Аннотация

The paper describes physical characteristics of drying animal- and plant-based raw materials with pulsed infrared emitters. Furthermore, it discusses how to select and use infrared emitters to produce high quality products with a long shelf-life. Using an experimental facility, we identified basic patterns of changes in the heat flux density. We also analysed the drying thermograms and assessed the influence of process factors on the removal of moisture from raw materials and the preservation of biologically active substances in dried and concentrated products. We determined specific kinetics of drying in different modes of power supply and selected the most efficient pulsed cera- mic emitters. These emitters had a high rate of heat transfer and an ability to accurately target molecular bonds, thus reducing the drying time and energy costs. Mathematical modelling enabled us to obtain specific values of process parameters for pulsed infrared drying of plant materials. The heating time constant was calculated for root and tuber vegetables, depending on their moisture content and size. The study showed that root and tuber vegetables should not be heated to more than 60°C when irradiated with a 500 W medium-wave emitter at a working distance of 250 mm during a full 10-minute cycle. The optimal modes of drying liquid products with milk and plant proteins included a heating power of 400 W, a radiant heating temperature of 60°C, and a layer thickness of 10 mm. The selected modes of pulsed infrared drying of sugar-containing root and tuber vegetables reduced the duration of moisture removal by 16–20% and cut energy costs by 16.6%. This unconventional method of infrared drying of whole milk, whey, whey drinks, and milk mixture preserves beneficial microflora and increases the nutritional value and shelf-life, with a pos- sible content of chemically bound water of polymolecular and monomolecular adsorption ranging from 10 to 15.58%.Ключевые слова

Infrared, pulsed IR emitters, plant material, liquid raw milk, temperature, features, waterВВЕДЕНИЕ

Animal- and plant-based foods and raw materials have a short shelf-life, tasking food technologists with finding ways to preserve their quality for consumers [1]. One of the oldest methods of food preservation is drying, ensuring microbiological safety by dehydration [2, 3, 33].

The current research aims to develop new technologies using unconventional drying methods to create biologically valuable long-life products of high quality [4, 5]. Dry products are widely used in various branches of industrial processing. Plant- and animal-based raw materials are commonly dried with facilities that use electrical energy converted to infrared radiation. Since electrically charged particles are stimulated by electric, magnetic, and electromagnetic fields, pulsed infrared treatment is considered one of the most effective methods of dehydrating raw materials and foods.

Infrared (IR) radiation is a transfer of energy from a radiation source to an object by means of electromagnetic oscillations at wavelengths between 0.78 and 750 microns through a medium that is transparent to thermal radiation. The technology of pulsed infrared drying of wet products can use almost 100% of delivered energy, with the drying process proceeding under gentle conditions [6, 7]. Infrared emitters used in this technology allow for drying at 40–60°C and thus preserving most of the original functional properties of food components. Biologically active substances and vitamins in the dried product account for about 90% of their content in the fresh product [8–11].

The physicochemical process can be described as follows: the product’s water molecules absorb IR rays, which intensifies the thermal motion of atoms and molecules and causes them to heat. This way the energy is delivered directly to the product water, making thermal evaporation highly efficient. Such a direct heat supply allows for drying at relatively low temperatures (40–60°C). This method has two advantages. Firstly, it prevents cells and vitamins from being destroyed and sugar from caramelising, thus preserving the properties of raw materials and foods. Secondly, the walls of the drying equipment do not heat, thus reducing heat losses.

The following methods are currently used in Russia and abroad to dry raw materials of animal and plant origin: natural drying, conduction, convection, microwave drying, infrared drying, sublimation, and pseudo-boiling. Each of the methods has its advantages and disadvantages.

Infrared drying is comparable to other methods in many respects and even surpasses them in terms of energy consumption for the evaporation of moisture. Due to a high penetrating ability of infrared radiation, heat is released in the depth of the material, increasing the drying intensity 1.5–2 times and thus reducing energy consumption.

We established that the specific effect of IR radiation on food products is determined by the intensification of biochemical processes. This is due to the resonant effect of the absorbed energy on the bonds of atoms in molecules, whose oscillation frequencies are equal or multiple to the frequency of the incident radiation.

Of all existing drying facilities, infrared drying equipment is versatile: it can be used for drying both plant- and animal-based raw materials and products from them. It includes drying chambers and apparatuses with ceramic-coated heating elements emitting infrared rays. Pulsed infrared radiation is known to destroy microorganisms on the surface of a raw material, making it suitable for long-term storage [6, 12–17].

