2012 gody» [Proc. of the International Scientific and Practical Congress of Biotechnology Faculty of Commodity and examination of goods “Biotechnological systems and innovative technologies of food product manufacture as a tool to implement the “State Program of Agriculture Development and Regulation of Crop Market, Raw Stock and Food for 2008 - 2012”]. Persianovsky, 2009, pp. 6-8.

- Panfilov V.A. System approach to the problem of machinery technology development in re-processing industries. Izvestia vuzov. Pishevaya tekhnologia, 1995, nos 1-2, pp. 98-100. (In Russian).

- Panfilov V.A. The system complex «Agrarian-Food Technology» and the sixth technological way in agrarian and industrial complex. Technologies for the food and processing industry of AIC - healthy food, 2014, no. 4, pp. 55-61. (In Russian).

- Smykov I.T. Modelirovanie protsessov strukturirovaniya i upravlenie strukturoobrazovaniem v geterogennykh biopolimernykh sistemakh [Modeling of cross-linkage processes and structurization control in heterogenetic biopolymer systems]. Diss. Dr. Sci. (Eng.). Uglich, 2014. 370 p.

- Podgorny N.A. Poluchenie novoy pishchevoy kompozitsii i ee primenenie v tekhnologii sinbioticheskogo napitka [Receipt of a New Food Composition and its Application in the Technology of Synbiotic Drink]. Abstract of Diss. Cand. Sci. (Eng.). Stavropol, 2013. 209 p.

- Kolodkin Yu.A. and Aleksandrova O.A. Ego velichestvo syr. Produkt, kotoryy pokoril mir [Cheese - His Majesty. Food that conquered the world]. Barnaul: n. publ., 2010. 128 p.

- Khramtsov A.G. Paradigm of formation technological platforms of high technologies of the food industry. Izvestia vuzov. Pishevaya tekhnologia, 2014, no. 2-3, pp. 9-12. (In Russian).

- Khramtsov A.G. Formation logistics of technological platform for obtaining lipid and protein bio-clusters from whey. Food Processing: Techniques and Technology, 2014, vol. 33, no. 2, pp. 102-106. (In Russian).

- Khramtsov A.G., Evdokimov I.A., Ryabtseva S.A., Shipulin V.I., and Lodygin A.D. Technological platform for modernizing food industry un Russian agroindustrial complex under real biocenose, market and WTO. Newsletter of north-caucasus federal university, 2014, no. 5(44), pp. 44-51. (In Russian).

- Osintsev A.M. Razvitie fundamental'nogo podkhoda k tekhnologii molochnykh produktov [Development of fundamental approcah to diary product technology]. Kemerovo: KemIFST Publ., 2004. 152 p.

- Khramtsov A.G. The dairying: logistics of the concept of conditioning «the living cycle» of raw materials and products. Dairy Industry, 2014, no. 6, pp. 38-40. (In Russian).

- Khramtsov A.G. Whey serum conditioning prior to processing. Milk Processing, 2015, no. 4, pp. 16-19. (In Russian).

- Emelyanov S.A. Teoreticheskoe obosnovanie i ehksperimental'nye issledovaniya tekhnologicheskikh aspektov bakterial'noj sanatsii molochnogo syr'ya v usloviyakh real'nogo biotsenoza [Theoretic justification and experimental researches of process aspects of bacterial sanitation of raw milk under real biocenosys]. Abstract of Diss. Dr. Sci. (Eng.). Stavropol, 2008. 38 p.

- Smirnov E.R. Razrabotka tekhnologii konditsionirovaniya molochnoy syvorotki [Development of technology for whey conditioning]. Cand. eng. sci. diss., Stavropol, 2009. 132 p.

- Vagner V.A. Razrabotka sposoba podgotovki moloka dlya proizvodstva syrov s vysokoy temperaturoy vtorogo nagrevaniya [Development of method to prepare milk for production of cheese at high second heating temperature]. Diss. Cand. Sci. (Eng.). Kemerovo, 1986. 124 p.

- Khramtsov A.G., Evdokimov I.A., Lodygin A.D., and Budkevich R.O. Technology development for the food industry: a conceptual model. Foods and Raw Materials, 2014, vol. 2, no. 1, pp. 22-26. DOI: 10.12737/412.

- Khramtsov A.G. Innovative priorities of high technologies. Milk Processing, 2015, no. 10, pp. 16-17. (In Russian).

- Khramtsov A.G., Lodygin A.D., Panova N.М., and Ryabtseva S.А. Innovatsionnye tekhnologii produktov pitaniya na osnove nanoklasterov molochnoy syvorotki [Innovative food technology based on whey nanoclusters]. Stavropol: NCFU Publ., 2013. 107 p.

- Khramtsov A.G. Dairying: scientific ensure of modernization. To the jubilee of the Professor Ivan Evdokimov. Dairy Industry, 2015, no. 10, pp. 43-45. (In Russian).

- Khramtsov A.G. Diary business logistics. Forecasting. Milk Processing, 2011, no. 6, pp. 48-50. (In Russian).

- Tumanov Yu.N., Tochilin S.B., and Dedov N.V. What principles should be create the new technological wave on? Bulletin of the Russian Academy of Sciences, 2014, vol. 84, no. 4, pp. 311-325. (In Russian).

- Kleshchevskiy Yu.N. and Kazantseva E.G. Assessment of food security in a country. Food Processing: Techniques and Technology, 2014, vol. 34, no. 3, pp. 163-168. (In Russian).