As a technological process, infrared drying is based on the fact that infrared rays of a certain wavelength are quickly absorbed by the water and not absorbed by the product microstructures. This allows for removing moisture at low temperatures (40–60°C) and thus preserving natural colour, vitamins, taste, aroma, and biologically active substances [6, 18–21].

Thus, infrared heating has the following advantages over other drying methods:

1. The amount of heat transferred, determined by the Stefan-Boltzmann law, is proportional to the difference in fourth powers of the temperatures of the emitter and the heated body. Infrared radiation is 4–5 times as in tense as heat transfer by convection at the emitter temperature above 500°C.

2. The radiant flux is directionally focused on the heated object with the help of reflectors, ensuring minimal radiation in other directions. The temperature of the air through which the rays pass makes almost no difference for the heating or drying process.

3. This method allows for selective heating. Due to the low energy of quanta, infrared rays have a very limited ability to cause chemical reactions. Only the absorbed part of the radiant flux can accelerate chemical reactions in a substance or its heating. Substances vary in the ability to absorb infrared rays. Therefore, molecules of different compounds can have pronounced absorption maxima, and the emitters or heating temperatures need to be carefully selected to ensure intensive heating of surfaces or particles.

This method of dehydration may be used to produce various types of food concentrates such as cereals, soups, main courses, snacks, vegetable- and fruit-based baking powders, and components for dry infant formulas. Vegetables subjected to infrared drying, rather than traditional drying, retain their taste as close as possible to that of fresh vegetables. In addition, powders produced by infrared drying have antioxidant, anti-inflammatory, and detoxifying properties.

The use of ingredients produced by infrared drying in the dairy industry, confectionery or bakery allows them to expand the range of products with specific sensory properties. In addition, such products are environmentally friendly and free from exposure to harmful electromagnetic fields and radiation, as infrared radiation is harmless to humans and the environment.

It should be noted that dry products are easily stored and resistant to the development of microorganisms. They can be stored without special packaging (at low environmental humidity) for a year, with a 5–15% loss of vitamins. When sealed, dry products can be stored for up to two years. Drying reduces the volume of a product 3–4 times and its weight, 4–8 times.

This work aimed to study physicochemical patterns and develop a technology for thermoradiation drying of animal- and plant-based raw materials using pulsed infrared emitters to produce foods with a high biological value and an extended shelf-life.

ОБЪЕКТЫ И МЕТОДЫ ИССЛЕДОВАНИЯ

The experimental studies of the dehydration of animal- and plant-based raw materials and their physicochemical characteristics were conducted at the Kemerovo State University and the Ezhevsky Irkutsk Agrarian University, Russia.

The objects of study were root vegetables (carrot, beetroot, turnip, Jerusalem artichoke, and potato), liquid products with milk proteins (whole milk, whey, whey drinks, and fermented milk drinks), purchased in the retail chains of Kemerovo and Irkutsk, and oat protein extract [22].

The studies consisted of several stages followed by a substantiation of the technology for producing highly nutritional food concentrates containing sugar, milk, and plant proteins.

An experimental production facility with IR power supply was designed to dry vegetables and fruits (Fig. 1). Liquid products with milk and plant proteins were dried under vacuum. The facility contained automatic circuit breakers, heating elements, and an electric motor with a fan, and was insulated with a thermal non-flammable material to reduce thermal losses.

Pulsed ceramic heating elements of ECS, ECP, ECH, ECX, and ECZ types with a capacity of 1 kW each were used as sources of infrared radiation. The control system maintained the required temperature and operating mode of IR emitters, thus reducing power consumption. Shredded fruits and vegetables were placed on trays in a layer of 1.5 cm, and liquid products in a layer of 10 cm, in the drying chamber. The choice of thermal emitters depended on the type of material to be dried. The temperature in the chamber was maintained by the control system and thermocouples. Evaporated moisture was removed by the fan. After a certain time, the product was taken out of the drying chamber.

The temperature regime, T (°C), of the elementary layer of biological objects exposed to IR treatment and drying with a given radiation power p (W) and duration τ (min) was represented by the following function:

where T0 is the initial temperature, °C;

a is the heating time constant, °C/min;

b is the structural coefficient of the energy level, °C/(Wu minv); and

ε (p,τ) is the random deviation of experimental data from the calculated values.

Power consumption depends on radiation power and the ability of the material under treatment to absorb and accumulate energy:

where P is IR radiation power, W;

α, β are the process efficiency values in the IR-treatment cycles.

Changes in the moisture content, W (%), in the elementary layer of objects exposed to IR treatment and drying with a given radiation power P (W) and duration τ (min) were represented by the following function:

where aj, bij are unknown process parameters, determined by the material’s properties;

W0 is residual moisture, %; and

ε (P,τ) is the random deviation of experimental moisture data from the calculated values.

The characteristic numbers of the process operator representation λ1, λ2, λ3 are related to the parameters aj as follows:

where j =1, 2, 3.

Changes in the carbohydrate content, S (%), in the elementary layer of root vegetables exposed to IR treatment and drying with a given radiation power P (W) and duration τ (min) was represented by the following function:

where aj, bij are the process parameters under study, determined by the material’s properties;

S0 is the initial carbohydrate content, %;

ε (P,τ) is the random deviation of experimental sugar data from the calculated values.

Changes in the vitamin content, V (mg/100 g), in the elementary layer of vegetables exposed to IR treatment and drying with a given radiation power P (W) and duration τ (min) was represented by the following function:

V0 is the initial content of vitamins, mg/100 g; and

ε (P,τ) is the random deviation of experimental vitamin data from the calculated values.

The duration of radiation in the first cycle was determined by the formula given in [3, 23, 24]:

The base was calculated by the formula:

After taking the logarithm of the above:

Since the duration of drying is significantly affected by the maximum rate of heating (Vmh), formula (12) takes the following form:

We identified some patterns in intermittent irradiation control, which could be described with the theory of power series. The duration of irradiation for the second and subsequent cycles was calculated by the formula:

where Tcycle/TH is the relation between the cycle (or its part) time and the heating time constant.

The analytical model that we developed, as well as the patterns of irradiation control, enabled us to justify the following effective discrete operation modes for an infrared emitter:

The heating time constant is the time taken for the temperature rise to reach a steady-state value if there is no heat release to the environment. Since the drying process takes place in a closed chamber and there is practically no heat release to the environment, the heating time constant becomes a decisive factor for choosing the IR power feed mode. The heating time does not depend on the input power and is numerically equal to the ratio of the body heat capacity to its heat transfer [14, 21, 24]:

where C is the product’s heat capacity, J/°C;

Qpr is the product’s heat transfer, J/°C•s.

In case of heat transfer during the time equal to the heating time constant, the product temperature rise reaches a value equal to 0.632 of the steady-state value. The heat capacity of the material depends on the heat capacity of dry matter and water. The specific heat capacity of dry matter in plant raw materials ranges from 0.733 to 1.550 J/(kg•°C). Since the heat capacity of water (C = 4.1868•103 J/(kg•°C)) is much higher than that of dry matter, the heat capacity of plant raw materials decreases during drying.

The heat capacity of wet materials is determined by the formula:

where Cdm and CH2O are the heat capacity of the product’s dry matter and water, respectively, J/(kg•°C);

ω and U are the material’s initial and ultimate moisture content, respectively, %.

Eq. (17) determines a linear dependence between the heat capacity and the initial and ultimate moisture content of the object of drying. The temperature rise is accompanied with an increase in the heat capacity.

The heating time constant was determined by the following equation:

where C is the specific heat capacity of a root vegetable, J/kg•°C;

M is the mass of root and tuber vegetables, kg;

α is the heat transfer coefficient of root vegetables, J/m2 •°C•s;

and F is the surface of the product, m2, or as follows:

When V/F was expressed as σ, Eq. (19) for the heating time constant was as follows:

Each experiment was repeated three times and the data were expressed as a mean ± standard deviation. The data were processed by standard methods of mathematical statistics. The homogeneity of the sampling effects was checked with Student’s t-test. The differences between the means were considered significant when the confidence interval was less than 5% (p ≤ 0.05).

РЕЗУЛЬТАТЫ И ИХ ОБСУЖДЕНИЕ

Plant- and animal-based raw materials have certain electrophysical and thermal properties (heat capacity, thermal conductivity, electrical conductivity, dielectric and magnetic permeability, and optical properties) manifested at the exposure to electric, magnetic, and electromagnetic fields, as well as waves of different frequencies. The resulting changes in electrical charges lead to the release of heat and alter physicochemical characteristics of the materials.

Infrared treatment and drying work well for both vegetables (carrot, beetroot, turnip, celery, cabbage, spinach, tomato, parsley, pepper, potato, and Jerusalem artichoke) and fruits (apple, pear, plum, peach, apricot, grape, and banana). As objects of drying, they are characterised by a high water content and a relatively low dry matter content. About 5% of water is bound in cells, tissues, and colloids and is firmly held there, while the rest of it is in a relatively free mobile form.

Various modes of power supply and sources of pulsed infrared radiation were tried to establish effective modes of treatment and drying. The optimum was achieved with 700 W emitters and decreased power supply. The preservation of nutrients was provided by the emitters of any capacity with decreased power supply.

Changing humidity and achieving the required moisture content in the raw material or product in a short time reduces the duration of drying and saves energy. The most efficient reduction in moisture content was provided by the mode of repeated short-term heating with decreased power supply. In addition, this mode of infrared treatment and drying ensured increased carbohydrate content and maximum vitamin content in sugarcontaining root vegetables (beetroot).

The above method enabled us to control electromagnetic radiation fluxes at the Planck constant level and produce foods with an optimal composition of active substances. Modern electrical facilities with advanced electronics make it possible to realise the main principles of quantum electrodynamics.

Pulsed ceramic IR emitters are efficient due to a high rate of heat transfer and a possibility of targeting molecular bonds, reducing the duration of the process, and thus saving energy. Their use in the infrared drying technology ensures high-quality products with a long shelf-life. With pulsed IR emitters, there are three ways of controlling infrared power supply [26] with differing relations between the heating temperature, irradiation power, and power consumption during the drying process (Fig. 2).

Using formulae (7)–(20), we calculated the heating time constant for root and tuber vegetables depending on their moisture and size. The experimental studies of pulsed infrared drying of sugar-containing roots and tubers identified effective modes for controlling IR power supply and their influence on the quality of carrot, beetroot, and Jerusalem artichoke. In particular, those modes included a decreased power feed with a power density of 0.8 kW/m2 and a radiation surface temperature of 500°C at a 225–250 mm distance. Pulsed ceramic IR emitters operating in those modes created a uniform 40–60°C thermal field on the surface of root and tuber vegetables, thus maintaining the quality of the end product. Those effective modes of pulsed infrared drying of sugar-containing roots shortened the duration of moisture removal by 16–20% and reduced power consumption by 16.6%. The optimal modes for liquid products with milk and plant proteins included a heating power of 400 W, a radiant heating temperature of 60°C, and a product layer thickness of 10 mm.

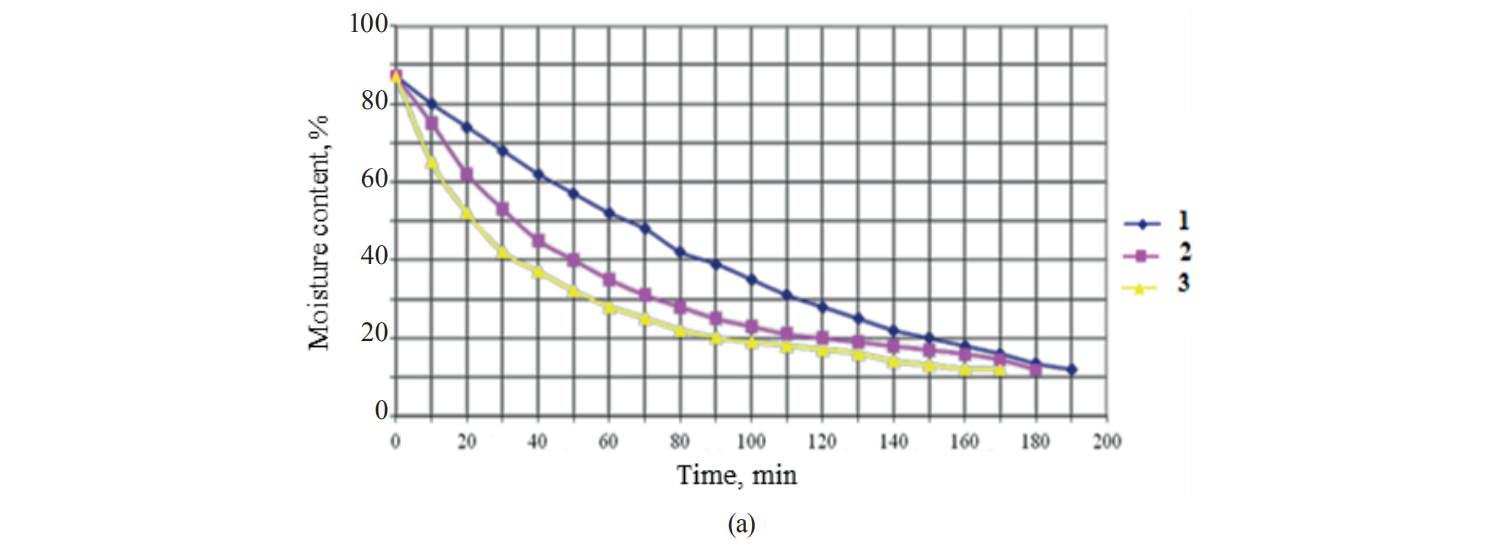

Fig. 3 shows thermophysical features of thermal evaporation of water under infrared radiation. We monitored changes in the moisture content of plant raw materials (root vegetables) during evaporation in an experimental facility using IR power supply (Fig. 1) with various types of IR emitters. Different modes of power supply produced different drying kinetics. The analysis of the drying curves showed that pulsed ceramic heaters ensured a residual moisture of 12% with a product temperature of less than 60°C in less time. A higher temperature reduced the quality and the content of nutrients in root and tuber vegetables.

The most effective mode of drying plant raw materials is the one that ensures minimal duration and power consumption, thus leading to greater preservation of biologically active substances. Such a mode requires that the working temperature and wavelength correspond to the biotechnical conditions of heating. In addition, the spectral characteristics of an infrared emitter need to be consistent with the optical properties of the product. In this case, the energy slowly penetrates into its inner layers and displaces moisture from the depth to the surface.

The above mode can be established with pulsed ceramic emitters, when a product is exposed to high density pulses in a certain spectral range (the depth of penetration in the first approximation is proportional to the pulse density) [14]. The source of primary infrared radiation in pulsed ceramic emitters is a nichrome spiral located in a quartz glass tube with a multilayer ceramic coating. Due to this coating, the full spectrum of infrared radiation is converted from a heating element to a very narrow range of radiation emitted in a series of pulses that are 10–3,000 μs long (Fig. 4) and have a density of 120–350 W/cm2 [14, 16, 21].

The effect of pulsed conversion is associated with cyclic energy transformations in the system. Ceramics accumulates thermal radiation, converts it and then ‘shoots’ impulses in a certain region of the spectrum. The wavelength of the radiation generated varies in the range of 1.7–5.8 microns. With pulsed infrared irradiation, the time required to heat plant raw materials to the ultimate temperature is significantly shorter than that with continuous irradiation. In addition, materials with a high specific thermal capacity heat up faster [14, 16, 27–29]. Furthermore, the high penetrating capacity of pulsed IR radiation leads to the dissociation of organic and bio-organic molecules and the destruction of microorganisms, spores, fungi, and viruses, thus increasing the product’s shelf-life.

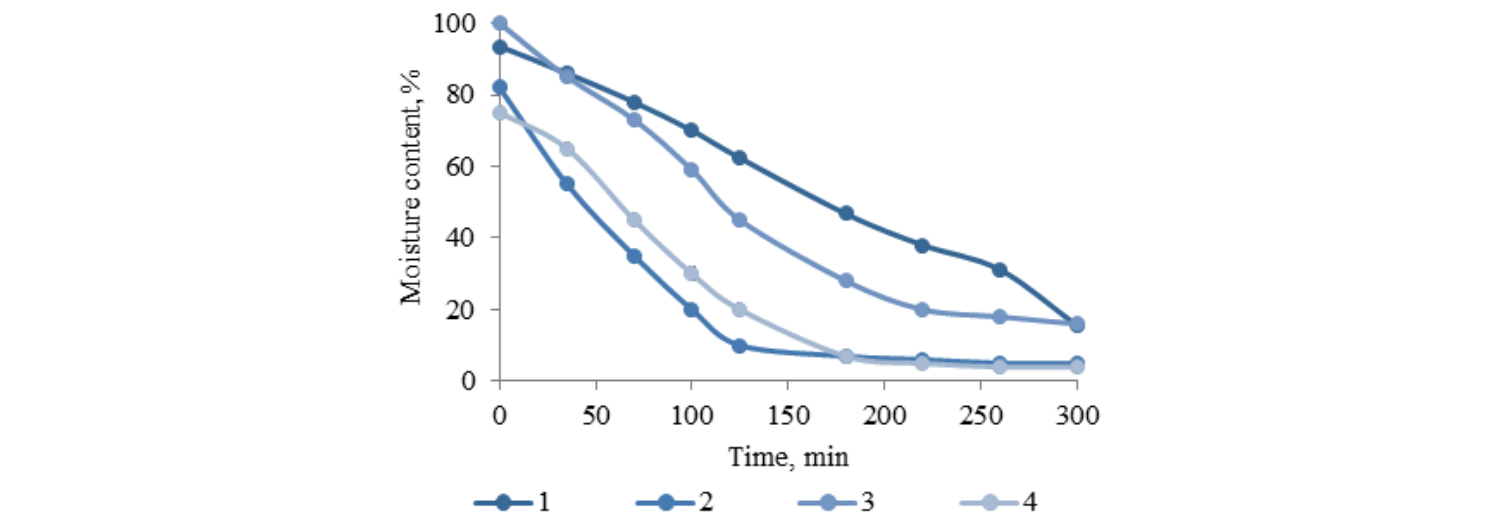

Fig. 5 shows the drying of whey and fermented milk drinks with pulsed ceramic IR emitters. We aimed for a dry matter concentration of 27% to 70%, depending on the further use of dried dairy materials [30–32].

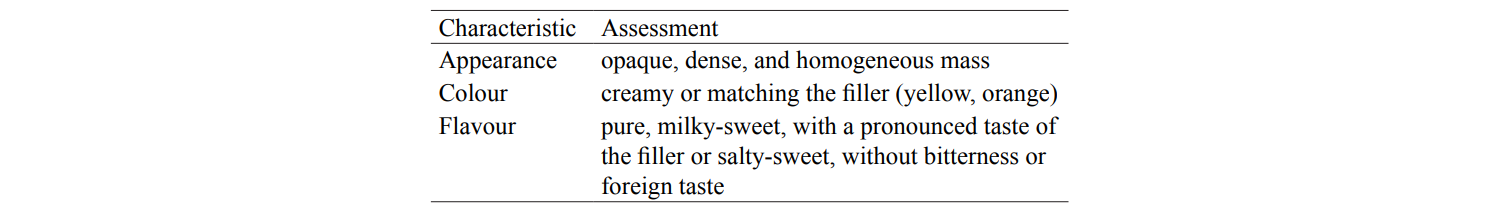

The analysis showed that all the samples of concentrated dairy raw materials and semi-finished products containing animal or plant proteins had the following characteristics (Table 1).

Evaluated on a 10-point scale of organoleptic properties, the samples received an average of 9 points. The physicochemical indicators of concentrated dairy raw materials were as follows: 41% dry matter; 6.0–6.4% fat, 7.6–7.8% protein (semi-finished products with plant proteins had 35% protein and 3% fat), and 1×109–1×1010 CFU/g of beneficial lactic acid microflora at a high functional level.

Some particular features of the process kinetics for various types of dairy raw materials and semi-finished products with plant proteins are determined by their chemical composition and moisture. The drying curves show the removal of the most energy-intensive adsorption moisture with an ordered structure. We established that the chemically bound moisture of polymolecular and monomolecular adsorption in liquid products with milk or plant proteins ranged from 4% to 15.58%, remaining so after drying.

ВЫВОДЫ

The results of thermal evaporation showed a correlation between growing duration of infrared drying and increasing mass fraction of dry matter in the product. The changes in the key quality indicators established 60°C as the optimal temperature of the heat flux in the drying chamber. In that case, the drying rate depended on the speed of moisture displacement inside the product, rather than on the rate of heat transfer.

The temperature graphs for infrared drying of whey and fermented milk drinks showed low temperatures on the surface of the samples (22–25°C), preserving their original natural properties. The analysis of experimental data on drying raw materials with milk and plant proteins established an optimal heating power of pulsed infrared lamps as 400–600 W. Concentrated dairy semi-finished products retained their properties after infrared drying at 22–25°C, with up to 90% of vitamins and other biologically active substances preserved.

The studies demonstrated that the temperature of heating root and tuber vegetables exposed to infrared radiation with a medium-wave 500 W emitter at a working distance of 250 mm during a full 10-minute cycle did not exceed 60°C. Since higher temperatures could lead to an irreversible loss of vitamins and mineral nutrients, those parameters of IR power supply were considered ‘effective’.

БЛАГОДАРНОСТИ

The work was carried out with partial financial support of the Ministry of Science and Education of the Russian Federation [Project No. 15.4642.2017/8.9].

СПИСОК ЛИТЕРАТУРЫ

- Prosekov A., Petrov A., Ulrich E., et al. A selection of conditions for the biodegradation of poultry wastes industry. Research Journal of Pharmaceutical, Biological and Chemical Sciences, 2016, vol. 7, no. 3, pp. 2659–2664.

- Danilchuk T.N. and Ganina V.I. Prospects of using extremely low doses of physical factors impact in food biotechnology.Foods and Raw Materials, 2018, vol. 6, no. 2, pp. 305–313. DOI: https://doi.org/10.21603/2308-4057-2018-2-305-313.

- Salehi F. and Kashaninejad M. Modeling of moisture loss kinetics and color changes in the surface of lemon slice during the combined infrared-vacuum drying. Information Processing in Agriculture, 2018, vol. 5, no. 4, pp. 516–523. DOI: https://doi.org/10.1016/j.inpa.2018.05.006.

- Kulinich A. Innovatsii v oblasti sushki moloka i syvorotki [Innovations in the drying of milk and whey]. Milk Proces- sing, 2010, vol. 131, no. 9, pp. 48–49. (In Russ.).

- Galstyan A.G., Buyanova E.O., and Ivanova A.Yu. New technology in the production of concentrated milk drinks.Food Processing: Techniques and Technology, 2011, vol. 20, no. 1, pp. 14–18. (In Russ.).

- Nowak D. and Lewicki P.P. Infrared drying of apple slices. Innovative Food Science and Emerging Technologies, 2004, vol. 5, no. 3, pp. 353–360. DOI: https://doi.org/10.1016/j.ifset.2004.03.003.

- Borah A., Hazarika K., and Khayer S.M. Drying kinetics of whole and sliced turmeric rhizomes (Curcuma longa L.) in a solar conduction dryer. Information Processing in Agriculture, 2015, vol. 2, no. 2, pp. 85–92. DOI: https://doi. org/10.1016/j.inpa.2015.06.002.

- Nawirska A., Figiel A., Kucharska A.Z., Sokół-Łętowska A., and Biesiada A. Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. Journal of Food Engineering, 2009, vol. 94, no. 1, pp. 14–20. DOI: https://doi.org/10.1016/j.jfoodeng.2009.02.025.

- Ashtiani S.H.M., Salarikia A., and Golzarian M.R. Analyzing drying characteristics and modeling of thin layers of peppermint leaves under hot-air and infrared treatments. Information Processing in Agriculture, 2017, vol. 4, no. 2, pp. 128–139. DOI: https://doi.org/10.1016/j.inpa.2017.03.001.

- Chen D., Wiertzema J., Peng P., et al. Effects of intense pulsed light on Cronobacter sakazakii inoculated in non-fat dry milk. Journal of Food Engineering, 2018, vol. 238, pp. 178–187. DOI: https://doi.org/10.1016/j.jfoodeng.2018.06.022.

- Babich O.O. and Prosekov A.Y. Optimization of L-Phenylalanine-Ammonia-Lyase Liophilization. Biomeditsinskaya Khimiya, 2013, vol. 59, no. 6, pp. 682–692. (In Russ.).

- Bondaruk J., Markowski M., and Blaszczak W. Effect of drying conditions on the quality of vacuum-microwave dried potato cubes. Journal of Food Engineering, 2007, vol. 81, no. 2, pp. 306–312. DOI: https://doi.org/10.1016/j.jfo- odeng.2006.10.028.

- Ochirov V.D. Obosnovanie rezhimov IK-ehnergopodvoda v tekhnologii sushki korneplodov morkovi impulʹsnymi keramicheskimi preobrazovatelyami izlucheniya. Diss. kand. tekhn. nauk [Substantiation of the IR energy supply modes in the technology for drying carrots with pulsed ceramic converters of radiation. Cand. eng. sci. diss.]. Kras- noyarsk, 2011, 189 p.

- Altukhov I.V. The experimental research results of the infrared drying of sugar-containing root crops. Bulletin of KrasGAU, 2014, vol. 89, no. 2, pp. 162–167. (In Russ.).

- Innocente N., Segat A., Manzocco L., et al. Effect of pulsed light on total microbial count and alkaline phosphatase activity of raw milk. International Dairy Journal, 2014, vol. 39, no. 1, pp. 108–112. DOI: https://doi.org/10.1016/j. idairyj.2014.05.009.

- Altukhov I.V. and Tsuglenok N.V. The operational features of pulse IR-emitters in root crop drying technology. Bul- letin of Altai State Agricultural University, 2015, vol. 4, no. 126, pp. 109–104. (In Russ.).

- John D. and Ramaswamy H.S. Pulsed light technology to enhance food safety and quality: a mini-review. Current Opinion in Food Science, 2018, vol. 23, pp. 70–79. DOI: https://doi.org/10.1016/j.cofs.2018.06.004.

- Sharma G.P., Verma R.C., and Pathare P.B. Thin-layer infrared radiation drying of onion slices. Journal of Food En- gineering, 2005, vol. 67, no. 3, pp. 361–366. DOI: https://doi.org/10.1016/j.jfoodeng.2004.05.002.

- Prosekov A.Yu., Mudrikova O.V., and Babich O.O. Determination of cinnamic acid by capillary zone electrophoresisusing ion-pair reagents. Journal of Analytical Chemistry, 2012, vol. 67, no. 5, pp. 531. (In Russ.).

- Doymaz I. Infrared drying of sweet potato (Ipomoea batatas L.) slices. Journal of Food Science and Technology, 2012, vol. 49, no. 6, pp. 760–766. DOI: https://doi.org/10.1007/s13197-010-0217-8.

- Altukhov I.V., Ochirov V.D., Bykova S.M., and Pozdeeva N.I. Time constant of carrot root heat. Vestnik of the Federal state educational institution of higher professional education “Moscow State Agroengineering University named afterV.P. Goryachkin”, 2013, vol. 58, no. 2, pp. 10–11. (In Russ.).

- Prosekov A., Babich O., Kriger O., et al. Functional properties of the enzyme-modified protein from oat bran. Food Bioscience, 2018, vol. 24, pp. 46–49. DOI: https://doi.org/10.1016/j.fbio.2018.05.003

- Garau M.C., Simal S., Femenia A., and Rosselló C. Drying of orange skin: drying kinetics modelling and functional properties. Journal of Food Engineering, 2006, vol. 75, no. 2, pp. 288–295. DOI: https://doi.org/10.1016/j.jfo- odeng.2005.04.017.

- Salehi F., Kashaninejad M., and Jafarianlari A. Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat and Mass Transfer, 2017, vol. 53, no. 5, pp. 1751–1759. DOI: https://doi. org/10.1007/s00231-016-1931-1

- Altukhov I.V. Discrete IK-energopodvod application in drying technology of sacchariferous root crops. Vestnik IrG- SHA, 2013, no. 55, pp. 100–104. (In Russ.).

- Siegel R. and Howell J. Thermal radiation heat transfer. New York: McGraw-Hill Publ., 1972. 814 p. (Russ. ed.:Zigelʹ R. and Khauehll Dzh. Teploobmen izlucheniem. Moscow: Mir Publ., 1975. 934 p.).

- Altukhov I.V. Snizhenie ehnergozatrat v protsessakh sushki plodov lekarstvennykh rasteniy putem upravleniya pre- ryvnym IK oblucheniem. Diss. kand.tekhn. nauk [Reduction of energy consumption in the process of drying fruits of medicinal plants by controlling discontinuous IR irradiation Cand. eng. sci. diss.]. Irkutsk, 2000, 230 p.

- Tsuglenok N.V. Formirovanie i razvitie struktury ehlektrotermicheskikh kompleksov podgotovki semyan k posevu. Diss. dokt. tekhn. nauk [The formation and development of the structure of electrothermal complexes to prepare seeds for sowing. Dr. eng. sci. diss.]. Barnaul, 2000, 44 p.

- Tsuglenok N.V. and Hudonogov I.A. Dinamicheskaya modelʹ vzaimodeystviya informatsionno-ehnergeticheskikh po- tokov IK- i SVCH- ehnergopodvoda v ehlektrotekhnologii ozdorovitelʹnogo chaya [The dynamic model of interaction between information and energy flows in the IR and microwave energy supply in the electrotechnology for revitalizing tea]. Bulletin KrasGAU, 2006, no. 5, pp. 246–250. (In Russ.).

- Buyanova E.O. Razrabotka tekhnologii kontsentrirovannykh kislomolochnykh produktov s primeneniem vakuum - ra- diatsionnogo obezvozhivaniya. Diss. kand. tekhn. nauk [Development of technology for concentrated fermented dairy products using vacuum radiation dehydration. Cand. eng. sci. diss.]. Kemerovo, 2011, 22 p.

- Technological bases for vacuum concentrating of milk whey. Dairy industry, 2017, no. 7, pp. 27–31. (In Russ.).

- Buyanova I.V. and Kotlyarova M.V. Vacuum decomposition of dairy raw material under infrared energy supply. Materialy mezhdunarodnoy nauchno-prakticheskoy konferentsii “Nauchnye innovatsii – agrarnomu proizvodstvu” [Proceedings of the international scientific and practical conference “Scientific Innovations for Agricultural Produc- tion”]. Omsk, 2018, pp. 1198–1201. (In Russ.).

- Timakova R.T., Tikhonov S.L., Tikhonova N.V., and Gorlov I.F. Effect of various doses of ionizing radiation on the safety of meat semi-finished products. Foods and Raw Materials, 2018, vol. 6, no. 1, pp. 120–127. DOI: https://doi. org/10.21603/2308-4057-2018-1-120-127.